Choosing the right fan blade design can make a big difference in how cool your space feels. When you select the best option, you can boost cooling efficiency by up to 8% and even save 20% on energy bills.

- Many customers, like Alex Li and Karen Müller, trust Linkwell’s fans for their quality and support, especially in major projects.

You get a wide selection of Types of Fan Blades, so you can find the perfect fit for your home, office, or industrial setup. Think about what you need most—quiet operation, strong airflow, or durability—and see how Linkwell can help.

Types of Fan Blades Key Takeaways

- Choosing the right fan blade design can improve cooling efficiency by up to 8% and reduce energy bills by 20%.

- Different blade types serve specific needs: backward-inclined blades are quiet and efficient, while airfoil blades maximize airflow with low energy use.

- Consider the number of blades; more blades can enhance airflow, but focus on blade shape and pitch for optimal performance.

- Select fan blades based on your environment: metal blades are durable for industrial use, while plastic blades are lightweight and quieter for home settings.

- Regular maintenance, like cleaning fan blades, ensures better performance and longevity, helping you save on energy costs.

Best Fan Blade Designs

Why Blade Design Matters

When you look at a fan, you might think all blades do the same job. That’s not true. The fan blade design shapes how air moves and how cool your space feels. You want a fan that gives you strong airflow and keeps things comfortable. The right design can boost cooling efficiency and make your fan performance stand out.

Here are some scientific principles that explain why blade design matters:

- Blade pitch changes how the blades cut through the air. A steeper pitch increases static pressure and can affect noise.

- RPM, or how fast the blades spin, impacts airflow and cooling efficiency. Faster blades move more air but can get noisy.

- Blade shape and curvature matter. Wide, flat blades push lots of air for effective cooling. Curved blades work better for high-pressure needs, like heavy-duty industrial fans.

You want to match the blade design to your needs. If you need quiet operation, choose blades with a gentle pitch. For heavy-duty industrial fans, go for blades built for high pressure and airflow.

Top Choices for Cooling

HVAC professionals often recommend certain blade types for maximum cooling efficiency. You can see the top choices in the table below:

| Fan Blade Type | Description |

|---|---|

| Backward-Inclined Blades | Designed for quiet operation and high efficiency, commonly used in air conditioners and heaters. |

| Backward-Curved Blades | Minimize energy consumption while maximizing airflow output. |

| Airfoil Blades | Most efficient design, reduces drag and maximizes air movement with low energy consumption. |

If you want effective cooling and top fan performance, these designs are a great place to start. Airfoil blades stand out for energy efficiency and smooth airflow. Backward-curved blades work well in heavy-duty industrial fans, giving you reliable cooling efficiency.

Does the Number of Fan Blades Affect Cooling Efficiency

You might wonder if more blades mean better cooling. Experiments show that adding more blades increases airflow volume. This means you get improved cooling efficiency and stronger fan performance. For heavy-duty industrial fans, a higher blade count can help you achieve effective cooling in large spaces.

When you choose a fan, think about blade count, shape, and speed. These factors work together to give you the best cooling efficiency and fan performance for your needs.

Types of Fan Blades by Linkwell

Recommended products

When you look for the best cooling solution, you want to know what sets Linkwell apart. Linkwell brings decades of experience in designing and manufacturing different types of fan blades for both industrial and residential use. You get access to a wide range of options, each crafted for specific cooling needs. Whether you need powerful airflow in a factory or quiet operation in your home office, Linkwell has you covered.

Tip: Choosing the right blade type can help you save energy and keep your equipment running longer.

Here’s a quick overview of the main types of fan blades you’ll find at Linkwell and where you might use them:

| Type of Fan Blade | Primary Applications |

|---|---|

| Axial Fan Blades | High airflow applications, cooling and ventilation units. |

| Propeller Fan Blades | Continuous ventilation in warehouses and industrial facilities. |

| Tube Axial Fan Blades | Quiet operation applications like computer cooling and air conditioning systems. |

| Centrifugal Fan Blades | High flow rate applications, overcoming high resistance. |

| Backward-Inclined Fan Blades | Air conditioners and heaters, prioritizing quiet and efficiency. |

| Forward Curved Fan Blades | Blowers and smoke exhaust systems, moving large volumes of air. |

You’ll see these types of fan blades in Linkwell’s Computer Chassis Fan and Electrical Enclosure Fan. These products use advanced blade designs to deliver reliable cooling and energy savings.

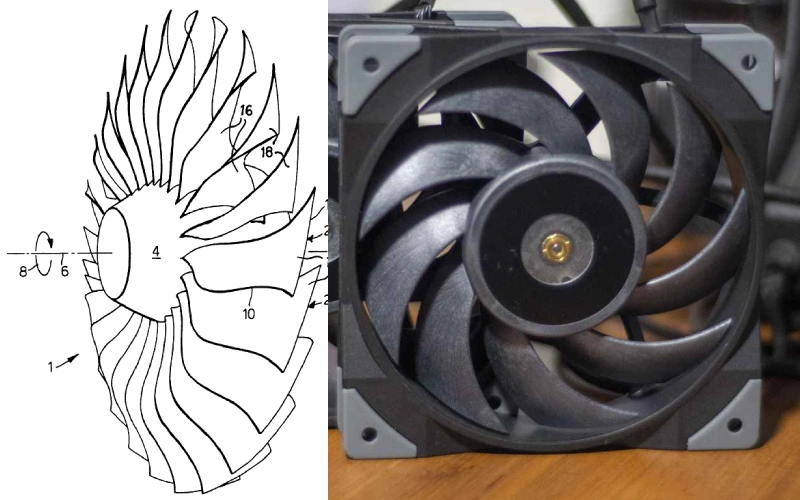

Axial Fan Blades

You’ll notice axial fan blades in many cooling systems. These blades move air in a straight line, parallel to the fan’s axis. You get high airflow with low pressure, which works well for large spaces that need lots of air movement. Axial fan blades have a compact design, so you can fit them into tight spots without losing performance.

Here’s what makes axial fan blades stand out:

| Characteristic | Description |

|---|---|

| Linear airflow | Moves air parallel to the fan’s axis. |

| High flow, low pressure | Ideal for large-volume airflow with minimal pressure. |

| Compact design | Requires less space compared to centrifugal fans. |

| Energy efficiency | Uses less power for moving large air volumes. |

| Multiple blade configurations | Available with mono-directional or reversible blades and airfoil profiles. |

You’ll find axial fan blades in industrial cooling, generator ventilation, HVAC systems, tunnel ventilation, and electronic equipment cooling. Linkwell’s Computer Chassis Fan uses these blades to keep your devices cool and running smoothly.

Propeller Fan Blades

If you need continuous ventilation in a warehouse or factory, propeller fan blades are a smart choice. These blades have a simple design with long, narrow blades attached to a hub. You get high airflow at low pressure, which is perfect for moving air in large open spaces.

| Feature | Propeller Fans | Axial Fans |

|---|---|---|

| Design | Simple design with long, narrow blades on a hub. | Shorter, wider blades housed in a casing. |

| Airflow | Generates high airflow at low pressure. | Moves air with higher pressure, suitable for ducts. |

| Applications | Ideal for ventilation in large spaces, cooling. | Used in industrial settings, heat exchangers. |

| Resistance | Best for minimal resistance applications. | Designed to overcome significant resistance. |

You’ll see propeller fan blades in Linkwell’s ventilation units for warehouses and industrial facilities. These blades keep air moving and help maintain a comfortable environment.

Tube Axial Fan Blades

Tube axial fan blades give you strong, directed airflow. Air enters from one side and exits from the other, staying aligned with the fan’s axis. You get efficient air movement, especially in places where you need quiet operation, like computer cooling and air conditioning systems.

| Advantage | Description |

|---|---|

| Airflow Direction | Air is drawn in through one side and expelled from the opposite side, aligned with the fan axis. |

| Efficiency | Highly efficient for moving large volumes of air at moderate pressures. |

| Application Suitability | Ideal for ventilation, cooling, and exhaust systems where air volume is prioritized over pressure. |

- Tube axial fans generate a strong and directed stream of air.

- They improve overall air circulation within workspaces.

- Designed for high airflow at relatively low pressures.

You’ll find tube axial fan blades in Linkwell’s Computer Chassis Fan, where quiet and efficient cooling is essential.

Centrifugal Fan Blades

Centrifugal fan blades work best when you need to move air against resistance. These blades create high static pressure, making them perfect for environments like dust collection systems and pneumatic conveying. You get reliable performance even in tough conditions.

| Fan Type | Best Applications | Key Benefits |

|---|---|---|

| Forward Curved | HVAC, electronics cooling | Quiet, compact, high airflow |

| Backward Curved | Cleanrooms, data centers, dust collection | High pressure, energy saving |

| Radial/Radial Tip | Material handling, dust, fibers | Handles dirty air, durable |

- Forward curved blades work well in HVAC systems and electronics cooling, giving you high airflow rates.

- Backward curved blades suit cleanrooms and data centers, offering better airflow control and higher efficiency.

- Radial fan blades handle dusty or contaminated air, known for their durability and ability to manage high resistance.

Linkwell’s Electrical Enclosure Fan uses centrifugal fan blades to keep sensitive equipment safe from overheating.

Backward-Inclined & Forward-Curved Blades

Backward-inclined fan blades give you smooth airflow and lower noise levels. You’ll appreciate their energy-saving design, which helps reduce power consumption across a wide range of operating conditions. These blades work well in air conditioners and heaters, where quiet and efficient cooling is important.

| Fan Type | Power Consumption Characteristics |

|---|---|

| Forward Curved Fans | Higher power consumption at partial loads or high static pressures. |

| Backward Curved Fans | Lower power consumption across a wide operating range, leading to energy savings. |

| Fan Type | Noise Level Characteristics |

|---|---|

| Forward Curved Fans | Generate slightly higher noise levels, especially in higher frequencies. |

| Backward Curved Fans | Operate quieter due to smoother airflow, producing lower frequency noise. |

You’ll find forward curved fan blades in blowers and smoke exhaust systems, moving large volumes of air. Backward-inclined fan blades are ideal for places where you want quiet operation and energy efficiency.

Radial and Airfoil Blades

Radial fan blades excel in industrial settings and HVAC systems. You get high static pressure and effective air movement, even in challenging environments. These blades handle dirty air and resist wear, making them a reliable choice for material handling and dust control.

Airfoil blades offer high efficiency and quiet operation. You’ll see them in chemical plants, power generation, and metals industries. These blades work well in clean air applications and environments with elevated temperatures.

| Fan Type | Applications | Benefits |

|---|---|---|

| Radial Fan | Industrial settings, HVAC systems | High static pressure, effective air movement |

| Airfoil Fan | Chemical, power generation, metals industries | High efficiency, quiet operation |

- Airfoil fans are efficient and operate quietly.

- Ideal for environments with elevated temperatures.

- Commonly used in clean air applications.

When you explore the different types of fan blades at Linkwell, you’ll find options for every cooling challenge. You can choose the right blade for your application, whether you need powerful airflow, quiet operation, or durability.

Blade Materials & Performance

Metal vs. Plastic Blades

When you pick a fan, you might wonder if metal or plastic blades work better. Both have unique strengths. Metal blades, like those made from aluminum or steel, give you strong airflow and handle high temperatures with ease. You often see them in big spaces or places that need quick cooling. Plastic blades, on the other hand, are lighter and quieter. They resist rust and work well in smaller rooms or quiet zones.

Here’s a quick look at how they compare:

| Blade Type | Airflow Strength | Efficiency | Suitable For |

|---|---|---|---|

| Metal | High | Steady | Large rooms, high ceilings |

| Plastic | Moderate | Gentle | Small rooms, quiet zones |

Tip: Linkwell uses advanced thermoplastic PC for plastic blades and laser-welded steel for metal blades. This means you get the best of both worlds—strength, durability, and energy efficiency.

Durability and Efficiency

You want your fan to last and save energy. Metal blades, especially steel, stand up to heavy use and tough environments. They work great in industrial settings where centrifugal fan blades or radial fan blades need to move air against resistance. Plastic blades, like those in Linkwell’s computer chassis fans, offer a lightweight option that cuts down on noise and energy use. They also allow for creative fan blade design, which can boost airflow and lower power bills.

Backward-curved fan blades and backward-inclined fan blades, often made from steel, shine in places where you need both quiet and efficient cooling. Forward curved fan blades, usually plastic, work well in blowers and exhaust systems. No matter the material, Linkwell’s focus on quality means you get blades that last and perform.

Does the Number of Fan Blades Affect Cooling Efficiency

You might think more blades mean better cooling, but that’s not always true. Thanks to modern design and technology, both 3-blade and 5-blade fans can deliver top performance. The shape, pitch, and motor matter more than the number of blades. Centrifugal fan blades, for example, use smart engineering to keep airflow strong and noise low, no matter how many blades you see.

So, when you choose a fan, focus on the overall design and material. You’ll get the cooling you need and enjoy better energy efficiency.

Blade Count & Shape

Impact on Airflow and Noise

When you look at a fan, you might notice the number of blades, their shape, and how they are angled. These features play a big role in how your fan works. The blade count and shape affect both airflow dynamics and noise levels. If you want a quiet fan, you need to pay attention to these details.

Most of the noise from a fan comes from the way air swirls off the blade’s trailing edge. The leading edge of each blade also creates pulses of air, which can add to the noise. If the blades are not balanced, you might hear extra sounds.

Here’s a quick look at how blade thickness and design affect noise:

| Aspect | Findings |

|---|---|

| Blade Thickness | Thicker blades usually make less noise at most frequencies. |

| Noise Generation | Noise comes from air bubbles and how they hit the blade surface. |

| Prediction Method | Engineers use special equations and experiments to predict fan noise. |

The pitch, or angle, of the blade also matters. A steeper angle pushes more air, but if it’s too steep, the air can get turbulent and noisy. A gentle angle may not move enough air for your needs.

Choosing the Right Design

Picking the right fan blade design means thinking about your space and what you want from your fan. Do you need strong airflow, or is quiet operation more important? Here are some things to consider:

- Understand your airflow needs. Large rooms need more air movement.

- Choose the right material. Steel blades are strong and last long. Aluminum blades are light and resist rust.

- Look at blade shape and pitch. Curved blades often move air more smoothly and quietly than straight ones.

- Think about energy efficiency. The right design can help you save on power bills.

| Blade Angle Change | Effect on Airflow | Effect on Cooling Efficiency |

|---|---|---|

| Increased Angle | More airflow, better heat dissipation | Too much angle can make air turbulent and less efficient |

| Decreased Angle | Less airflow | May not cool well in busy or hot spaces |

Linkwell’s design philosophy focuses on balancing airflow, noise, and energy efficiency. You get fans that work well for your needs, whether you want a quiet office or a cool industrial space.

Selecting the Right Fan Blade

Matching Blade Type to Application

Choosing the right fan blade for your space starts with understanding your needs. You want to match the fan blade design to your environment, whether it’s an industrial workshop or a home office. Here’s a simple way to break it down:

- Figure out how much air you need to move. Measure your room or cabinet and calculate the cubic feet.

- Decide how often you want the air to change each hour. Hotter spaces need more air movement.

- Multiply your room’s volume by the number of air changes, then divide by 60. This gives you the cubic feet per minute (CFM) you need.

- Pick the right fan type. Axial fans work well for broad coverage. Centrifugal fans handle higher pressure, like in ducted systems.

- Check the blade size and pitch. Make sure they fit your airflow goals.

- Look at where you’ll mount the fan. Make sure your ceiling or cabinet can support it.

Tip: In tough environments, like places with high heat or moisture, choose blades that resist corrosion and can handle extreme temperatures.

What factors should be considered when choosing fan blades for optimal cooling performance?

You want your fan to deliver optimal cooling performance without wasting energy. Here are some key things to keep in mind:

- Airflow rate: Make sure the fan meets your cooling needs.

- Noise level: Choose a design that keeps things quiet if you’re working or relaxing nearby.

- Energy efficiency: Look for fans with high Fan Energy Index (FEI) ratings and efficiency curves.

- Blade type: Different fan blade types, like axial or centrifugal, affect airflow and noise.

- Installation: Proper setup boosts performance and reduces noise.

- Maintenance: Regular cleaning and checks keep your fan running smoothly.

Selecting the right fan is not just about immediate airflow. It’s about long-term reliability and energy savings. A well-chosen fan runs in its best efficiency range, saving you money over time.

Linkwell Solutions for Every Need

You have lots of choices when it comes to different fan blade types. Linkwell makes it easy to find the perfect fit for your application. If you need a fan for a computer chassis, Linkwell’s Computer Chassis Fan uses advanced plastic blades for quiet, efficient cooling. For electrical enclosures, their fans feature robust metal blades that handle tough industrial conditions.

Linkwell offers customization options, so you can get the exact size, material, and blade count you need. Bulk buyers get fast delivery and expert support. Whether you want to boost energy efficiency or need a unique fan blade design, Linkwell has a solution for you.

If you’re not sure which fan to pick, reach out to Linkwell’s team. They’ll help you choose the right blade for your space and make sure you get optimal cooling performance every time.

You’ve seen how the right fan blade design and material can boost airflow, cut energy costs, and keep noise low. Linkwell leads the way with advanced engineering, rigorous testing, and certifications that set them apart. Take a look at the impact factors and Linkwell’s strengths:

| Factor | Impact on Cooling Performance |

|---|---|

| Aerodynamic Efficiency | Better airflow, less turbulence |

| Energy Efficiency | Lower power bills |

| Noise Reduction | Quieter operation |

| Feature/Recommendation | Details |

|---|---|

| Customization Options | OEM/ODM available |

| Protection Ratings | IP54, IP55, IP56 |

| Contact | info@linkwell.org, 0086-400-671-6715 |

If you want expert advice or need bulk orders, Linkwell’s team is ready to help you find the perfect solution.

FAQ

What is the most important factor when choosing a fan blade design?

You want to focus on airflow needs and noise level. Think about where you will use the fan. The right fan blade design helps you get the best cooling and energy savings.

Can I use the same fan blade for different environments?

No, you should match the blade type to your space. Industrial areas need strong, durable blades. Quiet rooms work better with lightweight, low-noise blades.

How often should I clean my fan blades?

You should check your fan blades every few months. Dust and dirt can build up fast. Clean blades help your fan run better and last longer.

Does blade material affect cooling performance?

Yes, it does. Metal blades move more air and handle heat well. Plastic blades are lighter and quieter. Pick the material that fits your cooling needs.