Water to Air Heat Exchanger

High-Performance Water to Air Heat Exchanger Solutions for Electrical and Telecom Cabinets

We manufacture high-performance Water to Air Heat Exchanger units specifically for control cabinets, electrical enclosures and telecom signal cabinets.

At LinkwellElectrics, we offer custom sizing, materials and support to meet wholesale, OEM and distributor demands.

Size range

“Small to large cabinet heat exchanger options”

Voltage

“Supports a range of AC and DC inputs”

Operating temperature range

“Designed for extreme ambient conditions cooling”

Speed

“Efficient fan/blower speeds matched for capacity”

Service life

“Long-term durability under industrial conditions”

Our Water to Air Heat Exchanger Series

We provide customized axial fan solutions with flexible sizes, fast delivery, and OEM/ODM support. Contact us now for a free quote!

EIA Series 05

Provides full internal and external isolation, effectively blocking dust, oil mist, and moisture ingress to ensure stable, contamination-free cabinet operation.

EIA Series 10

Features a compact, space-saving design compatible with major industry models, supporting flexible temperature settings from -15°C to +55°C for various environments.

LK-ANU/AN

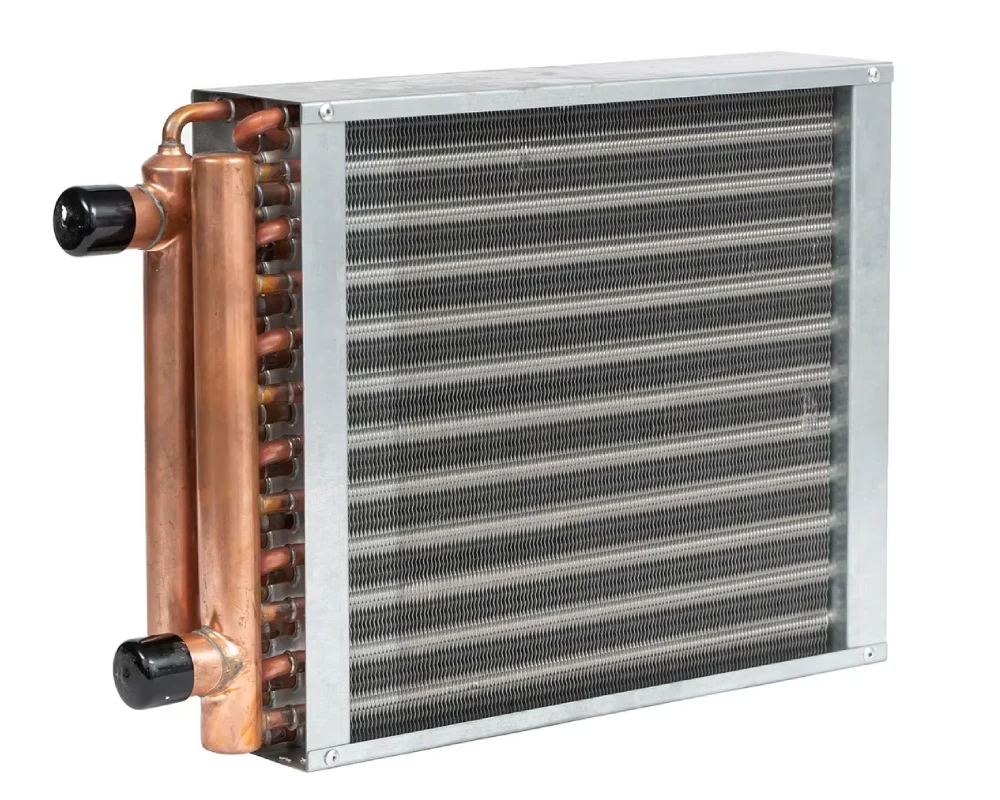

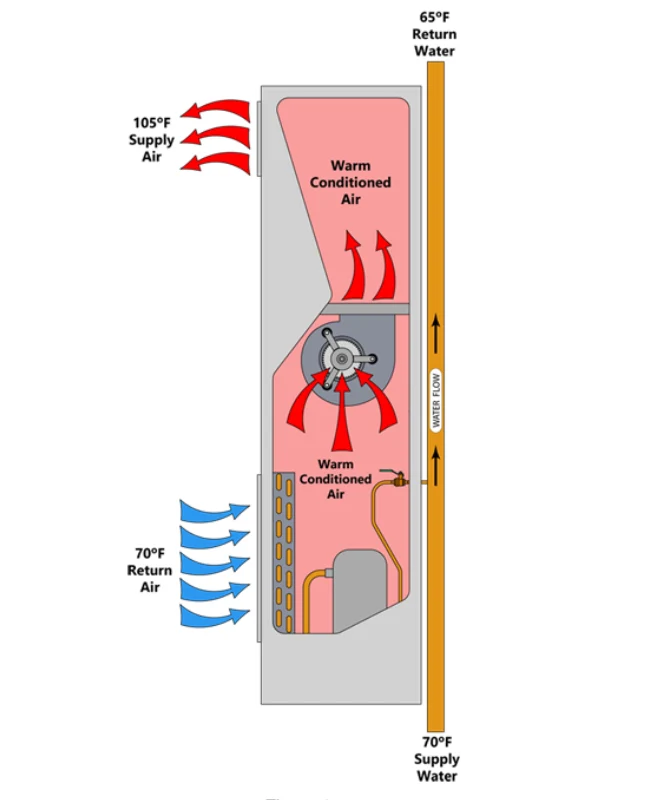

The Water to Air Heat Exchanger operates by circulating cooling water through a finned coil, efficiently transferring heat from inside the enclosure to the external environment for reliable thermal management.

Exceptional Water to Air Heat Exchanger Performance from Our Quality Materials

High-Efficiency Aluminum Heat Exchange Core

Our Water to Air Heat Exchangers are built with a precision-engineered aluminum fin-and-tube core, designed to maximize thermal conductivity. The dense fin spacing ensures efficient heat transfer between the internal air and circulating coolant, maintaining stable cabinet temperatures even under high load.

IP65 and IP68 Protection Levels

Each unit is sealed to meet IP65 or IP68 ratings, providing complete protection against dust and moisture. This allows the heat exchanger to operate reliably in outdoor, marine, or dusty industrial environments without performance degradation or corrosion.

Exceptional Thermal Stability and Long Service Life

Our exchangers use corrosion-resistant materials and robust brazed joints to maintain structural integrity under continuous heat cycling. This ensures consistent performance and long-term durability, even in demanding applications such as telecom or control cabinets.

Precision-Crafted Housing for Optimal Airflow

The enclosure and ducting are manufactured with CNC accuracy to guarantee balanced airflow and uniform heat dissipation. The optimized design minimizes pressure drop, reduces noise, and enhances the cooling efficiency of the entire system.

01. Diverse Product Range

We offer nearly 40 heat-exchanger models across compact to large-format cores, multiple flow capacities, and assorted mounting configurations (top, side, rear) to suit control cabinets, telecom racks, and outdoor enclosures.

02. Bespoke Control Solutions

We provide integrated control options: thermostatic valves, proportional flow valves, PWM pump controllers, and BMS/PLC interfaces for precise temperature regulation and system monitoring.

03. Fluid & Leak Protection Options

Choose coolant compatibility (water, glycol mixes, or closed-loop coolant), double-wall tubes for leak safety, and optional leak detection ports for high-risk or mission-critical installations.

04. High Temperature Resistance

Custom cores and brazing allow units rated for elevated coolant temperatures and pressures—specified up to 120°C and high working pressures as required for industrial applications.

05. All-Weather Waterproofing

We can supply IP65–IP68 sealed housings, corrosion-resistant coatings, and marine-grade finishes for reliable operation in wet, salty, or dusty environments.

06. Customizable Speeds

Tailor heat transfer capacity by selecting core size, fin density, tube diameter, and coolant flow rates to achieve precise ΔT and airflow/pressure targets for your enclosure.

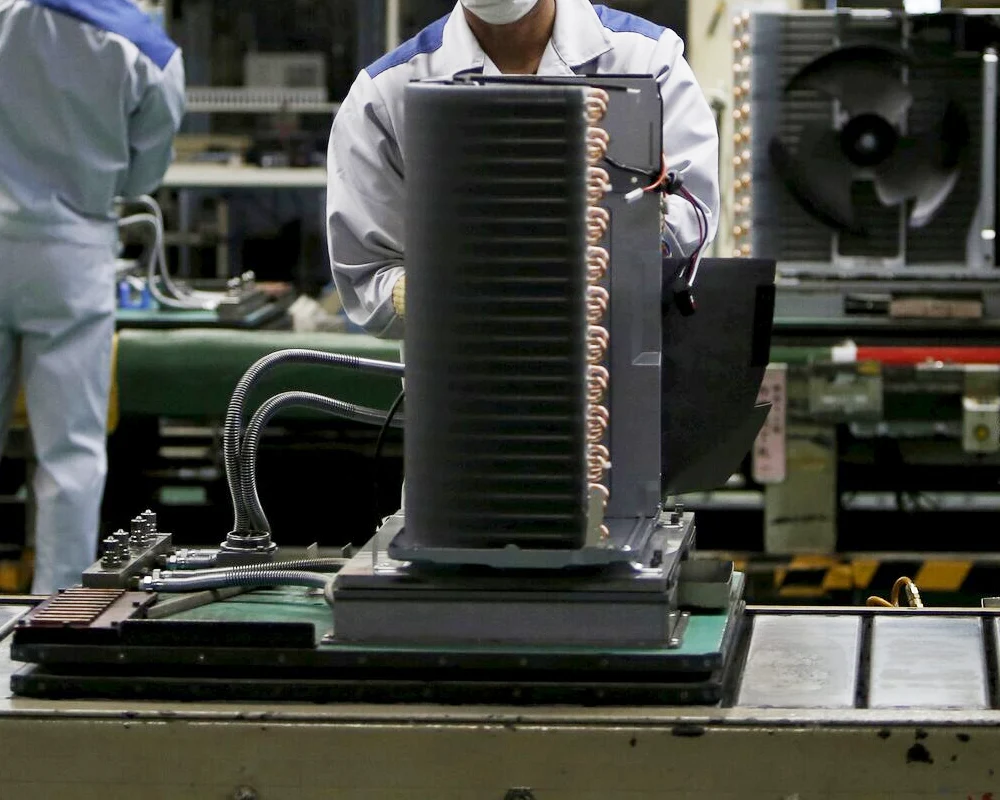

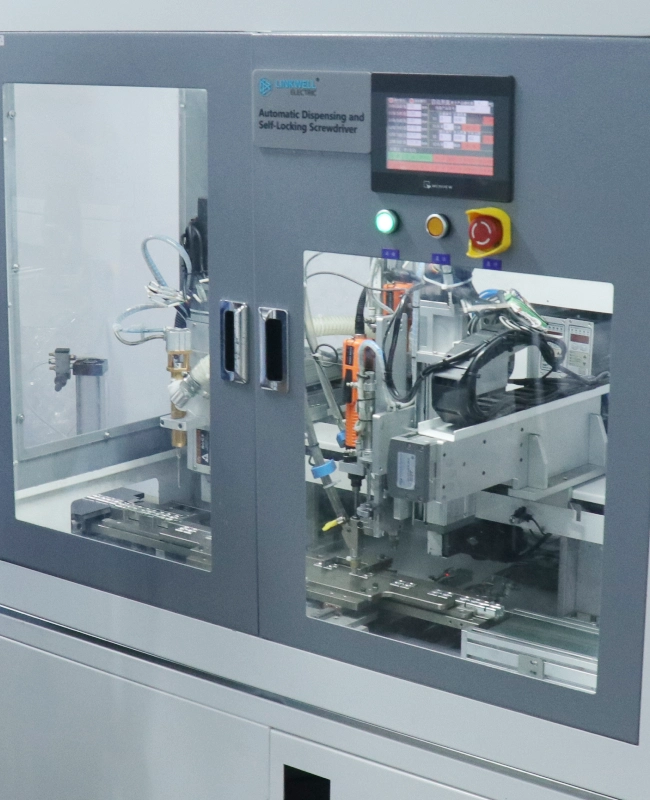

From Concept to Manufacturing: How We Produce Top-Notch Water to Air Heat Exchanger

Design & Development

We begin with thermal-load analysis and CFD airflow simulation, then develop prototypes using 3D CAD and rapid prototyping to validate form, fit, and thermal performance before tooling.

Premium Raw Materials

We source premium aluminum fins, copper or stainless tubes, high-grade brazing alloys, and durable housings — each batch inspected to meet strict thermal and corrosion standards.

Precision Component Manufacturing

Cores are produced via fin stamping and tube insertion, with precision brazing or soldering to ensure excellent thermal contact and leak-proof joints for long service life.

Assembly Process

Skilled technicians assemble cores, housings, interface fittings and sensors. We ensure alignment, mounting tolerances and secure coolant connections for leak-free operation in the field.

Testing & Calibration

Every unit undergoes pressure/leak testing, flow verification, thermal performance (ΔT, BTU/W), and environmental cycling to simulate real-world conditions before release.

Packaging & Shipping

Units are packaged with shock-absorbing inserts, protective covers and moisture barriers. Bulk orders are palletized with reinforced crates to ensure safe arrival at project sites.

Why Choose Us: The Water to Air Heat Exchanger Manufacturer You Can Trust

Innovative R&D Capability

We hold 20+ patents in cooling technologies. Our R&D focuses on eco-friendly materials and sustainable cooling solutions tailored to high-demand industrial cabinets and telecom sites.

Fast and Reliable Shipping

We understand lead time matters. Our streamlined production and logistics enable large-volume orders of heat exchangers with rapid delivery, helping you meet project deadlines without compromise.

Premium Protective Packaging

To ensure safe delivery, units are packed using high-quality materials, individual slots, reinforced pallets and protection to avoid damage from handling or shipping.

Rapid Response & Development

Our support team replies to inquiries and after-sales requests within 12 hours. We can produce prototypes via 3D printing within 10 days — enabling faster time-to-market.

Comprehensive Warranty Protection

Our standard units carry a 2-year warranty; custom-design units have a 1-year warranty. This gives you peace of mind and support if any issue arises post-installation.

Expert Technical Support

Our team offers: – Application guidance – Installation advice – Performance optimisation – Troubleshooting assistance — all available to assist your engineering or procurement team.

FAQs

What is a Water to Air Heat Exchanger and how does it support cabinet cooling?

A water-to-air heat exchanger transfers heat from the air inside an enclosure into a water-based coolant loop or water side. This removes internal heat without opening the cabinet to outside air, maintaining a sealed environment and protecting sensitive electronics from dust, moisture and humidity.

Why choose water-to-air vs air-to-air for control cabinets?

Water-to-air systems use a liquid coolant that typically offers higher heat transfer capacity and allows for lower internal temperatures than ambient air alone. When you already have a chilled water loop or cooling infrastructure, this is more efficient than air-to-air exchange.

What protection ratings should I look for in cabinet heat exchangers?

For outdoor or harsh environments, IP ratings such as IP65, IP67 or IP68 are preferred. These ratings indicate resistance to dust and water ingress. Our units support these ratings, so you can trust them in telecom, outdoor and industrial enclosures.

How do you determine the correct size or capacity for a cabinet heat exchanger?

You must calculate the heat load (watts or BTU) inside the cabinet, factor ambient conditions, and consider the enclosure design. We assist by analysing power dissipation, temperature rise and required cooling capacity so you choose the right model.

Can these units integrate into my existing control cabinet design?

Yes. Our heat exchangers are designed for side, top or rear mounting and can be customised in size, power input (AC/DC) and control features (sensors, RS485) to integrate seamlessly with your cabinet design.

What customization services do you offer for Water to Air Heat Exchangers?

We offer tailored sizing, finishes, control interfaces, power inputs, waterproofing levels and OEM branding. This allows wholesale buyers, distributors and OEM partners to match project specs or brand requirements.

What materials and manufacturing standards ensure reliability in your units?

We use high-grade aluminum, PBT plastics, premium bearings and sealed loops. All components are tested for durability, heat cycling and environmental exposure to ensure long-life performance in demanding environments.

How quickly can you deliver bulk orders of customized units?

Our manufacturing process, logistics systems and supply chain allow for rapid lead times on both standard and customised models. We aim for prompt delivery to help you meet project schedules and reduce downtime.

What warranty and technical support do you offer with your heat exchangers?

Our standard units come with a 2-year warranty, custom versions carry at least a 1-year warranty. We provide application advice, installation guidance, performance optimisation and troubleshooting support for partner distributors.

Contact & Inquiry

Contact us today for detailed product information, quotes, or expert technical support. Simply complete the form with your name, email, company, country, and inquiry, and our team will get back to you quickly. You can also connect with us directly via WhatsApp, email, or phone for fast and reliable assistance.