Junction boxes and pull boxes are both crucial components in electrical wiring systems, serving as enclosures for conductors. However, their primary functions and design characteristics differ significantly. Junction boxes are primarily used for housing wire connections and protecting them, while pull boxes are strategically placed to facilitate the pulling of wires through conduit runs, especially in longer or more complex installations.

Understanding these distinctions is essential for proper electrical system design and installation. Choosing the correct type of box for the intended purpose ensures both safety and efficiency in managing electrical conductors.

This blog will delve into the key differences between junction boxes and pull boxes, clarifying their specific roles and applications within electrical systems.

What Is Junction Box

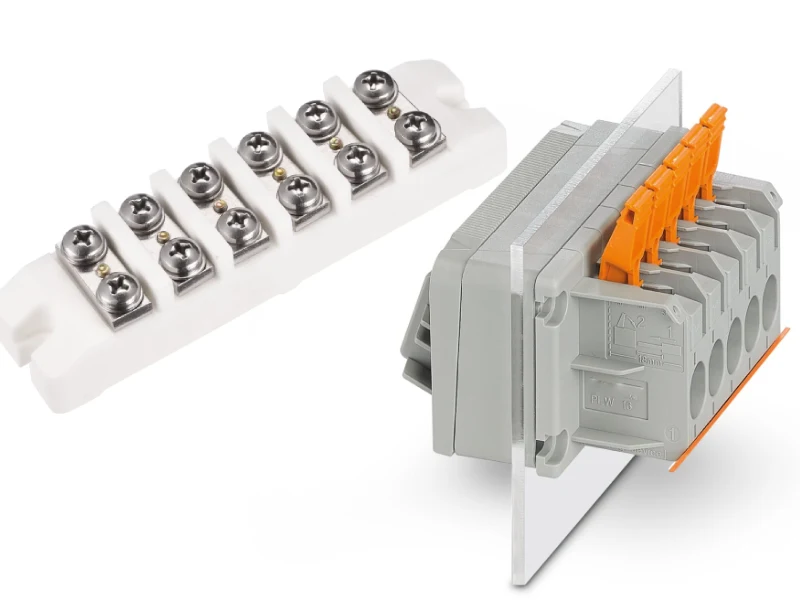

A junction box is an enclosure, typically made of metal or plastic, that protects electrical connections from the environment and accidental contact. It serves as a central point where two or more wires are joined together to distribute electrical power to various outlets, lights, and appliances within a building’s electrical system. These boxes are essential for safety and code compliance, ensuring that wire splices are contained within a fire-resistant enclosure and are not exposed.

Beyond protection, junction boxes also provide a degree of organization for wiring, making it easier to troubleshoot and modify circuits in the future. They offer a secure mounting point for electrical devices like light fixtures and switches, and they help to contain any potential electrical faults, preventing them from spreading. The size and type of junction box used depend on the number and gauge of wires being connected, as well as the specific application and local electrical codes.

What is Pull Box

A pull box, in electrical systems, is an enclosure designed to provide access to conductors that are being pulled through a raceway or conduit system. Unlike junction boxes, pull boxes are primarily intended to facilitate the pulling of wires over long distances or through multiple bends without causing damage or excessive strain on the wires. They act as intermediate access points, allowing electricians to break up long runs into more manageable segments.

While junction boxes are designed for making splices and housing electrical connections, pull boxes typically do not contain permanent connections or devices. They are essentially empty enclosures that provide working space for pulling cables. However, in some instances, particularly larger pull boxes, they can be used to store cable slack or even house splices, provided they are adequately sized and comply with relevant electrical codes for junction box requirements.

Junction Box vs Pull Box

Understanding the distinction between junction boxes and pull boxes is crucial for anyone involved in electrical installations. While both are enclosures used in electrical systems, their primary functions, design considerations, and typical applications differ significantly. Choosing the correct type of box for a specific purpose ensures safety, facilitates efficient wiring, and complies with electrical codes.

This comparison will delve into the key aspects about the difference between junction box and pull box in the following:

Purpose

Junction boxes serve as protective housings for electrical connections, providing a safe and organized space where two or more wires are joined. Their primary role is to enclose wire splices, protecting them from physical damage, environmental factors, and accidental contact, thereby preventing electrical hazards. Addtionally, junction boxes often act as mounting points for electrical devices like light fixtures and switches, integrating seamlessly into the building’s electrical system to distribute power effectively.

Pull boxes, on the other hand, are primarily designed to facilitate the pulling of electrical conductors through conduits or raceways, especially over long distances or around numerous bends. They act as accessible intermediate points that allow electricians to reduce the friction and tension on the wires during installation, making the pulling process more manageable and preventing damage to the insulation. Unlike junction boxes, pull boxes are not typically intended for making permanent wire connections or mounting devices, serving instead as a temporary aid during the wiring phase.

Size and Shape

Junction boxes come in a variety of sizes and shapes, ranging from small rectangular or square boxes used for single outlets or light fixtures to larger enclosures for multiple circuits or complex wiring scenarios. The size of a junction box is determined by the number and size of the conductors it needs to contain, as well as any internal devices or splices, adhering to fill capacity regulations outlined in electrical codes to prevent overcrowding and ensure proper heat dissipation.

Pull boxes are generally larger than typical junction boxes to provide ample working space for electricians to grip and pull wires. Their size is dictated by the size and number of conduits entering and exiting the box, as well as the bending radius of the conductors being pulled. Electrical codes specify minimum dimensions for pull boxes based on these factors to ensure that wires are not damaged during installation and that there is sufficient room for workers to maneuver and access the conduits effectively.

Wire Connections

The primary function of a junction box is to house and protect permanent electrical connections or splices between wires. These connections are typically made using wire connectors such as wire nuts, terminal blocks, or crimp connectors, ensuring a secure and electrically sound bond. Junction boxes are designed to contain these connections safely, preventing them from becoming loose or exposed, which could lead to electrical faults or hazards.

In contrast, pull boxes are generally not intended for making permanent wire connections. They serve as pass-through points to aid in the installation of conductors within a raceway system. While it is sometimes permissible to make splices within a pull box, especially in larger enclosures, this is usually secondary to their main purpose of facilitating wire pulling and is subject to specific requirements regarding box size and fill capacity as outlined in electrical codes for junction boxes.

Accessibility

Junction boxes are designed to be accessible for inspection, maintenance, and future modifications to the electrical wiring. While they are often concealed within walls or ceilings, they must have covers that can be removed without damaging the surrounding structure. Electrical codes specify requirements for the accessibility of junction boxes to ensure that connections can be checked and worked on safely if needed.

Pull boxes are also designed for accessibility, but primarily during the initial wiring installation. They provide points of entry and exit for conduits and offer a space for electricians to pull wires through difficult sections of a raceway. Once the wiring is complete, pull boxes are typically covered, but they should remain accessible for future wire pulls or system modifications, similar to the accessibility requirements for junction boxes.

Materials and Construction

Junction boxes are commonly made from metal (steel or aluminum) or non-metallic materials (plastic polymers like PVC or fiberglass). The choice of material depends on the application, environmental conditions, and electrical code requirements. Metal boxes offer durability and can provide grounding continuity, while plastic boxes are lightweight and corrosion-resistant. Both types are designed to contain electrical connections safely and meet fire safety standards.

Pull boxes are also constructed from similar materials, including steel, aluminum, and various plastics. The material choice is often influenced by the environment and the type of raceway system being used. Durability and ease of access are key considerations in their construction, as they need to withstand the stresses of wire pulling and provide a robust enclosure. Larger pull boxes may have hinged covers with latches for easier access and secure closure.

Here is a table showing you the difference between pull box and junction box as follows:

| Feature | Junction Box | Pull Box |

| Primary Purpose | Housing and protecting wire connections/splices | Facilitating wire pulling through conduits |

| Wire Connections | Typically contains permanent wire connections | Generally does not contain permanent connections |

| Size & Shape | Varies; sized for wire capacity and devices | Generally larger; sized for conduit and wire bending |

| Accessibility | Must be accessible for maintenance and inspection | Must be accessible for wire pulling and future work |

| Typical Location | Throughout electrical circuits; device mounting | Along long conduit runs or at multiple bends |

| Materials | Metal (steel, aluminum) or non-metallic (plastic) | Metal or non-metallic |

| Device Mounting | Often used to mount light fixtures, switches | Typically does not mount devices |

| Wire Pulling | Not its primary function | Designed specifically to aid wire pulling |

How to Choose the Junction Box and Pull Box

Selecting the appropriate electrical enclosure, whether a junction box or a pull box, is a critical decision that impacts the safety, efficiency, and longevity of your electrical system. Understanding the distinct purposes and characteristics of each type is paramount.

You must carefully assess the specific requirements of your wiring project, including the number and size of conductors, the presence of splices, the length and complexity of conduit runs, and the environmental conditions of the installation location.

Determine the Primary Purpose

First, clearly define the primary function the enclosure needs to serve. If the main goal is to house and protect wire connections or splices at a specific point in the electrical circuit, then a junction box is the appropriate choice. Consider the number of wires that will need to be joined and the space required for safe and compliant connections. Conversely, if the primary need is to facilitate the pulling of wires through a conduit system, especially over longer distances or around multiple bends, then a pull box is the necessary component.

Assess Wire Capacity and Size

For junction boxes, carefully calculate the required internal volume based on the number and gauge of the wires that will enter the box, as well as the volume occupied by any devices or splices. Electrical codes specify fill capacity rules to prevent overcrowding, which can lead to overheating and unsafe conditions. For pull boxes, the size should be determined by the size and number of conduits entering and exiting the box, as well as the bending radius of the conductors being pulled to ensure wires are not damaged during installation.

Consider the Installation Environment

The environment where the enclosure will be installed plays a significant role in material selection and the required protective features. For indoor, dry locations, standard metal or non-metallic junction boxes and pull boxes are typically sufficient. However, for outdoor or damp locations, enclosures with appropriate NEMA or IP ratings are essential to protect against moisture, dust, and corrosion. The material (aluminum, steel, plastic) should be chosen based on its resistance to the specific environmental conditions.

Evaluate Accessibility Requirements

Both junction boxes and pull boxes must be accessible for inspection, maintenance, and future modifications. Junction boxes need to be accessible to check connections, while pull boxes need to be accessible for initial wire pulls and potential future re-pulling or system changes.

Ensure the chosen location allows for easy access to the enclosure without requiring significant demolition or obstruction. Consider the ease of removing the cover and working within the box.

Plan for Mounting and Installation

Determine how the enclosure will be mounted (surface, flush, suspended) and select a box with appropriate mounting features or plan for necessary mounting hardware. For junction boxes that will also support devices like light fixtures, ensure they are rated for that purpose.

For pull boxes, consider their size and weight and ensure the mounting location can adequately support them, especially for larger enclosures. Ease of installation and available space for maneuvering during installation should also be considered.

Conclusion

In summary, while both junction boxes and pull boxes serve as enclosures for electrical wiring, their primary purpose and design differ significantly. Junction boxes are intended for housing wire connections, protecting them and providing mounting points for devices. Pull boxes, on the other hand, are larger and designed to facilitate the pulling of wires through long conduit runs or around multiple bends.

Understanding these distinctions is crucial for selecting the appropriate enclosure for your electrical project. Using the right box ensures both safety and efficiency in your wiring system, making installation and future maintenance more manageable. Choosing the correct enclosure size and type based on the wiring needs and conduit runs is paramount for code compliance and long-term reliability.

Need a reliable supply of junction boxes for your electrical projects? Linkwell Electronics offers a wide range of high-quality junction boxes at wholesale prices. Contact us today to explore our selection and find the perfect solutions for your wiring needs. Choose Linkwell for dependable and cost-effective electrical enclosures.