You might wonder about the difference between an irrigation controller transformer VS Control Transformer. It all comes down to how these transformers serve your needs. Irrigation controller transformers power your irrigation systems, while control transformers keep industrial control circuits running smoothly. Picking the right transformers really matters. The right choice boosts efficiency, helps you meet safety standards, and even cuts down on maintenance. Take a look at the table below to see how transformer selection affects your setup:

| Key Points | Description |

|---|---|

| Impact on Efficiency | Transformers step down voltage for steady power in industrial applications. |

| Safety Features | Non-flammable insulation lowers fire risk. |

| Environmental Compliance | Transformers reduce oil leaks and spills. |

| Maintenance | Low maintenance needs save you money over time. |

Linkwell offers top-tier control transformers for industrial use, trusted by global leaders. Before you decide, think carefully about your system and what you need from your transformers.

Key Takeaways

- Irrigation controller transformers power your watering systems, ensuring plants receive the right amount of water.

- Control transformers are essential for industrial settings, providing stable power for sensitive equipment like relays and timers.

- Choosing the right transformer boosts efficiency, enhances safety, and reduces maintenance costs.

- Always match the voltage and power ratings of transformers to your specific system needs to avoid damage.

- Regularly inspect transformers for dust and damage to ensure they operate safely and effectively.

Understanding Irrigation Controller Transformers

What Is an Irrigation Controller?

You might see an irrigation controller as the brain of your irrigation system. It tells your system when to turn on and off, making sure your lawn or garden gets the right amount of water. Most irrigation controllers work with transformers to step down the voltage from your home’s power supply. This keeps everything safe and reliable. You can find smart controllers that use weather data and soil sensors to adjust watering schedules. These smart devices help you save water and keep your plants healthy. Many irrigation controllers now connect to your phone, so you can control watering from anywhere.

Role in Irrigation Systems

Transformers play a big part in every irrigation system. They take the 120 VAC from your wall and turn it into a lower voltage, usually 24 or 30 VAC. This lower voltage powers the irrigation controller and the valves that open and close to let water flow. Without the right transformer, your irrigation system might not work at all. Smart controllers need steady power to run their advanced features, like tracking weather and adjusting watering times. If you want your irrigation system to run smoothly, you need a transformer that matches your controller’s needs. Some transformers even offer surge protection to keep your irrigation system safe during storms.

Tip: Always check the transformer’s input and output ratings before you connect it to your irrigation controller. This helps prevent damage and keeps your watering on schedule.

Typical Applications

You use irrigation controllers and transformers in many places. Homeowners rely on them for lawns and gardens. Sports fields and parks use them to keep grass green and healthy. Farmers depend on irrigation systems to water crops at the right time. Smart controllers make it easy to manage large areas by adjusting watering based on weather and soil. You can find irrigation controllers in greenhouses, golf courses, and even rooftop gardens. The right transformer ensures your irrigation system gets enough power for every watering cycle.

Here’s a quick look at common technical specs for irrigation controller transformers:

| Specification Type | Details |

|---|---|

| Transformer Input | 120 VAC, 50 Hz to 60 Hz |

| Power Output | 24-30 VAC, up to 1.45 amp output |

| Solenoid Specification | 400 mA inrush current |

| Surge Protection | Up to 10 levels |

| Enclosure Options | Wall Mount and Pedestal |

Smart irrigation systems and smart controllers help you save water, lower your bills, and keep your landscape looking great. When you pick the right transformer, your irrigation system will deliver water exactly when and where you need it.

Linkwell Control Transformers Overview

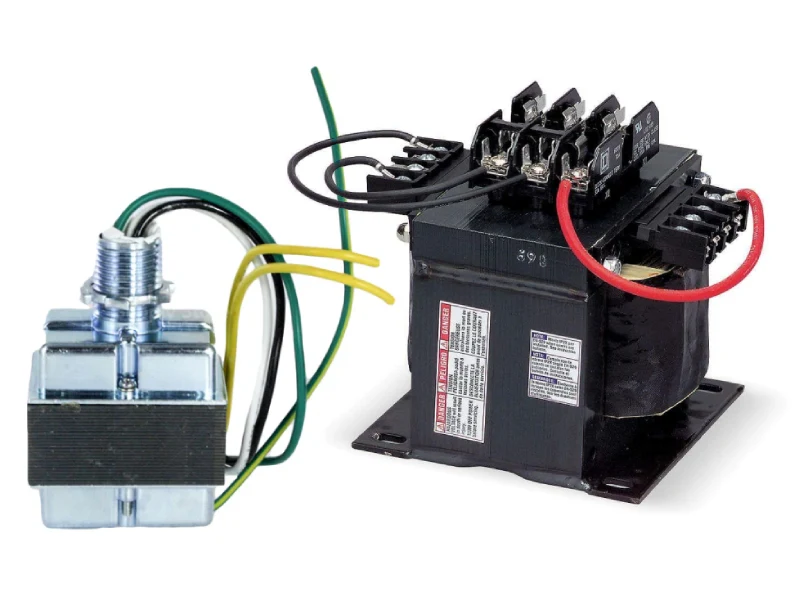

Recommended products

What Is a Control Transformer?

You might wonder what makes control transformers different from the ones you use for irrigation. Control transformers step down high voltages to safer levels for control circuits in industrial settings. You use these transformers to power sensitive devices like relays, switches, and timers. When you install transformers in control cabinets or telecom systems, you keep your equipment running smoothly. These transformers protect your circuits from voltage spikes and electrical noise. You get reliable performance and peace of mind.

Features of Linkwell Control Transformers

If you want transformers that last, Linkwell gives you plenty of reasons to choose their products. You get strong durability and low maintenance. Linkwell transformers handle high inrush currents, so your automation systems stay safe. You can pick custom options for voltage and power ratings. This means you get transformers that fit your exact needs. Linkwell transformers use copper conductors and robust insulation. You get energy-efficient designs that help you save on electricity bills. Every transformer goes through strict testing. You can trust the safety and reliability.

Here’s a quick look at the certifications Linkwell transformers meet:

| Certification/Standard | Description |

|---|---|

| UL | Underwriters Laboratories |

| CE | Conformité Européenne |

| ISO9001 | International Organization for Standardization 9001 |

Tip: You can ask Linkwell for transformers with special enclosures if you work in harsh environments.

Industrial Applications

You see Linkwell transformers in many industries. Factories use them in control panels and automation lines. Telecom stations rely on transformers for stable voltage. Power plants and energy storage systems need transformers to protect sensitive equipment. You find these transformers in robotics, charging stations, and infrastructure projects. When you use Linkwell transformers, you get stable voltage and fewer breakdowns. You keep your business running and avoid costly downtime. Linkwell transformers help you meet safety standards and boost efficiency. You get fast delivery and expert support, so your projects stay on track.

Irrigation Controller Transformer vs Control Transformer: Key Differences

When you look at irrigation controller transformer vs control transformer, you see two types of transformers that serve very different needs. You might use one to keep your garden green and the other to keep your factory running. Let’s break down the main differences so you can pick the right power transformers for your project.

Design and Construction

You notice the design of irrigation controller transformer vs control transformer right away. Irrigation controller transformers usually have a compact, weather-resistant build. You can mount them outside or near your water system. These transformers often come with simple enclosures that protect against rain and dust. You want them to last through all seasons, so they use materials that resist rust and moisture.

Control transformers, like the ones from Linkwell, have a more robust construction. You find thicker insulation, heavy-duty copper windings, and strong mounting brackets. These transformers fit inside control panels or cabinets. You get options for open or enclosed designs. Linkwell’s transformers stand out because they meet strict industrial standards and offer custom enclosures for harsh environments. You can trust them to handle tough jobs in factories or telecom stations.

Distribution transformers and power transformers in industrial settings need to handle more stress. You see extra layers of protection and better cooling systems. This keeps your voltage steady and your equipment safe.

Voltage and Power Ratings

You need to match the voltage and power ratings to your system. Irrigation controller transformer vs control transformer shows a big difference here. Irrigation controller transformers step down household voltage, usually from 120 volts AC to 24 or 30 volts AC. This lower voltage is safe for water valves and irrigation controllers. You don’t want high voltage near water, so safety comes first.

Control transformers handle much higher input voltages. You might see them take in 480 volts or even 600 volts and step it down to 120 volts or 24 volts for control circuits. These transformers support heavy loads and can handle high inrush currents. Linkwell’s power transformers can manage up to 7.5 kVA, which means you get reliable power for big machines and automation lines.

Distribution transformers in industrial settings need to deliver steady voltage to many devices at once. You want to avoid voltage drops that could stop your machines. With Linkwell, you get transformers that keep your voltage stable, even when your power demand changes.

Application-Specific Features

You pick irrigation controller transformer vs control transformer based on what you need to power. Irrigation controller transformers focus on water systems. You use them to run sprinkler valves, timers, and smart irrigation controllers. Some models offer surge protection to keep your water system safe during storms. You can find basic models for small gardens or advanced ones with WiFi and weather tracking for large landscapes.

Control transformers, especially from Linkwell, come with features for industrial automation. You get noise filtering, electrostatic shielding, and the ability to handle high inrush currents. These transformers protect sensitive equipment like relays, switches, and timers. You can customize them for special voltage or power needs. Linkwell offers transformers that fit inside cabinets, telecom stations, and even robotics systems.

When you compare power transformers for water systems to those for industrial control, you see that irrigation controller transformers focus on outdoor durability and simple operation. Control transformers give you advanced features for complex automation and distribution transformers in factories.

Safety and Compliance

Safety matters most when you deal with electricity and water. Irrigation controller transformer vs control transformer shows different safety needs. Irrigation controller transformers use non-flammable insulation and weatherproof cases. You want to avoid any risk of electric shock near water. These transformers often meet basic safety standards for home and garden use.

Control transformers from Linkwell go further. You get UL, CE, and ISO9001 certifications. These transformers pass strict tests for industrial safety. You can trust them to protect your equipment from overloads, voltage spikes, and overheating. Linkwell’s transformers also meet NEMA and other international standards. This means you get peace of mind in factories, telecom stations, and energy storage systems.

Distribution transformers and power transformers in industrial settings must meet even higher standards. You want to keep your workers and equipment safe. Linkwell’s focus on compliance and quality makes their transformers a top choice for demanding jobs.

💡 Note: The cost of irrigation controller transformers can vary a lot. Basic models start around $45, but smart controllers with WiFi and weather features can go up to $300. While you might pay more upfront for advanced technology, you could save water and money over time. Control transformers for industrial use, like those from Linkwell, offer long-term value with their durability and energy efficiency.

When you compare irrigation controller transformer vs control transformer, you see that each type has a clear role. You want the right transformer for your water system or your industrial setup. Linkwell’s control transformers give you the safety, reliability, and compliance you need for any industrial application.

Choosing the Right Transformer for Your Application

For Irrigation Systems

You want your irrigation system to run smoothly every day. Picking the right transformers makes a big difference in how your watering works. Start by checking the voltage and power needs of your irrigation controller. Most irrigation systems use transformers that step down household voltage to a safe level for water valves and smart timers. If you use a smart timer, you need steady power for features like remote control and weather tracking. Always match the transformer’s output to your irrigation controller’s requirements. You can boost watering efficiency by using transformers with surge protection, especially if your area gets storms. When you set up your watering schedule, make sure your transformers can handle the load for every watering cycle. You want reliable power so your irrigation system delivers water exactly when your plants need it.

Tip: If you upgrade to a smart timer, check if your current transformers support extra features like WiFi or advanced watering schedule options.

For Industrial Control Circuits

Industrial control circuits need transformers built for tough jobs. You use these transformers in automation systems, motor controllers, and lighting circuits. Your application might require transformers with higher power ratings and better insulation. Take a look at the table below to see what most automation industry standards recommend:

| Parameter | Typical Range / Example | Notes |

|---|---|---|

| Rated power (kVA) | 0.5–10 | Higher power may need special cooling |

| Primary voltage | 230/400 V, 480 V | Matches regional mains and PLC input |

| Secondary voltage | 24 V, 120 V, 48 V | Control circuits often use 24 V or 120 V |

| Insulation class | Class B/F/H | Higher classes for harsh environments |

| Enclosure type | Open-frame, Totally enclosed | IP65+ for harsh environments |

| Cooling method | Natural air, Forced air | Forced air for high duty cycles |

| Isolation | 2 kV, 3 kV, 4 kV | Based on safety standards |

| Regulation (% @ load) | ±2% to ±5% | Tighter for sensitive control systems |

| Ambient temperature | -20°C to 40°C | Specialized designs for extended ranges |

| Mounting | Wall, DIN rail, Panel | Depends on cabinet layout |

| Standards | UL, CE, CSA, RoHS | Compliance for global deployments |

You use transformers in industrial machinery, automation systems, and motor controllers. These transformers help your application run safely and efficiently. You want transformers that protect your equipment from voltage spikes and keep your control circuits working during every watering schedule in automated production lines.

Common Mistakes to Avoid

You can avoid headaches by steering clear of common mistakes when choosing transformers for your irrigation system or industrial application. Here’s what industry experts say:

- You might miscalculate load requirements if you forget to include all devices and their power needs.

- You could pick oversized transformers, which cost more and waste energy.

- You may overlook regular maintenance, which keeps your transformers working longer.

- You might use incorrect calculation methods, like relying only on nameplate ratings instead of actual operating conditions.

Remember: Always review your irrigation system’s specs and your application’s needs before buying transformers. You want your watering schedule to stay on track and your water supply to remain reliable.

Transformers Comparison Table

You might feel overwhelmed when you try to choose between different transformers for your project. You want to make sure your water system or industrial setup runs smoothly. To help you out, I’ve put together a simple table. This table shows you how irrigation controller transformers and control transformers stack up side by side. You can see which one fits your water needs or your automation goals.

| Feature | Irrigation Controller Transformers | Control Transformers (Linkwell) |

|---|---|---|

| Main Use | Powering water irrigation systems | Powering industrial control circuits |

| Typical Input Voltage | 120V AC | 230V, 400V, 480V, or 600V AC |

| Typical Output Voltage | 24V or 30V AC for water valves | 24V, 48V, or 120V AC for control |

| Power Rating | Up to 1.45 amps for water systems | Up to 7.5 kVA for automation |

| Enclosure | Weather-resistant for outdoor water use | Open or enclosed for cabinets |

| Surge Protection | Often included for water safety | Advanced protection for equipment |

| Certifications | Basic safety for water environments | UL, CE, ISO9001 for industry |

| Customization | Limited for water systems | Wide options for transformers |

| Application Examples | Lawns, gardens, water parks, farms | Factories, telecom, robotics |

| Durability | Built for water exposure | Built for heavy-duty use |

💡 Tip: Always check if your transformers match your water system’s voltage and power needs. You don’t want to risk damaging your water valves or your automation equipment.

You use irrigation controller transformers when you want to control water flow in your yard, farm, or greenhouse. These transformers keep your water valves working and your plants healthy. You rely on control transformers when you need steady power for industrial machines. These transformers protect your equipment and keep your automation running.

If you want to avoid water problems, pick transformers that handle outdoor conditions. For industrial jobs, choose transformers that meet strict standards. You can always reach out to experts if you feel unsure about which transformers work best for your water or automation project.

You’ve seen how irrigation controller transformers and control transformers serve different needs. You use irrigation controller transformers to power water systems, making sure your water valves and timers work every day. Control transformers keep industrial machines running, protecting sensitive equipment from power surges. When you pick transformers, always match them to your water or industrial setup. Regularly inspect transformers for dust, loose hardware, or signs of water damage. Clean them with care and call a professional if you spot issues. Experts recommend choosing transformers that handle future water demands and harsh environments. Linkwell gives you reliable transformers for any industrial project. If you want your water system or factory to run smoothly, talk to a specialist or reach out to Linkwell for guidance.

FAQ

What is the main difference between irrigation controller transformers and control transformers?

You use irrigation controller transformers for watering systems at home or on farms. Control transformers work in industrial settings. Each type of transformer supports different equipment and safety needs.

Can I use the same transformers for both irrigation and industrial control systems?

You should not use the same transformers for both jobs. Irrigation controller transformers handle lower power and outdoor conditions. Control transformers support higher voltages and protect sensitive industrial equipment.

How do I know which transformers fit my application?

You start by checking your system’s voltage and power needs. Look at your equipment’s requirements. Choose transformers that match those numbers. If you feel unsure, ask an expert or reach out to a trusted supplier.

Do transformers need regular maintenance?

Yes, you should inspect transformers often. Look for dust, loose wires, or signs of damage. Clean them gently. If you spot problems, call a professional. Regular checks help your transformers last longer and work safely.

Why should I choose Linkwell transformers for industrial use?

You get transformers from Linkwell that meet strict safety standards. They offer strong durability, energy efficiency, and custom options. Linkwell transformers help your business run smoothly and protect your equipment from power issues.