Custom Screw Terminal Manufacturer in China

Screw Terminals are essential components used in control cabinets, electrical enclosures, and telecom signal boxes for secure wire connections. Their design makes wiring easier and more reliable in industrial applications.

As a direct Screw Terminal manufacturer, Linkwellelectrics offers a wide selection of screw terminals to meet various installation needs. We provide not just products but full support from selection guidance to bulk logistics. Our products are built for durability and safety, trusted by wholesalers, distributors, and established brands worldwide.

If you’re sourcing high-quality screw terminals for your industrial or commercial applications, contact us today—we’re ready to support your success!

Linkwell Electrics - Your Trusted Screw Terminal Manufacturer from China

Certified by UL and CE for safety and durability.

Flame-retardant and corrosion-resistant housing materials.

Compatible with both solid and stranded wires.

Long lifespan with over 10,000 connect/disconnect cycles.

We offer top-grade quality, on-time delivery, and flexible order solutions—ensuring that your supply chain stays smooth and your customers stay happy. Our terminals meet industry demand at scale.

Global Partnership

Various Screw Terminal Series

Beyond manufacturing, we act as your long-term Screw Terminal supplier partner. We offer fast OEM & ODM services, flexible bulk order handling, and dependable logistics solutions. We understand the urgency of restocking and deliver on time, every time.

Our experienced team also provides technical assistance, installation guidance, and after-sales support to ensure you get the right product for your market. Whether you’re a distributor or sourcing manager for a major brand, working with us means smoother supply chains and reliable components.

Contact us now to learn more about our professional solutions tailored to your business!

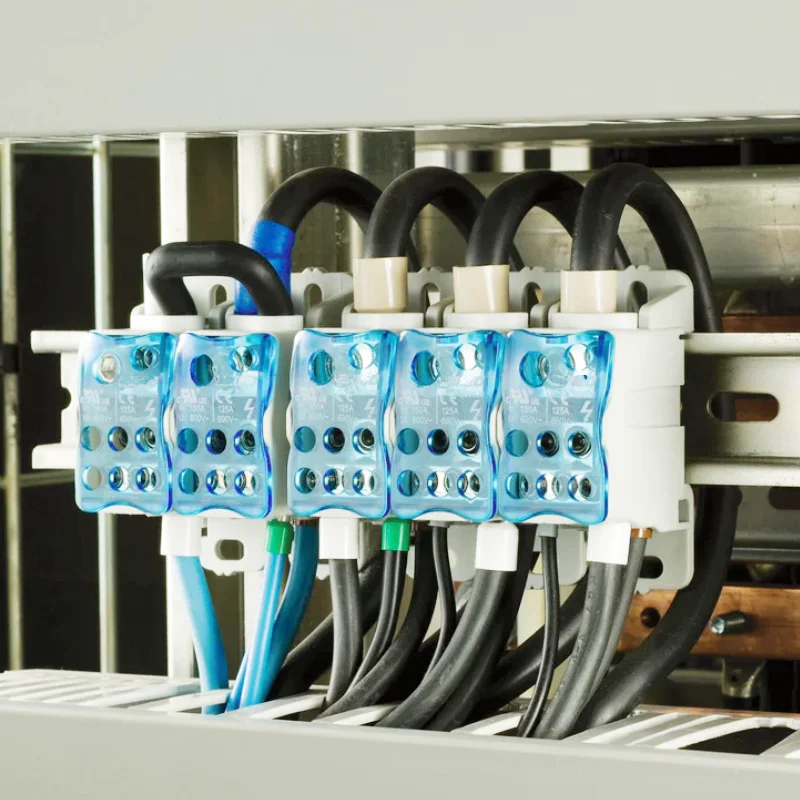

Distribution Terminal Blocks

Distribution Terminal Blocks are used in control panels, telecom signal enclosures, and electrical cabinets for organizing and distributing power or signals efficiently. They are ideal for complex installations with multiple wire connections. These blocks improve safety, streamline wiring layouts, and help reduce wiring errors. For wholesalers and integrators, stocking reliable distribution terminal blocks increases product value and customer satisfaction. Their modular design makes them easy to install and expand in base stations or cabinet upgrades. Better wiring means fewer callbacks—improving your profit margins and reputation.

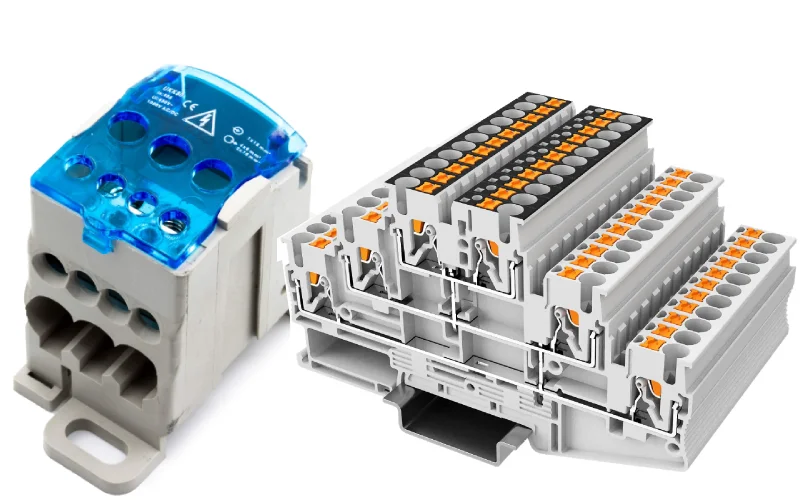

AL/CU Universal Terminals

AL/CU Universal Terminals are designed to connect both aluminum and copper conductors safely in industrial power systems. They eliminate galvanic corrosion issues and ensure long-lasting conductivity. Often used in base stations and control cabinets, these terminals simplify procurement by eliminating the need for different models. Their versatility and compatibility help distributors streamline inventory and offer faster solutions to end-users. For engineers, these terminals reduce installation errors and improve project timelines. If you’re looking to boost business with universal compatibility, AL/CU terminals are a smart investment.

Modular terminal blocks

We at Linkwellelectrics manufacture Modular Terminal Blocks that bring flexibility, safety, and efficiency to telecom boxes, control cabinets, and power distribution systems. Their stackable design allows easy customization and space-saving wiring. Built for high vibration and thermal resistance, our blocks ensure stable connections in harsh environments. We offer OEM customization and large-volume support. As a professional Screw Terminal supplier, we provide bulk ordering options, fast delivery, and personalized service. Contact us today to enhance your product line with modular, high-performance solutions tailored to your market needs.

Screw Terminal Key Parts

Enclosure Types

Metal, polycarbonate, wall-mounted, or free-standing. Performance: High ingress protection, safe for indoor/outdoor Durability: UV-stable and corrosion-resistant materialsIntegration: Supports terminal blocks, cable glands, filters

Main Circuit Breaker Types

MCBs, MCCBs, thermal-magnetic Performance: Fast response to overloads and short circuits Durability: 10,000+ cycles certified per IEC standards Integration: Mounts directly into DIN rails and busbars

Fan and Filter Types

AC/DC fans with replaceable filtersPerformance: Maintains optimal temperature in control cabinetsDurability: IP54-rated filters with long service lifeIntegration: Easily mounts into enclosure cutouts

Distribution Terminal Blocks Types

Feed-through, multi-level, ground, fused Performance: Reliable, clean signal and power distribution. Durability: Withstands vibration and high current loadsIntegration: Clips onto DIN rail or panel mounts

CMS Cable Management Types

Cable ducts, holders, ties, and trunking systems. Performance: Organizes cables for airflow and safety. Durability: Heat-resistant plastic, non-deforming under Integration: Compatible with various panel layouts

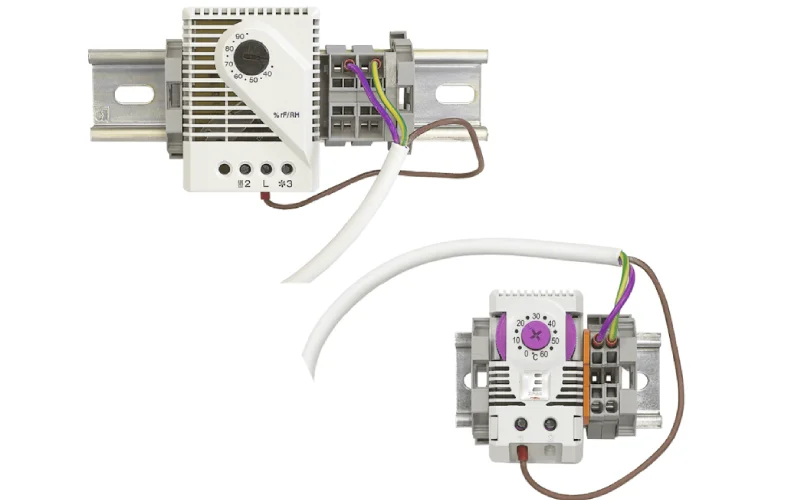

Thermostat and Hygrostat Types

Mechanical or electronic models availablePerformance: Maintains optimal humidity and temperature Durability: Reliable for over 100,000 switching cyclesIntegration: DIN-rail mount, plugs into control loops

Application of Screw Terminal in Different Industries

Industrial Automation

Telecom Infrastructure

Renewable Energy

Customize Your Screw Terminal

Product Quality

We use flame-retardant, industrial-grade plastics for safety.

Terminals are rigorously tested before shipment.

Certified under UL, CE, and RoHS for global compliance.

Supply Chain Efficiency

We maintain ready stock for fast dispatch.

Short lead times even for large-volume orders.

Custom packaging for easy handling and branding.

Customization Flexibility

Wide range of terminal sizes and colors available.

Custom screw types and connection layouts supported.

OEM labeling and private branding are welcome.

Buyer-Focused Support

Dedicated account managers for every client.

Multilingual support for global markets.

Samples and catalogs available for testing and promotion.

What is Screw Terminal? How Does It Work?

A Screw Terminal is a simple and effective electrical connector used to join wires securely inside electrical enclosures. These terminals are widely used in industrial control panels, base stations, HVAC systems, and telecom signal cabinets.

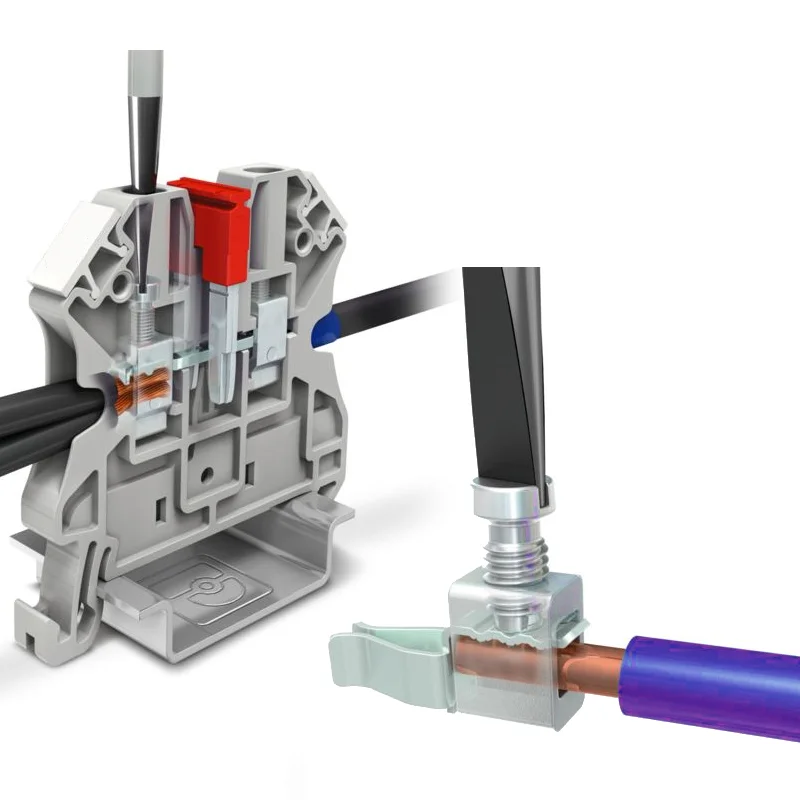

How Does It Work?

Strip the Wire: Remove the insulation from the wire tip.

Insert the Wire: Place the bare wire into the metal contact area.

Tighten the Screw: Secure the wire by turning the screw to create pressure against the conductor.

Hold Securely: The wire stays fixed, and a strong mechanical and electrical connection is formed.

Screw terminals provide a tool-friendly, reconfigurable solution without the need for soldering. This makes them ideal for quick installations, testing, and future maintenance. They work with both solid and stranded wires and are often used where durability and reusability are key. For engineers and installers, their simplicity and reliability make them an essential component in industrial wiring.

| Step | Action | Tool Needed | Benefit |

|---|---|---|---|

| 1 | Strip the wire | Wire stripper | Clean, exposed conductor |

| 2 | Insert wire | None | Quick setup |

| 3 | Tighten the screw | Screwdriver | Firm electrical connection |

| 4 | Confirm tightness | Hand check | Safe, vibration-resistant |

What are the Benefits of Screw Terminal?

An AC for electrical cabinets prevents heat-related failures, extends equipment lifespan, and reduces downtime. It ensures stable operation in telecom, control, and EV systems—boosting reliability and lowering maintenance costs while supporting system integrators or distributors with consistent, energy-efficient performance.

Customer Testimonials

FAQ of Screw Terminal

Where are Screw Terminals commonly used?

They are most commonly used in control cabinets, industrial automation, telecom enclosures, HVAC systems, and other electrical panels. Their main advantage is making connections fast and secure, especially in environments that require frequent maintenance or rewiring. You’ll also find them in large-scale distribution boxes and machinery.

Are Screw Terminals safe to use?

Yes, they are very safe when used correctly. They meet international standards like UL and CE. Screw Terminals reduce the risk of wire slippage and short circuits. The housing is often made of flame-retardant material, and the metal parts are corrosion-resistant. Always make sure the screw is properly tightened.

Can Screw Terminals be reused?

One of the major benefits of screw terminals is reusability. You can loosen the screw, replace or reinsert the wire, and retighten it. This is particularly helpful in industrial setups where wires are updated or rerouted often.

How do I choose the right Screw Terminal?

You need to consider wire size, current rating, mounting method, and environmental conditions (like heat or moisture). If you’re unsure, our technical team is happy to recommend the right model based on your project specs.

Do Screw Terminals support solid and stranded wires?

Yes, our Screw Terminals work with both solid and stranded wires. Just make sure to use the proper wire gauge and tighten the screw to the recommended torque level. This ensures stable electrical contact.

Can I buy Screw Terminals in bulk?

Yes, we offer bulk orders for wholesalers and distributors. We support OEM and private label packaging too. Contact us for quantity pricing, lead times, and shipping details. We’ll help you meet your sourcing targets efficiently.

What is your minimum order quantity (MOQ)?

Our standard MOQ for Screw Terminals is flexible based on product type and customization needs. Contact us to get a tailored quote.

Battery Terminal Screws vs Dryer Terminal Block Screws vs Speaker Screw Terminals

Our standard MOQ for Screw Terminals is flexible based on product type and customization needs. Contact us to get a tailored quote.

All-in-one Screw Terminal Solutions for Your Project

We offer complete customization options for Screw Terminals—from terminal size, current rating, and screw type to mounting style and color coding. These tailored features help your products stand out in a competitive market and simplify end-user installation.

Our factory-scale operations mean you benefit from lower costs, stable lead times, and strict quality control. We manufacture according to international standards like UL and CE, ensuring consistent product performance.

Let us help you build custom terminal blocks that meet your technical and branding requirements.