High-temperature issues in cabinet transformers can put your equipment at serious risk. You might notice high-temperature issues in cabinet transformers when they run for long periods or face heavy loads. These high-temperature issues in cabinet transformers often happen because of poor quality, overloading, or lack of maintenance. According to industry reports, overheating causes about 70% of cabinet transformer failures in factories. You can avoid high-temperature issues in cabinet transformers by choosing the right transformer and taking care of it. High-quality models, such as small 1000VA Single Control Step Down Isolation Electric Transformers, use better materials and advanced technology, so you see fewer high-temperature issues in cabinet transformers. You have options—simple steps and smart choices keep your system safe and reliable.

Key Takeaways

- Overloading transformers can lead to overheating. Always operate within the rated capacity to extend lifespan.

- Regular inspections help catch overheating signs early. Look for hot surfaces, strange smells, or tripped alarms.

- Ensure proper ventilation in transformer cabinets. Good airflow prevents heat buildup and protects equipment.

- Choose high-quality transformers for better performance. Reliable products reduce the risk of overheating and failures.

- Implement regular maintenance and monitoring. This proactive approach helps avoid costly repairs and keeps systems running smoothly.

Main Causes of Overheating

When you look at cabinet transformers, you’ll find several reasons for transformer overheating. Let’s break down the main causes so you can spot problems early and keep your system running smoothly.

Overloading

You might think your transformer can handle a little extra work, but excessive load is one of the fastest ways to create heat problems. When you push a transformer past its rated capacity, the current increases. This extra current causes more heat inside the copper windings and the core. Overheating happens quickly, and you’ll notice the temperature climbing. If you keep running above the rated thermal load, the insulation ages faster, and the transformer’s lifespan drops.

- Overloading occurs when the actual load exceeds the rated capacity.

- This leads to excessive heating through increased current flow.

- Increased current generates additional I²R losses, rapidly raising internal temperatures.

- Continuous overloading can cause overheating.

- This results in accelerated aging of insulation and other components.

- Ultimately, it shortens the transformer’s lifespan.

You want to avoid regular operation above the rated thermal load. Reliable products, like small 1000VA Single Control Step Down Isolation Electric Transformers, are designed to handle their rated loads without overheating, giving you peace of mind.

Insulation Breakdown

Insulation keeps the heat where it belongs and prevents electrical faults. Poor insulation or aging insulation can’t do its job. When insulation breaks down, you get hotspots and more heat.

- Degradation of insulating oil produces acidic byproducts that reduce dielectric strength.

- Moisture ingress can drastically lower insulation capabilities.

- Overheating is a common sign of transformer failure, indicating excessive heat generation due to high load or cooling system issues.

- Signs of insulation damage include hot transformer casing and discoloration due to heat.

- Aging or contaminated insulating oil can degrade insulation capabilities.

- Paper insulation can become brittle and develop cracks, leading to partial discharge and thermal breakdown.

- Partial discharge activity is critical for detecting insulation defects that can lead to transformer failure.

If you notice hot surfaces or discoloration, you might be dealing with insulation problems. High-quality transformers use advanced insulation materials to resist heat and prevent breakdown.

Poor Materials and Design

Not all transformers are created equal. Low-quality windings and poor design choices can trap heat and cause thermal issues.

- The insulation class significantly affects the expected life and performance of a dry-type transformer. Operating above the rated insulation temperature class drastically reduces service life, following the Arrhenius Law where every 10°C increase can halve insulation life.

- Heat is the worst destructive agent for electronic components. When heat accumulates in a contained area, it leads to catastrophic failures, as described by the Arrhenius equation, which states that the operational life of components is halved with every 10 °C increase above nominal operating temperature.

- A cabinet with only 15% free space can experience a temperature increase of 20-25 °C above ambient, while one with 40% free space may only see a 10-15 °C increase. This 10 °C difference can significantly affect the lifespan of the system.

You want a transformer with high-quality windings and smart design. Products like small 1000VA Single Control Step Down Isolation Electric Transformers use premium materials and thoughtful engineering to keep heat under control and extend service life.

Lack of Cabinet Cooling

Cabinet cooling and ventilation play a huge role in managing heat. Without proper airflow, heat builds up and causes thermal stress.

Environmental conditions such as extreme temperatures, high humidity, or corrosive substances can accelerate the degradation of both the transformer’s core and its insulation. Corrosion, in particular, can impair heat dissipation and lead to overheating.

Check out this table for recommended airflow rates in different applications:

| Application Type | Airflow Rate (m³/h per kW) |

|---|---|

| Standard electrical enclosures | 50–100 |

| High-density PCS racks in energy storage | 120–150 |

| Outdoor charging kiosks | +10–20% margin |

If your cabinet doesn’t have enough ventilation or cooling, heat will build up fast. Make sure you have enough free space and airflow to keep temperatures down, especially in areas with high ambient temperature.

Incorrect Voltage and Defects

Voltage problems and manufacturing defects can sneak up on you and cause serious heat issues.

- A 5% voltage imbalance can create a 25% current imbalance in motors, which reflects back to the transformer, leading to asymmetric heating and degradation of specific windings.

- Events like lightning strikes or grid disturbances can cause overvoltages that exceed the transformer’s insulation capacity, leading to insulation breakdown and overheating.

- Manufacturing defects can lead to insulation aging and dielectric oil degradation, which contribute to localized heating and thermal runaway.

- Overvoltage conditions can lead to insulation breakdown, which is a critical factor in transformer overheating.

- Manufacturing defects can cause localized heating and thermal runaway, which are significant contributors to transformer overheating.

You want to choose transformers with strict quality control and reliable voltage settings. High-quality models help you avoid these problems and keep your system safe.

Tip: Always select a transformer that matches your load and environment. Reliable products, like small 1000VA Single Control Step Down Isolation Electric Transformers, offer advanced thermal management and superior insulation, helping you avoid overheating and costly downtime.

Signs of High-Temperature Issues in Cabinet Transformers

Spotting high-temperature problems early can save you from expensive repairs and downtime. You don’t need to be an expert to notice the warning signs. Regular inspection and monitoring help you catch issues before they get out of hand.

Odors and Smoke

If you smell something strange or see smoke near your cabinet transformer, take it seriously. Burning odors often mean insulation or oil is breaking down. Smoke can show up during the day, while at night, you might notice bright flashes before a failure.

- Smoke and oil spray are usually more visible than flames in daylight.

- These signs often come before catastrophic failure.

Tip: If you notice any unusual smells or smoke, shut down the transformer and call a technician right away.

Hot Surfaces

Touching the cabinet and feeling excessive heat is a clear sign of trouble. You can check the temperature with a simple infrared thermometer.

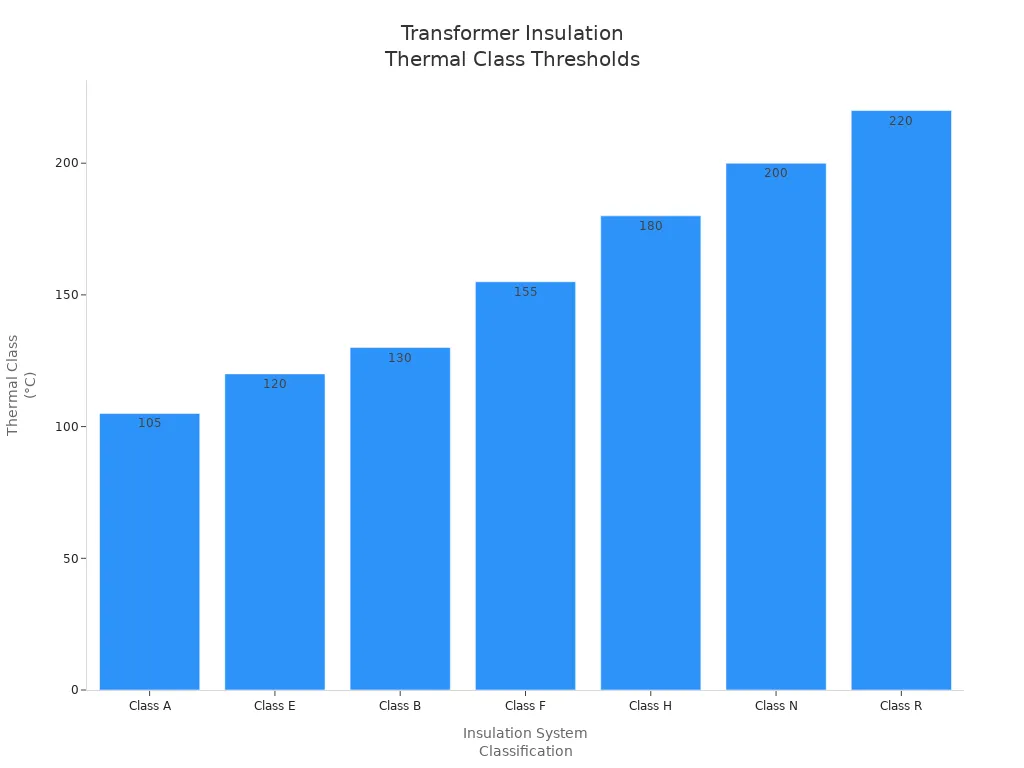

Here’s a quick look at temperature thresholds for transformer insulation systems:

| Classification | Insulation System | Thermal Class, °C |

|---|---|---|

| Class A | 105 | |

| Class E | 120 | |

| Class B | 130 | |

| Class F | 155 | |

| Class H | 180 | |

| Class N | 200 | |

| Class R | 220 |

If the surface temperature goes above the rated class, your transformer is at risk. High-quality models, like our small 1000VA Single Control Step Down Isolation Electric Transformers, stay cool under pressure.

Tripped Breakers or Alarms

When breakers trip or alarms go off, your system is trying to protect itself.

Here’s how overheating events usually play out:

| Cause of Overheating | Detection Method | Protection Device | Trip Outcome |

|---|---|---|---|

| Load-induced heating | RTDs, OTI | Thermal relay (ANSI 49) | Breaker opens to isolate transformer |

| Cooling system failure | Oil temp sensor, WTI | Trip at 95–105°C | System alarm, unit disconnected |

| Ambient spike + overload | SCADA input + RTDs | Auto-compensated threshold | Trip + dispatch for inspection |

If you see repeated trips or alarms, don’t ignore them. These are your system’s way of telling you something’s wrong.

Performance Drops

You might notice your equipment running slower or not delivering enough power. This can mean your transformer is struggling with heat.

- Overheating can cause voltage drops and irregular performance.

- Unusual noises or oil leaks may also signal trouble.

Note: Keep an eye on performance and listen for odd sounds. Regular thermal scanning helps you spot hotspots before they become a problem.

Staying alert to these signs and choosing reliable transformers helps you avoid costly breakdowns and keeps your operations running smoothly.

Immediate Actions for Overheating

When you spot signs of overheating in your cabinet transformer, you need to act fast. Quick action helps prevent bigger problems and keeps your system safe. Here’s what you should do right away:

Power Down Safely

First, turn off the transformer and disconnect it from the power source. You want to avoid any risk of fire or further damage. Make sure you check the area around the electrical cabinet. Remove any materials that could catch fire. Review the transformer ratings to confirm they match your system’s needs. Mark clear “no storage zones” around your cabinets so nothing blocks airflow or creates hazards.

Inspect for Damage

After you shut down, inspect the transformer for visible damage. Look for signs like burned insulation, melted wires, or oil leaks. Sometimes, the damage hides inside. If you have access to dissolved gas analysis, check for gases like hydrogen, methane, or ethane in the transformer oil. High levels of these gases mean the insulation may have suffered from a temperature rise. If the ratio of carbon dioxide to carbon monoxide drops below 5, you’re likely dealing with serious insulation damage. Careful inspection helps you decide what to do next and guides your maintenance plan.

Call a Technician

If you notice any major issues, call a certified technician right away. Problems like winding faults, oil degradation, or insulation failure need expert attention. Technicians use special tools to test and diagnose the transformer. Outsourcing maintenance services ensures you get accurate results and follow safety standards. When you maintain the device with professional help, you boost reliability and extend its life. Overloading or poor heat dissipation can cause permanent damage, so don’t wait to get help.

Do Not Restart Until Checked

Never restart a transformer after overheating until a thorough check is complete. Symptoms like vibration, buzzing, or a strong smell from insulation mean you need more inspection. Technicians should check transformers that supply nonlinear loads to make sure everything operates within safe limits. Monitoring temperature and checking for any lingering heat or odor helps you avoid another failure. Waiting for a full inspection before restarting is a key part of good maintenance.

Immediate action and regular maintenance keep your cabinet transformers running smoothly. High-quality products and smart monitoring temperature strategies help you avoid emergencies and keep your operations reliable.

Cabinet Cooling and Long-Term Prevention

Keeping your cabinet transformers cool isn’t just about comfort—it’s about safety, reliability, and saving money. If you want your equipment to last, you need to focus on cabinet cooling and long-term prevention strategies. Let’s break down what you can do to keep things running smoothly.

Ensure Proper Ventilation

You need to maintain ventilation inside your cabinet. Good airflow keeps temperatures down and protects your transformer from overheating. If you ignore airflow, heat builds up and insulation starts to break down. That’s when failures happen.

- Proper ventilation regulates internal temperatures and prevents overheating.

- Adequate airflow extends the lifespan of your transformer by dissipating heat during operation.

- If ventilation is poor, insulation can degrade and your transformer might fail.

Want to boost cooling efficiency? Try these cabinet cooling strategies:

- Size the thermal load first. Estimate the heat your system produces and pick a cooling solution that exceeds total watt loss by 15–25%.

- Design a true air path. Place the intake low and the exhaust high to direct airflow effectively.

- Separate hot and cold zones. Isolate high-loss components in a ‘hot aisle’ to protect sensitive equipment.

- Maintain static pressure and filtration. Use high-efficiency filters and check them often.

- Control ambient temperature. Keep the temperature inside your cabinet at or below 40°C (104°F).

- Manage braking resistor heat. Put resistors outside the cabinet or in isolated ducts.

If you follow these steps, you’ll see a big improvement in heat dissipation and overall reliability.

💡 Tip: Always check that nothing blocks airflow around your transformer. Even a small obstruction can raise temperatures fast.

Use Temperature-Activated Devices

You can install temperature control device systems to keep your transformer safe. These devices watch the temperature and react before problems start.

- Display the temperature of each phase and switch to the highest phase for quick checks.

- Automatically control the fan based on set temperature, keeping your transformer cool.

- Activate an over-temperature alarm with sound and light if things get too hot.

- Trip the power automatically when critical temperatures are reached, protecting your equipment.

- Show fault indications and alarms for sensor problems, so you know when maintenance is needed.

If you use these devices, you get real-time protection and peace of mind. You don’t have to worry about missing a warning sign.

Regular Maintenance

Regular maintenance is your best defense against overheating. You should check your transformer every day and schedule deeper inspections throughout the year.

- Inspect radiator fins for dust and make sure cooling fans work.

- Confirm vents are clear and unobstructed.

- Sample oil and run dissolved gas analysis every year or after any abnormal event.

- Test oil moisture and acidity every quarter.

- In high-risk areas, increase maintenance frequency and use anti-condensation heaters.

If you keep up with these tasks, you’ll catch problems early and avoid costly repairs.

Choose High-Quality Transformers

Not all transformers are built the same. If you want reliability, you need high-quality products. Our small 1000VA Single Control Step Down Isolation Electric Transformers use advanced proprietary technology that prevents overheating. You won’t see the same problems you get with inferior market options.

Here’s how top-tier transformers stand out:

| Feature | Description |

|---|---|

| Design Quality | Precision engineering delivers better thermal management and reduces overheating risk. |

| Material Quality | Silicon steel cores and copper windings boost longevity and keep temperatures low. |

| Quality Control | Rigorous audits ensure every transformer can handle operational stress without overheating. |

If you compare our transformers to low-quality alternatives, you’ll notice the difference right away. Our products maintain stable voltage, provide electrical isolation, and extend the life of your control components. You get enhanced system stability, increased safety, and improved efficiency—all while avoiding overheating.

| Benefit | Description |

|---|---|

| Enhanced System Stability | Stable voltage keeps control circuits running smoothly. |

| Increased Safety | Electrical isolation protects your equipment and your team. |

| Prolonged Equipment Lifespan | Less electrical interference means longer life for your control components. |

| Improved Efficiency | High-efficiency transformers save energy and lower your costs. |

If you want peace of mind, choose a transformer that’s built to last.

Monitor Load and Environment

You need to control the load and watch your environment. If you push your transformer too hard, heat builds up and problems start. Monitoring systems help you spot trouble before it gets serious.

| Function | Description |

|---|---|

| Cooling Systems | Manage heat during operation to prevent overheating and keep things efficient. |

| Real-time Monitoring | Track environmental factors and cooling performance to extend transformer life. |

| Automated Alarms | Alert you to cooling failures or temperature spikes so you can act fast. |

- Always monitor transformer loading to prevent overheating.

- If you see high temperatures often, consider reducing the load.

If you keep an eye on airflow, cabinet cooling, and environmental conditions, you’ll avoid most heat-related issues.

When you combine proper ventilation, temperature-activated devices, regular maintenance, and high-quality transformers, you build a system that’s safe, efficient, and reliable. Our small 1000VA Single Control Step Down Isolation Electric Transformers set the standard for cabinet cooling and long-term prevention. You don’t have to worry about overheating—our technology keeps your operations running smoothly.

conclusion

You’ve learned why cabinet transformers overheat and what you can do to prevent it. Overloading, poor insulation, weak materials, and bad ventilation all raise the risk. If you spot odors, hot surfaces, or tripped alarms, you need to act fast. Power down, inspect for damage, and call a technician before restarting. These steps keep your system safe.

Remember: Regular maintenance and smart monitoring help you catch problems early. You don’t have to wait for a breakdown.

Choosing high-quality transformers makes a big difference. Our small 1000VA Single Control Step Down Isolation Electric Transformers use advanced technology and premium materials. You get stable performance, better safety, and longer life for your equipment. Low-quality options can’t match this level of reliability.

Here’s a quick checklist to keep your cabinet transformers cool and safe:

- Check ventilation and airflow every month.

- Use temperature-activated devices for real-time protection.

- Schedule regular inspections and oil tests.

- Monitor load and reduce it if temperatures rise.

- Pick transformers with proven quality and strong support.

| Action | Benefit |

|---|---|

| Regular checks | Early problem detection |

| Smart cooling | Lower risk of overheating |

| Quality products | Reliable operation |

If you want peace of mind, don’t settle for less. Talk to an expert, choose trusted products, and stay proactive with your maintenance. Your cabinet transformers will thank you with years of safe, efficient service.

You’ve seen how overloading, poor insulation, weak connections, and bad ventilation can make cabinet transformers overheat. You can prevent these problems by improving airflow, tightening connections, and using high-quality oil. Regular maintenance and real-time monitoring help you catch issues early. Choosing reliable transformers with advanced design and proper installation keeps your system safe for years.

| Best Practice | Why It Matters |

|---|---|

| Routine Maintenance | Extends lifespan and boosts reliability |

| High-Quality Products | Withstand stress and reduce failure risk |

| Expert Consultation | Ensures safe installation and long-term safety |

Stay proactive. Talk to experts and pick trusted transformers for peace of mind.

FAQ

What causes cabinet transformers to overheat most often?

You usually see overheating when you overload the transformer, block airflow, or use low-quality products. Poor maintenance also plays a big role. Choosing a reliable transformer, like our small 1000VA Single Control Step Down Isolation Electric Transformer, helps you avoid these problems.

How can I tell if my transformer is overheating?

Look for these signs:

- Hot cabinet surfaces

- Strange smells or smoke

- Tripped breakers or alarms

- Drops in performance

If you spot any of these, act fast to prevent damage.

What should I do if my transformer overheats?

First, power down the transformer safely. Next, inspect for visible damage. Call a technician for a full check. Do not restart the transformer until an expert says it’s safe.

How do I keep my cabinet transformer cool?

You can:

- Make sure the cabinet has good ventilation

- Use temperature-activated fans or alarms

- Schedule regular maintenance

- Choose high-quality transformers for better heat control

Why should I choose a high-quality transformer?

High-quality transformers last longer and run cooler. You get better safety, fewer breakdowns, and more reliable performance. Our small 1000VA Single Control Step Down Isolation Electric Transformers set the standard for reliability and peace of mind.