In today’s increasingly electronic world, where devices communicate and operate at high frequencies, the unseen force of electromagnetic interference (EMI) poses a significant challenge. This pervasive “noise” can disrupt sensitive equipment, degrade signal quality, and even lead to system failures, making reliable operation crucial across industries.

This ultimate guide will demystify EMC cable, a specialized solution designed to combat these invisible threats. We’ll explore what makes EMC cable unique, how its construction effectively shields against electromagnetic disturbances, and its vital role in ensuring the integrity and performance of electrical systems in diverse applications.

What is EMC Cable?

EMC (Electromagnetic Compatibility) cable is a specialized type of cable designed to minimize or prevent electromagnetic interference (EMI) in electrical and electronic systems. These EMC cables typically incorporate shielding layers, such as metallic braids or foils, that surround the conductors.

This shielding acts as a barrier, absorbing or reflecting unwanted electromagnetic energy, thus protecting sensitive signals from external interference and preventing signals within the cable from interfering with other nearby equipment.

What is EMC Cable Gland?

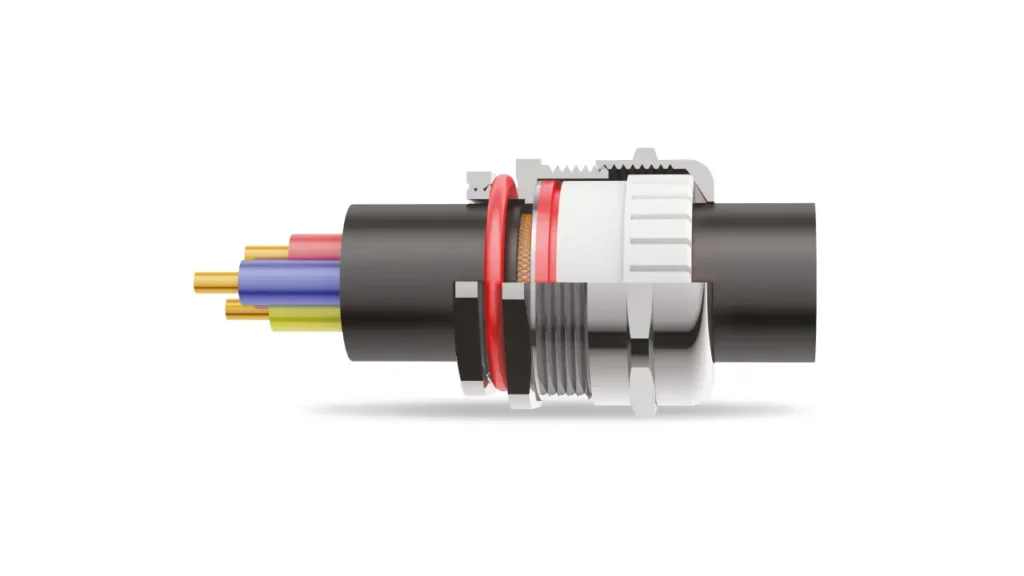

An EMC cable gland is a specialized cable entry device designed to maintain electromagnetic compatibility at the point where a shielded cable enters an enclosure or equipment.

It provides a 360° low-impedance connection between the cable’s shield and the enclosure’s ground, preventing electromagnetic interference from entering or exiting the system and ensuring signal integrity.

EMC Cable Gland Installation

Proper EMC cable gland installation is critical for ensuring effective electromagnetic shielding and maintaining system integrity. Following specific steps during installation guarantees the gland performs its intended function, preventing unwanted electromagnetic interference.

Here is the step-by-step guide about how to install EMC cables:

Step 1: Prepare the EMC Cable

Carefully strip the outer sheath of the shielded cable to the specified length, exposing the cable shield (braid or foil). Ensure the shield is intact and free from damage. This precise preparation is crucial for achieving a proper circumferential contact with the gland.

Next, fold back the exposed shield over the inner sheath or prepare it according to the gland manufacturer’s instructions. This step creates a larger surface area for the gland’s contact elements to grip, maximizing the electromagnetic connection and minimizing resistance for effective shielding.

Step 2: Assemble the Gland Components

Thread the cable through the gland’s components in the correct order, typically including the cap nut, sealing insert, and grounding cone or spring. Ensure all parts are aligned properly according to the manufacturer’s diagram, as incorrect assembly will compromise the EMC performance and sealing capabilities.

Position the grounding component (cone or spring) firmly against the exposed cable shield. This component is designed to make optimal 360° contact with the shield, providing the low-impedance path to ground that is essential for diverting electromagnetic noise away from sensitive equipment.

Step 3: Secure and Tighten

Insert the assembled gland into the pre-drilled hole of the enclosure, ensuring it is correctly seated. Then, carefully tighten the gland’s components according to the manufacturer’s torque specifications. Overtightening can damage the cable or gland, while undertightening will result in poor sealing and inadequate EMC contact.

Finally, conduct a visual inspection to confirm proper installation and ensure a secure, watertight, and electromagnetically tight seal. Verify that the cable is firmly gripped and that the shield makes continuous contact with the gland’s grounding element, completing the critical EMC barrier.

EMC Cable Glands Market

The EMC cable glands market is experiencing significant growth driven by increasing demand for reliable electromagnetic compatibility in various industries. With the proliferation of sensitive electronic equipment and the rise of IoT devices, stringent regulations for EMI/RFI shielding are becoming commonplace.

This market for EMC cable glands is characterized by innovations in materials, design, and sealing technologies to provide robust, high-performance solutions.

Here are key aspects of the EMC Cable Glands Market:

- Growing Demand: Driven by the increasing use of electronics in industrial automation, telecommunications, renewable energy, and medical sectors.

- Regulatory Compliance: Strict EMC directives and standards (e.g., CE, FCC) in various regions necessitate the use of EMC-compliant components, including cable glands.

- Technological Advancements: Continuous development in materials like nickel-plated brass and stainless steel, and designs that ensure 360° shield contact, are enhancing performance.

- Application Diversification: Expanding use beyond traditional industrial settings into areas requiring high levels of EMI protection, such as railway, marine, and hazardous environments.

- Key Players: The market includes a mix of global manufacturers and specialized regional providers, all competing on product quality, innovation, and compliance.

- Customization: Growing need for tailored EMC cable gland solutions to meet specific industry requirements, including unique sizes, materials, and IP ratings.

How to Choose Suitable EMC Cables

Choosing the right EMC cable is crucial for ensuring the reliable operation and electromagnetic compatibility of your electronic systems. A well-selected cable will effectively mitigate interference, while an unsuitable one can lead to system malfunctions and compliance issues.

Assess the Environment

First, evaluate the operating environment where the cable will be deployed. Consider factors such as temperature extremes, humidity levels, exposure to chemicals or UV radiation, and potential for mechanical stress or abrasion. These environmental conditions will dictate the necessary jacket material and overall cable ruggedness required for long-term performance and durability.

Define Interference Levels

Identify the type and severity of electromagnetic interference (EMI) present in your application, both internal and external. Determine whether the primary concern is conducted interference, radiated interference, or both. Understanding the frequency range and strength of the noise will guide the selection of appropriate shielding effectiveness and cable design to ensure adequate suppression.

Consider Shielding Requirements

Select the appropriate shielding type based on the defined interference levels. Options include braided shields (good for low frequencies and mechanical strength), foil shields (effective for high frequencies and 100% coverage), or a combination of both (braid-and-foil for broad-spectrum protection). The shielding material (e.g., copper, aluminum) also impacts performance and flexibility, influencing the cable’s suitability for specific applications.

Evaluate Electrical Parameters

Carefully consider the electrical characteristics required for your application, including voltage rating, current capacity, impedance, and capacitance. Ensure the cable’s conductors are appropriately sized for the current load and that its electrical properties align with the signal transmission requirements to prevent signal degradation or power loss, guaranteeing optimal system performance.

Verify Compliance and Standards

Finally, ensure the chosen EMC cable complies with relevant industry standards and regulatory requirements for your specific application and region. This might include standards for flammability, hazardous substances (e.g., RoHS), and specific EMC directives. Compliance is crucial for product certification, market access, and ensuring the safety and reliability of your electrical system.

Conclusion

In conclusion, understanding EMC cables is fundamental for anyone involved in modern electrical and electronic systems. Their specialized design and shielding capabilities are indispensable for mitigating electromagnetic interference, ensuring signal integrity, and maintaining the reliable, safe operation of critical equipment across diverse industrial and commercial applications.

The proper selection and implementation of EMC cables are vital for compliance with stringent electromagnetic compatibility standards and for preventing costly system malfunctions or data loss. Investing in high-quality EMC cabling not only safeguards your equipment but also contributes significantly to the overall stability and efficiency of your electrical infrastructure.

For all your EMC cable needs, consider Linkwell Electrics. As a leading manufacturer based in Qingdao, Shandong, China, we offer a comprehensive range of wholesale EMC cables designed to meet the highest performance and compliance standards. Contact us today to secure reliable EMC cable solutions for your next project.