Ever had your PLC reset out of nowhere, or noticed relays clicking off and indicator lights going dim? These headaches often trace back to picking the wrong control transformer. Take a look at some common issues:

| Problem | What Happens |

|---|---|

| Wrong power rating | Overheating or voltage drops |

| Bad voltage compatibility | Low output or device damage |

| Poor wiring | Transformer fails |

| Ignoring heat and humidity | Insulation breaks down |

You need a transformer that fits your panel’s real needs, not just the voltage ratio. Linkwell gives you certified, high-quality solutions for reliable automation.

Key Takeaways

- Calculate the total load and inrush VA for your control devices. This ensures your transformer can handle peak demands without overheating.

- Match the input and output voltage to your panel’s requirements. Proper voltage alignment prevents equipment damage and ensures reliable operation.

- Check the environment where the transformer will be installed. Factors like temperature and humidity can affect performance and lifespan.

- Ensure compliance with industry standards like UL and CE. This protects your equipment and keeps your operations safe.

- Choose a trusted supplier like Linkwell for quality and customization. Reliable support and certified products lead to better performance.

Control Transformer Basics and Types

Key Functions in Industrial Panels

You rely on your control circuits to keep everything running smoothly. A control transformer sits at the heart of your panel, making sure your PLCs, relays, and indicator lights get the right voltage every time. Here’s what these transformers do for you:

- Voltage regulation keeps your control circuits stable, even when the main supply fluctuates.

- Noise isolation shields your sensitive equipment from electrical interference, which is common in busy industrial environments.

- System reliability protects your devices from power surges and extends their lifespan.

A control transformer converts high voltage into a lower, safer voltage for your control circuits. It also separates control and power circuits, so you avoid damage from unexpected spikes. You get steady output voltage, which means your panel works reliably, even when loads change. Managing inrush currents is another big plus. This prevents voltage drops that could cause your automation to fail.

Linkwell’s control transformers come with UL and CE certifications. You get peace of mind knowing your panel meets international safety standards. These transformers handle tough environments and deliver stable performance for years.

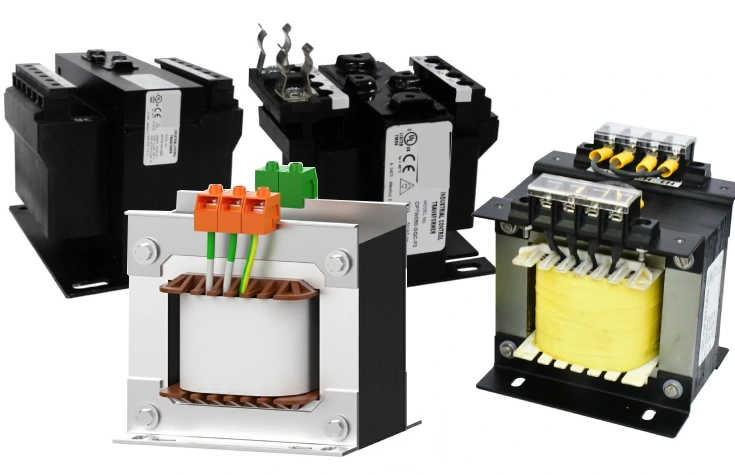

Main Types and Applications

You have several options when choosing a control transformer. Each type fits a different job. Check out this table for a quick overview:

| Type of Control Transformer | Description | Typical Use Cases |

|---|---|---|

| Single-phase Control Transformer | Converts single-phase power to lower voltage | Control circuits in industrial panels |

| Three-phase Control Transformer | Handles higher power for complex systems | Large-scale industrial applications |

| Furnace Control Transformer | Steps down voltage for heating systems | Gas and electric furnaces |

| Isolation Control Transformer | Provides electrical isolation | Protects circuits from faults and noise |

| Enclosed Control Transformer | Enclosed for safety and protection | Harsh industrial environments |

| Control Power Transformer | Supplies stable low-voltage power | Automation equipment and relays |

Linkwell offers a wide range of transformers for every application. You can choose standard models or request custom designs to match your panel’s needs. With certifications like UL and CE, you know you’re getting quality and safety.

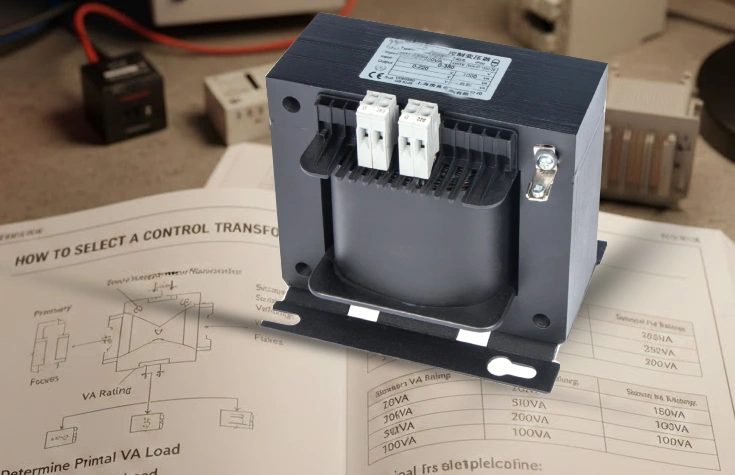

How to Select a Control Transformer

Choosing the right control transformer for your industrial panel doesn’t have to feel overwhelming. You can break it down into a few clear steps. Let’s walk through the process together.

Calculate Load and Inrush VA

Start by figuring out how much power your control devices need. This isn’t just about adding up numbers on nameplates. You need to consider both the steady-state load and the inrush current that happens when devices like contactors or relays first turn on.

- Add up the VA ratings of all control devices that will run at the same time. This gives you your steady-state VA.

- For each inductive device, multiply its VA by its inrush factor. If you don’t know the exact factor, use 5x as a safe default.

- Take the highest inrush VA and add it to your steady-state total.

- Add a safety margin of 20-25%. This helps your transformer handle voltage dips and future upgrades.

Tip: Always plan for a little extra. It’s better to have a transformer that’s slightly oversized than one that struggles under peak loads.

Match Input and Output Voltage

You want your control transformer to fit your panel’s power supply and your control circuit’s needs. Use this table to check the key parameters:

| Parameter | Description |

|---|---|

| Rated power (kVA) and output voltage (V) | Make sure the transformer can handle both peak and average loads. |

| Primary voltage and frequency | Match your plant’s power supply (usually 50 or 60 Hz). |

| Regulation and tolerance | Look for stable output even when loads change. |

| Temperature rise and cooling method | Pick a transformer that stays cool in your environment. |

| Insulation class and safety certifications | Check for UL, CE, or other required marks. |

| Mounting style and enclosure protection (IP rating) | Choose a design that fits your cabinet and protects against dust or moisture. |

| Availability of taps or adjustable outputs | Fine-tune voltage without swapping transformers. |

| End-of-life support and serviceability | Make sure you can get spare parts and test equipment when needed. |

Assess Environment and Installation

Your transformer’s environment matters more than you might think. High temperatures can break down insulation and cause overheating. Cold conditions can make insulating oil thick, which hurts cooling. Humidity is another big factor. Too much moisture can lead to insulation failure and rust, while very dry air can make insulation brittle.

To get the most out of your control transformer, follow these best practices:

- Use partial discharge detection and insulation monitoring to spot early problems.

- Try thermal imaging to catch overheating before it becomes a big issue.

- Keep your transformer clean. Dust can block airflow and trap heat.

- Run regular electrical tests and check for loose bolts or connections.

- Don’t overload your transformer. Make sure air can flow freely around it.

Check Compliance and Certifications

You need to meet industry standards for safety and efficiency. Here’s a quick look at what to check:

| Compliance Standard | Description |

|---|---|

| DOE Certification | Needed in the U.S. for efficiency. |

| Energy Star | Shows high energy efficiency in some markets. |

| BEE Star Ratings | Used in India for efficiency ratings. |

| CE Mark | Proves compliance with European standards. |

- Look for UL certification for safety in the U.S.

- IEEE C57.12.00 covers testing for power transformers.

- DOE 2016 standards apply to transformers up to 2500kVA.

Note: Always check your local regulations. Using certified transformers protects your equipment and keeps you compliant.

Finalize Selection with Linkwell

You don’t have to settle for a one-size-fits-all solution. Linkwell offers a range of customization options to make sure your control transformer fits your exact needs. Here’s how you can benefit:

| Customization Option | Benefit |

|---|---|

| Specific voltage, frequency, and capacity | Matches your machines and boosts reliability. |

| Multi-tap primary or secondary voltage | Lets you fine-tune output for different control devices. |

| Specific VA ratings | Handles both steady and inrush loads without voltage drops. |

| Integrated fuse blocks or clips | Saves space and makes wiring easier. |

| Different mounting footprints | Fits perfectly in your panel layout. |

| Various termination options | Simplifies installation for your team. |

You also get strong technical support from Linkwell:

| Service Type | Description |

|---|---|

| Product Selection Guidance | Get help picking the right transformer for your job. |

| OEM Customization | Order transformers built to your specs. |

| Quality Inspection | Receive products that meet strict standards. |

| Fast Delivery | Meet tight project deadlines with quick shipping. |

| After-Sales Support | Access help for installation and troubleshooting. |

When you choose Linkwell, you get more than just a transformer. You get a partner who helps you build safer, more reliable panels—every time.

Common Mistakes to Avoid

Underestimating Power Needs

You might think your panel doesn’t need much power, but that’s a trap many fall into. When you underestimate the power requirements, your transformer works harder than it should. This causes heat, lowers efficiency, and can even shorten the life of your equipment. Take a look at what happens when you size your transformer too small:

| Impact of Underestimating Power Needs | Description |

|---|---|

| Excessive Heat Generation | Your transformer gets hot and risks damage. |

| Reduced Efficiency | You lose performance and pay more for energy. |

| Premature Insulation Breakdown | Insulation fails, leading to electrical problems. |

| Potential System Failures | Your whole panel can shut down or malfunction. |

| Shortened Service Life | The transformer wears out faster than expected. |

Always add up the steady-state and inrush loads, then include a safety margin. If you skip this step, you risk downtime and expensive repairs.

Ignoring Installation Factors

You can have the best transformer, but poor installation will ruin its performance. Many people skip pre-install checks or place the transformer where airflow gets blocked. Improper grounding and bonding create safety hazards. Incorrect load calculations cause voltage swings and overheating. If you don’t follow installation protocols, sensitive equipment can get damaged.

Here’s a quick list of common installation mistakes:

- Skipping pre-install checks

- Incorrect sizing

- Improper grounding and bonding

- Wrong overcurrent and tap protection

- Bad placement that blocks ventilation or ignores enclosure ratings

Tip: Always check your installation site for ventilation, grounding, and proper mounting. Good installation keeps your transformer safe and efficient.

Overlooking Isolation and Standards

You need to protect your control circuits from electrical noise and surges. If you overlook isolation, your sensitive devices can fail. Ignoring standards like UL or CE means you risk compliance issues and unsafe operation. Transformers with proper isolation and certifications keep your panel running smoothly and protect your investment.

Don’t cut corners on isolation or safety standards. Choose certified transformers and follow all guidelines for installation and operation. Your panel—and your peace of mind—depend on it.

Linkwell Control Transformer Features

Quality and Reliability

You want your control panel to run smoothly every day. Linkwell’s transformers give you that peace of mind. These transformers go through strict quality checks. The defect rate stays at one thousandth, which is much lower than the international standard. You get products that meet UL, CE, CCC, and ROHS certifications. That means your panel stays safe and reliable.

| Quality Assurance Aspect | Details |

|---|---|

| Defect Rate | Maintained at one thousandth, significantly below the international standard of 3000ths. |

| Certifications | Holds multiple international certifications including UL, CE, CCC, ROHS, etc. |

You can trust Linkwell to deliver consistent performance. Your equipment stays protected from voltage drops and surges.

Energy Efficiency and Safety

You save money when your transformer uses less energy. Linkwell designs transformers to cut down on wasted power. You get lower electricity bills and less heat in your cabinet. Safety matters, too. These transformers use strong insulation and smart cooling methods. You avoid overheating and keep your panel safe from electrical faults. Every transformer meets strict safety standards, so you never have to worry about compliance.

Tip: Energy-efficient transformers help your panel last longer and reduce maintenance costs.

Customization and Support

Every panel is different. Linkwell lets you customize your transformer to fit your needs. You can choose custom busbar configurations, terminal layouts, and labeling options. This makes installation easier and keeps your panel organized.

- Custom busbar configurations

- Terminal layouts

- Labeling options

You also get fast and expert support. Linkwell responds to your questions within two hours. You get help from skilled engineers who know control transformers inside and out.

| Company Name | Review Score | Avg. Response Time |

|---|---|---|

| Linkwell Electric (Shanghai) Co., Ltd. | 5.0/5.0 | ≤2h |

You get a partner who cares about your project’s success. That’s why panel builders around the world choose Linkwell.

Conclusion

You’ve made it to the end of this guide. Now you know how to pick the right control transformer for your industrial panel. Let’s recap the main steps you need to follow:

- Calculate the total load and inrush VA for your control devices.

- Match the input and output voltage to your panel’s requirements.

- Check the environment and installation conditions.

- Make sure your transformer meets all compliance and certification standards.

- Choose a trusted supplier like Linkwell for quality, customization, and support.

If you skip any of these steps, you risk downtime, equipment failures, or safety hazards. You want your panel to run smoothly and last for years. Careful transformer selection gives you peace of mind and keeps your automation reliable.

Tip: Don’t settle for “good enough.” Invest in a transformer that fits your real needs. You’ll save money on maintenance and avoid costly surprises.

Linkwell stands out as a partner who understands industrial panels. You get certified products, fast delivery, and expert advice. If you have questions or need a custom solution, Linkwell’s team is ready to help. You can reach out anytime for support.

| Benefit of Choosing Linkwell | What You Get |

|---|---|

| Certified Quality | UL, CE, ISO9001 transformers |

| Customization | Tailored solutions for your panel |

| Fast Response | Answers within two hours |

| Reliable Delivery | On-time shipping for your project |

Ready to build a robust control panel? Contact Linkwell today. You’ll see the difference that quality transformers make. Your automation deserves the best.

You want your control panel to run smoothly and safely. Here’s a quick checklist for picking the right control transformer:

- Assess your system’s voltage and power needs.

- Check industry standards for compliance.

- Evaluate your installation environment.

- Make sure voltage stays steady during peak loads.

- Plan for future upgrades.

- Choose energy-efficient models.

Careful selection gives you stable voltage, protects your equipment, and lowers energy bills. When you choose Linkwell, you get expert support and reliable products. Invest in quality transformers—your automation deserves the best!

FAQ

How do you figure out the right VA rating for your transformer?

You add up the VA ratings of all devices running at the same time. Then, include inrush VA for starters or relays. Add a safety margin. This keeps your transformer cool and reliable.

Can you customize a control transformer for your panel?

Yes, you can! Linkwell offers custom voltage, power ratings, mounting styles, and enclosures. You get a transformer that fits your exact needs. Just ask for help.

What certifications should you look for?

Always check for UL, CE, and ISO9001 certifications. These marks show your transformer meets safety and quality standards. You stay compliant and protect your equipment.

How long does a control transformer last?

Most control transformers last 10–15 years. If you install it right and check it regularly, you can stretch its life even longer. You save money on replacements.

Where can you use Linkwell control transformers?

| Application | Benefit |

|---|---|

| Control Cabinets | Stable voltage, safe circuits |

| Telecom Systems | Reliable operation |

| Automation Panels | Smooth performance |