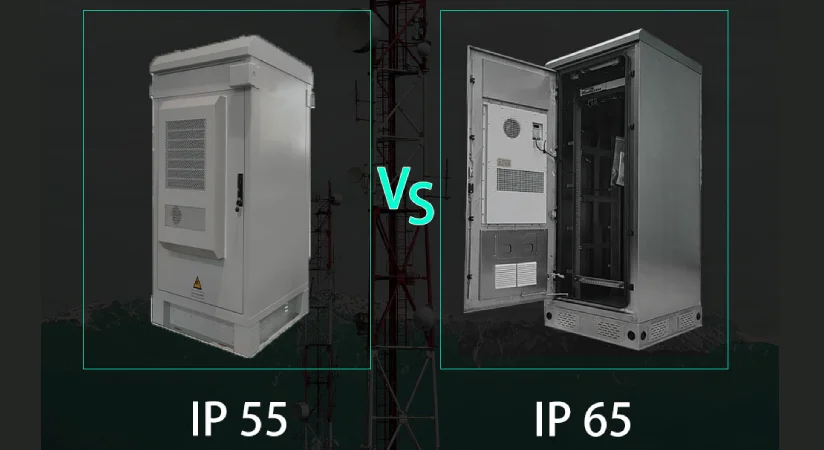

When you look at IP55 vs IP65, you might wonder how much difference a single number makes for your electrical cabinets or control panels. Choosing the right IP rating keeps your equipment safe from dust and water, which means fewer breakdowns and repairs.

The right protection saves you money over time, helps your gear last longer, and keeps your workplace safer. You want to match the rating to your real environment so you don’t overspend or risk equipment failure.

Ip55 vs Ip65 Key Takeaways

- IP55 offers good protection against moderate dust and water jets, making it ideal for mild industrial environments and outdoor areas with light rain.

- IP65 provides complete dust-tight sealing and stronger resistance to water jets, perfect for harsh, dusty, or wet conditions requiring reliable, long-lasting protection.

- Choosing the right IP rating helps prevent equipment damage, reduces maintenance needs, and saves money by matching protection to your environment.

- IP55 enclosures cost less but need more frequent cleaning and checks, while IP65 enclosures cost more upfront but require less upkeep and last longer.

- Assess your environment’s dust and water risks carefully; select IP55 for moderate conditions and IP65 for demanding settings to ensure safety and durability.

Ingress Protection and IP Ratings

What Is Ingress Protection?

When you work with electrical cabinets or control panels, you want to keep dust and water out. That’s where ingress protection comes in. Ingress protection means how well an enclosure stops solid particles and liquids from getting inside and damaging your equipment. You’ll see this term a lot when you shop for industrial gear, especially if you need your systems to run safely in tough environments.

Manufacturers use special seals, gaskets, and engineering tricks to boost protection. The better the ingress protection, the longer your equipment lasts and the less you worry about breakdowns. This is especially important for electrical cabinets in factories, outdoor installations, or places with lots of dust or moisture.

Tip: Always check the ingress protection ratings before you buy or install new equipment. It’s your first line of defense against costly repairs.

IP Rating Structure

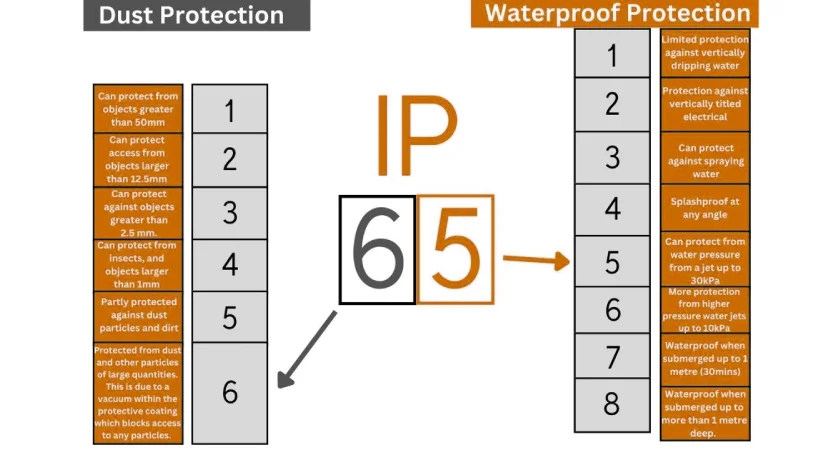

You’ve probably seen codes like IP55 or IP65 on product labels. These ip ratings tell you exactly how much protection your cabinet or enclosure offers. The ip code always starts with “IP” and then two digits. Each digit has a specific meaning:

| Digit Position | Represents | Range | Description |

|---|---|---|---|

| First digit | Protection against solid objects | 0-6 | 0 = no protection, 6 = dust tight |

| Second digit | Protection against water | 0-8 | 0 = no protection, 8 = continuous immersion |

For example, if you see IP55, the first “5” means your cabinet is protected against most dust (but not totally dust tight). The second “5” means it can handle water jets from any direction. If you see IP65, the “6” means total dust protection, and the “5” still means water jets. These ratings help you compare products and pick the right level of protection for your needs.

You don’t have to guess what each rating means. The ip system is standardized, so you always know what kind of ingress protection you’re getting. This makes it easier to choose the right enclosure for your electrical cabinets, especially when you need to meet safety standards or pass inspections.

IP55 Rating Overview

IP55 Dust and Water Resistance

When you see the ip55 rating on an electrical cabinet or control panel, you know it offers solid protection. The first digit, “5,” means the enclosure gives you protection against dust. It blocks most dust from getting inside, so your equipment stays safe in moderately dusty places. You might still get a tiny bit of dust, but nothing that will harm your electronics. This level of protection against dust is great for city streets, light industrial zones, or anywhere you expect some dust but not a sandstorm.

The second digit, “5,” tells you about water resistance. With ip55, your cabinet can handle water jets from any direction. Think about rain, splashes, or cleaning sprays. You do not have to worry about water ruining your gear during a storm or routine wash-down. However, ip55 is not for submersion or high-pressure water. It keeps your equipment safe from the most common water risks in industrial settings.

Note: IP55 enclosures use strong materials like aluminum, carbon steel, or stainless steel. You often see features like locks, hinges, and custom cutouts for extra convenience.

Typical IP55 Applications

You will find ip55 enclosures in many real-world applications. They work well in manufacturing, energy, and telecom industries. These cabinets protect your electrical systems from dust and water, so your operations run smoothly. You might see them outdoors in agriculture, construction, or even marine environments. They are also common in light industrial areas where you need protection but do not face extreme conditions.

- Manufacturing plants use ip55 cabinets to keep control panels safe from dust and water sprays.

- Telecom companies rely on ip55 enclosures for outdoor equipment in cities or near roads.

- Energy and utility companies choose ip55 for electrical cabinets exposed to weather but not heavy flooding.

If you need a balance between cost and protection, ip55 is a smart choice for many industrial applications.

IP65 Rating Overview

IP65 Dust and Water Resistance

When you see the ip65 rating on an electrical cabinet or control panel, you know you’re getting top-tier protection. According to the IEC 60529 standard, an enclosure with this rating must be completely dust-tight. No dust can get inside, even in the harshest industrial settings. This means your sensitive electronics stay clean and safe, no matter how dusty the environment gets.

The second digit in ip65 stands for protection against water jets. Your cabinet can handle water sprayed from any direction, thanks to strict testing with nozzles at different angles. You don’t have to worry about rain, hose-downs, or cleaning sprays damaging your equipment. This level of protection keeps your systems running smoothly, even when you face tough weather or regular washdowns.

Tip: If you work in a place with lots of dust or frequent cleaning, ip65 enclosures give you peace of mind and help you avoid costly repairs.

Here’s a quick comparison to help you see the difference:

| Feature | IP65 Rating | Lower Ratings (e.g., IP44, IP54) |

|---|---|---|

| Dust Protection | Complete dust-tight protection (6) | Partial dust protection; some dust ingress allowed (4 or 5) |

| Water Resistance | Resistant to low-pressure water jets (5) | Protection against water splashes only (4) |

| Suitability in Industry | Suitable for harsh environments with high dust and moderate water exposure | Suitable for mild indoor or less demanding environments |

Typical IP65 Applications

You’ll find ip65 enclosures in some of the toughest industrial environments. These cabinets protect control panels and electrical gear in places where dust, dirt, and water are constant threats. You might use them in food processing plants, outdoor telecom stations, or factories with heavy machinery. They’re also common in energy, transportation, and infrastructure projects.

- Outdoor electrical cabinets that face rain and dust every day

- Control panels in car washes or food factories that need regular cleaning

- Telecom enclosures on rooftops or remote sites exposed to the elements

If you need reliable protection for your equipment, ip65 is a smart choice. It keeps your systems safe, reduces downtime, and helps you meet strict industry standards. You can trust ip65 enclosures to deliver the performance you need in demanding applications.

IP55 vs IP65: Key Differences

Dust Protection Comparison

When you compare ip55 vs ip65 for your electrical cabinets, dust protection stands out as one of the key differences between ip55 and ip65. Both ratings offer some level of defense, but the details matter a lot for your equipment’s safety.

Here’s a quick table to help you see how each rating handles dust:

| Aspect | IP55 Dust Protection | IP65 Dust Protection |

|---|---|---|

| Dust Ingress Level | Limited dust ingress allowed; some dust may enter but not enough to interfere with operation | Completely dust-tight; no dust ingress allowed |

| Protection Code Meaning | ‘5’ indicates partial protection against dust ingress | ‘6’ indicates total dust-tight protection |

| Impact on Equipment | Dust may enter but will not disrupt equipment function | No dust penetration, ensuring full protection |

| Application Consideration | Suitable for environments with moderate dust levels | Suitable for environments requiring full dust protection |

With ip55, your cabinet can handle moderate dust. Some dust might get inside, but it won’t mess up your controls or wiring. If you work in a place with lots of dust, like a factory floor or a construction site, ip65 gives you complete protection against dust. No particles get in, so your sensitive electronics stay clean and safe. This difference can make a big impact on how long your equipment lasts and how often you need to clean or repair it.

Tip: If you want total protection against dust, ip65 is the way to go. For less dusty areas, ip55 usually does the job.

Water Resistance Comparison

Water can be a big problem for electrical cabinets. When you look at ip55 vs ip65, you’ll notice both ratings protect against water jets, but ip65 takes it a step further.

- IP55 Strengths:

- Gives you solid protection against dust, though not fully dust-tight.

- Handles water jets from a 6.3mm nozzle from any direction.

- IP55 Shortcomings:

- Not built for submersion or high-pressure water jets.

- IP65 Strengths:

- Offers complete dust protection.

- Stands up to low-pressure water jets from a 12.5mm nozzle, making it great for outdoor use.

- IP65 Shortcomings:

- Costs more because of the extra features.

- Might be more than you need for basic environments.

| Feature | IP55 Enclosure | IP65 Enclosure |

|---|---|---|

| Water Resistance Level | Protects against water jets from a 6.3mm nozzle from any direction; not waterproof or suitable for submersion or high-pressure jets | |

| Protects against low-pressure water jets from a 12.5mm nozzle from any direction; suitable for harsher outdoor environments | ||

| Dust Protection | Partial dust protection, not fully dust-tight | Fully dust-tight, providing comprehensive dust protection |

| Suitable Industrial Scenarios | Indoor or sheltered outdoor areas with moderate water exposure (e.g., light rain) | Outdoor, harsh environments such as construction sites, marine applications, and areas with regular hosing or intense moisture |

| Durability and Maintenance | Moderate sealing, may require more frequent maintenance in demanding conditions | Robust sealing, better durability, less frequent maintenance |

| Practical Implication | Suitable for moderate water exposure environments where occasional water jets occur | Suitable for environments with intense moisture exposure and where equipment needs to withstand stronger water jets |

In real-world use, ip55 works well for indoor or sheltered outdoor areas where you might get some rain or cleaning sprays. If your cabinets face heavy rain, frequent washdowns, or harsh weather, ip65 gives you the extra protection you need. The stronger sealing on ip65 means you can trust it in places like marine docks, outdoor telecom stations, or construction sites.

Durability and Maintenance

Durability and maintenance are big concerns when you choose between ip55 and ip65 for your electrical cabinets. The level of ingress protection affects how often you need to check, clean, or repair your enclosures.

| Aspect | IP55 Rating | IP65 Rating |

|---|---|---|

| Dust Protection | Limited dust ingress; dust may accumulate but usually does not affect function | Fully dust tight; no dust ingress, ideal for dusty environments |

| Water Protection | Protection against moderate water jets; cannot tolerate heavy rain or high-pressure jets | Protection against high-pressure water jets; suitable for harsh cleaning and heavy rain exposure |

| Durability | Suitable for less demanding, indoor or sheltered environments; materials less resistant to harsh conditions | More durable materials and sealing; withstands harsh outdoor, industrial, and construction environments |

| Maintenance Needs | Requires regular inspection and careful cleaning to prevent dust buildup and water intrusion | Requires less frequent maintenance; enhanced sealing prevents dust accumulation and allows cleaning with high-pressure water |

| Installation | Requires careful installation to avoid exposure to extreme dust or water jets | Easier installation in harsher environments due to better sealing |

| Longevity | Shorter lifespan in harsh conditions; prone to degradation with dust and water exposure | Longer lifespan; reliable under harsh weather and physical impacts |

| Cost | More budget-friendly, suitable for mild environments | Higher cost but cost-effective for demanding environments due to durability |

| Typical Use Cases | Indoor lighting, office equipment, sheltered outdoor areas with low dust/water exposure | Outdoor security cameras, industrial machinery, construction and agricultural equipment |

If you pick ip55, you’ll need to check your cabinets more often, especially if you work in a place with lots of dust or water. You might have to clean out dust or check for leaks after storms. With ip65, you get tougher materials and better sealing. This means less maintenance, longer life, and fewer worries about breakdowns. You can even clean ip65 cabinets with stronger water jets, which saves you time and effort.

Note: Choosing the right ingress protection rating helps you balance cost, durability, and maintenance. Think about your environment and how much protection your equipment really needs.

Use Cases in Industrial Applications

Choosing IP55 for General Use

You often see ip55 enclosures in places where dust and water are present but not extreme. If you work in a factory, workshop, or even outdoors with light rain, ip55 protection keeps your electrical cabinets and control panels safe. Here are some of the best applications for ip55:

- Industrial control panels in workshops and factories

- HVAC units exposed to light spray and dust

- Outdoor motors that face occasional water jets

- Solar battery storage in mild climates

- Public electrical installations where dust and water jets happen but not every day

ip55 stops most dust from getting inside and shields your equipment from low-pressure water jets. You do not need to worry about dust buildup or water splashes ruining your electronics. This rating works well in automotive manufacturing, electronics, and food and beverage industries where you clean equipment but do not use high-pressure washdowns. If you want reliable protection without overpaying, ip55 is a smart choice.

Selecting IP65 for Harsh Environments

When your environment gets tough, you need stronger protection. ip65 enclosures give you complete dust-tight sealing and stand up to water jets from any direction. You should pick ip65 for outdoor panels, factory floors with lots of dust, or places that need regular cleaning. Here are some of the best applications for ip65:

- Outdoor electrical cabinets exposed to rain and dust

- Control panels in food processing plants needing frequent washdowns

- Security cameras and telecom gear in harsh weather

- Warehouses and pharmaceutical plants with strict hygiene rules

- Marine and agricultural sites with dirt, debris, and water jets

ip65 keeps your sensitive electronics safe from dust, dirt, and water. You can trust this rating in challenging conditions, especially when you need to meet strict safety or hygiene standards. If you want peace of mind in harsh environments, ip65 is the way to go.

Linkwell Outdoor Enclosure Solutions

You want enclosures that meet your needs and last a long time. Linkwell offers outdoor enclosures that cover both ip55 and ip65 requirements. These enclosures protect your electrical cabinets and control panels in all kinds of settings. Linkwell products carry certifications like UL, CE, and CSA, so you know they meet global safety and quality standards. They also comply with IEC 60529 and NEMA 250, which define ip55 and ip65 ratings.

| Certification | What It Means for You |

|---|---|

| UL, CE, CSA | Safety and quality assurance for ip55 and ip65 enclosures |

| IEC 60529 | Verified dust and water protection |

| NEMA 250 | Extra protection against corrosion and harsh weather |

Linkwell enclosures come with real-world testing. You can customize size, material, and accessories to fit your project. Whether you need ip55 for general use or ip65 for harsh environments, Linkwell has a solution that keeps your equipment safe and your operations running smoothly.

Cost and Maintenance Considerations

Price Differences

When you shop for electrical cabinets or control panels, price always matters. You want to get the best value for your money. IP55 enclosures usually cost less than IP65 enclosures. Many engineers pick IP55 because it gives dependable protection at a lower price. If your environment is not too harsh, IP55 often makes sense for your budget.

IP65 enclosures cost more because they offer stronger dust and water protection. You pay extra for the peace of mind that comes with a dust-tight seal and better water resistance. Sometimes, the price difference between IP55 and IP65 is small, but in large projects, even a small difference can add up. You should think about your long-term needs. If you expect lots of dust or water, the higher cost of IP65 may save you money on repairs and downtime later.

Tip: Choose IP55 for cost-effective solutions in moderate environments. Pick IP65 if you need extra protection and want to avoid future problems.

| Feature | IP55 Enclosure | IP65 Enclosure |

|---|---|---|

| Initial Cost | Lower | Higher |

| Protection Level | Moderate | Superior |

| Best For | Mild environments | Harsh environments |

Maintenance Needs

You want your electrical cabinets to last and work with as little fuss as possible. Maintenance is a big part of that. IP55 enclosures need more regular checks, especially if you have dust or water nearby. You might need to clean out dust or check for leaks after storms or cleaning.

IP65 enclosures make your life easier. The tight seals keep dust and water out, so you spend less time on maintenance. You can even wash them down with a hose, which saves time in busy factories or outdoor sites. Less maintenance means fewer surprises and lower costs over time.

- IP55: Clean and inspect more often, especially in dusty or wet areas.

- IP65: Less frequent cleaning, easier to maintain, better for tough conditions.

Note: Investing in the right IP rating now can save you time and money on maintenance for years to come.

Conclusion (70 words):

Choosing between Ip55 vs Ip65 for your electrical cabinets depends on your environment, budget, and maintenance needs. IP55 gives you reliable, affordable protection for moderate conditions. IP65 costs more but offers top-level defense against dust and water, saving you on repairs and upkeep. Always match the rating to your real-world risks. For expert advice and custom solutions, reach out to Linkwell and protect your operations with confidence.

Meta Description (150 characters):

Ip55 vs Ip65: Compare costs, protection, and maintenance for electrical cabinets. Get expert advice from Linkwell for custom enclosures. Inquire or buy today!

SEO Title (60 characters):

Ip55 vs Ip65: Cost, Protection & Maintenance for Electrical Cabinets

Article Summary (30 words):

Ip55 vs Ip65: Discover the cost, protection, and maintenance differences for electrical cabinets. Contact Linkwell for custom solutions, expert advice, and fast quotes for your project needs.

Industry Standards and Compliance

IEC 60529 and Testing

You want to make sure your electrical cabinets and control panels can handle tough environments. That’s where industry standards come in. IEC 60529 is the main international standard for ingress protection. It tells you how well an enclosure keeps out dust and water. You’ll see this standard used everywhere in industrial settings. It helps you compare different ratings and pick the right one for your needs.

Testing for these ratings happens in special labs. These labs use probes, water jets, and dust chambers to check how well your cabinet stands up to real-world challenges. Accredited labs follow strict rules, so you can trust the results. They test for everything from dripping water to powerful jets and even full immersion. This process gives you confidence that your equipment will last.

Here’s a quick look at how IEC 60529 breaks down the IP code:

| Digit Position | Meaning | Protection Range |

|---|---|---|

| First Digit | Protection against solids (dust) | 0 (no protection) to 6 (dust-tight) |

| Second Digit | Protection against liquids | 0 (no protection) to 9 (high-pressure water jets) |

Tip: Always check for IEC 60529 certification when you choose enclosures for your projects. It means your equipment meets global standards for durability and safety.

Other IP Ratings

You might wonder what other ratings exist besides IP55 and IP65. Industrial environments often need different levels of protection. Some areas need to handle strong water jets, while others face full immersion or even high-pressure cleaning.

Here’s a table to help you see how common IP ratings compare:

| IP Rating | Dust Protection Level | Water Protection Level | Typical Industrial Environment | Example Use Case |

|---|---|---|---|---|

| IP55 | Partial dust ingress (level 5) | Low-pressure water jets (level 5) | Light spray and dust | HVAC units, indoor/outdoor motors |

| IP65 | Fully dust-tight (level 6) | Low-pressure water jets (level 5) | Dust-heavy, outdoor | Conveyor motors, outdoor panels |

| IP66 | Fully dust-tight (level 6) | Powerful water jets (level 6) | Harsh washdown, outdoor | Industrial equipment, exposed machinery |

| IP67 | Fully dust-tight (level 6) | Temporary immersion (level 7) | Areas with water submersion | Submerged motors, temporary flood zones |

| IP68 | Fully dust-tight (level 6) | Continuous immersion (level 8) | Continuous underwater use | Submerged equipment, wet environments |

| IP69K | Fully dust-tight (level 6) | High-pressure, high-temp washdowns | Food processing, sanitation | Equipment needing frequent cleaning |

You can also see the differences in this chart:

You’ll notice that as the numbers go up, the protection gets stronger. IP55 and IP65 are common for electrical cabinets, but higher ratings like IP66, IP67, and IP69K give you even more defense. If you work in food processing or places with lots of water, you might need those higher ratings.

🛡️ Note: Picking the right rating helps you avoid costly repairs and keeps your equipment running longer. Always match the rating to your real environment.

How to Choose the Right IP Rating

Assessing Environmental Risks

Choosing the right ingress protection for your electrical cabinets or control panels starts with understanding your environment. You want to look at the real risks your equipment faces every day. Is your site dusty, wet, or both? Do you expect occasional splashes or regular washdowns? These questions help you decide if ip55 or ip65 fits your needs.

Here’s a quick table to help you compare:

| IP Rating | Dust Protection Level | Water Protection Level | Environmental Risk Factors to Assess |

|---|---|---|---|

| ip55 | Partial dust protection (not dust-tight) | Protection against water jets from any direction, limited water exposure | Moderate dust presence and occasional water exposure (like light sprays) |

| ip65 | Dust-tight (complete dust protection) | Protection against water splashes and low-pressure jets from any direction | Heavy dust and more intense water exposure (like frequent splashes or jets) |

You should always check the intensity and type of dust and water exposure. For example, if your electrical cabinet sits in a woodworking shop with sawdust everywhere, ip65 gives you complete dust protection. If your control panel is outdoors but only faces light rain, ip55 might be enough.

Don’t forget about the quality of the enclosure’s sealing and hardware. Even the best rating won’t help if the gaskets or latches don’t match the standard. Make sure every part of your enclosure, from the door to the hinges, meets the rating you choose.

Tip: The most common mistake is picking an IP rating that doesn’t match your real-world risks. Always match the rating to your actual environment, not just what looks good on paper.

Balancing Cost and Protection

You want to get the most value for your money. That means finding the right balance between cost and protection. Sometimes, you might feel tempted to pick the highest rating, but that can lead to overspending. Other times, you might go for the cheapest option and end up with equipment failures.

Here’s how you can make a smart choice:

- ip55 enclosures work well in mild environments. If your electrical cabinet stays indoors or under a shelter, and only faces light dust or water splashes, ip55 gives you reliable protection at a lower cost.

- ip65 enclosures cost more, but they offer full dust-tight protection and better resistance to water jets. If your control panel sits outside, in a factory with lots of dust, or in a place that gets washed down often, ip65 is worth the investment.

- Investing in ip65 can save you money in the long run. You’ll spend less on repairs and maintenance because your equipment stays safer.

- Always think about where you’ll install your cabinet. Is it indoors or outdoors? Will it face heavy dust or water? The answers help you balance upfront cost with long-term reliability.

You can use this simple decision guide:

- Look at your environment. Is it dusty, wet, or both?

- Check how often your equipment will get cleaned or sprayed with water.

- Decide if you need partial or complete dust protection.

- Think about your budget and how much downtime costs you.

- Pick ip55 for moderate risks and lower cost. Choose ip65 for harsh conditions and peace of mind.

🛡️ Guidance: If you’re not sure, talk to experts who know the ins and outs of ingress protection. They can help you avoid costly mistakes.

Decision Guide: IP55 vs IP65 for Electrical Cabinets

You can use this checklist to help you decide:

- Choose ip55 if:

- Your cabinet is indoors or in a sheltered spot.

- You expect only light dust or occasional water splashes.

- You want a cost-effective solution for general use.

- Maintenance is easy and downtime is not critical.

- Choose ip65 if:

- Your cabinet is outdoors or in a dusty, wet, or harsh environment.

- You need complete dust protection and resistance to water jets.

- You want to reduce maintenance and avoid unexpected failures.

- Your operation can’t afford downtime or equipment damage.

Linkwell’s Support and Customization Services

You don’t have to make this decision alone. Linkwell stands out as a trusted partner for industrial clients around the world. You get more than just a product—you get a team that helps you from start to finish.

- Linkwell offers custom enclosures rated from ip55 to ip65 (and even higher), built from powder-coated steel or stainless steel.

- You can customize the size, internal layout, wiring, and even the brand of components inside your cabinet.

- Every enclosure goes through full load testing, so you know it will perform in your environment.

- Linkwell provides 24/7 support, fast delivery, and real-time order tracking. You get help with design, installation, and ongoing maintenance.

- Pre-assembled units save you time and labor on site.

If you need tailored solutions for your electrical cabinets or control panels, Linkwell delivers. You get peace of mind knowing your equipment is protected, your project runs smoothly, and your investment pays off.

Note: Reach out to Linkwell for expert guidance and custom solutions. You’ll get the right protection for your needs—every time.

Choosing between IP55 vs IP65 for your electrical cabinets comes down to your environment and needs. Here’s a quick comparison:

| Aspect | IP55 | IP65 |

|---|---|---|

| Dust Protection | Partial, some ingress allowed | Complete, dust-tight |

| Water Resistance | Resists low-pressure jets | Superior sealing for harsher jets |

| Cost | More affordable | Higher, but less maintenance needed |

- Matching the right IP rating prevents costly failures, extends equipment life, and boosts safety.

- Not sure what you need? Reach out to Linkwell for expert advice and custom outdoor enclosure solutions.

FAQ

What does IP55 or IP65 mean for my electrical cabinet?

IP55 and IP65 show how well your cabinet keeps out dust and water. IP55 blocks most dust and water jets. IP65 gives you total dust protection and stronger water resistance.

Can I use an IP55 cabinet outdoors?

Yes, you can use an IP55 cabinet outdoors in mild conditions. It handles rain and dust but not heavy storms or high-pressure cleaning. For harsh weather, you should pick IP65.

How do I know which IP rating I need for my control panel?

Check your environment. If you see lots of dust or water, go with IP65. For light dust and occasional splashes, IP55 works well. Think about how often you clean or hose down your cabinet.

Are Linkwell enclosures customizable for different IP ratings?

Absolutely! You can customize Linkwell enclosures for IP55, IP65, or even higher. Choose your size, material, and accessories. Linkwell helps you get the right fit for your project.

Do IP65 cabinets need less maintenance than IP55?

Yes, IP65 cabinets need less cleaning and fewer checks. The tight seals keep out dust and water, so you spend less time on upkeep and avoid surprise repairs.

Conclusion

Choosing between Ip55 vs Ip65 for your electrical cabinet or control panel depends on your site’s dust and water risks. IP55 offers solid, affordable protection for mild conditions. IP65 gives you peace of mind in harsh, dirty, or wet environments. Always match the rating to your real needs. For expert advice, custom designs, and fast quotes, contact Linkwell. Protect your equipment and keep your operations running strong.