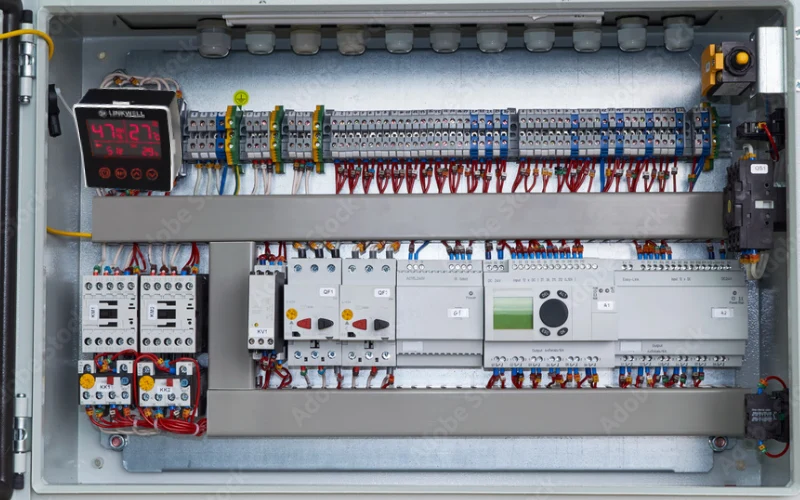

With the popularization of industrial Internet of Things and the participation of AI intelligence, more industries are relying more on control cabinets. Modern electronics are shrinking, and with this downsizing comes a rise in power density. Higher densities mean more heat generated in smaller spaces—pushing passive cooling methods to their limits. This is where active enclosure climate control becomes crucial.

Enclosure Climate Control-Control Panel Ventilation Fan Importance

Among the arsenal of cooling technologies—air conditioners, air-to-air exchangers, and more—filter fans offer a cost-effective, energy-efficient solution for moderate environments. By maintaining a safe operating temperature, these systems extend equipment life and prevent costly breakdowns.

Common Heat Transfer Mechanisms—How Heat is Transferred

Natural Convection Forced Convection

Heat moves from one place to another through three key processes:

- Conduction: Transfer through physical contact—like heat moving through metal walls.

- Convection: Transfer through fluid movement, either:

- Natural convection (buoyancy-driven by heat differences)

- Forced convection (driven by fans or pumps)

- Radiation: Emission of heat as electromagnetic waves, effective even in a vacuum.

Filter fans rely heavily on forced convection, making airflow calculations and pressure management critical for success.

Why Effective Climate Control Is Critical

Electronic components are sensitive to heat. Using the Arrhenius equation, it’s estimated that for every 10 °C (18 °F) increase in temperature above the maximum rating, the lifespan of a component is cut in half.

Even environments with minimal dust and oil can cause overheating if airflow is poorly managed. Therefore, choosing the right cooling method isn’t just smart—it’s essential.

Optimal Conditions for Using Filter Fans–When to Use a Filter Fan

Filter fans shine in clean to mildly dirty environments where ambient temperature is lower than the internal enclosure temperature. They are the simplest and most cost-effective active cooling solution, ideal for applications not requiring tight climate control.

Despite appearing limited at first glance, filter fans are widely used in various applications due to their ease of installation and energy efficiency.

Decision Flow for Selecting Cooling Solutions

Choosing the right cooling strategy isn’t guesswork—it follows a clear decision process:

Step Decision Criteria Condition Recommended Action Notes 1 Compare temperatures Ambient temp < Enclosure temp? Proceed to Step 2 If No, go to Step 5 2 Enclosure rating requirement NEMA 12 (or better) protection required? Proceed to Step 3 If No, use Louvered Grille and/or Roof Vent 3 Environmental cleanliness Is the environment mildly dirty? Use Air-to-Air Heat Exchanger For dusty or slightly oily areas Is the environment clean? Use Filter Fan Cost-effective, efficient solution 5 Check for extreme contamination Is the environment extremely dirty? Proceed to Step 7 If No, continue to Step 6 6 Evaluate ambient temperature Is ambient temp > 130°F (54°C)? Use Air Conditioner High-heat environments 7 Assess cooling infrastructure Is chilled water available? Use Air-to-Water Heat Exchanger Efficient if infrastructure exists If No Use Chiller System External cooling requirement

The presence of chilled water, required NEMA rating, and ambient temperatures all play a role in guiding you toward the right system—whether it’s a filter fan, heat exchanger, or air conditioner.

Determining Required Airflow

Filter fans must provide sufficient airflow to remove excess heat. There are three primary methods for calculating the airflow needed:

Computational Fluid Dynamic (CFD) Analysis

CFD software creates detailed airflow simulations but is costly and complex. It’s more suited to highly customized or critical systems.

Manual Airflow Calculation Method

This method uses known variables and simple formulas:

- Enclosure surface area (A)

- Internal temperature (Ti)

- Ambient temperature (Ta)

- Heat load (Qv)

These inputs feed into a formula like:

Where:

Uis the overall heat transfer coefficient,ΔTmis the temperature difference between inside and outside the enclosure.

This helps calculate:

- Heat loss through the enclosure (Qs)

- Required cooling (Qe = Qv – Qs)

- Volumetric airflow (V̇)

General Sizing Software

Instead of complex math, you can now input the same values into Linkwell Electrics sizing software for faster, more accurate results.

Linkwell Electrics software uses practical assumptions:

U = 5.5 W/m²Kfor steel- Standard air density and heat capacity

- Elevation-adjusted parameters

This saves time and reduces the risk of error—especially for recurring applications.

Key Filter Fan Specifications

Recommended products

Filter fan selection depends on several variables:

| Specification | Description |

|---|---|

| Air Throughput | Measured in cfm or m³/h (use real-world values) |

| Voltage & Frequency | AC or DC, 50 Hz or 60 Hz |

| Power Consumption | Must match system capacity |

| Fan Dimensions | Compatibility with enclosure cutouts |

Air throughput values listed as “unimpeded airflow” may not reflect performance under actual installation conditions.

Performance Characteristics of Filter Fans

Filter fans work best in systems designed with low resistance. A fan’s performance curve shows how airflow decreases with increasing static pressure.

[Illustration Placeholder: Fan Curve Performance Chart showing airflow drop due to resistance]

For example, a fan rated at 25 m³/hr unimpeded might only deliver 18 m³/hr when installed with filters and internal obstructions.

Always refer to performance charts, not just nameplate specs.

Filter Fan Designs and Airflow Patterns

Filter fans come in three design types:

- Axial fans: Efficient and quiet, but struggle with high resistance.

- Centrifugal fans: Handle pressure well but with lower airflow.

- Diagonal (hybrid) fans: Combine benefits of both for better pressure stability and airflow consistency.

Diagonal fans are especially effective for industrial enclosures.

Introduction to EC (Electronically Commutated) Fans

EC fans offer precision and efficiency. Unlike traditional fans, they use brushless DC motors with electronic control circuits, enabling:

- Variable speed based on heat load

- Reduced energy consumption

- Tighter temperature control

They eliminate the waste caused by basic thermostats that operate with hysteresis delays.

Push vs. Pull Installation Techniques

Airflow direction significantly affects cooling performance:

| Push (Blow In) | Pull (Blow Out) |

|---|---|

| Positive pressure (cleaner) | Negative pressure (dust risk) |

| Turbulent flow (better distribution) | Laminar flow (less efficient) |

Blowing air in also ensures all intake air passes through the filter, keeping the enclosure cleaner.

Different Fan Configurations and Effects

Standard Configuration

One fan + one outlet filter = standard setup.

Larger Outlet Filters

Doubling outlet filter size can reduce pressure drop but increases airflow by only about 10–20%.

Fans in Series

One fan pushes, one pulls. Increases flow close to unimpeded value.

Fans in Parallel

Two fans side-by-side, each with its own filter. Nearly doubles airflow, offering best temperature distribution.

Certifications and Compliance

Filter fans help maintain enclosure ratings like:

- UL Type 12 (dust-tight)

- UL Type 3R/4/4X (rain-proof, hose-proof with hoods)

UL certification involves multiple tests and may be “recognized” or “listed”—both valid under UL 508A if installed per manufacturer instructions.

Final Thoughts on Filter Fan Selection

Filter fans are ideal for many applications. They offer:

- Easy setup

- Low acquisition and operational cost

- Compatibility with common enclosure designs

Use Linkwell Electrics sizing software to confirm airflow needs. If filter fans can’t meet requirements, consider air-to-air exchangers or air conditioners.

FAQs

1. When should I use a filter fan instead of an air conditioner?

Use filter fans when the ambient temperature is lower than the enclosure temperature and the environment is not extremely dirty.

2. What factors influence filter fan performance?

Static pressure from filters, internal components(Thermostat Heaters), and fan type all impact airflow.

3. How do EC fans save energy?

They adjust fan speed based on heat load, minimizing unnecessary runtime.

4. Can I reverse the airflow direction of a filter fan?

Yes, modern filter fans can be configured for either intake (push) or exhaust (pull).

5. What happens if I oversize my filter fan?

Oversizing may lead to inefficient energy use and increased wear, especially with thermostats that cause long runtimes.

6. Is software necessary for selecting the right fan?

While not mandatory, Linkwell Electrics software simplifies the process and helps avoid costly miscalculations.

Conclusion

Heat is a primary enemy of electronics. Just a small temperature increase can drastically cut component life. Among active cooling methods, filter fans offer the best combination of simplicity, affordability, and efficiency for many applications.

With the right calculations—and tools like Linkwell Electrics —you can ensure your systems stay cool, reliable, and cost-effective.