You need a control cabinet heater when you want to stop condensation from forming inside your control cabinet enclosures. Condensation often appears when the temperature inside the cabinet drops below the dew point, causing moisture to settle on surfaces. This moisture can lead to rust, short circuits, or even equipment breakdowns. Even with high IP or NEMA ratings, control cabinet enclosures still face condensation risks because heat loss and outside temperature changes can cause moisture buildup.

Using a control cabinet heater helps keep the temperature and humidity stable, which protects your electronics and extends the life of your cabinet. Effective heat management and condensation prevention are key for reliable performance.

Condensation Risks

What Causes Condensation

Condensation forms inside control cabinet enclosures when warm, moist air cools down and reaches its dew point. You often see this happen when the temperature inside the cabinet drops quickly or when the outside air is very humid. If the surface of the cabinet becomes colder than the air inside, water vapor turns into liquid and settles on the surfaces. This process can start when the relative humidity reaches about 65%. Outdoor control cabinet enclosures face even higher risks because they deal with changing weather and high humidity. Cabinets that are not airtight let in moisture-rich air, which increases the chance of condensation. Even high IP-rated enclosures can trap vapor inside, making condensation more likely if heat dissipation is not managed well. Rapid temperature changes, poor sealing, and lack of proper heat control all make condensation a bigger problem.

Tip: Keeping the internal temperature of your cabinet between 33°C and 40°C can help prevent condensation, especially in harsh environments. Good heat dissipation and steady heat levels are key to stopping moisture from forming.

Dangers for Electronics

Condensation inside control cabinet enclosures can cause serious trouble for your electronics. When water collects on circuit boards and metal parts, it can lead to rust, corrosion, and even short circuits. Studies show that nearly 70% of accidents in control cabinets happen because of condensation. Moisture weakens insulation and can cause dangerous flashover accidents. If you do not control heat and humidity, you risk damaging your equipment. Corroded connections increase resistance, which leads to overheating and more damage. Water on printed circuit boards can break traces or create new paths for electricity, causing malfunctions and data loss. Batteries inside the cabinet may lose efficiency and have a shorter life if exposed to moisture. Without proper heat dissipation, these problems get worse, leading to higher maintenance costs and possible system failure. Managing heat and preventing condensation keeps your control cabinet enclosures safe and your electronics working longer.

When to Use a Control Cabinet Heater

Risk Environments

You should use a control cabinet heater when your control cabinet enclosures face environments with high humidity, rapid temperature changes, or outdoor exposure. These conditions often lead to condensation, which can damage sensitive electronics and cause system failures. Many industries rely on anti-condensation heaters to keep their equipment safe and running smoothly.

Note: Condensation forms when the temperature inside your cabinet drops below the dew point. For example, if the air inside is 27°C with 75% relative humidity, a drop to 22°C or lower can cause moisture to appear. This is a common risk in many industrial settings.

Some environments have a much higher risk of condensation:

- Outdoor Installations: Cabinets placed outside, such as those used in wind power or telecommunications, face changing weather, rain, snow, and direct sunlight. These factors make it hard to keep the temperature steady inside the enclosure.

- Renewable Energy Systems: Wind power and energy storage systems often use outdoor hybrid power supply cabinets. In these cases, keeping the relative humidity between 40% and 60% is critical. High humidity can cause condensation, leading to short circuits and corrosion. Low humidity can increase static electricity, which also harms electronics.

- Energy Storage Applications: In battery storage systems, high humidity and temperature swings cause repeated cycles of condensation and drying. This can lead to dust buildup, insulation breakdown, and even fires. International standards recommend careful management of temperature and humidity in these systems.

- EV Charging Stations: Electric vehicle charging cabinets often operate outdoors or in parking garages. These locations experience wide temperature swings and high humidity, making condensation a constant threat.

- Industrial Automation: Factories with high heat loads or frequent washdowns need anti-condensation heaters to protect control cabinet enclosures from moisture and corrosion.

Here is a table showing environmental parameters linked to condensation risk and how you can control them:

| Environmental Parameter | Link to Condensation Risk | Explanation and Control Measures |

|---|---|---|

| Dew Point Temperature | Condensation occurs when surface temperature falls below dew point, causing moisture accumulation inside. | Maintain enclosure temperature above dew point using heaters to prevent condensation. |

| Relative Humidity (RH) | High RH alone does not cause condensation but contributes when combined with temperature drops. | Control RH below certain thresholds (e.g., below 60%) to reduce condensation risk. |

| Internal Temperature | Fluctuations can cause surfaces to reach dew point, triggering condensation. | Calculate heat load and design for conservative max/min internal temperatures to avoid dew point crossing. |

| External Ambient Temperature | Influences internal temperature and condensation risk, especially in outdoor installations. | Use climate data to assess and design cooling or heating solutions accordingly. |

| Solar Radiation | Can increase internal temperatures, affecting condensation dynamics. | Mitigate with shading and orientation to reduce heat gain. |

| Atmospheric Pollution | Corrosive vapors and dust can worsen damage from condensation. | Use sealed enclosures and closed-loop cooling to prevent ingress. |

| Water, Snow, Ice | Outdoor moisture sources increase condensation and corrosion risk. | Use enclosures with appropriate weather protection ratings. |

You can see that managing temperature, humidity, and dew point is essential. Using a control cabinet heater helps you keep the internal temperature above the dew point, which stops condensation from forming.

LINKWELL ELECTRIC stands out as a trusted manufacturer of control cabinet heaters and enclosure heating solutions. Their products are designed for harsh environments, including wind farms, photovoltaic energy, energy storage, electric power distribution, and EV charging stations. LINKWELL’s anti-condensation heaters and climate control solutions help you maintain safe and reliable operation in these demanding applications.

Signs You Need Enclosure Heating

You may wonder how to tell if your cabinet needs a control cabinet heater. Here are some clear signs and situations where enclosure heating becomes necessary:

- Visible Moisture or Water Droplets: If you see water droplets on the inside walls or components of your control cabinet enclosures, condensation is already happening. This is a strong signal that you need anti-condensation heaters.

- Corrosion or Rust: Rust on metal parts or corrosion on terminals and connectors means moisture has been present. This can quickly lead to electrical failures.

- Frequent Temperature Swings: If your cabinet experiences rapid changes in temperature, especially in outdoor or unheated indoor spaces, condensation risk increases. Heaters help stabilize the temperature.

- High Relative Humidity: When the relative humidity inside your cabinet stays above 60%, the risk of condensation rises. You should consider installing a control cabinet heater to keep humidity in check.

- Electrical Malfunctions: Unexplained short circuits, tripped breakers, or equipment failures can result from moisture inside the cabinet. Anti-condensation heaters can prevent these costly problems.

- Dust and Pollution Exposure: Cabinets in dusty or polluted environments are more likely to suffer from condensation-related damage. Moisture combines with dust to form conductive paths, increasing the risk of shorts and corrosion.

Tip: Use dew point sensors and logic controllers to monitor the temperature and humidity inside your cabinet. Try to keep the internal temperature at least 3–5°C above the dew point to avoid condensation.

In real-world case studies, control cabinet heaters have proven effective in extreme environments. For example, an environmental control unit for radar systems used a 2kW electric heater to maintain stable temperatures from -34°C to 49°C. This setup allowed remote monitoring and quick deployment, showing how heaters can adapt to harsh climates.

Tests comparing different types of heaters found that infrared panel heaters provided faster and more uniform heating. They also kept humidity levels steadier, which reduced condensation and mold growth. Infrared heaters used less energy and did not stir up dust, making them a good choice for sensitive environments.

Heat Dissipation in Control Cabinet Enclosures

Cooling Methods

You need to manage heat dissipation in your control cabinet to keep your electronics safe and working well. When you use electrical equipment, it creates heat. If you do not remove this heat, the temperature inside the cabinet rises. This can damage your devices and shorten their lifespan. You can use different cooling solutions to control the cabinet heat load and equipment heat load.

Natural convection cooling uses the movement of warm air rising and cool air falling. This method works best when the heat load is low and the cabinet has enough space for air to move. For higher heat loads, forced air cooling becomes important. Fans and filters from LINKWELL ELECTRIC help move air through the cabinet, pushing hot air out and pulling cool air in. Their LK3238 and LK3245 series fans and filters offer strong airflow capacity and low noise. You can also use cabinet air conditioners for active heat dissipation when the environment is very hot or the cabinet heat load is high. These cooling solutions keep the temperature stable and prevent condensation.

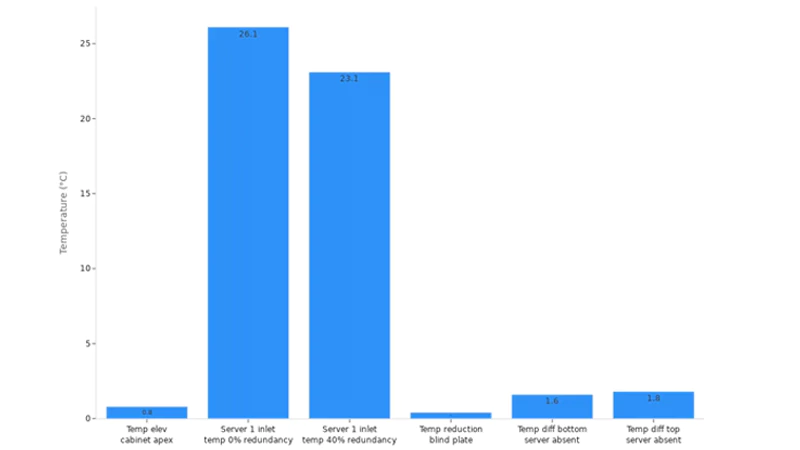

Experimental studies show that the design of the cabinet, such as using partitions or fins, changes how heat moves. Good design improves convection and radiation, making heat dissipation more effective. In outdoor battery cabinets, using forced air cooling and insulation keeps battery temperatures safe, even when it is very hot outside. This protects your equipment and helps it last longer.

Airflow and Ventilation

Proper airflow and ventilation are key for heat dissipation in control cabinets. You want cool air to reach your equipment and hot air to leave the cabinet quickly. Forced air cooling with fans helps prevent hot spots and keeps the temperature even. LINKWELL ELECTRIC’s fans and filters support this by moving air efficiently and quietly.

Thermal simulations and airflow analysis show that good ventilation stops hot air from building up. You can use CFD (Computational Fluid Dynamics) to check how air moves inside your cabinet. This helps you place fans and vents in the best spots. Sealing gaps and using the right panels also improve airflow. When you balance airflow, you keep the cabinet cool and protect your electronics.

Scientific measurements prove that keeping enough space and airflow inside the cabinet helps remove heat. You can use fan speed controls to adjust airflow as needed. This saves energy and extends fan life. When you use proper ventilation and forced air cooling, you manage heat dissipation well and keep your control cabinet safe.

Choosing and Installing Enclosure Heating

Types of Heaters

You have several options when choosing heaters for your control cabinet. The most common types include anti-condensation resistors, fan heaters, and panel heaters. Anti-condensation resistors work well in small enclosures and help prevent moisture by gently raising the temperature. Fan heaters use a built-in fan to spread heat evenly, making them a good choice for larger cabinets or places with high humidity. Panel heaters mount directly on the wall and provide steady heat without taking up much space.

When you select a heater, you should look at the size of your cabinet, the amount of heat needed, and the environment where you will install it. Calculate the heating requirements by adding up the heat from all internal components, the difference between the optimal temperature range and the outside temperature, and the heat lost through the cabinet walls. For example, if your system has a 345 Watt internal heat load and a 14°F temperature difference, you need a heater with enough power to keep the temperature stable. Studies show that convector heaters use less energy than baseboard or radiant heaters while still keeping the cabinet comfortable. This helps you save energy and protect your equipment.

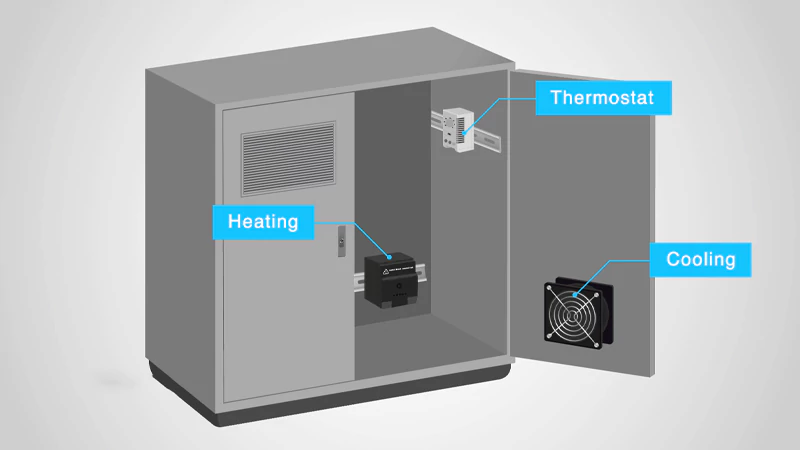

Controls and Thermostats

You need reliable controls and thermostats to regulate temperature inside your cabinet. Modern thermostats let you set the exact temperature you want. Some models combine heating and cooling control, using sensors to track both temperature and humidity. Smart thermostats offer remote monitoring and alarms, so you can check your system from anywhere.

Thermostats with precise controls help you keep the heat steady and avoid cold spots. They also prevent overheating, which protects your electronics. Many thermostats include safety features like thermal fuses and automatic shut-off. These features make sure your system runs safely and efficiently. You can find thermostats that work with different types of heaters, including anti-condensation resistors, to fit your specific needs. Quality certifications, such as ISO 9001:2015 and UL, show that these controls meet high standards for safety and performance.

Installation Tips

Proper installation ensures your heating system works well and keeps your cabinet safe. Always hire a qualified technician to install heaters and controls. Check that your cabinet can handle the voltage and power of the heating elements. Place heaters where air can flow freely, away from dust and moisture.

After installation, test the system by checking thermostat accuracy, airflow, and safety features. Make sure the system shuts off automatically if it gets too hot. Schedule regular maintenance to inspect and clean the heaters, check for leaks, and verify that all controls work correctly. Keep records of all maintenance to help with future servicing.

- Verify voltage and power requirements before installation.

- Use PID controllers for precise temperature control.

- Add safety features like indicator lights and alarms.

- Customize your panel to match the environment, including NEMA ratings for harsh locations.

- Ensure proper ventilation to support efficient heat distribution.

A well-installed heating system helps you regulate temperature, prevent condensation, and extend the life of your equipment.

You should use a control cabinet heater when you want to stop condensation and protect your electronics. Keeping steady heat inside your enclosure helps prevent moisture and damage. Heat dissipation and enclosure heating both play a big role in making your equipment last longer. Trusted brands like LINKWELL ELECTRIC offer solutions that help you control heat and humidity. Follow tips such as using fans, thermostats, and proper ventilation to manage heat. Place enclosures away from direct heat sources and use good sealing to keep heat stable and reduce condensation.

FAQs

What is the main reason to install a control cabinet heater?

You install a control cabinet heater to stop condensation. When you keep the temperature above the dew point, you prevent moisture from forming. This protects your electronics from damage caused by water and helps your equipment last longer.

How do you know if your cabinet needs extra heat?

You notice signs like water droplets, rust, or frequent electrical problems. If your cabinet sits outdoors or in a humid place, you likely need extra heat to keep the inside dry and safe.

Can you use fans and filters with a heater?

Yes, you can use fans and filters with a heater. Fans help move air, while the heater adds heat to prevent condensation. This combination keeps the temperature steady and protects your equipment from moisture.

What type of heater works best for small enclosures?

For small enclosures, you should use anti-condensation resistors or compact panel heaters. These provide enough heat to keep the temperature stable without taking up much space or using too much energy.

How do you control the amount of heat inside the cabinet?

You use thermostats or smart controllers to manage the heat. These devices turn the heater on or off as needed. This keeps the temperature in the right range and stops overheating.