A Power Distribution Center is the central hub where you direct and control electrical power to various circuits throughout your building or facility. This setup ensures you receive safe, consistent power by taking electricity from a main source and then splitting and managing it for each specific area or machine.

Modern industries depend on a reliable Power Distribution Center for seamless operations—especially as the global market grows, fueled by the expansion of data centers and cloud computing.

Linkewell stands out as a trusted provider of Power Distribution Center solutions, delivering unmatched reliability and expert support.

Key Takeaways

- A power distribution center safely manages and directs electricity to different parts of a building or facility.

- Key components like circuit breakers, busbars, and control panels work together to protect equipment and keep power flowing smoothly.

- Power distribution centers use backup systems and smart monitoring to prevent outages and keep operations running without interruption.

- Choosing a custom solution that fits your needs helps ensure safety, efficiency, and easy future upgrades.

- Linkewell offers reliable, certified power distribution products with expert support to help your facility run safely and efficiently.

Power Distribution Center Basics

What Is a Power Distribution Center

When you walk into a factory, data center, or even a large office building, you might not see where all the power comes from. That’s the job of a power distribution center. Think of it as the main control room for electricity in your facility. This secure enclosure holds important electrical equipment like switchgear, control panels, and backup power systems. You use a power distribution center to manage and distribute electricity safely and efficiently to every part of your building.

Here’s what a power distribution center does for you:

- It protects your electrical systems from faults and short circuits using breakers, switches, and fuses.

- It keeps your operations running during outages with backup systems like UPS units.

- It automates power management with control panels and remote monitoring, so you don’t have to worry about sudden failures.

- It maintains the right voltage and current for your machines, making sure everything works smoothly.

- It keeps your team and equipment safe by isolating faults quickly.

- It even includes HVAC systems to keep everything cool and extend the life of your equipment.

You rely on power distribution centers to power up heavy machinery, keep lights on, and make sure every device gets the right amount of electricity. This setup helps you avoid voltage drops, surges, and other problems that could damage your equipment or slow down your work.

Tip: If you want your facility to run smoothly, you need a power distribution center that matches your needs and meets strict safety standards.

How Power Distribution Works

Let’s break down how power distribution works inside your facility. The process starts when electricity arrives from the main transmission system. Here’s a simple step-by-step look at what happens next:

- Your facility receives high-voltage electricity from the grid at a distribution substation.

- Transformers inside the power distribution center step down the voltage to safer, usable levels.

- Circuit breakers and switches let you control where the power goes and disconnect parts of the system for maintenance or emergencies.

- Busbars split the power and send it in different directions to reach all areas of your building.

- Distribution lines carry the electricity to different rooms, machines, or departments.

- Near the point of use, smaller transformers reduce the voltage again for specific equipment, like computers or lighting.

- Finally, the power reaches your devices through service drops and meters, making sure each one gets exactly what it needs.

You can see how this process helps you manage and distribute electricity efficiently. By balancing loads across circuits and phases, you prevent overloads and keep your equipment running at peak performance. You also protect your team and assets with circuit breakers that cut off power during faults.

Linkewell takes this process a step further. The company follows strict certifications like UL 508A, IEC 61439, and NFPA 70, which means you get panels and systems that meet global safety and quality standards. Here’s a quick look at how Linkewell’s approach stands out:

| Certification/Standard | Region Covered | Focus Area | Key Compliance Aspects |

|---|---|---|---|

| UL 508A | U.S. & Canada | Industrial Control Panels | Electrical safety, proper part selection, wiring, enclosure requirements |

| IEC 61439 | International | Low-voltage Assemblies | System testing and design standards |

| NFPA 70 (NEC) | U.S. & Canada | Electrical Installation | Safety rules for electrical system installations |

Linkewell also offers customization options for layout, size, voltage, and labeling. You get fast order completion, real-time updates, and support like wiring diagrams and remote technical help. This customer-focused approach makes it easier for you to manage and distribute electricity in any environment, whether you’re running a factory, a telecom site, or a data center.

Components of a Power Distribution Center

Main Components Overview

When you look inside a power distribution center, you find several important parts working together to keep your facility running smoothly. These key components of a power distribution center help you manage and distribute electricity safely and efficiently:

- Main Switch: Lets you turn off the entire electrical supply for safety or maintenance.

- Circuit Breakers: Protect your circuits from overloads and short circuits by stopping the flow of electricity when needed.

- Busbars: Thick metal bars that carry and split electrical power to different circuits.

- Protective Devices: Fuses, RCDs, and RCBOs break the connection if there’s a fault or earth leakage.

- Switchgear: Includes fuses, breakers, and switches that control and protect the electrical system.

- Remote Terminal Units (RTUs): Allow you to monitor and control the system from a distance.

- Control Panels: Work with RTUs to automate and manage the power supply.

- AC/DC Panels: Supply power to different types of equipment, from heavy machines to small sensors.

- UPS Systems and Batteries: Keep your systems running during power loss and allow safe shutdowns.

- HVAC Systems: Keep the inside of the enclosure cool and safe for all electrical parts.

These components of a power distribution center make sure you get reliable power distribution and quick protection if something goes wrong.

Note: Modern power distribution centers often use smart technology for real-time monitoring and fast fault detection, which helps you avoid long outages and keeps your operations steady.

Electrical Power Distribution Box by Linkewell

You want a distribution box that stands up to tough conditions and keeps your electrical systems safe. Linkewell’s electrical power distribution box does just that. It comes with international certifications like UL, CE, CCC, and ROHS, so you know it meets strict safety and quality standards. The box features a strong, anti-corrosion enclosure with high protection ratings (IP65/IP66), making it perfect for both indoor and outdoor use.

Linkewell’s boxes are easy to install, with pre-cut cable entries and clear labels. You can choose from different materials, sizes, and layouts to fit your needs. The company also offers fast lead time and full customization, including OEM and private-label options. Each box goes through industrial-grade testing to ensure it performs reliably in any environment.

Electrical Control Panel by Linkewell

If you need to control and automate your electrical systems, Linkewell’s electrical control panel is a smart choice. This panel acts as the brain of your power distribution center. It manages power flow, protects against overloads, and helps you monitor everything in real time. The panel includes safety devices like emergency stop buttons and interlock switches, so you can respond quickly to any hazard.

Sensors inside the panel track temperature and machine status, giving you early warnings if something isn’t right. The modular design makes upgrades and maintenance simple. Linkewell’s panels meet UL 508A and IEC 61439 standards, so you get proven safety and reliability. With clear labeling and organized layouts, you can troubleshoot issues fast and keep downtime to a minimum.

If you want a solution that grows with your business, Linkewell’s custom designed panels and boxes give you the flexibility and support you need for any project.

Power Distribution Center Operation

Receiving and Regulating Power

When you power up your facility, the process starts with receiving high-voltage electricity from the grid. Here’s how it works step by step:

- Your power distribution center takes in high-voltage power from the main grid.

- Transformers inside the center step down this voltage to safer, usable levels for your equipment.

- Uninterruptible Power Supply (UPS) systems condition the power, keeping voltage steady and providing instant backup if the grid fails.

- Power Distribution Units (PDUs) then send this conditioned power to different parts of your building.

- If both the grid and UPS go down, backup generators kick in automatically to keep everything running.

You often see redundancy models like N+1 or 2N in action. These setups give you backup components, so your operations stay up even if one part fails. Voltage regulators also play a big role. They keep voltage within safe limits, using smart controls that sense changes and adjust quickly. This helps your machines run smoothly and protects sensitive equipment.

Distributing to Circuits

Once the power is regulated, your system needs to send it where it’s needed. Here’s what happens:

- Bus ducts and busways act as highways, moving electrical current from the main source to different areas.

- Switchgear and circuit breakers protect each circuit, stopping power if there’s an overload or fault.

- Transformers adjust voltage again if certain equipment needs a different level.

- Finally, panel boards or bus ducts split the power into branch circuits, delivering electricity to lights, machines, and outlets.

You get reliable power distribution because each part of the system works together. This setup helps you manage and distribute electricity efficiently, so every device gets what it needs without risk of overload.

Safety and Monitoring

Safety sits at the heart of every modern power distribution center. Advanced materials like GPO-3 insulate and protect against short circuits and fire. Switchgear with circuit breakers, fuses, and relays isolates faults fast, keeping your team and equipment safe. Enclosures shield internal parts from dust, water, and accidental contact.

Monitoring systems make your job easier. Human-Machine Interfaces (HMI) let you check the status of breakers and disconnectors in real time. Alarm systems alert you with lights or sounds if something goes wrong. Digital displays and mimic diagrams help you spot problems quickly. These systems often require two-step confirmation before making changes, reducing mistakes.

Linkewell’s solutions meet strict standards like IEC, UL, and NEMA, so you know your power distribution systems are safe and reliable. With smart monitoring, you can catch issues early, prevent hazards, and keep downtime to a minimum.

Tip: Always choose a power distribution center that offers strong safety features and real-time monitoring. This keeps your facility running smoothly and protects your investment.

Design, Installation, and Customization

Design Considerations

When you plan a power distribution center, you want to make sure it fits your needs today and in the future. Here are some key things to think about:

- Choose equipment that can handle the voltage and frequency changes you expect. This keeps your system safe and reliable.

- Decide on the layout, number of feeders, voltage levels, and how you’ll connect emergency backup systems.

- Size your equipment for the right voltage, current, and fault protection. Make sure you have enough space for safe clearances.

- Place your equipment close to where you need power. This reduces cable lengths, power losses, and voltage drops.

- Think about the environment. High temperatures, humidity, dust, or chemicals can affect your equipment, so pick the right enclosures.

- Plan for growth. You might need more power in five years, so leave room for expansion.

- Use design tools to help you document and select the best equipment.

You should also check your total electrical needs early. Work with experienced teams to get accurate load estimates and make sure your building’s power grid can handle everything. Don’t forget about lighting, outlets, and IT needs like WiFi and servers.

Tip: Following standards like the International Building Code and National Electric Code helps you stay safe and compliant.

Installation Process

Getting your power distribution center up and running takes careful steps. Here’s a simple guide:

- Pick the right distribution box for your environment—indoor or outdoor, with the right IP or NEMA rating.

- Install the box in a dry, easy-to-reach spot with good airflow, usually about 1.5 meters high.

- Wire everything neatly. Ground all metal parts, use the right wire size, and make sure breakers match your loads.

- Add protective devices like circuit breakers and surge protectors for each circuit.

- Follow all electrical codes and use certified parts.

- Test everything before turning on the power. Check voltage, continuity, and breaker function.

- Label all circuits and wires clearly. This makes future maintenance much easier.

- Keep records of your installation, including photos and layout diagrams.

- Plan for regular inspections and maintenance to keep your system reliable.

- Consider modular designs for easy upgrades later.

You might face challenges like finding skilled workers, managing project risks, or dealing with advanced cooling and network systems. Careful planning and teamwork help you avoid delays and keep your project on track.

Custom Solutions from Linkewell

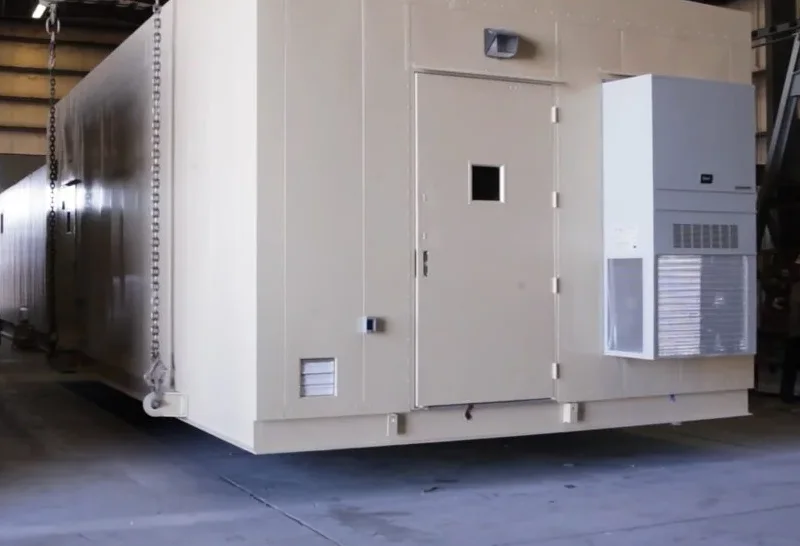

Every facility is different, so you need a custom designed solution that matches your exact requirements. Linkewell specializes in custom designed power distribution centers for all kinds of industries. Whether you need a prefabricated power distribution center for a data center or a rugged outdoor box for telecom, Linkewell has you covered.

You get products that meet IEC 61439 and UL 508A standards, with IP65/IP66 ratings for dust and water protection. Linkewell tests every unit for voltage handling, insulation, and durability. You can request extra certifications like ISO 9001, CE, or RoHS if your project needs them. The enclosures are tough and anti-corrosive, perfect for harsh environments.

Linkewell’s team works with you from design to delivery. You can customize the size, layout, and even the branding. Fast lead time and expert support mean you get reliable power distribution without the wait. If you want a solution that grows with your business, Linkewell’s flexible approach makes it easy to expand or upgrade in the future.

Note: Choosing a trusted partner like Linkewell ensures your power distribution systems are safe, efficient, and ready for whatever comes next.

Benefits of Power Distribution Centers

Safety and Reliability

When you use power distribution centers, you put safety and reliability first. These systems protect your facility from electrical faults and keep your operations running, even during unexpected events. Redundant paths and circuit breakers let you isolate problems fast, so you can fix issues without shutting down your whole operation. You also get real-time monitoring tools that help you spot trouble before it becomes a big problem. In manufacturing, busway systems give you a flexible and reliable power grid. You can add or move plug-in units anywhere, which means you can adjust your setup quickly and safely. This flexibility keeps your production floor running smoothly and reduces downtime.

Tip: Always look for systems with advanced monitoring and redundancy. These features help you avoid outages and keep your team safe.

Efficiency and Scalability

Power distribution centers help you manage and distribute electricity with maximum efficiency. You can expand your system as your business grows, without tearing apart your existing setup. Modular components like switchboards and power distribution units make it easy to add new circuits or equipment. You save time and money because you do not need to overhaul your infrastructure. Modern systems support rapid installation and upgrades, so you can scale up with minimal downtime. Intelligent power distribution also means your system adjusts to changing demands, keeping everything stable and energy efficient.

- Customizable components let you reconfigure your layout as needed.

- Compliance with industry standards ensures safe and reliable power distribution.

- Quick deployment means you spend less time waiting and more time working.

Linkewell Value Proposition

When you choose Linkewell, you get more than just electrical equipment. You get a partner who understands your need for reliable power distribution. Linkewell’s products meet strict global standards, so you know your facility is protected. You can customize your solution to fit your exact needs, whether you want a rugged outdoor box or a smart control panel. Fast lead time and expert support mean you never have to wait long for help. Linkewell’s focus on quality, flexibility, and customer service helps you stay ahead in a fast-changing world.

Note: With Linkewell, you can trust that your power distribution centers will deliver safety, efficiency, and reliable power distribution for every project.

You now know what a power distribution center does and why it matters. You saw how the key components of a power distribution center work together to manage and distribute electricity safely. When you choose the right solution, you get reliable power distribution and peace of mind. If you want a custom designed system with fast lead time, Linkewell gives you quality, flexibility, and expert support for every project.

FAQ

What is the main purpose of a power distribution center?

You use a power distribution center to manage and distribute electricity safely throughout your facility. It keeps your equipment running, protects against faults, and helps you control power for different areas or machines.

How do the key components of a power distribution center work together?

The key components of a power distribution center—like circuit breakers, busbars, and control panels—work as a team. They direct, protect, and monitor your electrical supply, making sure you always have reliable power distribution.

Can I get a custom designed power distribution center for my project?

Yes, you can! Many providers offer custom designed solutions. You choose the size, layout, and features you need. This way, your power distribution systems fit your exact requirements and help you manage and distribute electricity efficiently.

What is a prefabricated power distribution center?

A prefabricated power distribution center arrives ready to install. You save time on site and reduce lead time. These centers come fully assembled, tested, and certified, so you get reliable power distribution right away.

How often should I inspect my power distribution systems?

You should check your power distribution systems at least twice a year. Regular inspections help you spot problems early, keep your electrical equipment safe, and ensure your power distribution center keeps working smoothly.

Conclusion

A well-designed Power Distribution Center is the backbone of your facility’s electrical system. It ensures safety, boosts efficiency, and adapts to your growing power demands. With Linkewell, you get certified, customizable, and high-performance distribution solutions backed by expert support.

Whether you’re managing a factory, data center, or telecom site, Linkewell helps you power your operations with confidence and control—every step of the way.