You face real decisions every day about cooling solutions. If you work in a facility, you know how tricky it gets when choosing between AC, DC, and EC fans. The difference and introduction of ac fan dc fan ec fan can change how your equipment performs. Here’s a quick look at what you deal with:

| Challenge | Description |

|---|---|

| Fan Sizing | Picking the right size can impact performance and efficiency. |

| Static Pressure | Low pressure can hurt air distribution and comfort. |

| Control System Compatibility | Some fans don’t talk well with your current systems. |

| Noise and Vibration | Bad installation brings extra noise and vibration. |

| Lack of Expertise | Not enough training causes poor setup and maintenance. |

Linkwell gives you reliable Electrical Enclosure Fans and Computer Chassis Fans. You get smart choices and practical results every time. The Difference between AC, DC, and EC fans matters—your equipment and business depend on it.

Key Takeaways

- AC fans are reliable and easy to use, making them ideal for basic cooling needs in commercial settings.

- DC fans offer better energy efficiency and quieter operation, perfect for applications requiring precise cooling like computer cases.

- EC fans combine the benefits of AC and DC technology, providing high efficiency and smart control options for modern facilities.

- Choosing the right fan can significantly reduce energy costs and maintenance, enhancing overall equipment performance.

- Consider your specific needs—AC for simplicity, DC for quiet efficiency, and EC for advanced control and energy savings.

Difference and Introduction of AC Fan DC Fan EC Fan

You probably see fans everywhere in your facility, but not all fans work the same way. Let’s break down the basics so you can spot the difference and make smarter choices.

What Is an AC Fan?

AC fans run on alternating current. You plug them into a standard wall outlet, and they start moving air right away. These fans use induction motors, which means they rely on the flow of ac to spin the blades. AC fans are popular in industrial settings because they are simple and reliable. You get steady airflow, but they tend to use more energy compared to other types. If you need a fan that just works without much fuss, ac fans are a solid pick.

What Is a DC Fan?

DC fans use direct current, like what you find in batteries or power supplies. These fans have brushless motors, which help them run quietly and efficiently. You can control the speed of a DC fan more easily, so you get better performance and less noise. DC fans fit well in places where you want precise cooling, like computer cases or control panels. You save energy and get more flexibility with these fans.

What Are EC Fans?

EC fans combine the best parts of AC and DC technology. They use brushless motors and run on ac power, but they have built-in electronics that let you adjust speed and airflow. EC fans give you high efficiency and low power consumption. You get smart control options, which means you can fine-tune cooling for your exact needs. EC fans work great in modern facilities where energy savings and control matter most.

Here’s a quick table to help you compare:

| Fan Type | Power Supply | Motor Type | Efficiency |

|---|---|---|---|

| AC Fans | Alternating Current (e.g., 230 Vac, 115 Vac) | Asynchronous (Induction) | Higher energy consumption |

| DC Fans | Direct Current (e.g., 12 Vdc, 24 Vdc) | Synchronous (Brushless) | Better performance than AC |

| EC Fans | Alternating Current (e.g., 90 to 266 Vac) | Synchronous (Brushless) | Lower power consumption than AC with similar performance |

Tip: Linkwell designs and manufactures high-quality ac fans, DC fans, and EC fans for industrial and commercial use. You get reliable cooling and smart solutions for every application.

How They Work and Key Features

AC Fan Operation and Features

You see AC fans in many motor applications. These fans use single-phase or three-phase asynchronous motors, powered by alternating current. You plug them in, and they start moving air. AC fans work best when you need steady airflow and simple controls. They usually have a fixed speed, so you don’t get much flexibility. Efficiency ranges from 15% to 50%. If you want a fan that just works, AC fans deliver reliable performance. Linkwell’s Electrical Enclosure Fan uses high-quality AC motors to keep your cabinets cool and safe.

Note: AC fans are great for basic cooling needs, but they use more energy than other types.

| Fan Type | Motor Type | Characteristics |

|---|---|---|

| AC | Single-phase or three-phase asynchronous motors | Driven by alternating current power source |

DC Fan Operation and Features

DC fans run on direct current. You get better performance and quieter operation because these fans use brushless DC motors. You can adjust the speed easily, which helps you save energy and control noise. DC fans fit well in computer cases and control panels where you need precise cooling. Efficiency is about 30% higher than AC fans. Linkwell’s Computer Chassis Fan uses advanced DC technology for silent, efficient cooling in demanding environments.

- DC fans use direct current for power.

- Brushless motors mean less friction and longer life.

- You get variable speed control for better performance.

EC Fans: Technology and Benefits

EC fans, also called electronically commutated fans, combine the best of AC and DC. They use an electronically commutated motor and permanent magnets, plus built-in electronics for smart control. EC fans can run on both AC and DC, converting power as needed. You get up to 75% efficiency, and sometimes even 90%. These fans offer variable speed, low noise, and energy savings up to 70%. Electronically commutated fans work well in modern motor applications like HVAC, data centers, and industrial processes. Linkwell’s enclosure fans and chassis fans use EC technology for better performance and reliability.

| Advancement Type | Description | Benefits for Industrial Users |

|---|---|---|

| Smart Technology Integration | IoT remote monitoring and control | Real-time adjustments, energy savings |

| Advanced Materials | Lighter, durable, noise-reducing materials | Quiet, efficient operation |

| Sustainability Focus | Eco-friendly manufacturing and materials | Meets energy standards |

| Energy Conservation Capabilities | Reduces energy use by up to 70% | Lower operating costs |

Tip: Electronically commutated fans give you precise airflow control, longer life, and better performance for critical cooling needs.

Difference Between AC, DC, and EC Fans

Efficiency and Energy Use

When you compare the difference between ac, dc, and ec fans, efficiency stands out as a key factor. AC fans, powered by alternating current and often using an ac induction motor, tend to use more energy. In many commercial settings, these fans can account for 40-50% of total energy consumption in HVAC systems. DC fans improve on this, offering about 30% more efficiency than AC fans. However, ec fans take energy efficiency to a whole new level. They use advanced brushless motors and built-in electronics to cut energy use by up to 70% compared to traditional AC fans.

Here’s a quick look at how energy consumption stacks up:

| Fan Type | Efficiency | Energy Consumption |

|---|---|---|

| EC Fan | Up to 90% | 70% less than AC Fan |

| AC Fan | Lower efficiency | Higher energy consumption than EC Fan |

You can see that ec fans deliver the best efficiency, which means lower operating costs for your facility. If you use Linkwell’s Electrical Enclosure Fan with EC technology, you get reliable cooling and significant energy savings.

- EC fans are significantly more efficient than AC fans, consuming 70% less energy.

- AC fans can account for a large portion of your facility’s energy bill.

Durability and Maintenance

Durability and maintenance also highlight the difference between ac, dc, and ec fans. AC fans usually last longer than DC fans because they have fewer moving parts and less wear from brushes. DC fans, while efficient, can wear out faster due to brush friction. EC fans, with their brushless design, offer the best of both worlds—high efficiency and a long lifespan. You spend less time and money on maintenance because there are no brushes to replace.

| Fan Type | Efficiency | Lifespan Characteristics |

|---|---|---|

| AC | Standard | Generally longer lifespan compared to DC |

| DC | 30% more efficient than AC | Shorter lifespan due to wear and tear |

| EC | Higher efficiency than both AC and DC | Longer lifespan than AC, offsetting initial costs |

EC fans require less frequent maintenance due to their brushless design, which eliminates the need for brush replacement.

If you choose Linkwell’s Computer Chassis Fan with EC technology, you get a fan that runs longer and needs less attention, even in demanding environments.

Control and Flexibility

Control and flexibility make a big difference between ac, dc, and ec fans. AC fans usually run at a fixed speed. You don’t get much control over airflow or energy use. DC fans let you adjust speed, which helps with noise and efficiency. EC fans go even further. They use electronically commutated motors that adjust speed automatically based on real-time needs. This means you get precise airflow control and optimal cooling performance.

- EC fans provide precise control of airflow, allowing for optimal cooling performance.

- They can be adjusted to run at different speeds, optimizing airflow and energy consumption based on cooling needs.

- This variable speed capability is especially useful in systems that need to adapt to changing requirements, like data centers or smart buildings.

EC fans utilize advanced technology to minimize energy waste and deliver the right amount of cooling exactly when you need it.

If you install a Linkwell Electrical Enclosure Fan with EC technology, you can connect it to smart controls and automate your cooling system for maximum efficiency.

Applications and Use Cases

You’ll find the difference between ac, dc, and ec fans in the places they work best. AC fans are common in HVAC systems for air distribution and temperature control in commercial buildings, schools, and hospitals. DC fans shine in data centers and IT equipment cooling, where quiet operation and precise control matter. EC fans are the top choice for modern, energy-conscious facilities. You’ll see them in agriculture for greenhouse ventilation, in manufacturing for process cooling, and in smart buildings for automated climate control.

| Fan Type | Application Scenario | Sector |

|---|---|---|

| AC Fans | Used in HVAC systems for air distribution and temperature control | Commercial buildings, schools, hospitals |

| DC Fans | Employed in data centers for cooling IT equipment | Data centers |

| EC Fans | Utilized in agriculture for ventilation in greenhouses and livestock barns | Agriculture |

| Industrial Fans | Essential for cooling and air quality management in manufacturing | Manufacturing, plastics, textiles |

| Industrial Exhaust Blowers | Remove smoke and heat in commercial kitchens | Commercial kitchens |

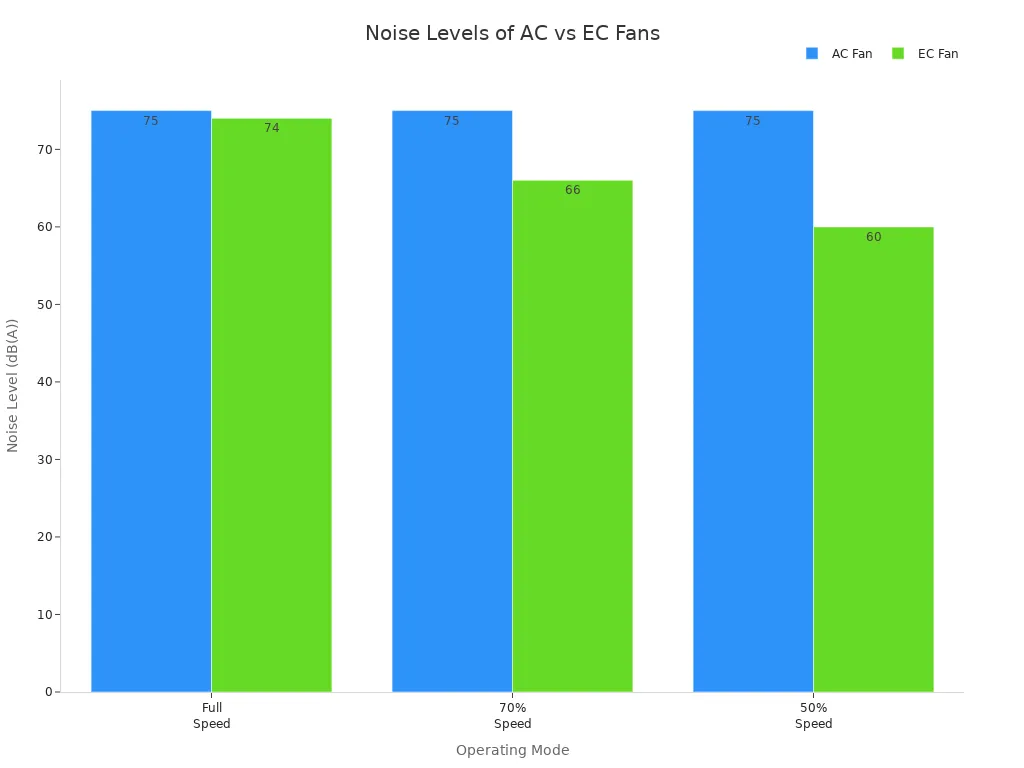

Noise levels also play a role in your decision. DC fans are generally quieter than AC fans because they don’t have brushes that create friction. EC fans can slow down during low demand, which cuts noise even more. Here’s a quick comparison of noise at different speeds:

| Operating Mode | AC Fan Noise (dB(A)) | EC Fan Noise (dB(A)) |

|---|---|---|

| Full Speed | 75 | 74 |

| 70% Speed | 75 (throttled) | 66 |

| 50% Speed | 75 (throttled) | 60 |

If you need quiet, efficient cooling in a sensitive environment, Linkwell’s Computer Chassis Fan with EC technology is a smart pick.

Tip: Always match your fan choice to your application. The right fan improves efficiency, reduces costs, and keeps your equipment running longer.

Choosing the Right Fan for Your Needs

Factors to Consider

You want the best cooling for your facility, but picking the right fans can feel tricky. Start by thinking about how your fans will run. If you need fans for continuous operation, EC motors give you better efficiency than AC motors. For places where fans only run sometimes, AC motors may work just fine. EC motors also let you control speed for variable airflow, which helps you save energy.

Let’s break down what matters most when choosing fans:

- Energy Efficiency: EC fans use less energy than AC fans. DC fans also help you save on power bills.

- Cost: AC fans usually cost less upfront. DC fans and EC fans cost more at first, but you save money over time because they use less energy.

- Noise Levels: DC fans run quieter than AC fans. EC fans can be even quieter, especially when you slow them down.

- Speed Control: AC fans have limited speed options. DC fans and EC fans let you adjust speed for better performance.

- Maintenance: AC fans need less maintenance. DC fans may need more attention. EC fans have a brushless design, so they last longer.

Here’s a quick table to help you compare:

| Factor | AC Fans | DC Fans |

|---|---|---|

| Energy Efficiency | Less efficient than DC fans | More energy-efficient |

| Cost | Generally lower upfront cost | Higher upfront cost |

| Noise Levels | Moderate noise levels | Quieter operation |

| Speed Control | Limited speed control | Offers variable speed settings |

| Maintenance | Minimal maintenance required | May require more maintenance |

Tip: AC fans are affordable and simple. DC fans save energy and run quietly. EC fans give you the best control and efficiency, especially for high-use areas.

Linkwell Solutions for Industrial Cooling

You want fans that fit your exact needs. Linkwell offers a wide range of fans for every industrial sector. You can choose from axial fans, EC axial fans, DC fans, and centrifugal fans. Each fan series has special features for different applications.

| Product Series | Key Features | Applications |

|---|---|---|

| LKA Series Axial Fans | Low noise, energy-efficient, customizable | Places with strict noise limits |

| LKE Series EC Axial Fans | High efficiency, precise speed control, waterproof | Smart control systems, harsh environments |

| LK Series DC Fans | Multiple speed options, fault detection | Automation, communication equipment |

| Centrifugal Fan Series | Large airflow, energy-saving | High-intensity usage |

Need something unique? Linkwell builds custom fans for special requirements. You can get industrial air conditioners with different cooling capacities, explosion-proof air conditioners for hazardous zones, and stainless steel air conditioners for food processing. Linkwell’s team helps you design fans that match your project, so you get reliable cooling and long-term savings.

Note: Linkwell supports you with OEM/ODM services, fast delivery, and expert advice. You get fans that work for your business, no matter the challenge.

Choosing between AC, DC, and EC fans comes down to what you need most—simplicity, efficiency, or smart control. Here’s a quick look:

| Fan Type | Power Reduction | Advantages | Applications |

|---|---|---|---|

| AC | N/A | Reliable, traditional | General cooling |

| DC | Up to 70% | Quiet, energy-saving | Electronics, automotive |

| EC | N/A | Most efficient, eco-friendly | Modern facilities |

Picking the right fan helps you cut energy costs, reduce maintenance, and boost efficiency. EC fans stand out for their energy savings and lower carbon footprint. If you want reliable, efficient cooling, try Linkwell’s Electrical Enclosure Fan or Computer Chassis Fan. Need help? Reach out to Linkwell for expert advice and custom solutions.

FAQ

What’s the main difference between AC, DC, and EC fans?

You’ll notice AC fans use alternating current, DC fans use direct current, and EC fans combine both with smart controls. EC fans give you the best energy savings and control. AC fans work well for simple jobs. DC fans run quietly and efficiently.

How do I know which fan type fits my application?

Think about your needs. If you want basic, reliable airflow, pick an AC fan. For quiet, precise cooling, go with a DC fan. If you need top efficiency and smart control, EC fans are your best bet.

Are EC fans worth the higher upfront cost?

Yes, you save money over time. EC fans use less energy and last longer. You’ll see lower power bills and spend less on maintenance. The investment pays off, especially in facilities that run fans all day.

Can I get custom fans for my project?

Absolutely! Linkwell offers custom solutions. You can request fans with special sizes, airflow, or features. Just reach out to Linkwell’s team for help with your unique requirements.