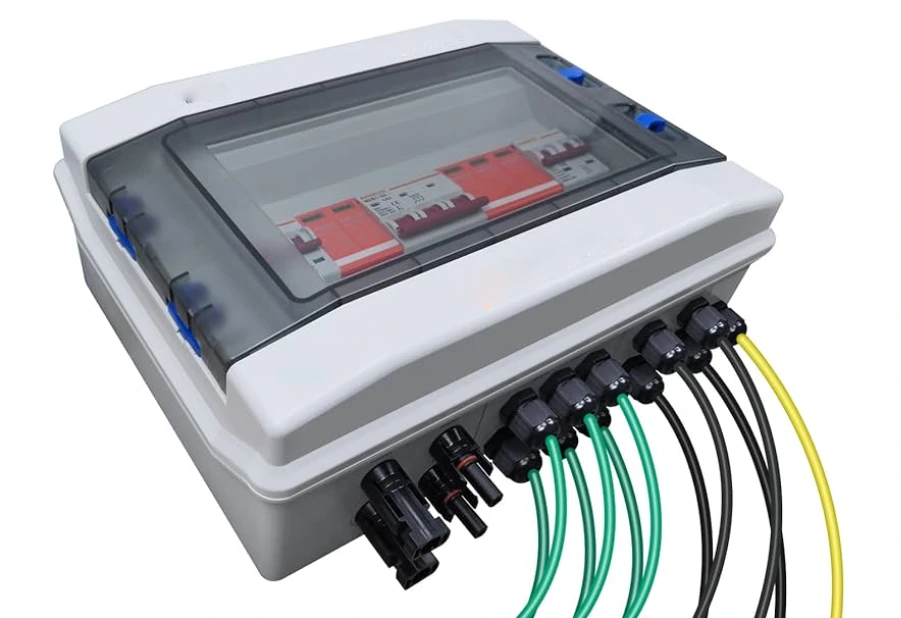

Large Electrical Junction Box Manufacture

High-capacity electrical junction boxes engineered for industrial control panels, power distribution systems, and complex wiring environments.

Key Features and Advantages

Engineered for extreme environments with IP65/IP67 protection, corrosion resistance, and full customization for wind, solar, EV charging, and industrial automation applications.

Large internal wiring space for high-capacity cable routing

Robust construction for industrial and commercial environments

Flexible knockout and cable entry configurations

Improved heat dissipation and cable organization

Enhanced safety and compliance with electrical standards

Why Choose Linkwell Large Electrical Junction Box?

As a manufacturer of electrical cabinet components, we provide OEM and ODM services for large electrical junction boxes.

Maximum Protection

IP65/IP67 rated for complete dust and water ingress protection. NEMA 4/4X certified for indoor/outdoor industrial use. Corrosion-resistant materials for harsh environments.

Full Customization

Tailored dimensions, materials, cut-outs, and mounting options. Integrated internal component layouts with our ventilation, wiring, and thermal management systems.

Global Certifications

UL listed, CE, ATEX, IECEx, NEMA compliant. Meets international standards for safety and performance across North America, Europe, and global markets.

One-Stop Integration

Complete cabinet solutions with pre-installed fans, filters, terminal blocks, and wiring ducts. Simplified procurement from a single trusted manufacturer.

Technical Specifications

Our large electrical enclosures are engineered to meet the most demanding industrial requirements with precision and reliability.

| Parameter | Specification | Options / Availability |

|---|---|---|

| Material Construction | PC-ALLOY Composite / Stainless Steel 304/316 | Fiberglass Reinforced Polyester, Aluminum |

| Protection Rating | IP65, IP66, IP67 (Standard) | IP68, IP69K (Available) |

| NEMA Equivalent | NEMA 4, 4X, 12 | NEMA 6, 6P (Optional) |

| Temperature Range | -40°C to +85°C | -60°C to +120°C (Special Order) |

| Standard Sizes | 500x400x200mm to 2000x1800x800mm | Fully Customizable Dimensions |

| UV Resistance | Excellent (Outdoor Rated) | UV-Stabilized Materials Standard |

| Color Options | RAL 7032, 7035 (Standard Gray) | Any RAL Color Available |

| Mounting Options | Wall, Pole, Floor, Rack | Custom Brackets & Hardware |

Industry Applications

Our large electrical enclosures protect critical systems across diverse industries with specialized solutions for each application.

Wind Power Generation

Vibration-resistant enclosures for turbine control systems, designed for extreme temperature fluctuations and corrosive coastal environments.

Solar & Photovoltaic

UV-resistant enclosures for inverters and combiner boxes, with optimized thermal management for prolonged sun exposure.

EV Charging Stations

Robust outdoor enclosures for charging controllers and payment systems, with security features and vandal resistance.

Certificate

OurLarge Electrical Junction Box meets CE, UL, and ISO standards for global compliance.

Linkwell Factory

Linkwell combines 15+ years of engineering expertise with strict quality control. We deliver durable, efficient, and Large Electrical Junction Box backed by global certification and dedicated technical support for your industrial needs.

What are the Benefits of Large Electrical Junction Box?

- Customizable box dimensions and depth

- Multiple cable entry points and knockout sizes

- Support for high wire-fill capacity

- Internal mounting plates, DIN rails, or terminal supports

FAQ of Large Electrical Junction Box

What is considered a “large” electrical junction box?

A large electrical junction box is defined by its expanded internal volume and wiring capacity, not just its external dimensions. It is designed to accommodate multiple conductors, larger cable diameters, terminal blocks, and complex branch circuits where standard junction boxes are insufficient.

In industrial applications, a junction box is typically considered “large” when it:

Supports high wire-fill requirements

Provides sufficient bending radius for power and control cables

Allows safe separation of multiple circuits

Large junction boxes are commonly used inside control cabinets, distribution panels, and machinery wiring systems.

What are large electrical junction boxes commonly used for?

Large electrical junction boxes are widely used in:

Industrial automation and control panels

Power distribution and branch circuit management

Machine and equipment wiring integration

Commercial building electrical systems

Outdoor electrical installations requiring protection

Their main purpose is to centralize connections, improve wire organization, and enhance electrical safety in systems with high wiring density.

What materials are available for large electrical junction boxes?

Large electrical junction boxes can be manufactured in several materials depending on the application environment:

Steel: High strength and excellent grounding, ideal for industrial control cabinets

Stainless Steel: Superior corrosion resistance for harsh or outdoor environments

Aluminum: Lightweight with good corrosion resistance

Engineering Plastic: Non-conductive, lightweight, and corrosion-resistant for indoor or low-voltage systems

Material selection directly affects durability, weight, grounding performance, and compliance requirements.

How do large junction boxes improve electrical safety?

Large junction boxes enhance safety by:

Preventing overcrowding of conductors

Maintaining proper cable bend radius

Reducing heat buildup from tightly packed wiring

Providing secure grounding and bonding points

Protecting connections from dust, moisture, and mechanical damage

Adequate internal space significantly reduces the risk of overheating, insulation damage, and code violations.

Are large electrical junction boxes customizable?

Yes. Large electrical junction boxes are often customized to meet specific project requirements. Customization options typically include:

Box dimensions and depth

Number, size, and position of knockouts or cable entries

Internal mounting plates or DIN rails

Material type and surface treatment

Branding, labeling, and packaging

Customization is especially important for OEM projects, panel builders, and system integrators.