Understanding the terms “NC” (Normally Closed) and “NO” (Normally Open) is fundamental to comprehending how thermostats function, particularly in industrial and enclosure applications. These designations define the default state of a thermostat’s electrical contacts when no external temperature influence is present. Grasping this concept is key to correctly wiring and applying thermostats for either heating or cooling purposes.

This blog post will demystify NC and NO thermostat operations. We’ll explore how these distinct contact configurations dictate whether a thermostat activates a device when the temperature falls (heating) or rises (cooling). Knowing this distinction is crucial for ensuring your thermal management system operates effectively and safely within your enclosures.

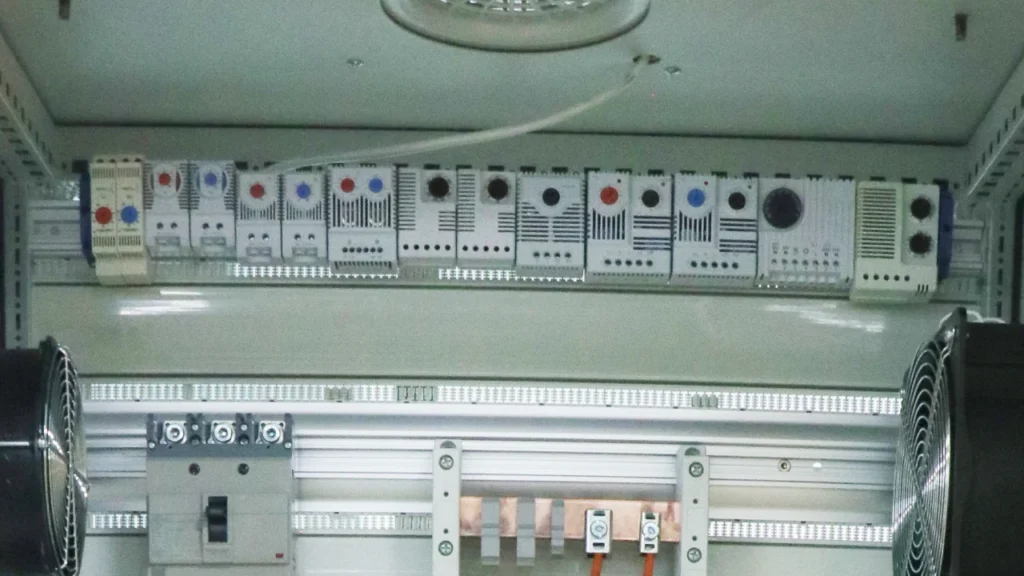

Recommended products

Enclosure Thermostat Working Principle

Core Working Principle

It operates on the basic principle of electromechanical or solid-state temperature sensing with a switch:

- Sense the internal air temperature of the enclosure.

- Compare it to a pre-set threshold (setpoint).

- Actuate an output (relay/switch) to control heating or cooling devices.

- Maintain the internal temperature within a safe operating range.

What is NC in the Enclosure Thermostat

In an enclosure thermostat, NC stands for Normally Closed.

This means that under normal operating conditions (i.e., when the temperature is below the thermostat’s set point), the electrical contacts inside the thermostat are closed, completing a circuit. When the temperature rises above the set point, these contacts will open, breaking the circuit.

NC thermostats are typically used for heating applications. For example, an NC thermostat would be wired to a heater: when the enclosure’s temperature drops too low (below the set point), the thermostat’s contacts remain closed, allowing the heater to turn on. When the temperature reaches the desired level, the contacts open, turning the heater off.

Visual Identification: In the industrial standard, NC thermostats are almost universally identified by a Red adjustment dial. This color coding helps technicians instantly recognize it as a heating control.

Circuit Symbol: On electrical schematics, the NC symbol typically shows the switch arm touching the contact point, indicating a completed path.

What is NO in the Enclosure Thermostat

In an enclosure thermostat, NO stands for Normally Open.

This means that under normal operating conditions (i.e., when the temperature is below the thermostat’s set point), the electrical contacts inside the thermostat are open, breaking a circuit. When the temperature rises above the set point, these contacts will close, completing the circuit.

NO thermostats are typically used for cooling applications. For example, an NO thermostat would be wired to a cooling fan: when the enclosure’s temperature gets too high (above the set point), the thermostat’s contacts close, allowing the fan to turn on. When the temperature drops to the desired level, the contacts open, turning the fan off.

Visual Identification: Industry standards designate NO thermostats with a Blue adjustment dial, symbolizing cooling applications.

Circuit Symbol: On schematics, the NO symbol shows the switch arm hovering above the contact point, indicating a gap in the circuit.

NC and NO Enclosure Thermostat

Enclosure thermostats utilize two primary contact configurations: Normally Closed (NC) and Normally Open (NO).

Understanding this distinction is crucial for proper wiring and ensuring the effective thermal management of sensitive equipment within electrical cabinets. These configurations determine whether a connected device, such as a heater or a fan, will be activated when the temperature rises above or falls below a specific set point.

- Normally Closed (NC) Thermostat: In an NC thermostat, the electrical contacts are closed (completing the circuit) when the temperature is below the set point. When the temperature rises above the set point, the contacts open, breaking the circuit. NC thermostats are typically used for heating applications, turning a heater ON when the enclosure is too cold and OFF when it reaches the desired temperature.

- Normally Open (NO) Thermostat: Conversely, in an NO thermostat, the electrical contacts are open (breaking the circuit) when the temperature is below the set point. When the temperature rises above the set point, the contacts close, completing the circuit. NO thermostats are primarily used for cooling applications, turning a fan or cooling unit ON when the enclosure gets too hot and OFF once the temperature returns to a safe level.

Thermostat Contacts in HVAC Systems

Role in Heating and Cooling Control

You use thermostats every day in hvac systems, but have you ever wondered how they actually control heating and cooling? NC and NO contacts make this possible. When you set a temperature, the thermostat watches for changes. If the room gets too warm, NO contacts close and start the cooling cycle. If the space gets too cold, NC contacts open and stop the heating. This switching keeps your environment comfortable and safe.

Here’s a table that shows how these contacts work in hvac:

| Type | Default State | Operation Upon Energizing | Typical Applications | Fail-Safe Behavior |

|---|---|---|---|---|

| NC | Closed circuit (allows current flow) | Opens the circuit (interrupts current flow) | Safety systems, emergency stop functions | Ensures continuity until a fault occurs |

| NO | Open circuit (prevents current flow) | Closes the circuit (allows current flow) | Standard motor controls, lighting systems | Ensures devices are off until activation is required |

You see these contacts in action every time your air conditioner or heater turns on or off. The thermostat sends a small voltage to the contactor, which then allows electricity to flow and start the cooling or heating cycle. When the set temperature is reached, the contactor opens or closes, stopping the system.

Application in Industrial and Enclosure Environments

In industrial settings, hvac systems need to be reliable and safe. You want your equipment to run smoothly, especially in control cabinets and electrical enclosures. NC and NO contacts help manage temperature and protect sensitive components. If you pick the wrong contact type, you risk safety problems or equipment failure.

Let’s look at some benefits of using these contacts in hvac:

| Benefit | Description |

|---|---|

| Safety | Ensures power is available unless interrupted, crucial for safety-critical applications. |

| Reliability | Known for long service life and robust construction, handling high currents and voltages. |

| Energy Efficiency | Helps save energy by activating systems only when needed. |

| Simplicity | Straightforward installation and operation for various applications. |

| Cost-Effective | Provides economical solutions for controlling circuits and equipment. |

Tip: Always check the contact type before wiring your hvac system. This step helps prevent costly mistakes and keeps your setup safe.

Linkwell Thermostats for HVAC

You want a thermostat that fits your hvac needs. Linkwell thermostats offer features that make them perfect for commercial hvac systems. They are compact, durable, and easy to install. You can mount them quickly with DIN rails. The manual knob lets you adjust temperatures from 0℃ to 60℃ without hassle. Linkwell uses flame-retardant materials and provides international certifications like CE and RoHS, so you know your system meets safety standards.

Here’s a quick look at what makes Linkwell thermostats stand out in hvac:

| Feature | Description |

|---|---|

| Compact and Durable | Small size, lightweight, and designed for secure connections and vibration resistance. |

| Easy Deployment | Supports DIN 35mm rail mounting for quick system integration. |

| Safety Protection | Made of UL94 V-0 flame-retardant material, IP20 rating, operational range of -20℃ to +80℃. |

| Flexible Adjustment | Manual knob for temperature settings from 0℃ to 60℃, easy to operate without complex configurations. |

| International Certifications | Certified with CE and RoHS, ensuring compliance with safety and environmental standards. |

You get peace of mind knowing your hvac system is protected and running efficiently. Linkwell thermostats help you avoid downtime and keep your equipment safe, whether you’re working in a factory, telecom cabinet, or commercial building.

Thermostat Contacts vs. Pressure Switches

Key Differences and Use Cases

You might wonder how thermostat contacts compare to a pressure switch. Both help you control devices, but they work in different ways. Thermostat contacts respond to temperature changes. A pressure switch reacts to changes in pressure. You use thermostat contacts when you want to manage heating or cooling based on temperature. You use a pressure switch when you need to control equipment based on air, water, or oil pressure.

Let’s look at a table that highlights the main differences:

| Feature | Thermostat Contacts | Pressure Switch |

|---|---|---|

| Sensing Method | Temperature | Pressure |

| Common Application | HVAC, cabinet heating/cooling | Pumps, compressors, safety alarms |

| Response Time | Depends on temperature change | Instant with pressure change |

| Maintenance | Minimal | May need calibration |

| Example Device | Linkwell thermostat | Mechanical pressure switch |

You see a mechanical pressure switch in places like water pumps or air compressors. It turns devices on or off when the pressure reaches a set point. Thermostat contacts do the same for temperature. You might use both in a single system if you need to control temperature and pressure.

Tip: Always check your system’s needs before choosing between thermostat contacts and a pressure switch.

When to Use Each in Industrial Systems

You face many choices in industrial setups. Sometimes you need a pressure switch. Sometimes thermostat contacts work better. If you want to keep a cabinet cool, you pick thermostat contacts. If you need to stop a pump when pressure gets too high, you use a pressure switch.

Here are some common scenarios:

- You want to protect a compressor. You install a pressure switch to shut it off if pressure rises too much.

- You need to keep electronics safe from overheating. You use thermostat contacts to start a fan when it gets hot.

- You want to control a hydraulic system. You rely on a mechanical pressure switch to keep pressure within safe limits.

- You need to manage temperature in a telecom cabinet. You choose thermostat contacts for precise control.

A mechanical pressure switch gives you reliable performance in harsh environments. You can adjust the set point easily. Thermostat contacts offer simple temperature control. You get fast response and easy installation.

Note: You can combine both devices for extra safety and control. Many industrial systems use thermostat contacts and a pressure switch together.

If you want help picking the right device, check your equipment specs. Look at the environment and the type of control you need. You can always reach out to experts for advice.

You now know how NC and NO contacts shape the way your thermostat controls heating and cooling. Picking the right contact type keeps your system safe and efficient. Wiring and device matching matter for long-term reliability:

- Proper compatibility reduces energy loss and keeps your equipment running longer.

- Good wiring prevents overheating and lowers repair needs.

Choosing Linkwell gives you extra peace of mind:

| Benefit Type | Description |

|---|---|

| Core Compliance Leaders | Linkwell delivers on time and offers durable, IP54/55-rated products. |

| Downtime Reduction Leaders | Their thermostats help prevent overheating, so your system stays up and running. |

| Technology Advancement Impact | Smart features like AI-driven maintenance make your setup smarter and easier to manage. |

If you want safe installation, check out guides like The Essential Guide to Thermostat Installation and tips on avoiding common mistakes. You can always reach out for support if you need help.

FAQ

How do you choose the right setpoint for your thermostat?

You pick a setpoint based on your equipment’s needs. Check the manufacturer’s recommendations. Adjust the dial until you reach the temperature that keeps your system safe and efficient. Always test the accuracy after setting.

What’s the difference between an electromechanical switch and an electronic pressure switch?

An electromechanical switch uses physical movement to open or close contacts. An electronic pressure switch relies on sensors and circuits for sensing. You use electromechanical switches for simple motor control. Electronic pressure switches work best for advanced applications needing high repeatability.

Why does accuracy matter in thermostat sensing?

Accuracy helps you maintain the right temperature. If your thermostat’s sensing is off, your system may overheat or cool too much. Reliable accuracy means your contactor and motor control devices work as intended, protecting your equipment.

How does repeatability affect motor control in industrial systems?

Repeatability ensures your thermostat triggers at the same setpoint every time. You get consistent motor control and stable operation. Poor repeatability can cause frequent cycling, which may damage your contactor or reduce system life.

Can you use a thermostat for both heating and cooling motor control?

Yes, you can. Many thermostats have both NC and NO contacts. You connect your heating or cooling device to the right contactor. Adjust the setpoint for each application. This setup gives you flexible motor control and reliable sensing.

Conclusion

Understanding the difference between NC (Normally Closed) and NO (Normally Open) contacts is fundamental to correctly applying cabinet thermostats. This distinction dictates whether your thermostat will activate a device when the temperature drops (NC for heating) or rises (NO for cooling). Correctly identifying and wiring these ensures optimal thermal management for your sensitive equipment.

When selecting your thermostat, always verify the maximum switching capacity (Amperage) to ensure it can handle the load of your specific heater or fan.

Misunderstanding NC and NO can lead to improper system function, risking both equipment damage from overheating or freezing, and wasted energy. By correctly configuring your thermostat, you ensure efficient and precise temperature control, protecting your valuable assets and extending their operational lifespan.

For reliable and accurately specified cabinet thermostats, look no further. We offer a comprehensive range of wholesale NC and NO models, designed to meet diverse industrial needs. Contact us today to secure the right thermal solutions for your projects and ensure peak performance and safety.