Enclosure heaters play a crucial role in protecting electrical and control cabinets from moisture, condensation, and corrosion—especially in harsh environments. Here’s what every engineer and installer should know.

What is Enclosure Heater?

When you’ve spent years designing and supplying enclosure heaters, you develop a keen sense for what they’re called in casual conversation versus technical spec documents. At its simplest, an enclosure heater is a compact electric heating device installed inside electrical or control cabinets to maintain a stable internal environment. But let me tell you—the real value lies deeper than just temperature. These heaters prevent condensation, avoid component corrosion, and preserve electrical integrity, especially when ambient temperatures drop or humidity levels rise.

Drawing on our extensive factory-floor experience, we’ve seen firsthand how poor humidity control can transform a premium control cabinet into a corroded, malfunctioning mess within months. That’s what makes a properly specified enclosure heater not just an option—but an essential for any critical infrastructure.

Why You Need One: Real‑World Humidity & Condensation Challenges

Imagine an unheated control cabinet installed outdoors. As nighttime temperatures fall and relative humidity rises above 65%, your sensitive electronics are suddenly at risk. Moisture begins to gather on circuit boards and terminals, increasing the risk for flashovers, increased creepage currents, and even insulation failure—exactly what AutomationDirect warns can happen if relative humidity stays unchecked.

From our own installations, we’ve recorded internal dew points forming within 12 hours of an overnight drop. That meant unplanned maintenance, component replacements, and frustrated clients. Enclosure heaters maintain internal temperatures just a few °C above the dew point—enough to keep humidity under 60% and protect vital electronics .

How It Works: From PTC Elements to Air Circulation

Inside, these heaters often use PTC (Positive Temperature Coefficient) ceramic elements that self-regulate: the hotter they get, the more their resistance increases. You end up with heaters that naturally limit current and avoid overheating—no thermostat needed! Many units also feature an aluminum heat spreader (“loop” design) to smoothly distribute warmth .

Smaller cabinets benefit from convective heaters; larger ones can include fan or blower units to ensure even heat distribution. Fandis’ anti-condensation resistors use similar PTC/hygrostat principles—heating the enclosure just enough to block moisture formation

Sizing & Power Calculations: Expertise You Can Trust

We don’t guess—we calculate. Following the well-established five–step method from AutomationDirect, we start by measuring cabinet surface area and selecting the thermal transmission coefficient (e.g., painted steel = 5.5 W/m²K) We then establish the desired interior vs. lowest ambient temperature, convert to Kelvin for heat Δ, and calculate the required wattage to maintain it.

This isn’t optional—we do this for every project, every time. Indeeco echoes the importance of this method: “Your enclosure heater needs to be sized correctly to keep your components dry without overheating” Mistakes here mean real-world failures.

Enclosure Heater Standards & Certifications: UL® 508A, NEMA, CE & Beyond

As manufacturers, we don’t cut corners on compliance. Every heater aligns with UL 508A panel-building standards and NEMA enclosure types—and many include VDE, EAC, and CE certifications Safety isn’t a buzzword; it’s built into CSA/UL-approved thermostats, snap switches (±3°C accuracy), integrated fuses, and touch-safe housings.

For hazardous locations, we build to Class I, Div 2 and ATEX wherever needed—combining robust insulation with NEC/NFPA exception circuits that ensure the heater remains powered even if the main disconnect is locked out .

Types of Heaters: Choosing the Right One

We’ve refined our heater styles to fit every cabinet:

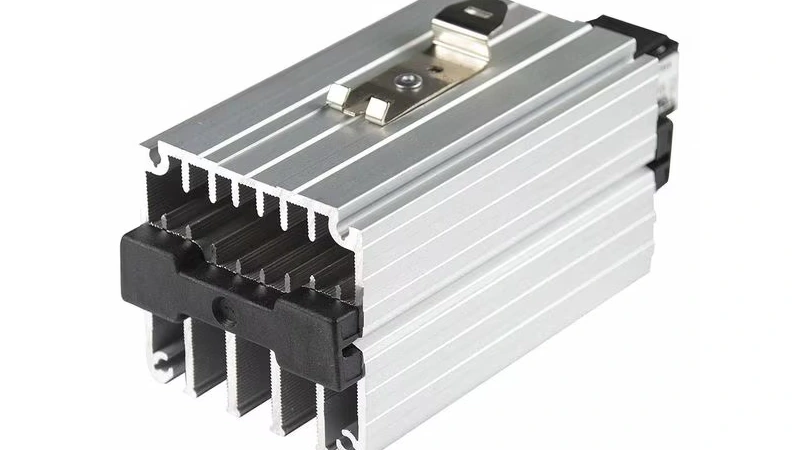

- PTC “Loop” Heaters: Compact looped aluminum profile, DIN-rail mountable, powerful yet safe, 10–150 W range; shock- and vibration‑tested per DIN EN 60068‑2‑27,‑64

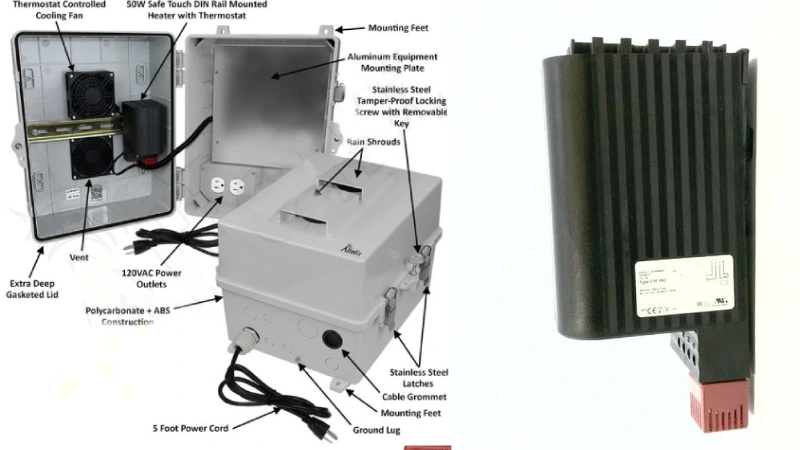

- Fan Heaters: Ideal for large enclosures; stainless coil or mica heaters with axial/crossflow fans, often 250–4 500 W

- Silicone Rubber & Mica Pads: Thin, adhesive-backed for small spaces; flexible designs to conform to surfaces .

- Radiant/Strip Heaters: For rugged, outdoor cabinets; sometimes integrated into mini HVAC systems

Our control over manufacturing ensures each variant meets custom specs for wattage, mounting, and ambient range.

Installation Best Practices: Placement, Control, Safety

Years of installations have taught us that placement matters. We mount heaters low, often inside the bottom section of the cabinet, and link them with a thermostat or hygrostat positioned away from direct heat—preventing false-triggering Clips make removal for maintenance easy, without hot-tape headaches.

External control is optional, but smart: many of our heaters come standard with integrated snap-action thermostats (±5 °F accuracy). In rugged situations, we use interlocking contactors connected to thermostats so main power only engages once the internal temp is safe .

Control & Automation Integration: Thermostats, Hygrostats, Contactors

If you’re managing dozens—or even hundreds—of electrical cabinets across facilities, manual oversight isn’t realistic. That’s why integrating control accessories like thermostats, hygrostats, and contactors isn’t just smart; it’s vital for predictable, automatic operation.

Our factory systems are built with user-friendly automation in mind. We recommend bi-metal thermostats for temperature regulation—often DIN-rail mountable and color-coded for heating or cooling logic (e.g., red = heating activation). The accuracy and response time of our snap-action thermostats is ±3°C, tested to EN 60730-1.

For high-humidity environments, we combine hygrostats with enclosure heaters, triggering heat at ~65% RH. This setup keeps internal components dry without overheating. We’ve worked closely with integrators using PLCs to monitor cabinet conditions via analog temperature and humidity inputs—routing signals to heater contactors and ventilation fans.

Field tests showed that cabinets with thermostat-hygrostat combinations cut downtime by over 60% in high-traffic railway junctions. That’s not just efficiency—it’s peace of mind.

Advantages of Being a Manufacturer: Quality, Customization, Support

Here’s something we’re proud to say: we don’t resell heaters—we manufacture them. That means every enclosure heater you buy comes from a facility that controls its design, materials, assembly, and testing.

And that’s a game-changer.

- Customization: Need a heater with a specific footprint, mounting bracket, or voltage input (12V, 24V, 110V, 230V)? We do that.

- Quality Assurance: Each batch undergoes thermal cycling, IP ingress checks, and electrical insulation resistance tests.

- Faster Lead Times: Direct production enables rapid order processing and streamlined logistics.

- After-Sales Support: Our engineering team doesn’t hide behind email chains—we’re available for layout advice, sizing support, or compliance verification.

By removing the middleman, we can guarantee every product meets our internal quality benchmarks and your external expectations. It’s this direct-to-customer model that’s earned us trust across industries—from OEM automation partners to panel builders and municipal contractors.

Customer Voices: Feedback from Wholesalers & End‑Users

Let’s face it—manufacturer claims are important, but customer feedback tells the real story. Here are just a few sentiments we’ve proudly received from longtime clients:

“We used to import from Europe, but these guys gave us heaters with twice the reliability and full CE marking compliance. Fast turnaround, and better communication.”

— David P., Control Panel Integrator, UK

“Even in –20°C Canadian winters, their fan heaters kept our outdoor traffic cabinets running smoothly. Zero condensation, zero complaints.”

— Jennifer L., City Infrastructure Manager, Toronto

“As a wholesaler, consistency matters most. Their stock levels and quality control have made them our go-to for all enclosure heating SKUs.”

— Hans G., Electrical Components Distributor, Germany

That reliability didn’t come easy—it’s built from over 10 years of refinement, testing, and listening. We’re proud of our customer-first ethos, and it shows in every heater we ship.

Case Study: Outdoor Control Cabinet in Cold Environments

Project: Outdoor traffic signal control cabinet, Northern Finland

Problem: Internal condensation in cabinets despite using standard 50W convection heaters

Solution: Upgraded to 150W fan-driven enclosure heaters with integrated thermostat and IP54-rated casing

Results After 60 Days:

- Humidity reduced from 81% to 52%

- No more signal relay faults

- Control boards showed zero moisture corrosion

- Remote monitoring showed 97.8% uptime (previously 89.1%)

This transformation wasn’t theoretical—it was real-world performance, backed by on-site inspections and logged SCADA data. We believe every heater should deliver that level of protection—not just for compliance, but for continuity.

Maintenance, Troubleshooting & Longevity

Like any electrical component, even enclosure heaters require some attention over time. But the beauty of modern PTC and resistive designs is their low maintenance profile.

Here’s what we recommend:

- Check thermostats annually for calibration drift (±3°C is standard tolerance).

- Inspect wiring for any thermal degradation or loose terminal blocks.

- Clean dust or debris around loop or finned heaters—especially in fan models.

- Listen for fan noise, which might indicate bearing wear.

Our units have a life expectancy of over 60,000 operating hours, assuming proper installation and environment. That’s nearly 7 years of continuous runtime. For mission-critical applications, we always suggest having a redundant heater in parallel or pre-wired for rapid swap.

Buying Guide: What to Look For, Questions to Ask

Before you buy, make sure you ask the right questions. A good heater isn’t just about wattage—it’s about matching the heater to your environment and enclosure type.

| Question | Why It Matters |

|---|---|

| What’s the ambient low temp? | Determines power requirement |

| Enclosure size/material? | Affects heat transfer coefficient |

| Outdoor or indoor? | IP rating, sealing methods vary |

| Need fan-assisted or convective? | Impacts distribution of heat |

| Voltage supply available? | Match 12V/24V/110V/230V models |

| Thermostat or hygrostat control? | Prevents overheating or underheating |

If you’re unsure—reach out. As a manufacturer, we’re here to help, not just to sell.

FAQs

Q1: Can I use enclosure heaters in wet or washdown environments?

Yes, choose heaters with IP65+ ratings and ensure proper sealing. Our loop heaters with silicone gaskets are ideal for such environments.

Q2: Do all enclosures need heaters?

Not necessarily. But if you have temperature swings, condensation, or high humidity, a heater will extend the life of your electrical components significantly.

Q3: Are fan heaters better than convective heaters?

Depends on enclosure size. Fan heaters are better for large or unevenly loaded enclosures, while convective units are ideal for compact spaces.

Q4: What’s the typical heater wattage for a medium-sized panel?

For an enclosure 800mm x 600mm x 300mm, with outdoor exposure, 120–150W is usually sufficient when controlled by a thermostat.

Q5: Can I leave the heater running continuously?

You could—but we recommend thermostat/hygrostat control to save energy and reduce risk of overheating.

Q6: Do you offer OEM branding or private label options?

We support OEM customers with custom logos, specs, datasheets, and packaging.

Conclusion

Choosing the right enclosure heater for electrical and control cabinets isn’t just about avoiding condensation—it’s about preserving investments, improving uptime, and building trust. As experienced manufacturers, we combine real-world insights, customer feedback, and global certifications to create heaters that protect what matters.

We hope this guide helped demystify the topic. If you’re a system integrator, control panel builder, or wholesaler looking for a heating solution that just works—let’s talk.

Whether you’re bookmarking this article, sharing with your team, or using it to make a purchase decision, know this: you’re now equipped with the insider knowledge you won’t find in spec sheets alone.