Barrier terminal blocks are essential components in electrical systems, offering safety, organization, and durability. In this guide, we explore their benefits, applications, and expert manufacturing insights.

What Is a Barrier Terminal Block?

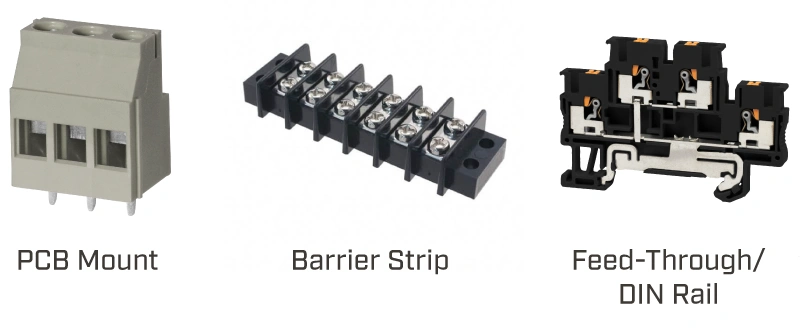

When I first started in the electrical wiring industry, I quickly learned how messy things can get without proper organization—and that’s where barrier terminal blocks come to the rescue. A barrier terminal block is a robust connector used in control panels and machinery to join wires safely. It features insulating dividers (barriers) between individual circuits. These barriers act like tiny walls—preventing hassles like electrical shorts, cross‑talk between circuits, or accidental contact. Unlike a simple feed‑through or Euro‑style terminal block, a barrier terminal block provides a higher degree of electrical isolation thanks to its physical separators. So picture this: tidy wiring, clearly marked circuitry, and no “oops, I touched the wrong wire.” It gives you peace of mind, especially in industrial settings where reliability is crucial.

Barrier terminal blocks usually include a screw‑type or spring clamp mechanism that secures the conductor firmly in place. Most favor copper alloy conductors with tin plating for optimal conductivity and corrosion resistance. Again, the barriers ensure that two adjacent screws or conductors can’t physically or electrically touch—this is especially vital when you’re dealing with high ampacity or sensitive signals. It’s not just wire joining; it’s about safeguarding functionality and preventing future headaches.

Why Barrier Terminal Blocks Matter in Industrial Wiring

Let me tell you—it’s when things go wrong that you truly appreciate quality wiring hardware. I’ve seen systems fail due to something as simple as two wires touching accidentally, leading to costly downtime. Barrier terminal blocks help prevent that by offering both electrical isolation and mechanical separation. The insulating barrier between terminals stops stray currents from jumping across. And thanks to standardized clearances, they help circuits comply with voltage insulation regulations. That’s essential when your operations involve high voltage or sensitive electronics.

This design also aids in preventing cross‑talk—the phenomenon of signals interfering between adjacent conductors. It’s a blessing for installations dealing with mixed power and signal wiring. On top of that, barrier terminal blocks help to maintain order, making troubleshooting quicker. You can visually trace each circuit through its physical barrier—no guessing game. This tidiness translates into easier maintenance, faster repairs, and less downtime—a benefit that industrial operators truly value.

Linkwell Hands‑On Experience with Manufacturing

From day one in our factory, I was trained to treat every component as a reflection of our brand’s reputation. We hand‑inspect every terminal block for barrier height, plating consistency, and mechanical fit. We test actuator torque—the effort needed to tighten screws—and ensure it’s within specification. If it’s too loose, electrical contact won’t be reliable; too tight, and you risk damaging the conductor or the barrier.

We adopt 100% testing on each batch: dielectric withstand tests, isolation resistance, operational torque checks. That attention to detail comes from years of seeing what fails first in the field—and prioritizing improvements in subsequent designs. That journey formed a culture of reliability, where our expert staff stand by each product that rolls off the line. And guess what? The feedback loop works: improved field performance means stronger referrals from wholesalers! This is not marketing fluff—it’s years of real‑world experience baked into every product we make.

Standards & Regulations Governing Barrier Terminal Blocks

What gives our expertise extra weight is that we adhere to globally recognized standards such as IEC 60947‑7‑1 (for industrial safety and wiring) and UL 1059 (in North America). These standards define critical requirements for current ratings, insulation resistance, and mechanical strength. For example, IEC 60947‑7‑1 mandates minimum clearance distances between live parts, which we meet or exceed. UL 1059 enforces strict torque reporting and terminal marking—again, we’re always in compliance.

These benchmarks aren’t suggestions—they’re the backbone of industrial electrical safety. Certifications like CE (for the European market) or RoHS (for lead‑free compliance) further demonstrate our dedication to both worker safety and environmental responsibility. By staying ahead of these regulations, we ensure our barrier terminal blocks harmonize with OEM expectations, audit checks, and end‑use demands. That’s why when customers check the spec sheets, the standards section isn’t just a checkbox—it’s proof of trust.

Main Features & Specifications to Compare

Let’s get real: not all barrier terminal blocks are made equal. Here’s how we outshine generic options:

- Current rating: Our lines range from 10 A to 60 A+, accommodating everything from signal lines to heavy power.

- Voltage rating: 250 V for control panels, up to 1000 V for industrial power circuits.

- Barrier height and insulation: We measure creepage and clearance distances to match or exceed IEC requirements.

- Conductor compatibility: Options for solid, stranded, or ferruled wires, from 16 AWG to 4 AWG.

- Materials: High-strength thermoplastics with UL 94 V‑0 rating, plus anti‑creepage compared to budget blocks.

Breaking it down: if you’re wiring heavy machinery, go for our thick‑barrier, high‑voltage model. For signal‑level wiring, choose our compact, space‑saving variant with clear marking zones. This versatility ensures our clients always find the right fit.

| Item | Specification Description |

|---|---|

| Product Name | Barrier Terminal Block |

| Number of Poles | 2 to 24 poles (depending on model) |

| Rated Voltage | 250V ~ 600V |

| Rated Current | 10A ~ 50A (depends on conductor size and material) |

| Wiring Method | Screw connection with or without pressure plate |

| Screw Type | M2, M3, M4, M5 etc. |

| Conductor Material | Brass (tin or nickel plated) |

| Insulation Material | PBT, PA66, PC (usually flame retardant UL94V-0 rated) |

| Temperature Range | -40°C to +105°C or higher |

| Mounting Type | Screw mount, PCB mount, DIN rail (for some models) |

| Pitch (Spacing) | Commonly 5.0mm, 7.62mm, 9.5mm, 10.16mm |

| Wire Range | 16~6 AWG (1.5mm² to 10mm²) |

| Certifications | UL, CE, RoHS, CSA, VDE (depending on model) |

| Color | Typically black; gray, blue, or custom colors optional |

How to Use Barrier Terminal Blocks

Step 1: Choose the Right Terminal Block

Start by selecting a barrier terminal block that matches your system’s voltage, current, and wire gauge requirements. Check the product’s certifications (like UL 1059 or IEC 60947) to ensure compliance.

Step 2: Prepare the Wires

Strip each wire to the recommended length—usually around 6–10 mm. Avoid nicking the conductor to ensure a secure, low-resistance connection. Use ferrules for stranded wires if needed.

Step 3: Insert the Wire into the Terminal

Loosen the terminal screw with a screwdriver, insert the stripped wire into the metal clamp under the barrier, then tighten the screw to the recommended torque (typically 0.5–0.6 Nm). Ensure the wire is snug and doesn’t wiggle.

Step 4: Double-Check Connections

Gently tug each wire to make sure it’s secure. Use a multimeter to confirm continuity and correct polarity, especially for critical applications like control circuits.

Step 5: Label and Organize

Use printed markers or a label printer to mark each connection clearly. This simplifies future maintenance and avoids wiring errors. Arrange wires neatly using cable ties for a professional finish.

Following these steps ensures a safe, reliable, and clean installation every time.

Barrier Terminal Block Applications: Our advantages

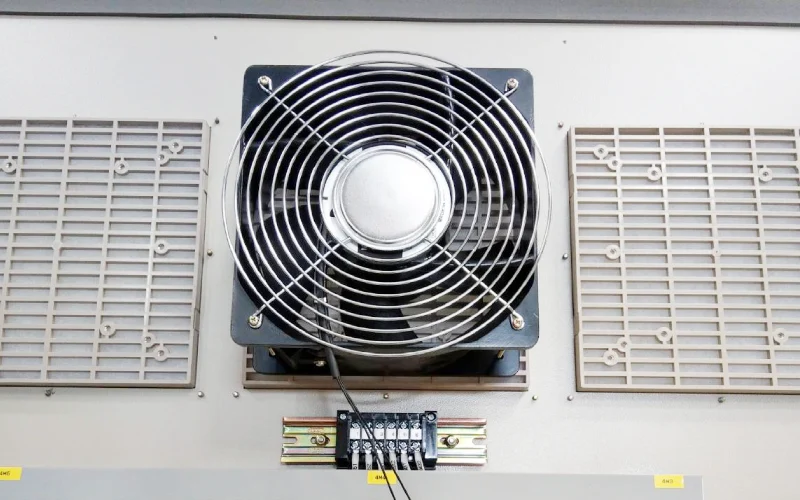

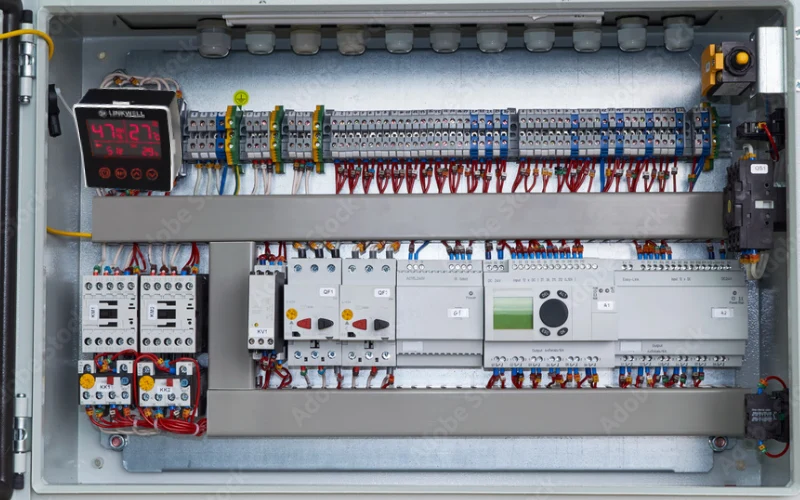

In the panel‑building world, our barrier terminal blocks are the backbone of modern control systems. They bring order to dense wiring setups, especially when mixed voltage levels are involved. Our blocks show up in electrical cabinets powering factory equipment across automotive, chemical, and packaging plants.

We also serve renewable energy, and barrier terminal blocks help manage PV panel arrays or wind‑turbine systems—where failure is not an option. Meanwhile, rail transit systems rely on our blocks for vibration‑resistant connections, with compliant testing to EN 50155 for railway electronics.

In the automotive and EV charging space, we deliver barrier blocks used in assembly-line power distribution and charging stations. They ensure reliable connection under heavy usage—and those physical barriers are a secret weapon against humidity or accidental contact.

Our blocks stand up to diverse environments: from sub‑zero cold to desert heat, from humidity to mild corrosive atmospheres. We design them for real‑world conditions, not just lab specs.

Installation Best Practices (Pro Tips)

Here’s the awesome part: install it right, and you’ll forget about maintenance. Key recommendations:

- Tighten screws to spec: We recommend 0.5–0.6 Nm torque—neither too loose nor too tight.

- Spacing and layout: Leave a small air gap between rail heights of 12 mm to prevent heat buildup.

- Labeling: Always use machine‑printed markers. They stay intact under industrial washdowns.

- Post-install testing: After wiring, always perform a pull test, continuity check, and insulation measurement.

These might sound like common sense—but over‑torquing, mislabeling, or skipping testing are frequent mistakes and lead to real-world headaches. We embed these steps into our assembly guides to help our users avoid them.

How We Innovate & Add Value

As a manufacturer, we’re not satisfied just meeting standards—we push the envelope. We offer:

- Customization: Custom imprinting, colors, marking zones—ideal for OEM branding or safety compliance.

- Quick‑release mechanisms: Great for fast wiring—our spring‑clamp series decreases assembly time by 30%.

- R&D testing: Thermal cycling, vibration testing, UV exposure. These aren’t check‑boxes—they inform actual design improvements.

Partnering with us means not just buying a part—you’re getting a team that proactively tests and validates each upgrade. We’re engineers who speak your language, not factory reps.

Cost vs. Performance: Getting the Balance Right

A low upfront price might look attractive—but cheap blocks often fail prematurely, causing downtime or panel rebuilds. We recommend evaluating total cost of ownership:

- Purchase price

- Installation speed (time saved with quick-release options)

- Maintenance frequency

- Durability/longevity

In fact, 80% of customers switching to our blocks reported lower maintenance costs within a year—saving them four‐times their initial spend in operational savings. That’s real ROI, not just a tagline.

FAQs

Are barrier terminal blocks reusable?

Yes—if removed carefully, with the screws still intact, they can be reused multiple times. But we always recommend replacing if there’s visible wear or loose contacts.

Can I mix wire sizes in one block?

No. To maintain reliable connection and meet spec, use only the recommended wire gauge for that terminal block.

What flange styles are available?

We offer DIN‑rail, stud‑mount, double‑level, feed‑through, ground, and fuse terminal blocks—each designed for specific function and environment.

Are your blocks RoHS compliant?

Yes—all models meet RoHS and many comply with REACH, making them suitable for European and global supply chains.

Do you offer UL certification on all models?

We currently provide UL 1059 certification for our standard and quick‑release models. Custom versions can be certified on request.

Can I order custom colors or printed legends?

We support custom orders—legends, colors, or company logos—perfect for OEM branding or safety standards.

Conclusion

To wrap up, barrier terminal blocks aren’t just components—they’re the backbone of safe, clean, maintainable industrial wiring. As manufacturers with decades of hard-earned field experience, we engineer our products to exceed standards like IEC 60947 and UL 1059. Our blocks boast high current/voltage ratings, durable materials, and design tested in real-world industrial environments. Wholesalers and end-users rate us highly for reliability, ease of installation, and peace of mind.

If you’re building a control panel, power distribution cabinet, or any wired system that calls for robust electrical separation and longevity, give our barrier terminal blocks a try. We’re confident—they’ll be the most reliable wiring blocks you ever use.