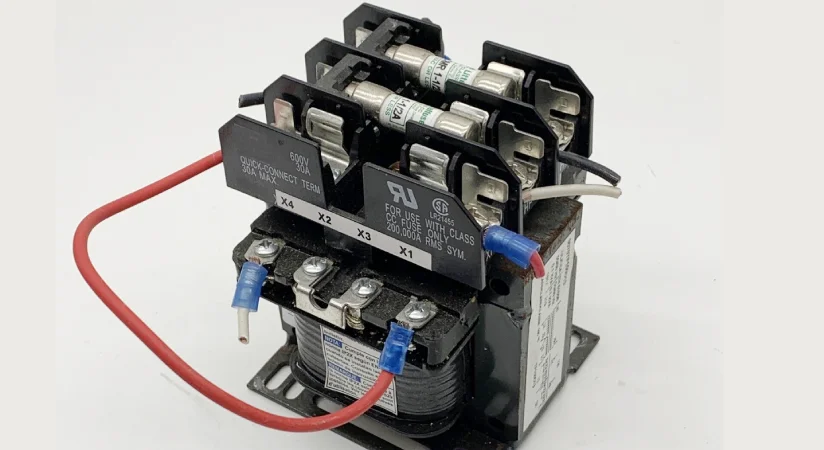

You want to know how to determine if a fuse is blown in a control transformer. First, always put safety first and grab the right tools before you start. Even though Linkwell’s Power Transformer stands out for reliability in machines, control cabinets, and distribution boxes, sometimes you still need to check the fuse. You can handle this with a simple process.

Check if a Fuse is Blown: Key Takeaways

- Always turn off power and use lockout/tagout before checking a fuse to stay safe from shocks and accidents.

- Wear proper safety gear like insulated gloves and glasses to protect yourself during fuse inspection.

- Locate the control transformer and fuse holder carefully using labels and wiring diagrams to avoid mistakes.

- Use a multimeter in continuity mode to test the fuse; a beep or low resistance means the fuse is good.

- Replace blown fuses with the exact type and rating, and check for underlying issues before restarting the system.

Safety Steps

Power Off

Before you do anything else, you need to make sure the control transformer is completely powered off. This step is not just a suggestion—it’s a must. Control transformers, like those in machine tools, tower cranes, control cabinets, and distribution boxes, can hold dangerous voltages even after you flip the main switch. You want to avoid any risk of shock or arc flash.

Tip: Always use the lockout/tagout method. This means you physically lock the power source in the “off” position and tag it so no one else turns it back on while you work.

Here’s a quick checklist to help you power off safely:

- Turn off the main power supply to the control panel.

- Apply lockout/tagout devices to the power switch.

- Double-check with a voltage tester or multimeter to confirm there’s no voltage present.

- Test your meter on a known live circuit first, so you know it works.

- If possible, ground the equipment to discharge any stored energy.

Skipping these steps can have serious consequences. There have been real incidents where people suffered burns or worse because they didn’t secure the equipment or check for live circuits. You don’t want to become another story in an accident report.

Safety Gear

Once you know the power is off, you still need to protect yourself. Electrical panels and control transformers can surprise you with hidden hazards. Always wear the right personal protective equipment (PPE) until you’re sure the area is safe.

- Wear insulated gloves and safety glasses.

- Use flame-resistant clothing if you’re working in a high-risk area.

- Keep your tools insulated and in good condition.

Note: Even if you trust your equipment, always follow OSHA and NFPA 70E safety standards. These rules exist because accidents can happen to anyone, even experienced technicians.

By taking these safety steps, you set yourself up for a smooth and safe fuse inspection. Remember, a few extra minutes spent on safety can save you from injury or costly equipment damage.

Locate the fuse in the Control Transformer

Locate Linkwell Power Transformer

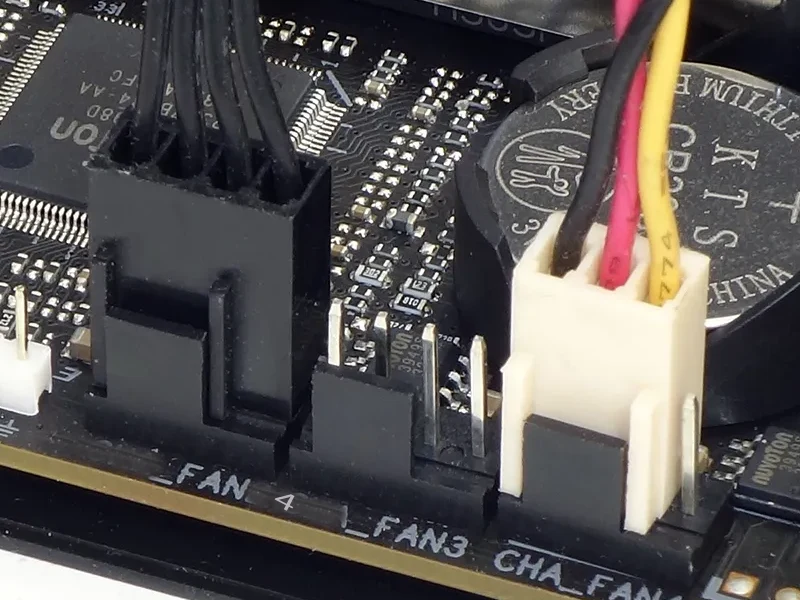

You’ve powered down and put on your safety gear. Now, it’s time to find the control transformer inside your control panel. In many machine tools, tower cranes, or distribution boxes, you’ll spot the Linkwell Power Transformer mounted on a backplate or DIN rail. Look for a sturdy, rectangular device with clear markings showing input and output voltages. You might see the Linkwell logo or a label with the transformer’s specs.

If you’re not sure which device is the transformer, check the panel’s wiring diagram. Most control panels have a diagram stuck inside the door or on the enclosure. This diagram shows where the transformer sits and how it connects to the rest of the system. You can also look for the main power wires coming into the transformer from the supply side and smaller wires heading out to the control circuits.

Identify Fuse Holder

Once you’ve found the transformer, your next step is to locate the fuse holder. The fuse protects both the transformer and the control circuit from overloads or short circuits. In most setups, you’ll find the fuse holder either on the primary (input) side or the secondary (output) side of the transformer. Sometimes, you’ll see both.

Here’s how you can identify the fuse holder quickly:

- Look for a small, cylindrical or rectangular component near the transformer, often with a cap or a flip-top cover.

- Check for labels like “F1,” “Primary Fuse,” or “Secondary Fuse.” These labels follow industry standards and make it much easier to spot the right fuse.

- Many control panels use color-coded labels and warning stickers. These help you match the fuse to its circuit and remind you not to replace fuses while the circuit is energized.

- If you see a warning label about arc flash or series ratings, you’re in the right spot. These labels give you important safety info and help prevent mistakes.

If you’re ever unsure, check the panel’s documentation or ask your supervisor. Following these steps will help you find the fuse quickly and safely, so you can move on to the next part of your inspection.

Visual Check Fuse is Blown

Signs of a Blown Fuse

You can often spot a blown fuse with just your eyes, especially if your control panel uses indicator fuses. Some fuses have a small window that turns black when the fuse blows. This makes it super easy to tell if you need to replace it. Other fuses use a spring-loaded pin that pops up when the fuse element melts. You might see this pin sticking out, which is a clear sign the fuse has failed. These features help you find a problem quickly, even if the power is off.

- Look for a dark or cloudy window on the fuse.

- Check for a pin that has popped up.

- Notice any labels or markings that say “blown” or “replace.”

Inspect for Damage

Sometimes, you won’t see an obvious sign like a popped pin or dark window. That’s when you need to look closer. Check the fuse and the area around it for burn marks, melted plastic, or a strange smell. These clues can point to a blown transformer or a bigger problem in your control system.

- Watch for cracks, swelling, or burn marks on the fuse holder.

- Look for loose or broken wires near the fuse.

- Pay attention to any signs of arcing or hot insulation at the connections.

A visual check is a great first step, but it doesn’t catch every problem. Some faults hide inside the fuse or transformer, so you might not see any damage at all. If you still suspect trouble after your inspection, you’ll need to use a multimeter or call a professional. Visual checks help you spot the obvious, but they can’t replace a full test.

How to Determine if a Fuse is Blown in a Control Transformer

When you want to know how to determine if a fuse is blown in a control transformer, you need a reliable method. The best way is to use a multimeter. This tool helps you test a transformer safely and accurately. Linkwell Power Transformers make this process even easier because they are built for simple maintenance and quick fuse access. Let’s walk through the steps together.

Test with Multimeter

You can use a multimeter to check if your fuse is still good or if it needs replacing. Here’s how to determine if a fuse is blown in a control transformer using a multimeter:

- Turn Off Power

Always start by switching off the power to your control panel. This keeps you safe from electric shock. - Remove the Fuse

Use insulated tools to carefully take the fuse out of its holder. Never use your bare hands. - Set the Multimeter

Turn your multimeter to continuity mode. If your meter does not have this, use the lowest resistance (ohms) setting. - Test the Fuse

Touch one probe to each end of the fuse.- If you hear a beep, the fuse is good.

- If there is no beep, the fuse is blown.

- Check Resistance

If you use resistance mode, a good fuse will show a low resistance value (close to zero). If the reading is very high or shows “OL” (over limit), the fuse is blown. - (Optional) Voltage Test

If you want to test a transformer with the fuse in place, you can measure voltage across the fuse. With the power on and all safety steps followed, place the probes on each side of the fuse. If you see the expected voltage, the fuse is good. If you see zero, the fuse is blown.

Check for Continuity

Continuity testing is the most reliable way to know how to determine if a fuse is blown in a control transformer. Here’s what you need to do:

- Place the multimeter in continuity mode.

- Touch the probes to both ends of the fuse.

- Listen for a beep or look for a low resistance reading.

If you get a beep or a low number, your fuse is working. If you get silence or a high number, your fuse is blown.

Note: Linkwell Power Transformers are designed so you can reach the fuse easily. This saves you time and keeps your maintenance simple.

Common Mistakes to Avoid

When you test a transformer or check a fuse, you might run into some common errors. Here’s what to watch out for:

- Never measure resistance on a live circuit. This can damage your meter and give you wrong results.

- Make sure your multimeter is set to the right mode. Using the wrong setting can break your meter or confuse your readings.

- Don’t swap fuse types. Always use the correct rating and type for your control transformer.

- Never bypass a fuse with wire or foil. This removes protection and can cause fires or injury.

- Watch out for auto-ranging meters. Sometimes, they show millivolts as volts, which can trick you.

Alert: If your fuse looks fine but your control transformer still does not work, check the rest of your control circuit. Sometimes, the problem is with wiring, overloads, or other components.

Knowing how to determine if a fuse is blown in a control transformer helps you keep your equipment running smoothly. With Linkwell Power Transformers, you get easy access and reliable performance, making every maintenance task a breeze.

Next Steps

Replace with Correct Fuse

You found the problem, so now it’s time to fix it. Always replace the blown fuse with one that matches the original type and rating. Check the label for the correct current and voltage. If you use the wrong rating, you risk damaging your equipment or causing a safety hazard. For example, a fuse with a higher rating than needed can let too much current flow, which may lead to overheating or even a fire. Using a fuse with the wrong voltage rating can cause insulation failure or unsafe current interruption. If you ever feel unsure, reach out to Linkwell’s product support team for help. They can guide you to the right replacement and answer your questions.

Here’s a quick table to help you avoid common mistakes:

| Mistake | Potential Risk |

|---|---|

| Wrong current rating | Fuse blows too soon or fails to protect during faults |

| Wrong voltage rating | Insulation failure, unsafe interruption |

| Ignoring environment | Unexpected failures from heat or humidity |

Address Underlying Issues

Don’t just swap the fuse and move on. Take a moment to figure out why it blew in the first place. The most common reason is an undersized transformer for the load. If your transformer can’t handle the inrush current or the total VA demand, the fuse will keep blowing. Sometimes, you might see voltage drops or hear contactors chattering. These are signs that your transformer or wiring needs attention. Always check the load, wiring, and transformer size before you restart the system.

- Make sure your transformer matches the load.

- Check for loose wires or signs of overheating.

- Look for signs of overload or short circuits.

When to Call a Pro

Some problems need an expert. If you hear strange noises like humming or crackling, or if you see repeated fuse failures, call a qualified electrician. Professionals have the tools and experience to spot hidden issues. They can also help you choose the right transformer and protection for your setup. Safety comes first, so don’t hesitate to get help if you feel out of your depth.

You now know how to check a fuse in a control transformer step by step. Always put safety first. Here are some quick reminders:

- Inspect fuses for cracks, discoloration, or burn marks.

- Check for overheating or strange smells.

- Use a multimeter to test for continuity.

- Keep panels clean and dry.

- Fix any loose wires right away.

Choose quality products like Linkwell Power Transformers for easy maintenance. If you run into tough problems, reach out to a professional or contact Linkwell’s support team for help.

FAQ

What does a control transformer do in a machine tool or control cabinet?

A control transformer gives stable, safe voltage to control circuits. You need this for relays, timers, and contactors to work right. It helps your equipment run smoothly and safely.

How often should I check the fuse in my control transformer?

You should check the fuse during regular maintenance or if you notice problems like equipment not starting. If your machine stops suddenly, always check the fuse first.

Can I use any fuse for my Linkwell control transformer?

Tip: Always use the exact fuse type and rating listed on your transformer label. The wrong fuse can damage your equipment or cause safety issues.

What should I do if the new fuse blows again right away?

You might have a bigger problem, like a short circuit or overload. Stop and check your wiring and load. If you cannot find the issue, call a professional or reach out to Linkwell support for help.

Conclusion

How to determine if a fuse is blown ensures your control systems run safely and reliably. By combining visual inspection with multimeter testing, you can spot issues early and prevent costly downtime. Linkwell Power Transformers make this process simple with accessible fuse holders and reliable construction.

For faster maintenance, fewer breakdowns, and expert support, trust Linkwell to help you choose the right transformer and protection for your electrical needs.