Custom Lighting Panelboards Manufacturer in China

Our Lighting Panelboards deliver safe, neat power distribution for control cabinets, electrical enclosures and telecom signal cabinets. At Linkwellelectrics we manufacture robust panels, provide technical drawings, OEM labelling, and fast bulk shipping — contact us to discuss your project and get a quote.

Reliable Lighting Panelboards for Control Cabinets, Telecom & Electrical Enclosures

Global Partnership

Thermostat and Hygrostat

Thermostats control panel heater ON/OFF based on temperature; hygrostats sense humidity and trigger dehumidifiers or alarms. In lighting panelboards these devices protect sensitive electronics from condensation and overheating. We fit reliable, field-replaceable units so installers can maintain optimal climate inside enclosures and reduce long-term failure rates.

Enclosure Heater

Enclosure heaters prevent condensation and keep internal temperature stable in cold or humid environments. For telecom racks and electrical cabinets, small thermostatically controlled heaters protect fuses, relays and LED drivers. We select energy-efficient elements sized to cabinet volume, reducing moisture risks and avoiding corrosion on busbars and terminals.

Distribution Terminal Blocks

Distribution terminal blocks organize incoming and outgoing lighting circuits, providing secure, labelled connections. They simplify wiring changes and maintenance for electricians. We supply screw, push-in, and fused terminal options with clear marking and high current ratings — ideal for mass installations in control rooms and telecom signal cabinets.

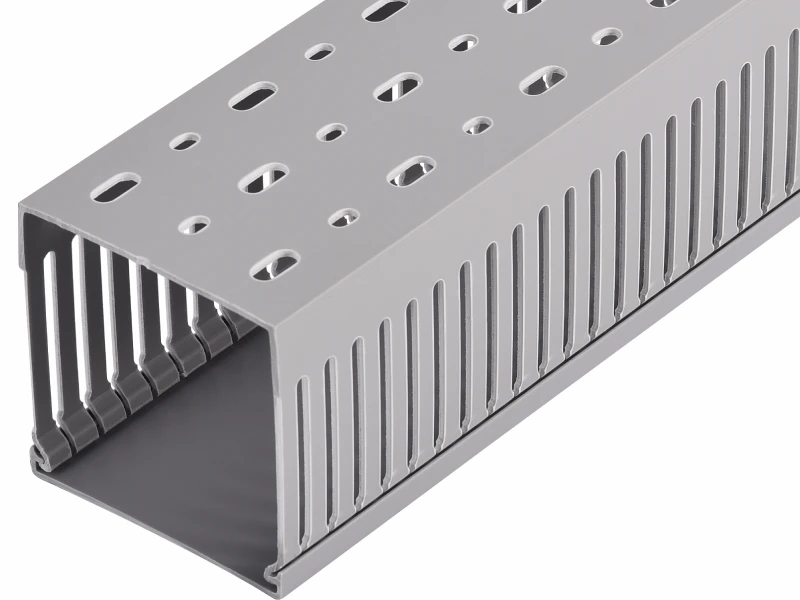

CMS Cable Management

Cable management systems route and secure cables inside the panelboard, preventing stress on terminals and improving airflow. Good CMS reduces cable wear and makes service jobs faster. We supply DIN-rail ducts, tie points and removable cable trays sized for high-volume builds so your installers save time on every job.

Related Components

Thermostat and Hygrostat

Types: Available in mechanical and electronic models for precise temperature and humidity regulation.

Performance: Ensures stable climate control inside electrical enclosures for efficient component performance.

Durability: Built with industrial-grade materials to resist corrosion and temperature fluctuations over time.

Integration: Easily connects with heaters, fans, and control systems for automatic environmental management.

Fan and Filter

Types: Offered in axial and centrifugal designs to suit different airflow and cooling requirements.

Performance: Delivers effective heat dissipation to maintain safe operating temperatures for electrical panels.

Durability: Long-life bearings and weatherproof housings ensure reliable operation in demanding environments.

Integration: Compatible with thermostats and enclosures, forming a complete ventilation and cooling system.

Air Conditioner

Types: Available in compact, wall-mounted, and roof-mounted models for flexible installation.

Performance: Provides high cooling capacity and energy efficiency to protect sensitive electrical components.

Durability: Designed with anti-corrosion coatings and sealed circuits for long-term use in harsh conditions.

Integration: Works seamlessly with thermostats and monitoring systems for automated temperature control.

Enclosure Lamp

Types: LED and fluorescent options designed for clear visibility inside control and electrical cabinets.

Performance: Provides consistent, bright illumination with minimal energy consumption and heat generation.

Durability: Shock-resistant design and long lamp life ensure dependable lighting in industrial settings.

Integration: Simple plug-in or magnetic mounting options for quick installation within enclosures.

Enclosure Heater

Types: Offered in PTC, fan-assisted, and convection models for varied heating needs.

Performance: Prevents condensation and moisture buildup to protect internal electrical components.

Durability: Constructed with anodized aluminum housing for long-lasting, corrosion-resistant performance.

Integration: Easily connects with thermostats or hygrostats for automatic climate control.

Terminal Blocks

Types: Screw, spring, and push-in types available for different wiring preferences and voltages.

Performance: Provides secure, low-resistance connections for stable and efficient electrical distribution.

Durability: Made from flame-retardant and high-dielectric materials to ensure long service life.

Integration: Designed for quick installation into Lighting Panelboards and control cabinets.

Control Transformer

Types: Single-phase and three-phase models designed for voltage conversion and isolation.

Performance: Ensures stable power supply for control circuits and sensitive equipment.

Durability: High-quality copper windings and epoxy encapsulation enhance resistance to vibration and moisture.

Integration: Easily mounted in panels and works with multiple electrical systems for voltage regulation.

CMS Cable Management

Types: Includes cable ducts, ties, and clips for organized wiring solutions in panel assemblies.

Performance: Keeps electrical wiring neat, accessible, and protected from mechanical stress.

Durability: Made from flame-resistant PVC and reinforced nylon for long-term structural integrity.

Integration: Compatible with most enclosures and terminal systems for efficient cable routing.

Push Button

Types: Momentary, maintained, and illuminated options for varied control panel functions.

Performance: Offers precise tactile response and reliable signal transmission for equipment operation.

Durability: Constructed with stainless-steel or polycarbonate housings for superior impact resistance.

Integration: Easily installs into control panels and works with indicator lights or emergency circuits.

Certificate

Why Choose Us: The Lighting Panelboards Manufacturer You Can Trust

Innovative R&D Capability

We constantly upgrade our Lighting Panelboards through advanced R&D, ensuring innovative, energy-efficient, and durable solutions for industrial applications.

Fast and Reliable Shipping

We guarantee fast production and global delivery, helping distributors and contractors meet tight project deadlines with consistent supply.

Premium Protective Packaging

Each panelboard is securely packed with reinforced materials to prevent damage during transport, ensuring safe arrival and performance.

Rapid Response & Development

Our team responds within 12 hours and offers fast prototyping to shorten customization time and speed up project completion.

Comprehensive Warranty Protection

Every Lighting Panelboard is backed by a solid warranty, giving you reliable support and peace of mind for long-term use.

Expert Technical Support

Our professional engineers provide installation guidance, performance optimization, and troubleshooting to ensure smooth operation in every project.

Customer Testimonials

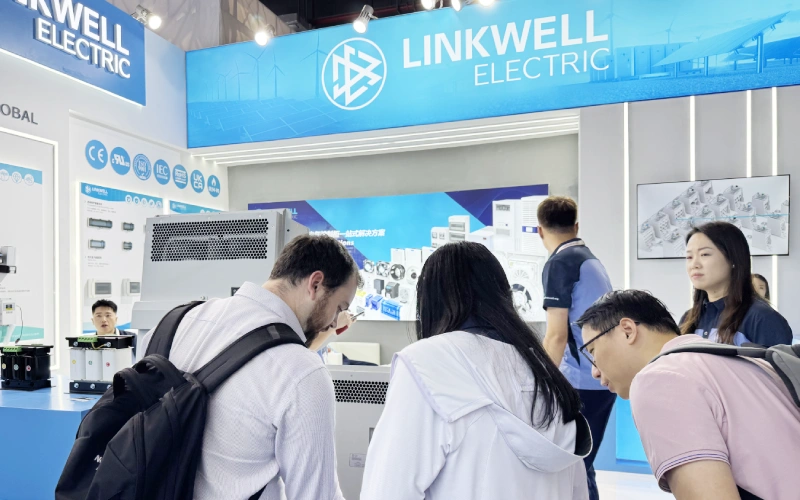

Lighting Panelboards International Exhibition

Customize Your Lighting Panelboards

Design & Development

We gather your electrical loads and mounting constraints, then produce CAD layouts and 3D enclosure mockups. Engineers specify busbar sizes, breaker types and thermal management to meet site and code requirements.

Raw Materials & Components

We source copper busbars, PCB assemblies, breakers, terminal blocks, and flame-retardant enclosures from vetted suppliers. Each part is assessed for durability, conductivity and compliance before production.

Component Fabrication

Busbars are precise-cut, drilled and tinned; sheet metal enclosures are laser-cut and powder-coated. We pre-assemble door hardware, gaskets and mounting brackets to ensure consistent fit and finish.

Testing & Calibration

We perform insulation resistance, continuity, polarity checks, and thermal/load testing. Each panel is run under simulated load to verify voltage drop, breaker operation and safe temperature rise.

What are the Benefits of Lighting Panelboards ?

Efficiently distributes electrical power, ensuring safe and reliable operation across multiple circuits.

Compact design saves space while simplifying maintenance and installation for technicians.

Customizable configurations meet diverse industrial, commercial, and telecom power distribution needs.

FAQ of Lighting Panelboards

What is a lighting panelboard and why use one?

A lighting panelboard distributes 12V/24V or mains power to multiple lighting circuits in a neat, protected enclosure. It centralizes fuses/breakers, simplifies wiring, and improves safety. For installers and wholesalers, panelboards reduce field wiring time and provide clear documentation for maintenance and code inspections.

How do I choose the correct busbar and breaker ratings?

Select busbar cross-section and breaker amperage based on total connected load plus safety margin. Consider inrush currents from LED drivers and emergency loads. We provide load calculations and recommended configurations so you order panels that prevent nuisance trips and avoid voltage drops under load.

Can your panelboards be used outdoors or in telecom base stations?

Yes. We offer IP-rated enclosures and weatherproof gaskets for outdoor or telecom installations. Choose corrosion-resistant hardware and appropriate ventilation or heaters to prevent condensation. We can supply panels with extended temperature components for harsh environments.

What documentation comes with each panelboard?

Every panel includes wiring diagrams, BOM, terminal ID list, test certificates and installation instructions. For OEM clients we add your logo, part numbers and packing lists. Good documentation speeds installation, support and inventory control for distributors and integrators.

How long is the typical lead time for custom panels?

Lead time depends on customization and quantity. Standard panels ship faster, typically 2–4 weeks. Custom layouts, special parts or certifications may extend time; we provide clear schedules and can expedite production for urgent projects.

What maintenance is required for lighting panelboards?

Inspect terminals, breakers and seals periodically (every 6–12 months). Look for loose connections, corrosion, dust or moisture ingress. Tighten terminals to recommended torque and replace worn gaskets. Regular checks prevent voltage drop and extend panel life.

All-in-one Lighting Panelboards Solutions for Your Project

At Linkwellelectrics, we integrate advanced engineering with dependable service. Our Lighting Panelboards deliver superior performance, verified safety, and on-time delivery. We provide flexible OEM customization to match your exact project requirements. Work with us to strengthen your electrical systems and grow your business with confidence.