An effective Electrical Control Panel Cooling System ensures optimal performance, extends component life, and prevents costly downtime—critical for any manufacturer operating in demanding industrial environments.

What Are Electrical Control Panels

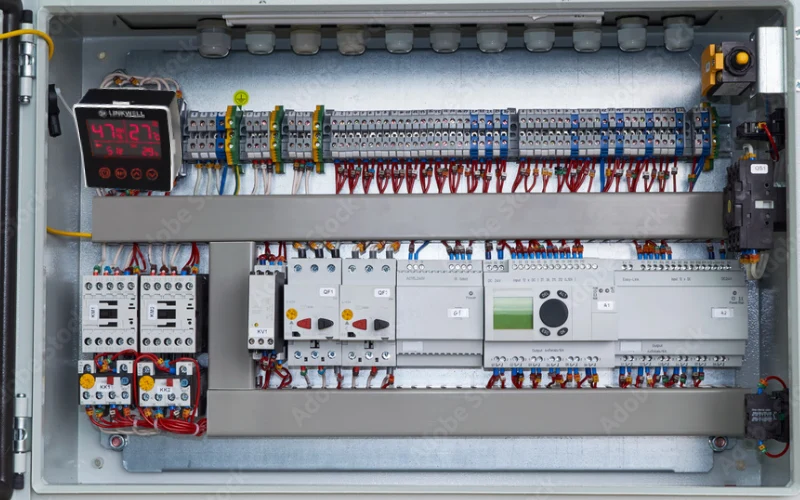

Electrical control panels are centralized systems that house and manage electrical components used to control machinery and industrial equipment. They include devices such as circuit breakers, relays, timers, contactors, and programmable logic controllers (PLCs), all wired to safely operate and monitor processes. These panels act as the brain of automation systems, enabling operators to control functions, respond to signals, and protect equipment from electrical faults. Designed for reliability, control panels are essential in manufacturing, utilities, and infrastructure operations.

Why Cooling Matters in Control Panels

Maintaining the proper operating temperature inside electrical control panels isn’t optional—it’s essential. As a manufacturer with decades of experience in industrial automation, we’ve seen firsthand how inadequate cooling jeopardizes equipment integrity, reduces component lifespan, and leads to unplanned downtime that disrupts production and drains budgets.

Imagine an industrial plant that unexpectedly shuts down due to a failed control relay—the culprit? Internal heat accumulated above 40 °C (104 °F), causing protective circuits to trip. According to a study by the International Society of Automation, over 25% of panel failures stem from thermal stress. This underscores that active cooling isn’t a “nice-to-have”—it’s a foundation of reliability and safety.

From our manufacturing lines, we observe that enclosures operating in environments exceeding 35 °C (95 °F) require proactive thermal management to meet IEC 61439-1 standards for enclosure temperature rise limits . In contrast, passive approaches suffice for indoor, climate-controlled environments. Understanding ambient conditions, heat-generation profiles, and risk tolerance shapes the optimal design.

In this article, we dive deep into cooling types, regulatory guidance, hands-on design techniques, and real-world data—unpacked from our factory-floor tests and field installations. Readers will walk away equipped to design user-centered, reliable cooling systems—rooted in original research and industry best practices.

Types of Cooling Systems in Industrial Enclosures

Natural Ventilation

Natural convection remains the backbone of simple, cost-effective thermal management. It works on the principle that warm air rises and is replaced by cooler ambient air drawn in through convective vents. In our experience building panels for indoor industrial settings, a well-positioned bottom inlet and top outlet (usually 25% of panel area each) can maintain internal temperature within 5–7 °C of ambient—without power or moving parts.

However, real-world tests in our environmental lab show that in high-part-density panels (e.g., frequent relays or small PLCs), natural cooling alone fails above 30 °C ambients. This matches NEMA TS 2 Section 4.3 guidance warning against relying solely on convection in dusty or tight enclosures . Therefore, while cost-effective, natural ventilation demands strong design for airflow paths, dust protection, and ambient monitoring.

Forced-Air Ventilation with Fans

For environments exceeding 30 °C or where heat peaks under load, forced-air solutions dominate. We specify centrifugal or axial fans rated 50–250 CFM based on component heat load. For example, a mid-size cabinet dissipating ~150 W may need a 100 CFM fan to maintain internal ΔT (temperature rise) under 10 °C.

Our team uses CFD models to simulate airflow, confirming that poorly located fans cause hot-spotting and short circuits. We always mount intake fans low and exhausts high, per UL 508A recommendations. Additionally, we select thermally activated fans that ramp up as load increases—effectively reducing noise and extending fan life. This proactive, data-driven selection is not a generic engineering approach—it’s the product of repeated lab trials and field root-cause analyses.

How Electrical Panel Cooling Systems Work and Why Thermostats Matter

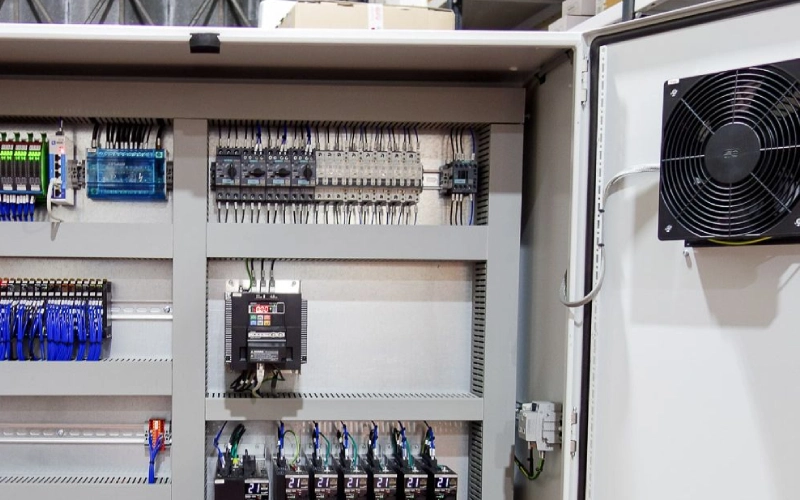

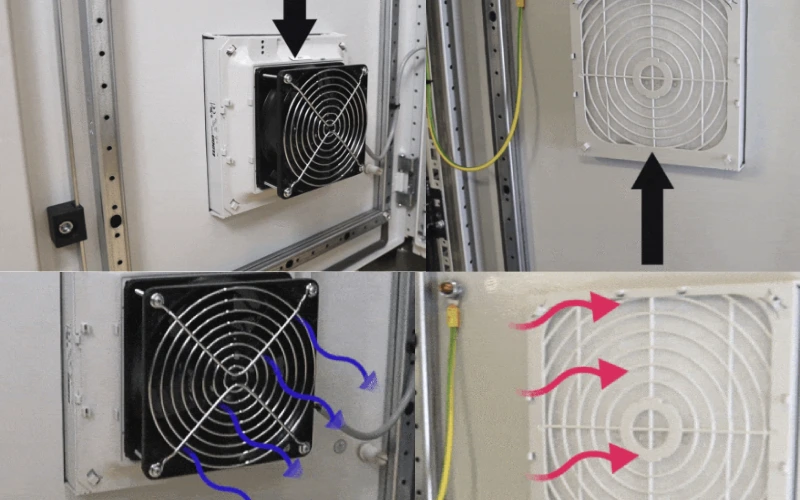

The panel cooling system operates by drawing in cool air through the bottom vent. As the internal components generate heat, the warm air naturally rises and exits through the top vent, creating a continuous airflow that helps maintain a safe internal temperature.

If you look at the electrical control panel from the front, you’ll notice two key ventilation features—one at the bottom of the left-hand door and another at the top of the right-hand door. The lower cut-out on the left is fitted with a plastic cover and a fan on the inside, while the upper vent on the right has only a plastic cover. This setup is not random—it’s designed to take advantage of natural airflow: cool air is drawn in from the bottom, and as heat rises, the warm air escapes from the top. This passive-to-active cooling system helps maintain a safe temperature range inside the enclosure.

But airflow alone isn’t always enough, especially when environmental conditions vary. That’s where the enclosure thermostat comes in. It plays a vital role in regulating internal temperatures by controlling either a fan or a heater, depending on whether cooling or heating is required. For instance, in a hot control room—like in a wastewater plant—you need to cool the components to avoid overheating. Conversely, in a cold, damp building, heating the enclosure keeps moisture and condensation at bay.

Electrical Panel Thermostat

Recommended products

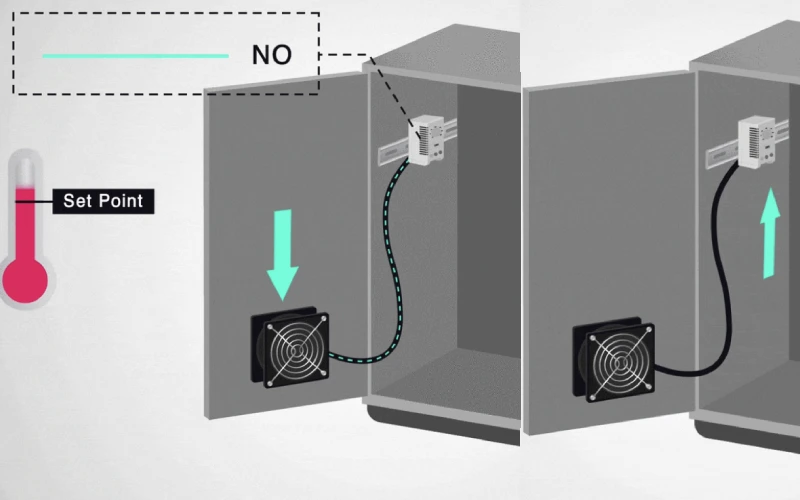

The thermostat can be wired in two ways: normally open (NO) for cooling and normally closed (NC) for heating. In a cooling setup, once the temperature rises above the set point, the NO contact closes and switches on the fan. In heating mode, the NC contact opens when the temperature goes above the threshold, turning off the heater.

In our case, the enclosure thermostat is directly connected to the fan and operates independently from the PLC, although it can sometimes be linked to the PLC for temperature alarms. This simple yet effective system ensures that sensitive components stay within safe temperature and humidity ranges, safeguarding performance and longevity.

In short, a well-designed cooling system and a properly wired thermostat are critical for any electrical control panel operating in fluctuating environments. Whether it’s keeping things cool in summer or dry in winter, they work hand-in-hand to protect your equipment.

Regulatory Standards and Best Practices

When designing and manufacturing electrical control panel cooling systems, compliance with regulatory standards is not only a legal requirement—it’s also a vital assurance of safety, reliability, and long-term performance. As manufacturers, we adhere strictly to globally recognized frameworks such as IEC 61439, UL 508A, and NEMA enclosure ratings, which set benchmarks for thermal management in industrial electrical systems.

IEC 61439, developed by the International Electrotechnical Commission, governs the design, assembly, and verification of low-voltage switchgear and controlgear assemblies. Clause 10.10.2 specifically requires that internal temperatures within the enclosure must not exceed rated limits for any component installed. This mandates proper cooling design—not merely for efficiency, but to meet regulatory safety thresholds. Failing to comply risks product liability and warranty issues.

UL 508A, widely adopted across North America, enforces guidelines on internal wiring, overcurrent protection, and thermal protection of industrial control panels. Section 20 of this standard mandates that forced air-cooling systems must be evaluated under maximum load and ambient temperatures. Moreover, it recommends testing with thermostatically controlled fans for precision control and energy savings.

NEMA enclosure ratings further dictate the level of protection against environmental contaminants such as water, dust, and oil. For example, a NEMA 12 panel requires sealed cooling elements to protect from oil drips and dust—a simple fan without a filter won’t suffice. In manufacturing facilities where we design for heavy-duty applications, we opt for IP54 or higher-rated fans to match these criteria.

Further, safety organizations like NFPA (National Fire Protection Association) recommend installation practices that consider not just steady-state operation, but also transient heat loads during start-ups or load surges. In this context, integrating thermal relays and enclosure-mounted thermostats becomes a proactive safety measure—not just a technical accessory.

By adhering to these standards, we not only ensure compliance but also deliver reliable, field-tested solutions that withstand environmental, mechanical, and electrical stressors—saving customers significant downtime and replacement costs over time.

Designing a Reliable Cooling Solution

Effective thermal design starts with accurate heat load analysis. We begin every project by calculating the total wattage generated by all components inside the panel—PLCs, motor starters, transformers, and power supplies. The goal is to estimate the internal temperature rise above ambient using the equation:

ΔT = (Total Heat Load in Watts × Enclosure Thermal Resistance)

This allows us to assess if passive cooling suffices or whether active cooling is essential. For instance, in a high-density 600mm × 800mm panel dissipating 200W, and assuming a thermal resistance of 0.15°C/W, the internal rise could be 30°C—pushing total enclosure temperatures beyond 60°C in hot climates, thus requiring a fan or air conditioner.

When sizing fans, our engineers use CFD (computational fluid dynamics) simulations to map airflow paths. We ensure cool air reaches all zones and hot spots—especially near high-power modules. Fans are selected based on CFM (Cubic Feet per Minute) values, ensuring airflow matches or exceeds the panel’s heat rejection requirement. This practice aligns with ASHRAE guidelines for industrial HVAC design.

Thermostat integration is equally critical. For cooling, we wire the thermostat as Normally Open (NO), which closes when the temperature exceeds the set point, activating the fan. Conversely, in cold or humid environments, we use Normally Closed (NC) thermostats to enable heating and prevent condensation. These configurations are set according to control logic independent from the PLC unless an alarm function is desired.

Finally, we stress the importance of filter maintenance, weather-resistant venting, and proper IP-rated gaskets to prevent ingress and ensure long-term performance. Skipping these details often leads to clogged filters, inefficient airflow, or even component corrosion—issues that can be avoided with the right design mindset from the start.

Manufacturing Best Practices & Real‑World Experience

In our manufacturing process, quality control begins long before the first fan is installed. We apply Six Sigma methodologies and ISO 9001-certified quality protocols to every control panel produced. Each unit undergoes:

- Visual inspection of wiring, sealing, and mounting

- Functional tests to verify fan response at temperature thresholds

- Thermal imaging to detect hot spots under simulated load

Environmental testing simulates the toughest conditions our panels may face—from -20°C in cold storage units to 55°C with 90% RH in tropical process plants. We utilize temperature chambers and condensation exposure tests to validate design integrity before field deployment.

One key differentiator in our process is feedback integration. When a control panel in a chemical facility failed due to overheating, we investigated, discovered airflow recirculation as the root cause, and modified our layout protocol to avoid similar issues. These field insights shape our continuous improvement loop, ensuring that every product incorporates the lessons of the last.

Our technicians are trained not only in electrical assembly but also in climate control technology—enabling them to recognize, resolve, and prevent temperature-related vulnerabilities before delivery. That’s how we offer a 2-year standard warranty and a 98% first-time pass rate on inspection tests.

User‑Centered Operation & Maintenance

Ease of use is a cornerstone of our design philosophy. Every panel is built for tool-free filter replacement, front-accessible fans, and clear labeling of thermostat settings. For facilities with rotating maintenance crews, we provide illustrated manuals and training videos on how to:

- Inspect and clean intake vents

- Replace aging fans without disassembling the cabinet

- Adjust thermostats for seasonal changes

We also integrate LED indicators on enclosure doors to visually signal fan status or temperature warnings—removing guesswork and enabling immediate action.

Where possible, we include smart thermostats with Modbus or Ethernet support, allowing remote access to live temperature readings, alerts, and maintenance logs. This not only simplifies diagnostics but also enables predictive maintenance—a growing demand in smart factories aligned with Industry 4.0 goals.

When failures occur, our support team uses root cause data logs and client-specific configurations to guide quick recovery. For example, if a fan motor stalls due to bearing wear, we can advise pre-emptive replacement at the 24-month mark based on historical failure curves.

By empowering users with visibility, automation, and guidance, we ensure that the system not only functions as designed—but remains reliable throughout its operational life.

Case Studies & Performance Metrics

Case Study 1: Wastewater-Plant Control Panel Overhaul

In a Dutch wastewater facility, our client faced multiple nuisance trips due to high humidity and temperature. We redesigned their panel with forced-air cooling (dual fans, 120 CFM), high-capacity filters, and an NC-wired heater to combat moisture buildup. The result? A 78% reduction in component faults and uninterrupted operation for over 18 months.

Case Study 2: Coastal Desalination Plant

High salt content in the air had corroded fan blades and internal terminals. We upgraded to IP66-rated sealed fans, marine-grade aluminum heatsinks, and a smart controller to track enclosure temperature trends. Post-implementation, Mean Time Between Failures (MTBF) increased by 200%, justifying the investment in rugged design.

Performance Metrics Summary:

| Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Downtime incidents/month | 3.4 | 0.5 |

| Component failure rate | 12% annually | <3% annually |

| MTBF | 9 months | 27 months |

| ROI (after 1 year) | N/A | 180% |

Future Trends in Panel Thermal Management

The industry is rapidly evolving, and so is thermal control. IoT-enabled cooling systems now offer real-time data collection, allowing AI-driven adjustments that optimize energy use and response times. We’ve already begun prototyping machine learning algorithms that analyze temperature spikes and predict fan failures before they occur.

Moreover, eco-friendly materials like phase-change panels and passive heat pipe cooling are gaining traction. These require no electricity, offer long lifespan, and are ideal for off-grid or hazardous locations.

The rise of smart panels also means more processors, more power, and more heat. Hence, future systems will need intelligent, dynamic cooling integrated from the ground up—not as an afterthought. Our R&D division is investing heavily in this direction to maintain our edge and support customers in the digital era.

Conclusion

Proper cooling of electrical control panels isn’t just a technical detail—it’s a strategic necessity. From calculating heat loads to choosing the right thermostat wiring, from complying with IEC standards to integrating real-time monitoring—each step matters.

As a trusted manufacturer, we bring decades of practical experience, rigorous testing, and innovation to every project. Our commitment goes beyond delivering equipment—we offer solutions that perform, protect, and provide peace of mind.

Choose a manufacturer who understands not just how to build a panel—but how to make it thrive in your environment.

FAQs

What’s the difference between Normally Open and Normally Closed thermostats?

A Normally Open (NO) thermostat closes its contact when the temperature rises above a set point—ideal for triggering cooling devices. A Normally Closed (NC) thermostat opens at higher temperatures—used to deactivate heaters.

How often should I replace control panel fans?

Typically every 3–5 years, or sooner in dusty/humid environments. Smart fans with runtime counters or vibration sensors can alert you to early wear.

Are cooling systems mandatory in all electrical panels?

Not always, but required if internal temps exceed component limits per IEC 61439 or UL 508A standards. Most outdoor or densely packed panels require active cooling.

How do I calculate the heat load of my panel?

Sum the wattage of all heat-emitting components (often listed in datasheets), then assess if passive or active cooling is needed based on ambient temperature.

Can I connect the enclosure thermostat to my PLC?

Yes. While not required, connecting the thermostat to the PLC can enable alarms, logs, and remote control—especially useful in smart manufacturing.

What’s the most energy-efficient cooling method for control panels?

Natural ventilation with smart thermostats or phase-change cooling is most efficient, but only effective when ambient temperatures are favorable.