You need to match transformer specifications to your application’s needs when choosing a single phase control transformer. Pay close attention to load, voltage, environment, and compliance. Overheating, insulation breakdown from moisture, and contamination often cause transformer failures. Linkwell offers certified control transformers with customizable features, helping you avoid common issues. Use a transformer selection process with a reliable transformer selection tool to ensure safe and efficient performance.

Key Takeaways

- Understand your load and voltage needs before selecting a transformer. This ensures reliable performance and protects your equipment.

- Always include a safety margin of 15% to 25% when sizing your transformer. This helps manage unexpected demand and extends equipment life.

- Choose transformers with important certifications like UL and CE. These certifications ensure safety and compliance with industry standards.

- Consider future expansion when selecting a transformer. This allows for growth without needing to replace equipment later.

- Pay attention to the installation environment. Proper grounding and enclosure choices protect your transformer and enhance its performance.

Define Load and Voltage Needs

Selecting the right transformer starts with understanding your current load profile and voltage requirements. You need to know how much power your equipment will use and what voltage levels your system demands. This step ensures your transformer delivers reliable performance and protects your control circuits.

Calculate Load (VA/kVA)

To size your transformer correctly, follow these steps:

- List all devices that will connect to the transformer. Write down their power ratings and operating details.

- Convert each device’s power usage into kVA using the appropriate formula for the load type.

- Consider that not all devices run at the same time. Apply a diversity factor to reflect real-world usage.

- Add a safety margin—typically 15% to 25% above your calculated maximum load. This buffer helps manage unexpected demand and future expansion.

- Compare your total kVA requirements with the transformer’s rating plate. Make sure your chosen transformer meets or exceeds this value.

Tip: Always include a safety margin when sizing single-phase transformers. This extra capacity helps prevent overloads and extends equipment life.

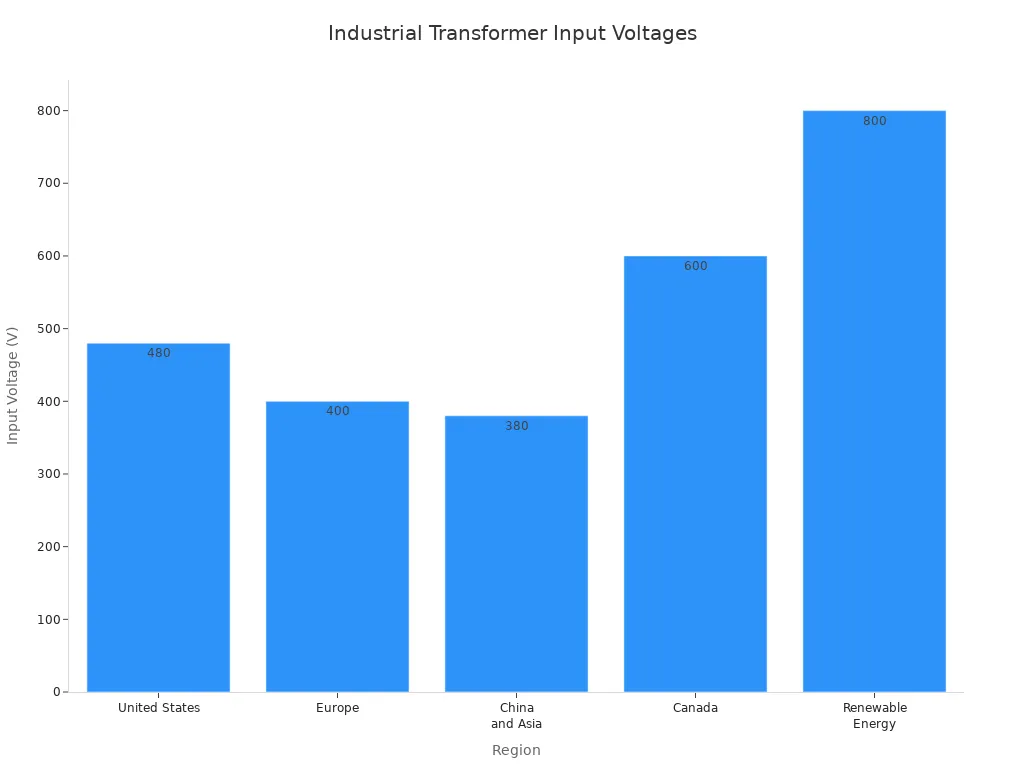

Identify Input and Output Voltage

You must match the transformer’s input and output voltage to your application. Industrial environments around the world use different standard voltages. The table below shows common values:

| Region | Common Industrial Socket Voltages | Features and Applications |

|---|---|---|

| United States | 480V, 240V, 208V | Used in factories and data centers; supports American 3-phase voltage. |

| Europe | 400V | Standard for industrial equipment in most European facilities. |

| China and Asia | 380V | Main supply for domestic production; export equipment must match voltage compatibility. |

| Canada | 600V | Used for high-voltage industrial equipment; some devices need transformers for adaptation. |

| Renewable Energy | 800V, 630V, 690V | Common in solar and wind systems; chosen based on system and inverter needs. |

Voltage fluctuations can affect your transformer’s performance. Motors may vibrate more, heating equipment may lose efficiency, and lights may flicker. Stable voltage input and output help your control circuits work smoothly and protect sensitive devices.

By carefully calculating your load and identifying the correct voltage, you set a strong foundation for choosing the best transformer for your needs.

Select the Right Single Phase Control Transformer

Choosing the right transformer for your application is a critical step in the transformer selection process. You want a single phase control transformer that not only meets your current needs but also supports future growth and ensures long-term reliability. Linkwell makes this process easier by offering advanced features, strong certifications, and flexible customization options.

Linkwell Control Transformer Features

When you compare different brands, you will notice that Linkwell single phase control transformers stand out for their quality and thoughtful design. These features help you achieve safe, efficient, and reliable operation in your control cabinets and industrial panels.

| Feature | Description |

|---|---|

| Secure connections | Ensures reliable and safe electrical connections for your equipment. |

| Copper windings | Provides better conductivity and higher efficiency than standard materials. |

| Flexible design | Allows you to customize input or output voltage for different applications. |

| Heat and short circuit protector | Enhances reliability and safety during operation. |

| Larger terminal screw | Makes wiring easier and more secure compared to other brands. |

| Vacuum soak painting | Improves insulation stability with high-quality materials. |

You can trust Linkwell transformers because they carry important certifications. These certifications show that the right transformer meets strict safety and quality standards.

| Certification | Significance |

|---|---|

| UL | Ensures safety and performance standards are met. |

| CE | Indicates compliance with European health, safety, and environmental rules. |

| ISO9001 | Shows a commitment to quality management and continuous improvement. |

Note: Always check for these certifications during transformer selection. They help you avoid safety risks and ensure your equipment meets industry regulations.

Sizing and Customization Options

Getting the right transformer size is essential for reliable performance. You need to consider both your current load and any possible future expansion. The transformer selection process should also account for inrush current, which is the surge of electricity when equipment starts up.

| Consideration | Description |

|---|---|

| Inrush Current | The transformer must handle inrush currents that exceed steady-state levels without causing voltage drops that affect operation. |

| Future Expansion | It is advisable to size the transformer with additional capacity to accommodate potential future circuit expansions. |

When you work with Linkwell, you gain access to a wide range of customization options. This flexibility helps you find the right transformer for unique industrial requirements. You can choose custom logos, packaging, and even special designs for your single phase control transformer.

| Customization Type | Minimum Order Quantity |

|---|---|

| Customized logo | 1,000 pieces |

| Customized packaging | 1,000 pieces |

| Graphic customization | 1,000 pieces |

| Minor customization | N/A |

| Sample-based customization | N/A |

| Full customization | N/A |

You should always match the transformer specs to your application. Start your transformer selection by listing your load, voltage, and installation needs. Then, consider inrush current and future expansion. Finally, review customization options to make sure you get the right transformer for your project.

Tip: A careful transformer selection process saves you time and money. It also protects your equipment from overloads and voltage drops.

The right transformer selection ensures your control circuits run smoothly, your equipment stays safe, and your business remains efficient. Linkwell’s certified, customizable single phase control transformer solutions help you meet these goals with confidence.

Consider Environment and Installation

Cabinet and Panel Applications

You must pay close attention to the environment when installing a single phase control transformer. Temperature and humidity can change how well your equipment works. The table below shows how these factors affect performance and what you can do to solve common problems:

| Environmental Factor | Impact on Performance | Solutions |

|---|---|---|

| Temperature | Accelerates insulation aging, leading to overheating and failure. | Use forced cooling or select transformers rated for higher temperatures. |

| Humidity | Reduces insulation effectiveness, increasing risk of short circuits. | Regularly test insulation quality and use dehumidifiers. |

You should always follow best practices for safe and reliable installation in cabinets and panels:

- Ensure proper grounding to prevent electrical accidents. Standards like NEC 250 give clear rules for grounding and bonding.

- Plan for wire management. Organized wires make maintenance easier and reduce hazards. Use wire ducts, ties, and labels.

- Group similar components together. This helps you separate high-voltage and low-voltage areas, which improves safety.

- Consider temperature. Install fans or filters to help with heat dissipation. Avoid crowding components.

- Follow proven safety practices. Label arc flash categories, assign short circuit current ratings, and add emergency stop buttons.

Tip: Good installation practices protect your equipment and make future maintenance much easier.

Enclosure and Mounting Choices

You need to choose the right enclosure and mounting option for your application. In harsh industrial environments, enclosures like NEMA 1, 3R, 4, and 12 rated housings offer strong protection. You can mount these enclosures on walls, floors, or panels, which gives you flexibility for both indoor and outdoor use.

NEMA 4X enclosures work well in chemical plants and coastal areas where moisture and salt are present. These enclosures keep your equipment safe and reliable, even in extreme conditions.

NEMA ratings focus on construction details, corrosion resistance, and environmental factors. IP ratings show how well the enclosure keeps out dust and water. Understanding these ratings helps you pick the best enclosure for your needs.

Note: The right enclosure and mounting choice extends the life of your transformer and keeps your system running smoothly.

Ensure Compliance and Efficiency

Certifications and Safety Standards

You need to make sure your control transformer meets strict safety and quality standards. Certifications like UL, CE, ISO9001, and NEMA show that a product follows international rules for safety and performance. Linkwell’s transformers carry these marks, which means you can trust their quality in your industrial projects.

If you use transformers that do not meet these standards, you may face serious risks. These include financial penalties, warranty disputes, project delays, and even equipment failures. You can avoid these problems by choosing certified products.

The table below shows important IEC standards for single phase control transformers:

| IEC Standard | Title / Scope | Safety / Environmental Focus |

|---|---|---|

| IEC 60076-1 | General Requirements | Electrical, mechanical, and operational safety |

| IEC 60076-2 | Temperature Rise Limits | Prevents overheating and fire risk |

| IEC 60076-5 | Short-Circuit Withstand Strength | Protects against mechanical and thermal damage |

| IEC 60076-7 | Loading Guides | Prevents overload and insulation deterioration |

| IEC 60076-10 | Sound Level Limits | Noise pollution control |

| IEC 60076-14 | Environmental and Climatic Classes | Oil leakage prevention, corrosion resistance |

| IEC 60076-22-1 | Fire Safety and Liquid-Immersed Transformers | Fire prevention and containment |

| IEC 60076-19 | Digital Monitoring and Diagnostics | Condition-based risk management |

Note: Always check for these certifications and standards before you install a transformer in your system.

Energy Efficiency and Reliability

You want your equipment to run smoothly and save money over time. Energy-efficient transformers help you lower your energy bills because they use less electricity. They also produce less heat, which means you spend less on cooling systems. Efficient designs reduce wear and tear on your electrical equipment, so you pay less for repairs and maintenance.

A high-quality transformer can last 20 to 30 years if you use it under normal conditions. Good care and proper installation can make it last even longer. This long lifespan gives you peace of mind and supports the reliability of your entire system.

Tip: Choosing an energy-efficient and certified transformer boosts your system’s reliability and helps you avoid costly downtime.

conclusion

Selecting the right single phase control transformer does not have to feel overwhelming. You can break the process into clear steps and make confident decisions for your project. Start by understanding your load and voltage needs. Calculate the total power your equipment requires. Identify the input and output voltages that match your system.

Next, choose a transformer that fits your application. Look for features that support safety, reliability, and future expansion. Consider inrush current and leave room for growth. Review customization options if your project has unique requirements.

Pay attention to the environment where you will install the transformer. Make sure you select the right enclosure and mounting style. Good installation practices help your equipment last longer and work safely.

Check for certifications like UL, CE, and ISO9001. These marks show that the product meets strict safety and quality standards. Energy efficiency and reliability should guide your final choice. A high-quality transformer saves you money and reduces downtime over the years.

Remember: Careful planning and selection protect your investment and keep your operations running smoothly.

Linkwell stands out as a trusted partner for industrial control solutions. You get certified products, flexible customization, and expert support. If you need help, use the checklist from this guide or contact Linkwell for advice. You can visit Linkwell’s website to explore more solutions or request a custom quote.

- Review your needs

- Match the right specs

- Choose certified quality

- Plan for the future

With the right approach, you ensure safe, efficient, and reliable performance for your control systems.

You can select the right single phase control transformer by following a clear process. Start with a checklist:

| Checklist Item | Description |

|---|---|

| Load Analysis | Review all parts in your control circuit. |

| Current Requirements | Know the coil and contact current needs. |

| Volt-Ampere Inrush | Check the initial current for energizing the coil. |

| Sealed Volt-Amperes | Find the current needed to keep contacts closed. |

Avoid common mistakes such as ignoring power factor or underestimating peak load. Linkwell gives you certified quality, flexible customization, and expert support. You get responsive help from design to installation. Reach out for guidance and ensure your transformer matches your needs.

FAQ

How do you choose the correct transformer size?

You should calculate the total load in VA or kVA. Add a safety margin of 15% to 25%. Check the transformer’s rating plate. Make sure the transformer can handle inrush current and future expansion.

Can you customize Linkwell control transformers for special applications?

Yes, you can request custom input/output voltages, power ratings, mounting styles, and enclosures. Linkwell offers flexible options for logos, packaging, and design.

Tip: Contact Linkwell for expert customization support.

What certifications do Linkwell control transformers have?

Linkwell control transformers carry UL, CE, and ISO9001 certifications.

| Certification | Purpose |

|---|---|

| UL | Safety and reliability |

| CE | European compliance |

| ISO9001 | Quality management |

How long does a Linkwell control transformer last?

You can expect a Linkwell transformer to last 10–15 years under normal conditions. Quality materials and proper installation extend lifespan.