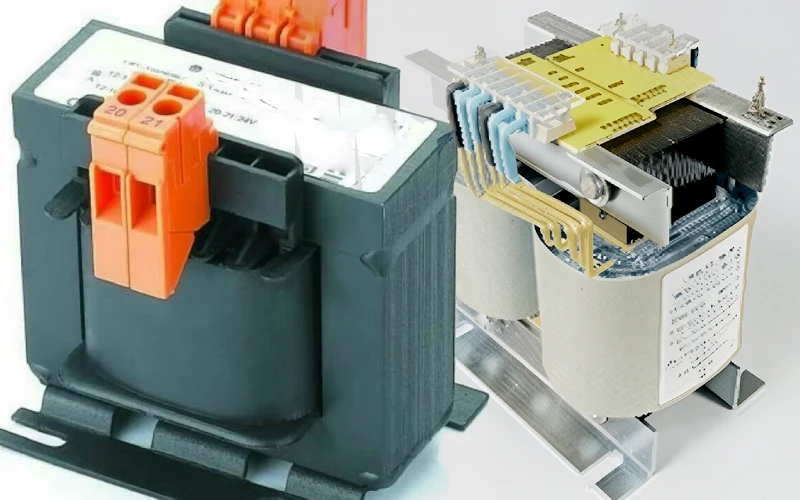

Control transformers are specialized transformers designed to provide regulated voltage to control circuits in industrial and machinery applications. They ensure reliable operation of critical components by stepping down higher voltage to safer, usable levels. Understanding the different types of control transformers is essential for selecting the right one for specific needs.

This blog post explores various types of control transformers, highlighting their unique features, benefits, and typical uses. By delving into their characteristics, you can gain valuable insights into how these transformers contribute to efficient and safe control systems across diverse industries.

What Are Control Transformers

Control transformers are isolation transformers designed to provide stable, low-voltage power to control circuits and devices. They step down higher voltages to a manageable level, ensuring the reliable operation of components in industrial and commercial applications.

Types of Control Transformers

Recommended products

Control transformers are specialized transformers that reduce voltage to supply power for control circuits in machinery and electrical systems. They offer isolation and stable output, crucial for protecting sensitive control components.

Various control transformer types cater to specific needs, ensuring efficient and safe operation across diverse applications.

Control Voltage Transformers

Control voltage transformers are specifically designed to provide the precise, lower voltage required by control circuits. They prioritize voltage regulation to ensure consistent power delivery to relays, contactors, and other control devices, even under fluctuating load conditions. This stability is critical for the reliable operation and longevity of connected components.

Features of control voltage transformers often include excellent voltage regulation, compact designs for easy integration, and robust construction to withstand industrial environments. Benefits include enhanced reliability of control systems, protection against voltage spikes and drops, and improved performance of connected devices.

These transformers find widespread use in automation systems, motor control centers, and various industrial machinery where a stable and specific control voltage is essential for proper operation. They are vital for ensuring the accurate and dependable functioning of control logic and associated components.

Enclosed Control Transformers

Enclosed control transformers are housed within protective enclosures, offering enhanced safety and durability, particularly in harsh or demanding environments. These enclosures safeguard the transformer core and windings from dust, moisture, and physical damage, extending their lifespan and ensuring reliable performance.

Key features include robust enclosures typically made of metal, various protection ratings (e.g., NEMA), and often integrated safety features like circuit breakers or fuses. The benefits of using enclosed transformers include increased safety for personnel, protection of the transformer from environmental factors, and reduced maintenance requirements.

Enclosed control transformers are commonly used in industrial settings, outdoor installations, and areas where exposure to contaminants or potential physical damage is a concern. They are ideal for powering control circuits in machinery, HVAC systems, and other equipment located in challenging environments.

Control Power Transformers

Control power transformers are designed to supply power to control circuits and auxiliary devices requiring a specific voltage level. While similar to control voltage transformers, they may sometimes be designed to handle slightly higher power demands and a broader range of load types within the control system.

Features often include good voltage regulation under varying loads, robust construction for industrial use, and terminal blocks for easy wiring. The benefits include reliable power supply for control components, isolation between the power source and control circuits, and enhanced safety for both equipment and personnel.

These transformers are widely used in industrial automation, process control systems, and various types of machinery to power relays, sensors, timers, and other control elements. They ensure the consistent and safe operation of the control logic within these systems.

Industrial Control Transformers

Industrial control transformers are specifically engineered to meet the rigorous demands of industrial environments. They are built with robust materials and designs to withstand vibration, temperature variations, and electrical noise commonly found in manufacturing and processing facilities.

Key features include heavy-duty construction, high insulation levels, and the ability to handle demanding load conditions. The benefits of using industrial control transformers include long service life in harsh environments, reliable power for critical control systems, and minimized downtime due to transformer failure.

These transformers are essential in factories, power plants, and other industrial settings to power control circuits for machinery, robotics, and automated processes. Their durability and reliability contribute significantly to the continuous operation of industrial facilities.

3-Phase Control Transformers

3-phase control transformers are designed to step down 3-phase power to a lower voltage for use in control circuits that require a 3-phase supply. They are typically used in larger industrial applications where 3-phase power is readily available and needed for certain control components or auxiliary equipment.

Features include balanced 3-phase output, robust construction suitable for industrial loads, and efficient power conversion. The benefits include providing the necessary 3-phase power for specific control applications, efficient operation in high-power systems, and reliable performance in demanding industrial environments.

These transformers are commonly found in large industrial machinery, HVAC systems for large buildings, and specialized control panels that require a 3-phase low-voltage supply for their operation. They ensure the proper functioning of 3-phase control devices.

Single-Phase Control Transformers

Single-phase control transformers are designed to step down single-phase power to a lower voltage for control circuits. They are the most common type and are used in a wide variety of applications where a single-phase low-voltage supply is sufficient for the control system.

Features include compact sizes, ease of installation, and reliable voltage transformation for single-phase loads. The benefits include providing the necessary low-voltage power for a broad range of control applications, cost-effectiveness for single-phase systems, and simple integration into existing electrical setups.

These transformers are used extensively in residential, commercial, and industrial settings to power control circuits in appliances, HVAC units, small machinery, and various electronic control systems that operate on a single-phase supply.

Furnace Control Transformers

Furnace control transformers are specifically designed to provide the low-voltage power required for the control circuits in heating, ventilation, and air conditioning (HVAC) systems, particularly furnaces. They ensure the safe and reliable operation of thermostats, relays, and other control components within these systems.

Key features include specific voltage outputs commonly used in HVAC controls (e.g., 24VAC), compact designs for integration within HVAC units, and built-in protection features like circuit breakers or fuses. The benefits include reliable power for HVAC control systems, safe operation of heating and cooling equipment, and compatibility with standard HVAC control components.

These transformers are essential components in residential and commercial furnaces, boilers, and air conditioning units, ensuring the proper functioning of the control logic that regulates temperature and airflow within these systems.

Isolation Control Transformers

Isolation control transformers provide electrical isolation between the power source and the control circuit, in addition to stepping down the voltage. This isolation is crucial for protecting sensitive control components from electrical noise, ground loops, and voltage transients, enhancing safety and system reliability.

Features include a high degree of electrical isolation, excellent noise attenuation, and often good voltage regulation. The benefits include enhanced safety for personnel and equipment, protection of sensitive control electronics, and improved system stability and reliability by eliminating ground loop issues and reducing noise.

These transformers are used in applications where electrical isolation is paramount, such as in sensitive electronic control systems, medical equipment, and industrial environments with high levels of electrical noise. They ensure the integrity and safety of the connected control circuits.

Low Voltage Transformers

Low voltage transformers step down high input voltage to a lower, safer voltage suitable for various applications. They provide stable and reliable power conversion, protecting connected equipment from voltage fluctuations, overloads, and electrical disturbances.

Features include efficient voltage conversion, robust construction, and reliable performance under continuous operation. The benefits include enhanced equipment protection, energy efficiency, and safer operation in both industrial and commercial environments.

These transformers are used in applications such as control panels, lighting systems, machinery, renewable energy systems, and other devices requiring low, stable voltage. They ensure safe, consistent power supply and prolong the lifespan of connected equipment.

Here are control transformer types widely used in the industry:

| Control Transformer Types | Key Features | Benefits | Common Uses |

| Control Voltage Transformers | Excellent voltage regulation, compact design, robust construction | Enhanced reliability, protection against voltage fluctuations, improved device performance | Automation systems, motor control centers, industrial machinery |

| Enclosed Control Transformers | Protective enclosure, various NEMA ratings, integrated safety features | Increased safety, protection from environment, reduced maintenance | Industrial settings, outdoor installations, harsh environments |

| Control Power Transformers | Good voltage regulation, robust construction, easy wiring terminals | Reliable power supply, isolation, enhanced safety | Industrial automation, process control systems, various machinery |

| Industrial Control Transformers | Heavy-duty construction, high insulation levels, handles demanding loads | Long service life in harsh environments, reliable power for critical controls, minimized downtime | Factories, power plants, industrial machinery and robotics |

| 3-Phase Control Transformers | Balanced 3-phase output, robust for industrial loads, efficient conversion | Provides necessary 3-phase power, efficient in high-power systems, reliable in demanding environments | Large industrial machinery, HVAC for large buildings, specialized 3-phase control panels |

| Single-Phase Control Transformers | Compact size, easy installation, reliable voltage transformation | Low-voltage power for broad applications, cost-effective for single-phase systems, simple integration | Residential, commercial, industrial (appliances, HVAC, small machinery, electronic controls) |

| Furnace Control Transformers | Specific HVAC voltage outputs (e.g., 24VAC), compact, built-in protection | Reliable power for HVAC controls, safe operation of heating/cooling, compatible with HVAC components | Residential and commercial furnaces, boilers, air conditioning units |

| Isolation Control Transformers | High electrical isolation, excellent noise attenuation, good regulation | Enhanced safety, protection of sensitive electronics, improved system stability and reliability | Sensitive electronic controls, medical equipment, noisy industrial environments |

Which is a Common Type of Control Transformer

Single-phase control transformers stand out as a particularly common type of control transformer due to their versatility and applicability across a wide spectrum of applications. Their primary function is to step down single-phase AC power to a lower, more manageable voltage suitable for control circuits. This makes them indispensable in numerous residential, commercial, and industrial settings where single-phase power is the norm for powering smaller control components.

Their prevalence can be attributed to several factors, including their relatively simple design, cost-effectiveness, and ease of installation. They are frequently employed to power control circuits in:

- Appliances (e.g., washing machines, refrigerators)

- HVAC systems (e.g., thermostats, control relays)

- Small industrial machinery

- Lighting control systems

- Various electronic control units

The widespread use of single-phase power in many applications naturally leads to the commonality of single-phase control transformers.

How to Choose the Best Control Transformers

Selecting the optimal control transformer involves careful consideration of several key factors to ensure reliable and safe operation of your control circuits. You need to thoroughly assess the specific requirements of your application, including the voltage and power demands of the connected devices. Understanding the environmental conditions where the transformer will operate is also crucial for choosing a unit with appropriate protection features and durability.

To choose the best control transformer, consider the following:

- Voltage Requirements: Determine the precise input voltage available and the required output voltage for your control circuit, ensuring the transformer has the correct turns ratio to step down the voltage appropriately for all connected components to function as intended and avoid damage due to incorrect power supply.

- VA Rating (Volt-Amperes): Calculate the total power потребление of all devices connected to the control transformer and select a transformer with a VA rating that meets or slightly exceeds this total to prevent overloading and ensure stable power delivery under varying operational conditions.

- Environmental Conditions: Evaluate the operating environment for factors like temperature, humidity, and the presence of dust or corrosive substances to choose a transformer with an appropriate enclosure rating (e.g., NEMA) that can withstand these conditions and maintain performance over time.

- Isolation Requirements: Decide if electrical isolation between the primary and secondary windings is necessary for safety and to prevent ground loops or electrical noise from affecting sensitive control components, opting for an isolation transformer if such protection is critical for your application.

- Mounting and Size Constraints: Consider the physical space available for installation and choose a transformer with dimensions and mounting options that fit within the designated area, ensuring proper ventilation and accessibility for maintenance if needed in the future.

- Safety Standards and Certifications: Verify that the control transformer meets relevant safety standards (e.g., UL, CSA) and has the necessary certifications to ensure compliance with local electrical codes and guarantee the safety and reliability of the power supply for your control system.

Conclusion

In conclusion, control transformers are essential components in numerous applications, providing stable and reliable low-voltage power for control circuits. Their key features, such as voltage step-down, isolation, and load regulation, offer significant benefits in ensuring the safe and efficient operation of connected devices. From industrial machinery to automation systems, control transformers play a crucial role in maintaining operational integrity.

Understanding the various types and their specific uses allows for informed selection based on application requirements. By providing the necessary voltage and isolation, these transformers protect sensitive control components and contribute to overall system reliability. For businesses seeking to acquire these vital components, Linkwell Electrics offers a range of wholesale control transformers.

Sourcing control transformers from reputable suppliers like Linkwell Electrics ensures access to quality products that meet diverse industrial and commercial needs. Their availability as wholesale options can provide cost-effective solutions for businesses requiring multiple units for their operations, ultimately supporting the efficient and safe functioning of various electrical systems.