If you have ever wondered what is encapsulated transformer, you are not alone. You will find these transformers use a special coating to shield their internal parts. This encapsulation keeps out dust, moisture, and airborne particles. It also boosts insulation and helps lower noise. Linkwell stands out as a trusted name in transformer solutions. When you work in industrial or automation settings, knowing how encapsulation works can help you choose equipment that lasts.

Encapsulated Transformer Key Takeaways

- Encapsulated transformers use a protective coating to keep out dust and moisture, ensuring better insulation and quieter operation.

- These transformers are maintenance-free, saving you time and effort while providing reliable power in tough environments.

- Choosing the right encapsulated transformer involves considering your power needs, installation space, and environmental conditions.

- Linkwell’s encapsulated transformers meet strict safety and quality standards, making them a trusted choice for industrial applications.

- Using epoxy encapsulated transformers reduces fire hazards and environmental risks, providing a safer and cleaner solution for your equipment.

What is Encapsulated Transformer

Definition

You might ask yourself, what is encapsulated transformer? It’s a type of transformer that uses a protective coating or enclosure to shield its internal parts. This special layer keeps out moisture, dust, and other harmful particles. When you use an encapsulated transformer, you get better insulation and less noise. You also enjoy a safer and more reliable power supply for your equipment. If you work in places with tough conditions, like factories or outdoor telecom shelters, you’ll find that encapsulated transformers last longer and need less attention.

Recommended products

Key Features

Let’s break down what makes encapsulated transformers stand out from other types. You’ll notice several important features:

- Dry-Type Insulation: These transformers use solid insulation instead of oil. You get a safer product and help the environment.

- Fire Safety: No flammable liquids inside. You can install them indoors without worrying about fire hazards.

- Environmental Friendliness: You avoid oil leaks and contamination. That’s good for your workspace and the planet.

- Maintenance-Free: You spend less time on upkeep. These transformers run smoothly with little effort.

- Installation Flexibility: You can put them almost anywhere. No need for special containment systems.

- Reduced Cooling Requirements: The insulation keeps things cool. You don’t need extra cooling equipment.

- Wide Range of Applications: You’ll see them in commercial buildings, hospitals, and data centers.

Tip: Encapsulated transformers work well in industrial machinery, manufacturing equipment, and automation systems. You can use them to adjust voltage levels and keep your machines running safely.

Linkwell Product Overview

You may wonder which brands lead the way in encapsulated transformer solutions. Linkwell Electrics stands out as a global supplier in the control transformer sector. You get affordable solutions and top-notch quality. Linkwell’s range of control transformers fits many industrial needs, making them a trusted choice in the market.

Here’s a quick look at one of Linkwell’s main product lines related to encapsulated transformers:

| Product Line | Description |

|---|---|

| Encapsulated Control Transformer | Protects windings against moisture, dust, and vibration. Perfect for outdoor telecom shelters and tough industrial environments. |

When you choose Linkwell, you get products designed for control cabinets, signal cabinets, and other demanding settings. You benefit from their experience and dedication to quality. Linkwell’s transformers help you keep your operations safe, efficient, and reliable.

Encapsulated Dry Type Transformer

Construction

When you look at an encapsulated dry type transformer, you see a design built for tough environments. Manufacturers use several construction methods to make sure these transformers last and perform well. Here’s a quick table to help you understand the main methods:

| Construction Method | Description | Applications |

|---|---|---|

| VPI (Vacuum Pressure Impregnation) | Uses high-temperature insulation and a polyester sealant applied under vacuum pressure. | Great for commercial and industrial spaces, up to 30 MVA. |

| VPE (Vacuum Pressure Encapsulated) | Similar to VPI but uses silicone resin and a thicker coating. | Works well in places with acids, alkalis, or high humidity. |

| Cast Coil | Coils are solidly cast in resin under vacuum for precision. | Perfect for buildings, tunnels, and offshore platforms. |

You’ll also find open wound and sealed designs. In these, the windings get dipped and baked, then sealed in silica and epoxy. This process keeps out dust and moisture, making the transformer reliable even in harsh settings.

Materials and Epoxy Resin

The heart of an encapsulated dry type transformer lies in its materials. You often see epoxy resin used for encapsulation. Why epoxy? It brings excellent electrical insulation, strong moisture resistance, and solid mechanical strength. Other materials like polyester, polyurethane, varnish, and silicone also play a role, but epoxy stands out for its all-around performance.

Here’s a table showing why epoxy resin is so popular:

| Benefit Description | Details |

|---|---|

| Environmental Protection | Withstands harsh conditions and keeps water out |

| Thermal Performance | Moves heat away from the core and windings |

| Reliability | Offers strong insulation and reduces electrical faults |

| Noise Reduction | Makes the transformer run more quietly |

Note: Epoxy resin not only protects the transformer but also helps it last longer and work more quietly.

Applications

You’ll find encapsulated dry type transformers in many places. They power control cabinets, signal cabinets, and telecom racks. Linkwell’s Control Transformer and Step Down Transformer are great examples. These products handle voltage changes and keep your equipment safe in factories, telecom stations, and automation systems.

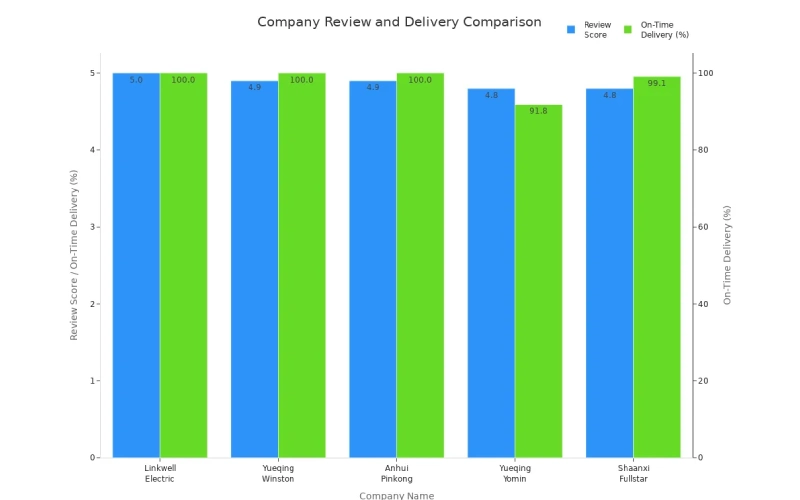

Linkwell’s transformers stand out for their quality and reliability. They meet ISO 9001 and CE certifications, so you know you’re getting a product you can trust. Just look at how Linkwell compares to other brands:

You can count on Linkwell’s encapsulated dry type transformers to deliver stable power and protect your sensitive equipment, even in the toughest environments.

How Encapsulated Transformers Work

Basic Principle

When you use encapsulated transformers, you rely on a simple but powerful principle. These transformers transfer electrical energy between circuits using electromagnetic induction. The core and windings sit inside a sealed enclosure. This design keeps out dust, moisture, and other harmful elements. You get a device that works quietly and safely, even in tough environments. Encapsulated transformers help you step voltage up or down, making sure your equipment gets the right power every time.

Step-by-Step Operation

You might wonder how to set up and operate encapsulated transformers. Here’s a step-by-step guide to help you:

- Measure the output voltage before you energize the transformer. Make sure it matches the nameplate voltages.

- Connect all primary taps for each coil to the same percentage tap positions, especially when windings run in parallel.

- Ground the enclosure with a conductor that fits the size requirements.

- For three-phase encapsulated transformers, check that the load is balanced across all phases.

- Inspect the clearance and tightness of every electrical connection.

- If you use a single-phase 3-wire 240/120 volt load, keep the neutral current below half the transformer’s kVA rating.

Tip: Following these steps helps you get the best performance and safety from your encapsulated transformers.

Impact of Encapsulation

Encapsulation changes the game for transformer performance and lifespan. Take a look at how it helps:

| Advantage | Explanation |

|---|---|

| Improved Durability | Encapsulated transformers have a metal casing that shields them from damage and extends their life. |

| Enhanced Safety | The enclosure blocks out harsh environmental factors, making these transformers ideal for demanding locations. |

| Better Thermal Management | The casing moves heat away from the core, cutting down on overheating and keeping things running smoothly. |

When you choose Linkwell, you get encapsulated transformers that meet strict standards. Check out these certifications:

| Certification Standard | Description |

|---|---|

| UL | Ensures safety and performance standards are met. |

| GB/T 19212.1 | National standard for electrical equipment safety. |

You also benefit from advanced material engineering, military-grade insulation, and flame-retardant epoxy resin casting. These features make Linkwell’s encapsulated transformers reliable for your most critical projects.

Epoxy Encapsulated Transformers Advantages

Environmental Protection

When you choose epoxy encapsulated transformers, you get a big boost in environmental protection. These transformers use a solid epoxy resin that seals every part inside. You don’t have to worry about oil leaks or messy spills. The resin keeps moisture, dust, and dirt out. You also cut down on fire hazards because there’s no flammable oil inside. Maintenance becomes easier, so you spend less time and money keeping things running.

Here’s a quick look at how epoxy encapsulated transformers compare to non-encapsulated types:

| Benefit | Epoxy Encapsulated Transformers | Non-Encapsulated Types |

|---|---|---|

| Oil Leakage Risk | No risk | High risk |

| Fire Hazard | Reduced | Increased |

| Maintenance | Lower | Higher |

Tip: If you work in places with lots of dust or moisture, epoxy encapsulated transformers help keep your equipment safe and clean.

Safety and Reliability

Epoxy encapsulated transformers give you peace of mind. You get strong protection from moisture, dust, and dirt. The resin makes the transformer tough against vibrations and shocks. You also avoid corrosion, which means a longer lifespan. The non-flammable material helps prevent fires. You stay safe because the insulation keeps you away from live electrical parts.

- Protection from environmental factors

- Vibration and shock resistance

- Protection against moisture and corrosion

- Fire safety with non-flammable resin

- Electrical insulation for safer operation

In tough industrial settings, these transformers keep working even when things get hot or dirty. You see them in steel mills and pulp plants, where reliability matters most. The insulation stops short circuits and keeps your system running smoothly.

Linkwell Product Benefits

When you pick Linkwell epoxy encapsulated transformers, you get products that meet strict global standards. Linkwell’s transformers carry UL, CE, and ISO9001 certifications. You know you’re getting quality and safety every time.

| Certification | Description |

|---|---|

| UL | Underwriters Laboratories certification |

| CE | Conformité Européenne certification |

| ISO9001 | International standard for quality management systems |

Linkwell transformers last longer and need less maintenance. You save money over time because they run efficiently and protect your equipment. You also get support from a team that knows how to keep your project on track. If you want reliable performance and peace of mind, Linkwell epoxy encapsulated transformers are a smart choice for your industrial needs.

Encapsulated Transformer Applications and Considerations

Industrial Uses

You see encapsulated transformers in all sorts of places. If you work with control cabinets or signal cabinets, you probably use these every day. Linkwell’s transformers fit right into these setups, making sure your equipment gets safe and steady power. You also find them in telecom racks, factory automation, and even in some distribution transformers for smaller loads. When you look at the different types of transformers, you notice that encapsulated models work best where you need protection from dust, moisture, or vibration. They help keep your machines running, even in tough environments.

Here are some common settings where you might use these transformers:

- Control panels in manufacturing plants

- Signal cabinets for traffic or railway systems

- Telecom base stations

- HVAC systems in commercial buildings

- Smaller distribution transformers for local power needs

Tip: If your workspace has lots of dust or moisture, encapsulated types of transformers give you extra peace of mind.

Selection Criteria

Choosing the right transformer can feel tricky, but you can break it down into simple steps. Here’s an easy checklist to help you pick the best fit:

- Figure out the base load your system needs.

- Think about future growth or expansion.

- Check how much space you have for installation.

- Look at the total cost, including how long the transformer will last.

You should also consider:

- The type of load you plan to power

- The application type (control, signal, or distribution transformers)

- The insulation type (dry or liquid-filled)

- The winding material (copper or aluminum)

- The environment—will it get hot, dusty, or wet?

When you compare the types of transformers, always match the transformer to your specific job. For heavy-duty uses, like welding, you need a transformer that can handle short bursts of high power.

Limitations

Encapsulated transformers work great in many places, but they do have some limits. You usually see them in power ratings below 25 MVA and voltage levels up to 36 kV. If you need something bigger, you might look at other types of transformers. These transformers can cost more at first than oil-filled ones. They also need good air flow to stay cool. For outdoor jobs, you might want to check if the transformer can handle lots of sun, rain, or dust.

Note: Always match the type of transformer to your environment and power needs. This helps you get the best performance and longest life from your equipment.

You now know that encapsulated transformers give you reliable power and strong protection in tough environments. Check out these key benefits:

| Benefit | Description |

|---|---|

| Compact Size and Weight | Fits easily in tight spaces, making installation simple. |

| High Efficiency | Saves energy and keeps things cool. |

| Minimal Electromagnetic Interference (EMI) | Keeps signals clear in sensitive systems. |

| Quiet Operation | Runs silently, perfect for noise-sensitive areas. |

| Improved Thermal Performance | Reduces heat, helping your equipment last longer. |

Linkwell stands out because:

- Their panels are UL certified for safety.

- They meet NFPA and IEC standards.

- Their products work in wind, solar, storage, and robotics industries.

In real factories, like steel mills, encapsulated transformers have cut downtime by 30%. If you want safe, efficient, and reliable power for your projects, you should consider Linkwell’s solutions.

FAQ

What is the main purpose of a transformer in industrial settings?

You use a transformer to change voltage levels for your equipment. This helps you run machines safely and efficiently. In factories, a transformer protects sensitive devices from power surges and keeps everything running smoothly.

How do you choose the right transformer for your control cabinet?

First, check your voltage and power needs. You want a transformer that matches your system’s requirements. Look at the load, space, and environment. If you need help, Linkwell can guide you to the best transformer for your setup.

Can you use a transformer outdoors?

Yes, you can use a transformer outdoors if it has the right enclosure. Make sure your transformer has weatherproof protection. Encapsulated designs work well in harsh environments. Always check the rating before you install a transformer outside.

Why do you need encapsulation for a transformer?

Encapsulation shields your transformer from dust, moisture, and vibration. This extra layer keeps your transformer safe in tough places. You get longer life and less maintenance. Encapsulated transformer models are perfect for control cabinets and signal cabinets.

How often should you maintain your transformer?

You should inspect your transformer regularly. Clean the enclosure and check for signs of wear. Encapsulated transformer types need less maintenance than oil-filled ones. Still, you want to make sure your transformer stays in top shape for reliable performance.