Custom Motor Control Cabinet Manufacturer in China

A Motor Control Cabinet is a centralized unit that houses electrical components like motor starters, contactors, and circuit breakers. It ensures safe, reliable, and efficient control of motors across industrial and commercial applications. These cabinets are essential in facilities such as factories, telecom sites, and data centers for cooling systems. At Linkwellelectrics, we manufacture high-quality Motor Control Cabinets tailored for performance and durability. We support our customers from design to delivery. Whether you need a standard setup or a fully customized solution, we are here to help. Contact us today to discuss your project needs.

Linkwell Electrics - Your Trusted Motor Control Cabinet Manufacturer from China

1. Cost-Effective Ventilation for Electrical Enclosures

2. Highly Versatile and Built for Long-Lasting Use

3. Effectively Regulates Internal Component Temperatures

4. Certified to Meet UL and CE Standards

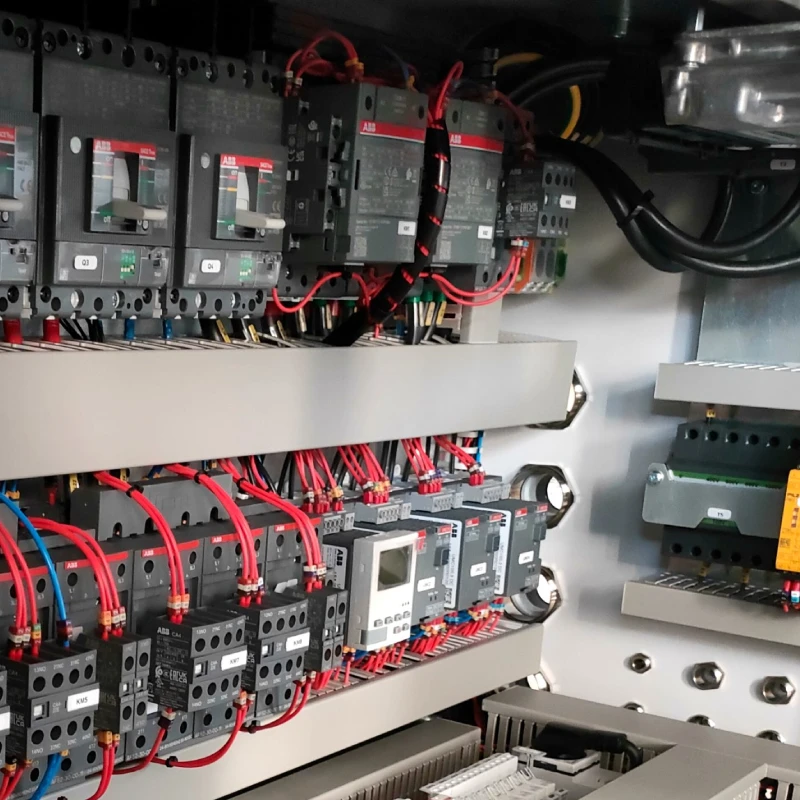

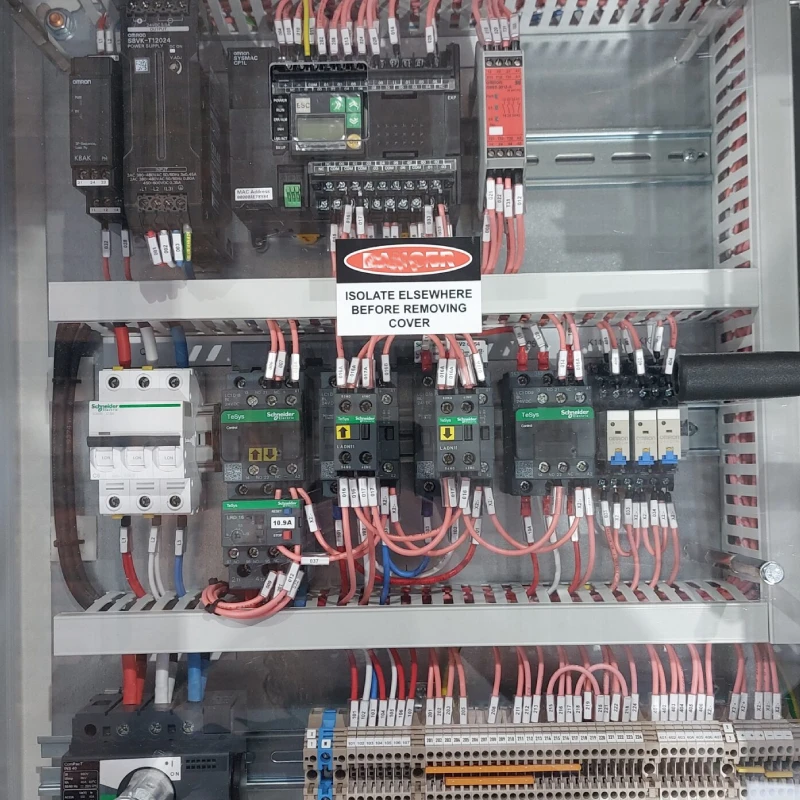

We specialize in custom Motor Control Cabinets to meet your exact needs. Our MOQ is flexible, and we offer customization in size, enclosure rating (IP55/IP66), component brand (ABB, Siemens, Schneider), internal layout, and wiring configuration.

With our streamlined production and material sourcing, we help lower your procurement cost while maintaining premium build quality. Quick turnaround times and on-time delivery are our commitment. Our solutions are engineered to match your industry’s demand and project scale — from small commercial builds to complex industrial systems.

Global Partnership

Various Motor Control Cabinet Series

We combine technical know-how, strict quality control, and strong delivery performance to bring you consistent results.

Our cabinets are built to last and perform in the toughest environments. Even Network Switch Cabinet is our specialty, We keep lead times short, pricing competitive, and customization easy.

Partnering with us helps you stay on schedule and on budget.

Work with us to simplify your procurement process and save time.

motor control box

Motor control boxes provide localized motor operation and protection in compact form. Ideal for telecom towers, HVAC, and industrial equipment, they reduce wiring complexity while improving service access. OEMs and integrators benefit from easy installation and fast troubleshooting.

motor control cabinets

Motor control cabinets centralize control and protection for multiple motors. Used in data centers, base stations, and process industries, they offer space efficiency, thermal protection, and easy maintenance. Distributors benefit from scalable supply and consistent quality across projects.

electrical control center with switches and fuses

These centers manage power distribution and circuit protection in mission-critical environments like telecom shelters or utility substations. They ensure safety and system stability. Ideal for bulk orders, they offer value to wholesale partners seeking robust, certified solutions.

Motor Control Cabinet Key Parts

Enclosures

Our enclosures are made from powder-coated steel or stainless steel, offering IP55 to IP66 protection. Designed for harsh environments, they guard internal components from dust, moisture, and impact. Suitable for both indoor and outdoor control systems.

Fan and Filter

Integrated cooling fans and filters manage internal temperatures and reduce dust ingress. This prolongs the life of motor drives and contactors. A must-have in high-heat or outdoor settings, especially in telecom and utility environments.

Power Distribution

Distributes incoming power safely to various motor branches. Includes breakers, busbars, and terminals. Engineered to support three-phase or single-phase power systems. Key for efficiency, safety, and equipment protection.

Motor Drives

Drives regulate motor speed and torque to match load requirements. They improve energy efficiency and reduce mechanical stress. We support brands like ABB, Siemens, and Schneider, or install per customer preference.

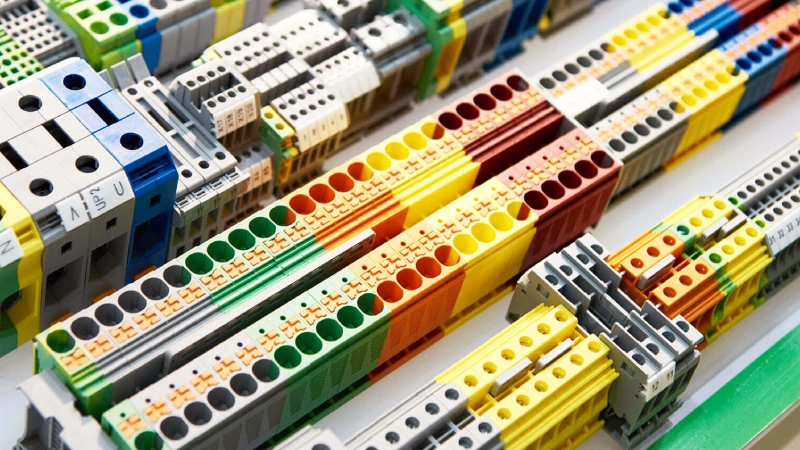

Terminal Blocks

Terminal blocks provide secure wire connections and organize internal wiring. We use flame-retardant, vibration-resistant types for safer, long-term reliability. They simplify future maintenance and upgrades.

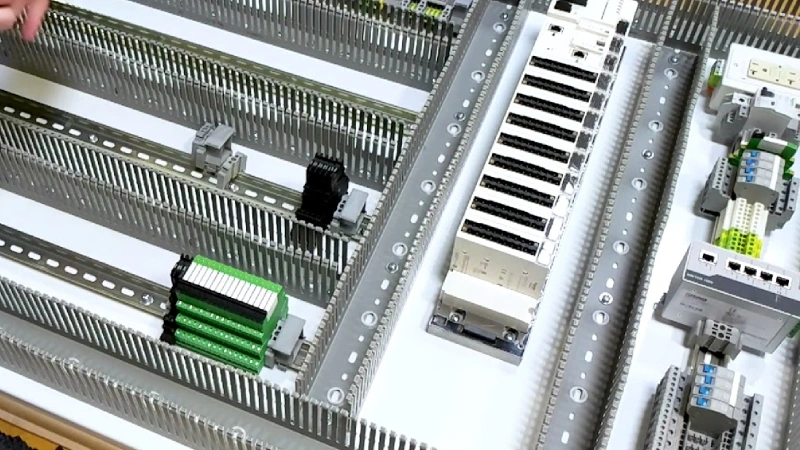

Wire Duct & Din Rail

Wire ducts manage cables neatly and reduce EMI. DIN rails allow quick mounting of relays, timers, and terminal blocks. Together, they create a modular, easy-to-service internal structure that installers appreciate.

Application of Motor Control Cabinet in Different Industries

Telecommunications

Manufacturing Plants

Customize Your Motor Control Cabinet

Performance & Safety

We use industrial-grade components with thermal and short-circuit protection.

Cabinets are tested under full load to ensure reliable operation.

Enclosures rated for both indoor and outdoor applications (IP65+).

Flexibility & Customization

Choose from top brands like Schneider, Siemens, ABB, and Eaton.

Cabinets can be built for single or multi-motor setups.

We design per your site layout or load conditions.

Cost Efficiency

Competitive pricing with no compromise on quality.

Pre-assembled units reduce installation labor costs.

Scalable production supports both low-volume and bulk orders.

Logistics & Delivery

Fast delivery to Asia, North America, and EU.

Sturdy packaging ensures zero damage during transit.

Real-time order tracking and responsive support.

What is Motor Control Cabinet? How Does It Work?

A Motor Control Cabinet is an enclosed electrical system that houses equipment to control electric motors. It’s used to start, stop, monitor, and protect motors in applications like water pumps, HVAC units, telecom systems, and factory machines.

The cabinet includes motor starters, contactors, circuit breakers, control relays, and often variable frequency drives (VFDs). These components manage how and when motors operate. For example, a VFD allows motors to start slowly and adjust speed based on real-time load — reducing wear and saving energy.

Control signals from sensors or a PLC (Programmable Logic Controller) can tell the cabinet when to start a motor, monitor performance, or shut down in case of fault. Some cabinets include fans, filters, and temperature monitors to protect internal components from overheating or dust.

Motor Control Cabinets are often customized depending on the size and number of motors, voltage, control method (manual or automatic), and environmental conditions (outdoor, indoor, humid, etc.).

We design and manufacture cabinets for base stations, manufacturing, and utility infrastructure. All units are tested, pre-wired, and ready for installation. Our clients benefit from faster commissioning and lower maintenance.

| Component | Function |

|---|---|

| Circuit Breaker | Overload and short-circuit protection |

| Contactor | Turns motor ON/OFF |

| VFD / Soft Starter | Controls motor speed/torque |

| Terminal Block | Connects wiring safely |

| Cooling Fan | Prevents overheating |

| PLC Interface | Connects to automation system |

What are the Benefits of Motor Control Cabinet?

Enhanced Safety – Protects equipment and personnel with built-in breakers and overload protection systems.

Centralized Control – Simplifies motor operation and monitoring from one organized, enclosed panel.

Improved Efficiency – Reduces energy use with soft starters or VFDs for smoother motor control.

Custom Integration – Easily adapts to industry needs with modular design and scalable components.

Customer Testimonials

FAQ of Motor Control Cabinet

What is a Motor Control Cabinet used for?

A Motor Control Cabinet houses the electrical devices needed to start, control, and protect electric motors. It is commonly used in factories, pump stations, HVAC systems, and data centers. These cabinets improve motor performance, ensure safety, and allow operators to centralize motor control from one location.

How do I choose the right Motor Control Cabinet?

You should consider factors like voltage, motor size, number of motors, application environment (indoor/outdoor), and safety requirements. If you’re unsure, we offer free consultation to help select the correct configuration based on your specific needs.

What's the difference between MCC and a Motor Control Cabinet?

An MCC (Motor Control Center) is a large, modular unit that controls multiple motors in industrial plants. A Motor Control Cabinet, by contrast, can be smaller and is often customized for specific applications or fewer motors. We offer both types depending on your scale.

Are your Motor Control Cabinets certified?

Yes. Our cabinets comply with international standards like UL508A, CE, and ISO9001. We use certified components and conduct 100% inspection before shipment, ensuring your system operates safely and efficiently.

Can I use a Motor Control Cabinet outdoors?

We manufacture cabinets with NEMA 3R, 4, and 4X, as well as IP55/IP66 ratings for waterproof and dustproof performance. These are perfect for telecom towers, pump stations, and outdoor process control systems.

How long is the lead time?

Standard cabinets usually ship within 10–15 business days. For custom orders, it ranges from 3–5 weeks depending on the complexity. We always strive to deliver ahead of schedule with full shipping support worldwide.

What is your MOQ for custom Motor Control Cabinets?

We accept low MOQs for custom cabinets, starting from as few as 5 units. For large orders, we offer better pricing and faster production slots.

All-in-one Motor Control Cabinet Solutions for Your Project

We provide a true one-stop service for Motor Control Cabinets, including both the enclosure and all internal components.

From cabinet fabrication to the integration of breakers, contactors, terminal blocks, and wiring, everything is manufactured and assembled in-house.

This ensures full quality control, faster delivery, and cost efficiency for our clients. Whether you need standard panels or fully customized solutions, we handle it all — design, production, and testing — under one roof.

Work with us to simplify your procurement process and save time.