Understanding dry-type transformer impedance is crucial for designing a safe and efficient electrical distribution system. Far from being just a nameplate value, impedance directly influences how the transformer interacts with the rest of the electrical network, particularly during fault conditions. This characteristic determines the amount of current that can flow through the transformer when a short circuit occurs, making it a cornerstone for proper protection coordination.

Effective system coordination relies heavily on accurate impedance knowledge. It dictates the sizing of protective devices like circuit breakers and fuses, ensuring they trip selectively to isolate faults quickly without unnecessarily shutting down healthy parts of the system. Neglecting this vital parameter can lead to over- or under-protected circuits, compromising both equipment integrity and operational continuity.

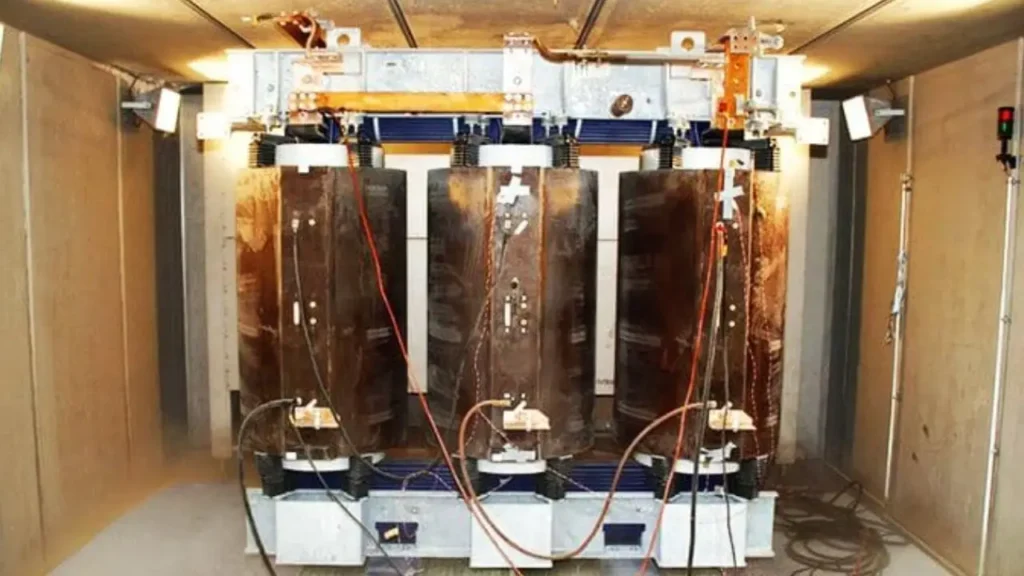

What is Dry Type Transformer Impedance?

Dry-type transformer impedance, typically expressed as a percentage, is a critical electrical characteristic that represents the internal opposition to the flow of alternating current within the transformer. It is essentially the “apparent resistance” of the transformer windings to AC, comprising both the winding’s ohmic resistance and its inductive reactance.

This percentage impedance is derived from a short-circuit test, indicating the percentage of the rated primary voltage required to circulate the full rated current in the secondary winding when the secondary is short-circuited. A lower impedance value generally means a higher short-circuit current capability, while a higher impedance value will limit the short-circuit current but may result in greater voltage drop under load.

What is the Standard for Transformer Impedance?

The impedance of dry-type transformers is governed by various industry standards and typically falls within a specified range, rather than a single fixed value. These standards are established by organizations like the Institute of Electrical and Electronics Engineers (IEEE) in North America, or international bodies like the International Electrotechnical Commission (IEC).

The specific percentage impedance can vary significantly depending on the transformer’s kVA rating, voltage class, and intended application (e.g., distribution vs. power transformer). Manufacturers generally provide the impedance value on the transformer’s nameplate, and standards also specify acceptable tolerances for this value.

Key aspects of impedance standards include:

- IEEE C57.12.01: This is a prominent standard for dry-type distribution and power transformers in North America, outlining general requirements, including impedance tolerances.

- KVA-Dependent Ranges: Standard impedance values are often given as ranges that correspond to different kVA ratings. For instance, smaller distribution transformers (e.g., 15-75 kVA) might have impedance ranges from 1.5% to 10%, while larger power transformers (e.g., 750-2500 kVA) could be around 5.75% to 6%.

- Tolerance: Standards typically allow for a certain percentage tolerance (e.g., ±7.5% for two-winding transformers) from the nominal or guaranteed impedance value.

- Application-Specific Values: While there are typical ranges, specific projects may require custom impedance values to meet unique fault current or voltage regulation requirements.

Why is Dry Type Transformer Impedance Important?

Dry-type transformer impedance is a critical design parameter that significantly impacts the overall performance, safety, and coordination of an electrical distribution system. Its importance stems from its direct influence on two major aspects: fault current limitation and voltage regulation. Without careful consideration of impedance, a system could be vulnerable to excessive fault currents that damage equipment, or experience unacceptable voltage fluctuations that impair the operation of sensitive loads.

The selection of a transformer with an appropriate impedance value is therefore not a trivial matter; it’s a fundamental step in designing a reliable and safe electrical infrastructure.

- Short-Circuit Current Limitation: Impedance is the primary factor limiting the magnitude of short-circuit currents during a fault. A higher impedance value will restrict the fault current to a lower level, which reduces the mechanical and thermal stresses on the transformer windings and other downstream equipment (like switchgear, cables, and circuit breakers). This allows for the use of lower-rated, and thus often more economical, protective devices. Conversely, a transformer with very low impedance will allow very high fault currents, potentially overwhelming protective devices and causing significant damage.

- Voltage Regulation: Transformer impedance also directly affects the voltage regulation, which is the change in secondary voltage from no-load to full-load conditions. A transformer with higher impedance will experience a greater voltage drop under load, leading to poorer voltage regulation. This can be problematic for sensitive electronic equipment that requires a stable voltage supply. Conversely, lower impedance leads to better voltage regulation, meaning the output voltage remains more consistent regardless of the load. Balancing fault current limitation with acceptable voltage regulation is a key challenge in transformer selection.

- System Coordination: Accurate knowledge of impedance is vital for coordinating protective devices (fuses, circuit breakers, relays) within the electrical system. By knowing the maximum fault current that can flow through the transformer, engineers can select and set these devices to trip selectively, ensuring that only the faulted section of the system is isolated, while the rest remains operational. This selective coordination minimizes outages and enhances overall system reliability.

How to Test Dry Type Transformer Impedance?

Testing a dry-type transformer’s impedance is a crucial step to verify its nameplate rating and ensure it meets design specifications for fault current limitation and voltage regulation. This test is typically performed as a short-circuit impedance test.

Step 1: Preparation and Safety Measures

Before commencing any testing, prioritize safety. This involves de-energizing the transformer completely and ensuring it is isolated from all power sources. Lockout/tagout procedures must be strictly followed. Additionally, securely ground the transformer tank and core.

Gather the necessary equipment, which typically includes a variable AC voltage source, ammeters, voltmeters, and a wattmeter (or a power analyzer) with appropriate ranges for the transformer’s ratings. Ensure all test leads are in good condition and correctly rated.

Step 2: Short-Circuit the Secondary Winding

The core of the impedance test involves short-circuiting the secondary winding of the transformer. This is done by securely connecting the terminals of the secondary winding together using low-resistance, high-current-rated conductors.

This short circuit must be robust and capable of safely handling the expected fault currents that will flow during the test. For a three-phase transformer, all three secondary phases must be short-circuited together.

Step 3: Apply Reduced Voltage to the Primary

With the secondary winding short-circuited, a variable, reduced AC voltage is slowly applied to the primary winding. The voltage should be gradually increased from zero until the full-load rated current flows through the primary winding.

During this process, continuously monitor the primary voltage, primary current, and the power consumed by the transformer. It is vital not to exceed the full-load current to prevent overheating or damage to the transformer during the test.

Step 4: Record Readings and Calculate Impedance

Once the full-load current is achieved on the primary side, record the applied primary voltage (Vsc), the primary current (Ifl), and the power consumed (Psc) during the short-circuit test. The percentage impedance () is then calculated using the formula:

, where Vrated is the rated primary voltage.

The short-circuit power factor (PFsc=Psc/(Vsc×Ifl)) and equivalent resistance (Req=Psc/Ifl2) and reactance (Xeq=Zeq2−Req2) can also be derived from these readings, where Zeq=Vsc/Ifl. Compare the calculated percentage impedance to the value stated on the transformer’s nameplate and against relevant industry standards to ensure compliance.

How to Calculate Transformer Impedance?

Calculating dry-type transformer impedance is a critical process, usually performed through a short-circuit test. This calculation allows engineers to predict the transformer’s behavior under fault conditions and ensure proper system coordination. The impedance value is usually expressed as a percentage, indicating the voltage drop across the transformer windings when rated current flows under short-circuit conditions.

Step 1: Conduct a Short-Circuit Test

To calculate the impedance, a short-circuit test must first be performed on the transformer. This involves short-circuiting the secondary winding(s) of the transformer. A variable, reduced AC voltage is then applied to the primary winding. The voltage is slowly increased until the full-load rated current flows in the primary winding. During this process, the primary voltage (Vsc), the primary current (Isc), and the power consumed (Psc) are precisely measured. It’s crucial that this test is conducted safely by qualified personnel, following all lockout/tagout procedures, and ensuring the secondary short circuit can handle the expected current.

Step 2: Calculate Equivalent Impedance in Ohms

From the short-circuit test readings, the equivalent impedance (Zeq) of the transformer, referred to the primary side, can be calculated using Ohm’s Law:

Where:

- Vsc is the voltage applied to the primary during the short-circuit test (in Volts).

- Isc is the full-load current flowing in the primary during the short-circuit test (in Amperes).

Additionally, the equivalent resistance (Req) and equivalent reactance (Xeq) can be calculated from the short-circuit power (Psc) and the equivalent impedance:

Step 3: Calculate Percentage Impedance

The impedance is most commonly expressed as a percentage, as this value is used directly in fault current calculations and system coordination. The percentage impedance () is calculated using the following formula:

Where:

- Vsc is the voltage applied to the primary during the short-circuit test when full-load current flows (in Volts).

- Vrated,primary is the transformer’s rated primary voltage (in Volts).

This percentage represents the percentage of the rated primary voltage required to circulate full-load current through the transformer when the secondary is short-circuited. It’s the most common way to represent transformer impedance on nameplates and in specifications.

Conclusion

Understanding dry-type transformer impedance is crucial for effective system coordination, ensuring that protective devices operate correctly during fault conditions. It directly influences fault current levels, dictating the necessary ratings for circuit breakers and fuses. Proper impedance selection and analysis are fundamental to designing a safe and reliable electrical distribution network, preventing cascading failures and protecting valuable assets.

Ultimately, mastering transformer impedance allows for precise calibration of overcurrent protection, minimizing downtime and enhancing equipment longevity. This technical insight ensures your electrical system responds predictably and safely to abnormal conditions, optimizing overall system performance and reducing the risk of costly damage.

For reliable dry-type transformers with accurately specified impedance values, get wholesale dry type transformers from us. We offer a range of products designed for optimal system coordination and dependable performance, supporting your project’s specific electrical requirements.