Dry-type transformers are everywhere in modern industry, powering factories, offices, and essential equipment. Instead of using oil, they rely on air or solid insulation, which makes them safer, cleaner, and easier to maintain. This simple design is why more businesses are choosing dry-type transformers for reliable and eco-friendly power distribution.

In this ultimate guide, we’ll delve into the inner workings of dry-type transformers, uncovering their various types, key advantages, and diverse applications across industries. Whether you’re an electrical engineer, facility manager, or simply curious, join us as we illuminate the world of these essential power transformation devices.

What are Dry Type Transformers

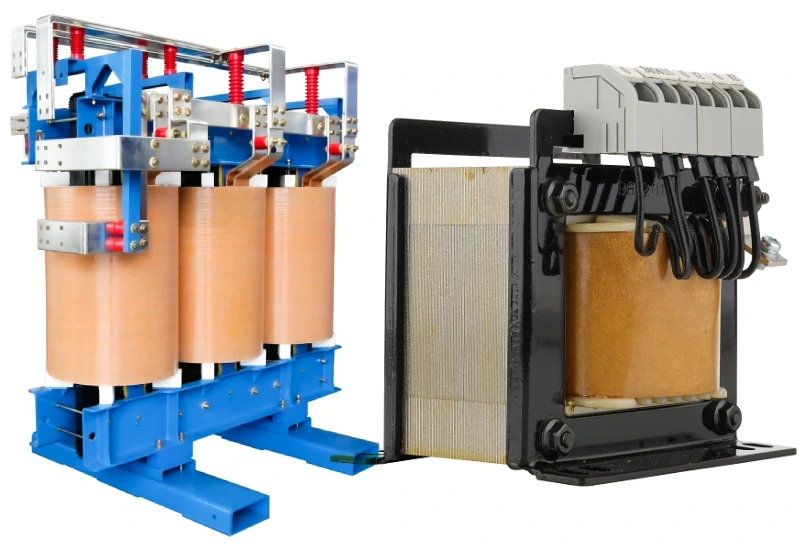

Dry-type transformers are a type of electrical transformer that utilizes air or other non-flammable solid insulation materials, such as resin or varnish, to insulate its windings instead of relying on liquid coolants like oil. This design inherently eliminates the risk of oil leaks, making them a safer and more environmentally friendly option, particularly for indoor applications or areas with strict fire safety regulations.

While they typically have lower overload capacity and can be larger in size compared to liquid-filled transformers of the same rating, their reduced maintenance needs and enhanced safety features make them a preferred choice for many commercial, industrial, and institutional installations.

What is a Dry Type Distribution Transformer

Recommended products

A dry-type distribution transformer is a type of electrical transformer used in power distribution systems to step down or step up voltage levels for localized use within commercial, industrial, or residential buildings.

Unlike liquid-filled transformers, they utilize air or solid insulation materials like resin for cooling and insulation, eliminating the risk of oil leaks and making them suitable for indoor and environmentally sensitive areas. They play a crucial role in safely and efficiently delivering the appropriate voltage to various loads, ranging from lighting and HVAC systems to machinery and electronic equipment within a facility.

Why We Use Dry Type Transformer

Dry-type transformers have gained significant popularity due to a multitude of advantages that make them suitable for a wide range of applications. Their primary appeal lies in the enhanced safety they offer by eliminating the use of flammable liquids like oil, thus mitigating fire hazards and making them ideal for indoor installations and densely populated areas. Furthermore, their environmentally friendly nature, devoid of any risk of oil leaks or the need for special disposal procedures, aligns with increasing sustainability concerns.

The reduced maintenance requirements, stemming from the absence of oil to monitor and maintain, contribute to lower operational costs and increased uptime.

Here are the key reasons why dry-type transformers are preferred in many situations:

- Enhanced Safety: Elimination of flammable oil significantly reduces fire risks, making them suitable for indoor and high-traffic areas.

- Environmental Friendliness: No risk of oil leaks or spills, simplifying disposal and minimizing environmental impact.

- Reduced Maintenance: Absence of oil eliminates the need for oil level checks, oil sampling, and potential oil replacement, lowering maintenance costs.

- Installation Flexibility: Can be installed indoors and closer to the load, reducing secondary distribution losses.

- Improved Aesthetics: Often have a more compact and cleaner design compared to oil-filled transformers.

- Resistance to Short Circuits: Some designs offer better resistance to the mechanical stresses caused by short-circuit faults.

- Suitability for Harsh Environments: Certain encapsulated designs offer excellent resistance to moisture, dust, and corrosive atmospheres.

Where Are Dry-Type Transformers Used?

Dry-type transformers are widely used in various applications where safety, environmental considerations, and reduced maintenance are important. Their absence of flammable oil makes them ideal for indoor and densely populated areas. Common applications include:

- Commercial Buildings: Supplying power for lighting, HVAC systems, elevators, and general electrical loads in offices, shopping malls, and hotels.

- Industrial Facilities: Powering machinery, control systems, and other equipment in factories and processing plants.

- Hospitals and Schools: Environments where fire safety is paramount and oil leaks could pose significant risks.

- Residential Buildings: Stepping down voltage for large residential complexes or specific high-power appliances.

- Transportation Hubs: Used in airports, railway stations, and subway systems for various power distribution needs.

- Renewable Energy Installations: Integrating with solar and wind power systems for voltage transformation.

- Data Centers: Providing reliable and safe power for sensitive electronic equipment.

- Offshore Platforms and Marine Vessels: Environments where oil spills would have severe environmental consequences.

Advantages of a Dry Type Transformer?

Dry-type transformers offer numerous advantages, making them a compelling choice for various applications, as highlighted by their inherent safety and environmental benefits. Their self-extinguishing nature and use of eco-friendly insulation significantly reduce fire hazards and eliminate the production of toxic gases under arcing conditions.

The zero oil usage not only lowers operational costs by removing the need for oil purchases and maintenance but also eliminates the risk of oil leaks and environmental pollution. Their robust design allows for low-cost installation due to fewer restrictions and ensures a long, sustainable service life often exceeding 20 years with minimal maintenance requirements, primarily involving routine inspections rather than dealing with liquid testing or frequent cleaning. These factors contribute to lower load losses and a more environmentally responsible operation with highly recyclable components.

- Self-extinguishing and low fire hazard: Featuring eco-friendly insulation, dry-type transformers are self-extinguishing and flame retardant, significantly reducing fire risks. They also avoid producing toxic gases even when exposed to electrical arcing, enhancing overall safety without the need for dedicated fire suppression systems.

- Zero oil usage: Eliminating the need for oil or other liquid coolants, dry-type transformers rely solely on air for cooling. This removes the expenses associated with purchasing and maintaining cooling liquids, leading to a virtually maintenance-free operation and preventing potential environmental contamination from leaks.

- Eco-friendly and safe: By not using oil, these transformers prevent environmental pollution from leaks. Their self-extinguishing properties minimize explosion risks, and their robust design allows them to withstand challenging weather and polluted environments, ensuring reliable and safe operation in diverse settings.

- Low-cost installation and lower load losses: The reduced fire risk associated with dry-type transformers leads to fewer installation restrictions and the elimination of environmental precautions like groundwater protection. Their efficient design also contributes to lower energy losses during operation, and they offer a long service life exceeding 20 years.

- Low maintenance: Requiring minimal upkeep, dry-type transformers primarily need routine expert inspections rather than the complex maintenance associated with liquid-filled units. The absence of oil eliminates the need for regular liquid testing and the concern of dirt buildup within the coolant, simplifying long-term operation.

- Sustainable: Choosing dry-type transformers supports environmental conservation through low electricity consumption and the use of predominantly recyclable materials (up to 90%). Their reliable service life of over two decades further contributes to sustainability by reducing the frequency of replacements and resource utilization.

Dry Type Transformer Applications

Dry-type transformers find widespread use across various sectors due to their safety, reliability, and environmental benefits, particularly in situations where the risks associated with liquid-filled transformers are undesirable.

Their design makes them suitable for indoor and sensitive environments, providing efficient voltage transformation without the concern of oil leaks or the need for extensive fire suppression systems. This versatility allows them to be implemented in a diverse range of applications, catering to different power needs and safety regulations.

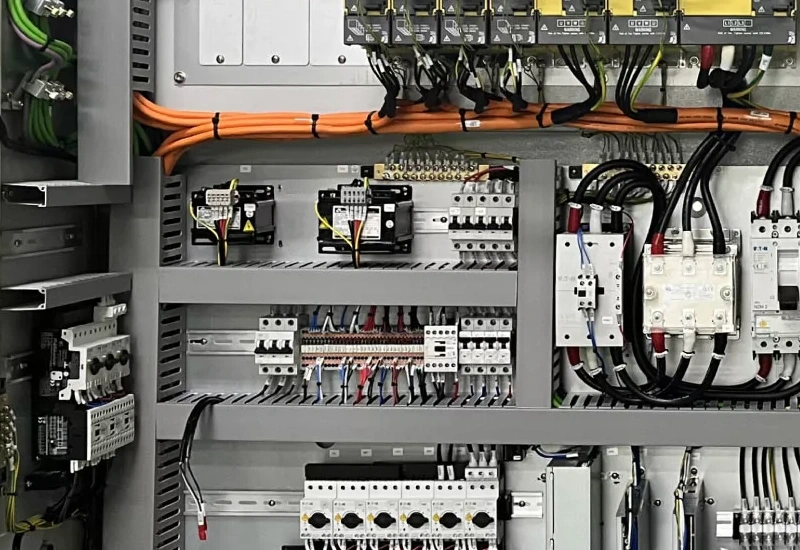

Dry-type transformers in electrical control panels deliver safe, stable voltage for sensitive circuits. With no oil risk, they reduce fire hazards, simplify maintenance, and ensure long-term reliability in industrial automation, HVAC, and power distribution systems.

Commercial Buildings: Dry-type transformers are essential in commercial buildings such as offices, shopping malls, and hotels. They efficiently step down the incoming medium voltage to lower voltages suitable for lighting, HVAC systems, elevators, and general power outlets. Their safe operation is crucial in densely occupied indoor spaces, and their low maintenance requirements minimize disruption to building operations.

Industrial Facilities: In industrial settings, dry-type transformers power a wide array of machinery, control systems, and automated processes. Their robust construction allows them to withstand the demanding conditions often found in factories, and their environmental safety is advantageous in industries with strict regulations. They provide reliable power for critical manufacturing operations.

Hospitals and Schools: Safety is paramount in healthcare and educational institutions, making dry-type transformers the preferred choice. They ensure a stable and safe power supply for vital medical equipment, lighting, and other essential services without the fire hazards associated with oil-filled transformers, protecting both occupants and sensitive equipment.

Residential Buildings: For large residential complexes and high-power appliances, dry-type transformers offer a safe and efficient way to manage voltage levels. They can be installed indoors without significant safety concerns, providing reliable power distribution for the residents’ needs while adhering to safety standards within living environments.

Transportation Hubs: Airports, railway stations, and subway systems rely on dry-type transformers for various power distribution requirements, including lighting, signaling systems, and powering auxiliary equipment. Their safety features are critical in these high-traffic public areas, and their reliable operation ensures the smooth functioning of transportation infrastructure.

Renewable Energy Installations: Dry-type transformers play a vital role in integrating renewable energy sources like solar and wind power into the grid or local distribution systems. They efficiently step up the voltage generated by these sources for transmission or step it down for local consumption, offering a safe and environmentally sound solution for power conversion in sustainable energy projects.

Data Centers: The continuous and reliable operation of sensitive electronic equipment in data centers is crucial, and dry-type transformers provide a stable and safe power supply. Their lack of flammable liquids minimizes fire risks within these critical facilities, protecting valuable data and ensuring uninterrupted service.

Offshore Platforms and Marine Vessels: In marine environments, the risk of oil spills poses significant ecological threats, making dry-type transformers a preferred option. They provide reliable power for various onboard systems without the environmental hazards associated with liquid-filled units, contributing to safer and more sustainable maritime operations.

Differences Between Dry Type and Liquid Transformer

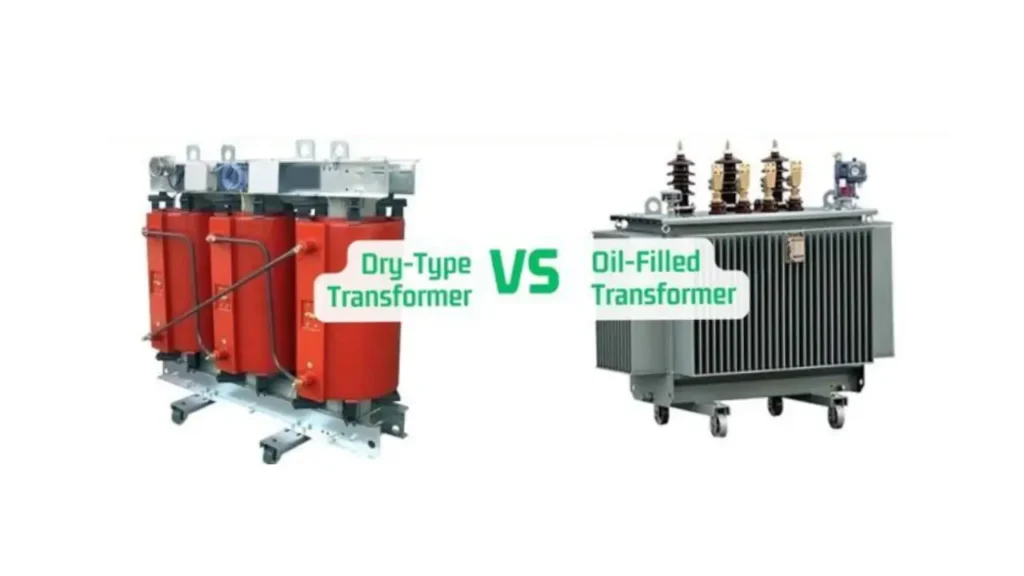

Dry-type and liquid-filled transformers differ fundamentally in their cooling and insulation methods, leading to distinct characteristics and applications. Dry-type transformers utilize air or solid insulation, eliminating the risk of leaks and making them safer for indoor use and environmentally sensitive areas.

They generally require less maintenance as there’s no fluid to monitor or replace. However, they typically have lower overload capacity and can be larger for the same power rating compared to liquid-filled units.

Liquid-filled transformers, on the other hand, use oil or other dielectric fluids for cooling and insulation, offering superior heat dissipation and making them suitable for high-voltage and high-power applications. Their compact design for a given rating is advantageous in space-constrained environments.

However, they require regular maintenance, including fluid testing and potential replacement, and pose an environmental risk due to the possibility of leaks.

- Cooling Medium: Dry-type uses air or solid insulation; Liquid-filled uses oil or other dielectric fluids.

- Environmental Impact: Dry-type is more eco-friendly with no risk of fluid leaks; Liquid-filled has a potential risk of fluid leaks.

- Maintenance: Dry-type requires minimal maintenance; Liquid-filled requires regular fluid checks and potential replacement.

- Application: Dry-type is preferred indoors and safety-critical areas; Liquid-filled is common for high-power outdoor applications.

- Size and Weight: Dry-type tends to be larger and heavier for the same rating; Liquid-filled can be more compact.

- Overload Capacity: Liquid-filled generally has a higher overload capacity due to more efficient cooling.

Dry Type Transformer Installation Tips

Installing a dry-type transformer requires careful planning and adherence to safety guidelines to ensure optimal performance and longevity. Begin by selecting a well-ventilated location with adequate space for the transformer itself and sufficient clearance for air circulation, as proper cooling is crucial for dry-type units.

Ensure the installation site can support the transformer’s weight and is protected from excessive dust, moisture, and vibrations. Always follow the manufacturer’s instructions meticulously regarding lifting, placement, and securing the transformer.

Electrical connections must be made by qualified personnel in accordance with local electrical codes. Before connecting any wiring, verify that the transformer’s voltage rating matches the supply and load voltages.

Ensure all connections are clean, tight, and properly insulated. Grounding the transformer correctly is essential for safety. After installation, perform a thorough visual inspection and conduct no-load testing to verify correct wiring and operation before energizing the connected loads. Regular inspections and cleaning of ventilation openings should be part of ongoing maintenance.

Why Choose Our Dry Type Transformers

Choosing our dry-type transformers means investing in reliability, safety, and sustainability for your power distribution needs. As a leading manufacturer, we prioritize quality materials and advanced designs, ensuring efficient and long-lasting performance.

Our dry-type transformers offer a safer, environmentally friendly alternative to liquid-filled units, requiring minimal maintenance and providing peace of mind for your operations.

- Enhanced Safety: Our dry-type transformers eliminate the risk of oil leaks and fire hazards, making them ideal for indoor and safety-critical applications.

- Environmentally Friendly: With no oil usage and recyclable components, our transformers support your sustainability initiatives.

- Low Maintenance: Designed for minimal upkeep, reducing operational costs and downtime.

- Reliable Performance: Built with high-quality materials for consistent and efficient voltage transformation.

- Customizable Solutions: We offer a range of sizes and configurations to meet your specific power requirements.

- Long Service Life: Our robust designs ensure years of dependable operation.

- Expert Support: Benefit from our extensive knowledge and dedicated customer service.

Conclusion

Dry-type transformers offer a safe, reliable, and environmentally friendly solution for voltage transformation, especially in sensitive environments. Their construction eliminates the risk of oil leaks and reduces the need for extensive maintenance, making them a cost-effective choice over their lifespan. Understanding their benefits and applications is crucial for informed power distribution decisions.

For businesses seeking a dependable supply of wholesale dry-type transformers, consider exploring the options available from reputable suppliers. A wide selection ensures you can find the perfect match for your specific voltage and power requirements.

Looking for reliable wholesale dry-type transformers? As a leading manufacturer from China, Linkwell Electrics offers high-quality, efficient solutions for your power distribution needs. Contact Linkwell Electrics today to discuss your bulk requirements and benefit from our manufacturing expertise and competitive pricing on dry-type transformers.