Dry type transformer insulation is critical for their safe and efficient operation, directly impacting their lifespan and reliability. A key aspect of this insulation is its temperature class, which dictates the maximum permissible operating temperature. Understanding these classes is fundamental to proper transformer selection and application.

This blog post will delve into the various temperature classes for dry type transformer insulation. We’ll explore what each class signifies, its implications for performance and longevity, and how choosing the correct temperature class can prevent premature failure and ensure optimal functionality in diverse operating environments.

What is Dry Type Transformer Insulation

Dry type transformer insulation refers to the non-liquid materials used to electrically isolate the windings from each other and from the core, while also facilitating heat dissipation. Unlike oil-filled transformers, which use oil for both insulation and cooling, dry type transformers rely on solid materials like epoxy resin, varnish-impregnated paper, fiberglass, or synthetic materials.

This insulation must withstand high temperatures generated during operation, resist electrical stresses, and provide mechanical strength to maintain winding integrity, ensuring safe and reliable performance without the fire risks associated with flammable liquid coolants.

Dry Type Transformer Insulation Class

Dry type transformer insulation class defines the maximum permissible operating temperature for the insulating materials used within the transformer. This critical classification ensures the transformer operates reliably without premature degradation of its insulation, which could lead to failure.

Insulation Class Definitions

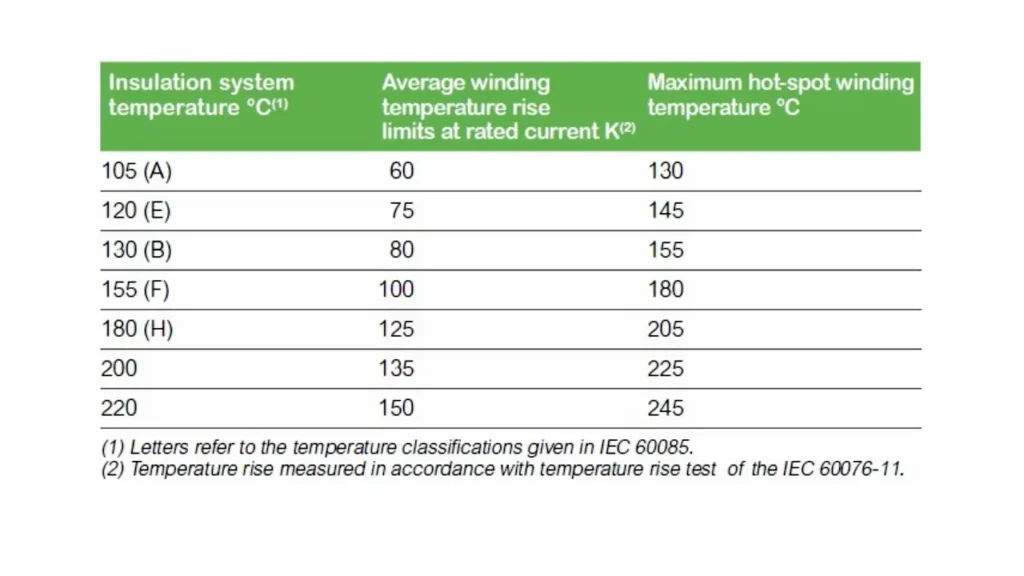

Insulation classes are categorized by a letter (e.g., A, B, F, H, N, R, S) or a numerical temperature rating, indicating the maximum allowable hottest-spot temperature of the insulation system. For instance, Class A is rated for 105°C, Class B for 130°C, Class F for 155°C, and Class H for 180°C.

These dry type transformer temperatures are cumulative, comprising the ambient temperature, the average winding temperature rise due to load, and a “hottest-spot” allowance. Adhering to these limits is vital because exceeding them accelerates the chemical degradation of insulating materials, dramatically shortening the transformer’s lifespan.

Impact on Transformer Life and Performance

The insulation class has a direct and significant impact on the expected life and performance of a dry-type transformer. Operating a transformer consistently above its rated insulation temperature class will lead to a drastic reduction in its service life, often following an “Arrhenius Law” relationship where every 10°C increase in temperature can halve the insulation life.

Conversely, a higher insulation class allows the transformer to operate safely at higher temperatures, potentially under heavier loads or in warmer ambient conditions, without compromising its longevity. This allows for greater flexibility in design and application, as well as providing a margin of safety against unexpected thermal stresses.

Here is a table summarizing common Dry Type Transformer Insulation Classes:

| Insulation Class | Maximum Hottest-Spot Temperature (°C) | Common Insulation Materials | Typical Application Considerations |

|---|---|---|---|

| Class A | 105 | Cotton, Paper, Silk, Wood | Rarely used in modern power transformers due to low thermal limit. |

| Class B | 130 | Mica, Fiberglass, Asbestos, etc., with suitable bonding substances | Good for general purpose dry-type transformers in controlled environments. |

| Class F | 155 | Materials in Class B, plus materials like synthetic enamels | Commonly used in many dry-type transformers, offering a balance of cost and thermal capability. |

| Class H | 180 | Silicone elastomers, Mica, Fiberglass with high-temperature bonding substances | Ideal for higher temperature environments, or when higher overload capacity is desired. |

| Class N | 200 | Inorganic materials like ceramic, mica, quartz, and asbestos with silicon binders | Used in specialized high-temperature applications. |

| Class R | 220 | Very high-temperature resistant materials, often proprietary | For extreme temperature applications, common in some railway transformers. |

| Class S | 250 | Specialized inorganic materials and binders | For very specialized, extremely high-temperature applications. |

Dry Type Transformer Insulation Materials

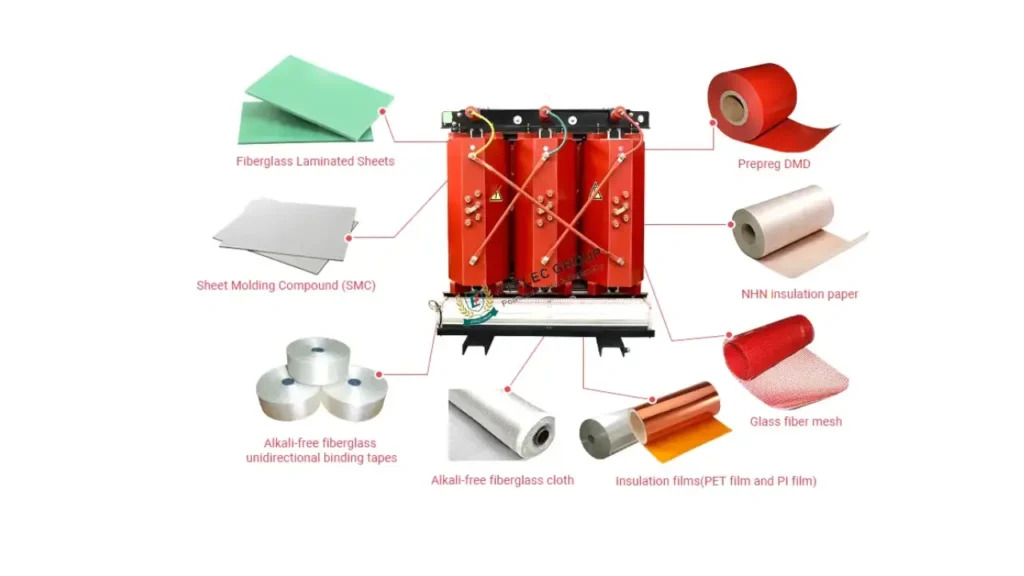

Dry type transformer insulation materials are critical components that determine the transformer’s thermal endurance, dielectric strength, and overall reliability. These materials are carefully chosen to withstand the operational stresses without degrading. The provided image illustrates several key materials used in their construction.

High-Temperature Resins and Composites

- Fiberglass Laminated Sheets: Typically consist of fiberglass fabric impregnated with epoxy or polyester resins, offering excellent mechanical strength, rigidity, and high-temperature resistance.

- Sheet Molding Compound (SMC): A ready-to-mold fiberglass reinforced thermoset material, often used for structural components or enclosures due to its robust mechanical properties and electrical insulation. These materials are crucial for forming the core insulation structures and providing robust protection for the transformer windings, resisting both electrical stress and environmental factors.

Impregnated Papers and Films

- Prepreg DMD (Dacron-Mylar-Dacron pre-impregnated with resin): Offers a flexible yet strong insulation with good dielectric properties and thermal stability, typically used for coil insulation.

- NHN insulation paper (Nomex-Kapton-Nomex): Provides exceptional thermal endurance (often Class H or higher), mechanical toughness, and dielectric strength, making it ideal for demanding high-temperature applications. These materials are vital for providing reliable electrical separation and thermal management within the compact winding structure.

Fiberglass and Other Reinforcements

- Alkali-free fiberglass unidirectional binding tapes: Used to tightly secure windings, providing mechanical stability and preventing movement during short circuits.

- Alkali-free fiberglass cloth: Often impregnated with resins to form rigid insulation barriers or to enhance the mechanical integrity of coils.

- Glass fiber mesh: Used in various forms for reinforcement and thermal stability. Their excellent thermal resistance, non-conductivity, and high tensile strength make them indispensable in dry-type transformers, ensuring the structural integrity and thermal performance of the insulation system.

Insulation Films

PI film (Polyimide) film: Renowned for its exceptional thermal stability (often Class H or higher), superior dielectric strength, and chemical resistance, making it suitable for high-performance and high-temperature winding insulation in more demanding dry-type transformer designs. These films are critical for providing thin, yet highly effective, electrical barriers within the transformer windings.

PET film (Polyethylene terephthalate) film: Offers good dielectric strength, mechanical strength, and moisture resistance, typically used for general-purpose insulation in lower temperature applications (e.g., Class B).

Dry Type Transformer Insulation Resistance Testing

Dry type transformer testing, specifically insulation resistance testing, is a vital diagnostic procedure to assess the condition of the transformer’s insulation system. This test measures the resistance of the insulation to a DC voltage, providing insights into its integrity and identifying potential degradation due to moisture, contamination, or aging.

A high insulation resistance reading indicates healthy insulation, while a low reading can signal a problem that requires further investigation or maintenance.

The procedure typically involves applying a DC voltage (e.g., 500V, 1000V, or 2500V, depending on the transformer’s voltage class) between the windings and ground, and between windings. The resistance is then measured after a specific period, often 1 minute or 10 minutes (for the Polarization Index test). Key aspects of this dry type transformer testing include:

- Safety Precautions: Always de-energize and ground the transformer before testing.

- Temperature Correction: Insulation resistance varies with temperature, so readings should be corrected to a standard reference temperature (e.g., 20°C or 40°C) for accurate comparison over time.

- Acceptable Values: Minimum acceptable insulation resistance values are usually specified by standards (e.g., NETA, IEEE) or the manufacturer, often based on the transformer’s voltage rating.

- Polarization Index (PI) Test: This involves taking resistance readings at 1 minute and 10 minutes. The ratio (10-minute reading / 1-minute reading) provides a more reliable indicator of insulation dryness and cleanliness than a single reading, helping to differentiate between surface moisture and internal degradation.

- Trend Analysis: Tracking insulation resistance values over time provides the most valuable diagnostic information, revealing trends that indicate a gradual deterioration even if individual readings seem acceptable.

Air Insulated Dry Type Transformer

An air-insulated dry-type transformer is a type of transformer that relies primarily on the surrounding air as its primary insulating and cooling medium, rather than liquid coolants like oil. These transformers feature exposed windings or windings encapsulated in solid insulation materials like epoxy resin or varnish, with air circulating through vents to dissipate the heat generated during operation.

The absence of flammable liquids makes them inherently safer and more environmentally friendly, particularly for indoor installations where fire safety is a critical concern.

These dry type transformers are generally classified by their cooling methods:

- Natural Air Cooled (AN): In this method, heat is dissipated through natural convection of air around the transformer coils and core. Air flows through vents at the bottom of the enclosure, rises as it heats up, and exits through top vents, creating a natural cooling cycle. This method is typically used for smaller KVA ratings or where continuous heavy loads are not expected, as it relies solely on passive airflow.

- Forced Air Cooled (AF): For higher KVA ratings or applications requiring greater cooling capacity, fans are used to force air through the transformer’s windings and cooling ducts. This significantly enhances heat dissipation, allowing the transformer to handle larger loads or operate more efficiently. AF cooling systems often include temperature sensors that activate the fans when the transformer reaches a certain temperature, providing active thermal management.

Conclusion

Temperature classes are fundamental to dry-type transformer insulation, directly dictating their operational limits and lifespan. Understanding these classes ensures you select a transformer that can reliably perform under your specific environmental and load conditions, preventing premature failure and costly downtime.

Choosing the correct insulation class is not just about meeting minimum requirements; it’s about optimizing performance and extending the transformer’s service life. Proper selection safeguards your investment, guarantees system reliability, and contributes significantly to overall electrical safety within your facility.

For a comprehensive range of dry-type transformers with various insulation temperature classes, tailored to your industrial and commercial needs, remember to get wholesale dry type transformers from Linkwell Electrics.