In any electrical system, managing power efficiently and safely is paramount. This is where a distribution block comes into play, acting as a central hub for organizing and splitting electrical power. Far more than just a simple connector, a distribution block is a crucial component that ensures an orderly and secure flow of electricity to various circuits.

This ultimate guide will delve into everything you need to know about distribution blocks. We’ll explore their fundamental purpose, how they differ from other electrical connectors, their diverse applications across industries, and the key factors to consider when selecting the right one for your specific project.

What is a Distribution Block?

Recommended Distribution Blocks

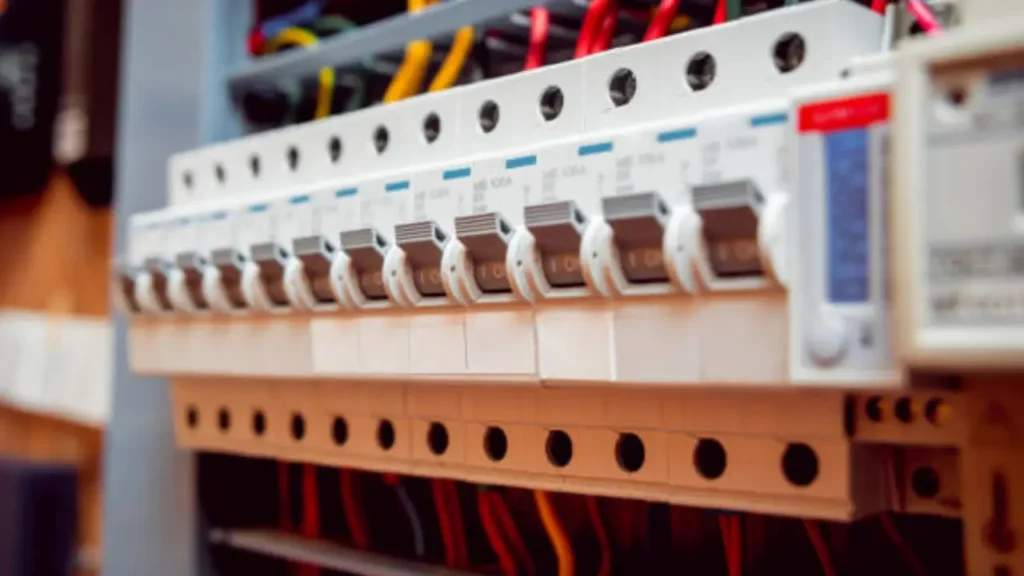

A distribution block, often referred to as a power distribution block, is an electrical component designed to take a single, larger electrical input and efficiently split it into multiple, smaller outputs.

Essentially acting as a central junction point, it allows a primary power source to be distributed to several different circuits or loads, consolidating wiring and simplifying power management within electrical panels, control systems, and various other applications, from industrial machinery to car audio systems.

What Does a Distribution Block Do?

A distribution block serves as a central hub for power distribution, taking a single, typically heavier-gauge power input and branching it out into multiple, lighter-gauge outputs. This consolidates wiring, reducing the need for numerous individual connections directly to the power source, thus simplifying panel layouts and improving overall system organization and troubleshooting efficiency.

The core functions of a distribution block revolve around power management and safety:

- Simplifies Troubleshooting: With organized wiring and clear connection points, identifying and resolving electrical issues becomes much faster and less complicated, reducing downtime.

- Splits Power: It efficiently divides a main power feed into several distinct circuits, enabling multiple devices or components to be powered from a single source without complex individual wiring runs.

- Organizes Wiring: By centralizing connection points, distribution blocks significantly reduce cable clutter and improve the neatness of electrical panels. This makes installations cleaner and maintenance tasks far more straightforward.

- Enhances Safety: Many distribution blocks offer a secure, insulated enclosure for connections, minimizing the risk of accidental contact with live parts. Fused versions add overcurrent protection for individual output circuits.

How Does a Distribution Block Work?

A distribution block functions on a straightforward principle of electrical conductivity and division. Inside its insulated housing, a common conductive busbar or series of interconnected metal plates receives a single electrical input from a main power source. This large input terminal is designed to accommodate a heavier gauge wire, capable of carrying the cumulative current for all subsequent outputs.

From this shared internal conductor, multiple smaller output terminals branch off. When current flows into the input terminal, it distributes across the internal busbar, making power available at each of the output terminals. Wires from individual loads or circuits are then connected to these output terminals, drawing the necessary current from the shared input. Some distribution blocks may also include integrated fuses for each output, adding an extra layer of overcurrent protection for the connected devices.

How to Install a Distribution Block?

Proper installation of a distribution block is crucial for electrical safety and system efficiency. While specific steps may vary slightly by block type, adhering to these general guidelines will ensure a secure and reliable power distribution setup.

Step 1: Planning and Preparation

Before anything else, carefully plan your wiring layout. Determine the optimal mounting location for the distribution block, ensuring it’s accessible and away from heat or moisture. Measure and cut all necessary wire lengths, accounting for proper slack. Gather all tools, including wire strippers, crimpers, screwdrivers, and any required mounting hardware.

Step 2: Disconnect Power

Crucially, always disconnect the power source to the main input wire before beginning any electrical work. This prevents electric shock and safeguards your equipment. Verify power is off using a voltage tester, and implement lockout/tagout procedures if working in an industrial setting. Safety is paramount.

Step 3: Mount the Distribution Block

Securely mount the distribution block to your chosen surface (e.g., DIN rail, panel, chassis) using appropriate screws or mounting hardware. Ensure it is firmly attached and won’t vibrate loose. A stable mounting prevents stress on connections and maintains electrical integrity over time.

Step 4: Wire the Input

Strip the insulation from the main power input wire to the recommended length. Insert the stripped end fully into the distribution block’s input terminal and tighten the set screw securely. Tug gently to confirm a firm connection. This connection carries the total current for all outputs.

Step 5: Wire the Outputs

Similarly, strip the insulation from each output wire and insert them into their respective output terminals. Tighten each set screw firmly. Double-check that no stray wire strands are exposed, which could cause short circuits. Ensure correct polarity if applicable.

Step 6: Verify Connections and Restore Power

Once all wires are connected, thoroughly inspect every terminal for tightness and proper insulation. Ensure there are no loose strands or potential shorts. After verifying all connections are secure, you can safely restore power to the system and test the functionality of your newly wired distribution block.

How to Make a Distribution Block?

Manufacturing a distribution block involves precision engineering and material selection to ensure safety and performance. While not a typical DIY project due to safety standards and specialized equipment, understanding the general process provides insight into their construction and reliability.

Step 1: Material Selection

Manufacturers begin by selecting high-quality conductive materials for the internal busbar, typically brass, copper, or aluminum, often tin-plated for enhanced conductivity and corrosion resistance. Insulating materials for the housing, such as flame-retardant thermoplastics or phenolic compounds, are chosen for their dielectric strength and heat resistance.

Step 2: Busbar Fabrication

The selected conductive material is precisely cut, shaped, and sometimes machined to form the internal busbar. This busbar is designed to accept one large input connection and multiple smaller output connections. For fused blocks, specialized sections are created to integrate fuse holders for each output circuit.

Step 3: Housing Molding

The insulating housing of the distribution block is typically created through an injection molding process. Molten thermoplastic is injected into a mold cavity to form the desired shape, including compartments for the busbar and terminals, mounting features, and access points for wiring.

Step 4: Terminal Integration

The fabricated busbar and individual screw terminals (often made from plated steel or brass) are precisely inserted and secured within the molded housing. This step ensures that the conductive parts are correctly aligned and firmly held in place, preventing movement and ensuring reliable electrical contact.

Step 5: Assembly and Testing

Components are assembled, often involving ultrasonic welding or snap-fit mechanisms to seal the housing. Each distribution block then undergoes rigorous quality control testing, including continuity checks, dielectric strength tests, and sometimes current carrying capacity tests, to ensure it meets safety standards and performance specifications.

Distribution Block vs Terminal Block

While both distribution blocks and terminal blocks serve to organize and connect electrical wires, their primary functions and internal structures differ significantly. Understanding these distinctions is crucial for proper electrical system design and safety.

A distribution block is fundamentally designed to take a single, often heavier-gauge, power input and efficiently split it into multiple outputs. It acts as a central power hub, distributing the main power feed to various branch circuits or loads. This simplifies the wiring by consolidating the main power entry point and eliminating the need for many individual connections to the primary power source.

In contrast, a terminal block (or terminal strip) is typically used for connecting two or more wires together in a specific circuit, often to provide an organized and secure connection point within a system. Each terminal on a block generally represents a distinct connection point, allowing for the termination of individual wires, bridging different circuits, or providing testing points.

Here’s a breakdown of their key differences:

Primary Function:

- Distribution Block: To split or distribute a single input power source to multiple outputs.

- Terminal Block: To connect or terminate wires within a circuit, often providing a point of transition or consolidation.

Internal Structure:

- Distribution Block: Features a common, internal conductive busbar or plate that links the single input to all output terminals.

- Terminal Block: Consists of individual, isolated conductive pathways (often screw terminals) for each connection, though some may have internal links for commoning.

Wire Configuration:

- Distribution Block: Typically has one large input terminal and multiple smaller output terminals, reflecting the distribution of power.

- Terminal Block: Usually has terminals designed to connect wires of similar gauges, facilitating direct wire-to-wire or wire-to-device connections.

Application Focus:

- Distribution Block: Centralized power distribution in control panels, automotive audio systems, machinery, or anywhere a main power line needs to feed multiple components.

- Terminal Block: General wiring connections, signal routing, circuit isolation, and organizing wires in control cabinets, PLCs, and various electronic assemblies.

Conclusion

Distribution blocks are indispensable components for managing electrical power efficiently and safely. They streamline wiring by consolidating a single input into multiple outputs, reducing clutter and simplifying troubleshooting in various applications from industrial panels to automotive systems. Understanding their types, ratings, and mounting options is key to optimal selection and integration.

Choosing the right distribution block ensures reliable power distribution, protecting equipment from overcurrents and enhancing overall system safety. Their versatility in accommodating different wire sizes and customization options makes them a fundamental part of modern electrical installations, contributing to organized and robust power management.

For all your project needs, consider Linkwell Electrics as your trusted source for wholesale distribution blocks. We offer a comprehensive range of high-quality, certified solutions designed for superior performance and durability in diverse industrial and commercial applications.