You might wonder what sets line and load wires apart in industrial electrical systems. The difference between line and load wires comes down to their roles: line wires bring electric power from the source, while load wires carry electric current to your devices. Knowing which wire does what keeps your electrical equipment safe. If you mix up line vs load, you risk improper circuit breaker function, which can lead to electrical faults, arcing, or even fires. Always double-check line wire placement in your electrical power distribution box. Linkwell makes this easier with clearly labeled terminals and smart design, helping you avoid wiring mistakes and stay safe during every electric installation.

Key Takeaways

- Line wires bring electric power from the source into your system, while load wires carry power from the system to your devices.

- Always identify and connect line and load wires correctly to prevent electrical faults, equipment damage, and safety hazards like fires or shocks.

- Use color codes, labels, and testing tools to find line and load wires easily and avoid wiring mistakes.

- Linkwell’s electrical power distribution boxes offer clear labels, organized wiring, and safety features that simplify installation and maintenance.

- Regularly inspect and maintain your wiring to keep your electrical system safe, reliable, and efficient.

Line and Load Basics

What Are Line Wires?

You see line wires every time you open an electrical panel or distribution box. These wires bring electric power straight from the source, like a transformer or main breaker, into your industrial system. Line wires act as the backbone of your electrical setup. They keep your machines running and your lights on. You rely on line wires to deliver electric current safely and reliably, even when your environment gets tough.

- Line wires transmit electric power from the supply to different circuits.

- They help balance loads across your system, making sure each part gets the right amount of electricity.

- You can add or change equipment easily because line wires support modular connections.

- These wires also protect your system. They allow you to isolate faulty equipment and keep everything else working.

- Line wires make maintenance and upgrades quick, thanks to standardized components.

When you use Linkwell’s electrical power distribution box, you get labeled terminals and pre-cut cable entries. This design helps you connect line wires correctly and avoid mistakes. You keep your system safe and efficient.

What Are Load Wires?

Load wires carry electric current from your distribution box or panel to the devices that actually use electricity. You connect load wires to machines, lights, control panels, and other equipment. These wires make sure electricity flows to the right places, so your operations run smoothly.

- Load wires deliver electric power from distribution points to your equipment.

- They help you connect distribution boards to final loads, supporting your industrial processes.

- You need to identify load wires correctly. This keeps your system safe and helps you follow electrical codes.

- Load wires make troubleshooting easier. You know where power goes and where problems might happen.

- These wires help balance electric loads across different phases, preventing overloads.

- When you need to repair or maintain equipment, load wires let you disconnect power safely.

If you use Linkwell’s electrical power distribution box, you get clear labels and organized wiring. You can spot load wires quickly, which helps you avoid errors and keeps your installation safe.

Line vs Load Flow

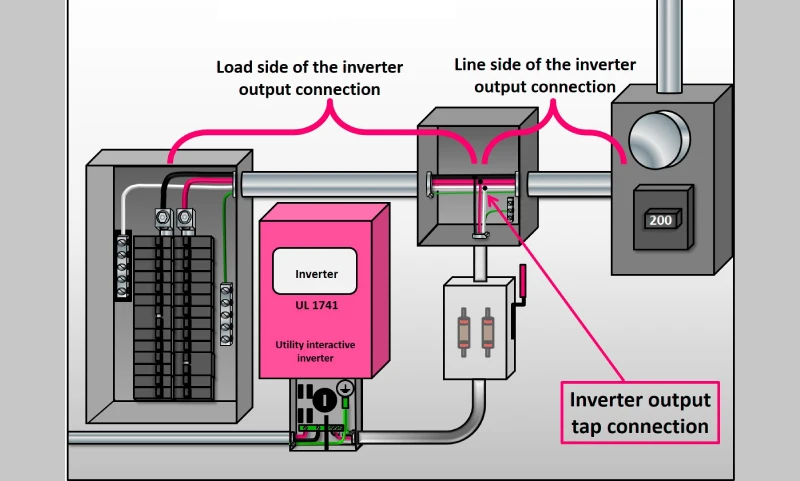

Let’s talk about how electric current moves in your system. Line wires bring electric current from the power source into your panel or device. These wires are always “hot” or live, carrying voltage even when your equipment is off. You connect line wires to the source side, so they stay energized unless you turn off the breaker.

Load wires take electric current away from the panel or device. They send electricity to the next part of the circuit or directly to your machines. Load wires are downstream. They only carry current when your equipment is on and drawing power.

Tip: Always double-check your line vs load connections. If you mix them up, you risk malfunction, safety hazards, or even fire. Devices like GFCI and AFCI breakers need correct line and load wiring to work. Linkwell’s distribution boxes make it easy to identify and connect wires the right way.

Here’s a quick table to help you remember the difference:

| Wire Type | Where It Connects | What It Does | When It’s Energized |

|---|---|---|---|

| Line Wire | Source side (main power) | Brings electric current into the panel | Always (unless breaker off) |

| Load Wire | Device side (equipment) | Sends electric current to the load | When equipment is on |

You need to understand line vs load flow to keep your industrial electrical system safe. Linkwell’s expertise and smart product design help you get it right every time.

Determine Line and Load Wires

Identification Methods

You need to determine line and load wires before you start any electrical work. The right method keeps your installation safe and helps you avoid costly mistakes. Start by looking at your electrical panel or distribution box. In most industrial setups, line wires connect directly to the incoming power source. Load wires run from the panel to your machines or devices.

Here’s how you can determine line wire and load wire positions:

- Check the Source Connection: Line wires always connect to the main power supply or breaker. Load wires connect to the output side, leading to equipment.

- Follow the Path: Trace the wires from the entry point. The first set you see from the power source are usually line wires. The wires leaving the panel and heading to devices are load wires.

- Use Labeled Terminals: Linkwell’s electrical power distribution box makes this step easy. You’ll find clear labels for line and load on each terminal. This labeling helps you determine line wire and load wire locations quickly, even if you’re new to the system.

- Look for Pre-Cut Cable Entries: These entries often separate line and load wires, reducing confusion and making your job faster.

Tip: Never guess when you determine line and load wires. Always double-check with diagrams and labels. If you’re unsure, ask a qualified electrician for help.

Common mistakes include mixing up line wires and load wires, which can cause equipment failure or safety hazards. Always verify before connecting anything.

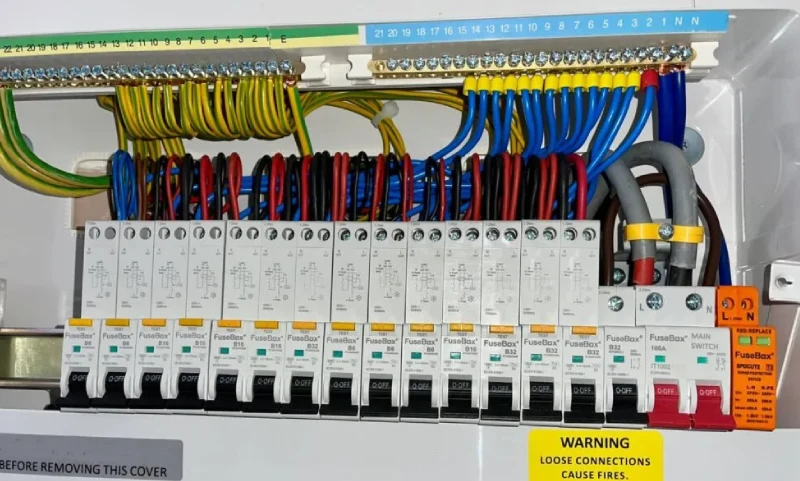

Color Codes and Labels

Color codes and labels are your best friends when you determine line and load wires. Industrial electrical systems follow strict color standards to keep everyone safe and make maintenance easier.

Here’s a quick reference table for standard color codes:

| Standard / Voltage | Phase 1 (L1) | Phase 2 (L2) | Phase 3 (L3) | Neutral | Ground (Earth) |

|---|---|---|---|---|---|

| IEC (IEC 60445:2021) | Brown | Black | Grey | Blue | Green/Yellow |

| UL / NEC (120/208/240V) | Black | Red | Blue | White/Gray | Green or Green/Yellow |

| UL / NEC (277/480V) | Brown | Orange | Yellow | Gray | Green, Green/Yellow, Bare |

You’ll see brown, black, and grey for line wires in IEC systems. In UL or NEC systems, black, red, and blue are common for line wires. Neutral wires use blue, white, or gray. Ground wires are always green, green/yellow, or bare copper.

Note: Always match the color code to your region’s standard. Never use a color meant for ground as a line wire or load wire.

Labels are just as important as color codes. Linkwell’s electrical power distribution box uses durable, high-visibility labels that meet industry standards. These labels stay readable even in harsh environments. They help you determine line wire and load wire positions at a glance. Good labeling reduces wiring errors, speeds up troubleshooting, and keeps your team safe.

OSHA and NFPA 70E require clear, durable labels for all electrical circuits. Proper labeling prevents miswiring and supports safe working conditions.

Testing Tools

Sometimes, you need more than just your eyes to determine line and load wires. Testing tools give you the confidence to work safely and accurately.

Here are some essential tools for the job:

- Wire tracers and locators: These tools help you trace wires through walls or conduits. You can follow the path from the power source to the device, making it easier to determine line wire and load wire.

- Continuity testers: Use these to check if a wire forms a complete circuit. This helps you confirm which wires connect to the source and which go to the load.

- Current testers (ammeters) and clamp meters: These measure electric current without disconnecting wires. Clamp meters are especially handy for identifying live line wires.

- Circuit testers: These combine voltage and continuity checks. They help you spot live wires and verify correct connections.

- Voltage detectors: Non-contact voltage detectors let you check if a wire is energized. Always test line wires before touching them.

Safety First: Always wear PPE like insulated gloves and safety glasses. De-energize circuits whenever possible. If you must test live wires, use non-contact tools and follow lockout/tagout procedures. Make sure your testing equipment matches the voltage and current levels in your system.

Before you start, review your electrical diagrams and get familiar with your tools. Document your testing results for future reference. Only trained personnel should use advanced testing equipment.

When you use Linkwell’s electrical power distribution box, you benefit from organized wiring, clear labels, and easy access to terminals. This design supports safe and efficient testing, helping you determine line and load wires with confidence.

Load Wires and Safety

Safety Risks

You need to pay close attention when working with load wires in any industrial electrical system. If you misidentify or incorrectly connect these wires, you can create serious safety hazards. Electric current flowing through the wrong path may cause overheating, arcing, or even fires. You also risk electric shock if you touch a wire you think is safe but is actually energized. Proper identification of load wires helps you avoid these dangers and keeps your team safe during installation and maintenance.

Tip: Always double-check labels and diagrams before touching any electrical wires. Even a small mistake with a load wire can lead to equipment failure or personal injury.

Compliance Standards

You must follow strict standards when installing and labeling load wires. The National Electrical Code (NEC) sets the minimum safety rules for electrical installations in the United States. Many states and local areas add their own codes to address specific needs. These codes require you to use durable, long-lasting labels on all electrical wires, including load wires. Labels must stay readable over time, even in tough industrial environments. This helps you and your team quickly identify each wire, making maintenance and repairs safer and easier.

International standards like IEC and UL also play a big role. For example:

- UL 508A requires you to use the correct wire gauge for each electric circuit. This prevents overheating and reduces fire risk.

- You must check that all components can handle short-circuit conditions without damage.

- IEC 61914 sets rules for securing cables so they stay safe during electric faults or mechanical stress.

These standards make sure your electrical system stays safe, reliable, and easy to inspect.

Linkwell Product Advantages

When you use Linkwell’s electrical power distribution box, you get several features that make managing load wires safer and easier:

- The box meets IEC 61439 and UL 508A standards, so you know it’s built for global safety and compatibility.

- Durable, anti-corrosion enclosures protect your electrical wires from dust, water, and harsh weather.

- IP65/IP66 ratings mean you can use these boxes indoors or outdoors without worry.

- Pre-cut cable entries and clearly labeled terminals help you connect load wires quickly and correctly, reducing mistakes.

- Circuit isolation lets you work on one part of your system without shutting down everything.

- Built-in breakers and ground fault protection stop electric hazards before they start.

Linkwell’s boxes also support safe installation practices. You can use multiple conduit openings and follow strict lockout/tagout procedures. The design supports the use of personal protective equipment, keeping you safe while you work. With these features, you can trust that your electrical system will meet international safety standards and protect everyone on site.

| Standard/Certification | Focus Area | Application |

|---|---|---|

| UL and CE Certifications | Electrical safety and reliability | Low-voltage transformers and control panels |

| IEC 61936 | Electrical safety, grounding | Industrial and residential installations |

| IEEE Standards | Arc flash protection, hazard zones | Industrial and control cabinet environments |

| OSHA and NFPA Codes | Personnel safety, fire prevention | All electrical installations |

Line vs Load in Practice

Industrial Applications

You see the importance of line vs load every day in industrial settings. In control cabinets, line wires bring electric power from the main source into your system. Load wires carry that electric current out to motors, pumps, or heaters. If you work with telecom cabinets, you know that organized line and load wiring keeps your signal equipment running smoothly and safely.

Here are some common places where line vs load matters:

- Line reactors sit between the power source and controllers or VFDs. They help reduce electric noise and keep current stable.

- Load reactors go between VFDs and motors. They protect your equipment from voltage spikes, especially when you have long electric motor leads.

- Contactors and relays use line wires for input power and load wires to send electric current to heavy equipment.

- Smart breakers and energy meters need correct line vs load wiring to measure and control electric power accurately.

If you mix up line and load, you risk damaging your equipment or voiding warranties. Linkwell’s cable entry systems and horizontal cable management products help you organize and protect your electrical wires. These solutions keep dust and moisture out, prevent cable damage, and make your cabinets safer and easier to maintain.

Device Installation

When you install a new device, you need to get line vs load wiring right. Here’s a simple step-by-step process:

- Turn off electric power at the breaker.

- Use a voltage tester to make sure the wires are not live.

- Label the breaker so no one turns it on by mistake.

- Wear insulated gloves and safety goggles.

- Use the right tools for cutting, stripping, and connecting wires.

- Identify line wires (from the power source) and load wires (to the device).

- Mark each wire clearly before you connect anything.

- If you feel unsure, call a licensed electrician.

Correct line vs load wiring is critical for devices like GFCI outlets, switches, and smart meters. If you swap the wires, the device may not protect you from electric shock or could fail to work at all. Linkwell’s labeled terminals and easy-to-use cable entry systems make installation faster and safer.

Maintenance Tips

Keeping your electrical system safe means regular checks on line and load wires. Here’s what you should do:

- Inspect wires for fraying, overheating, or loose connections.

- Use infrared cameras to spot hot spots during peak electric loads.

- Tighten all connections to the right torque.

- Clean dust and debris from enclosures and breaker housings.

- Look for signs of corrosion or arcing on connectors and supports.

- Test insulation resistance and check for voltage imbalances.

- Make sure all panels and doors seal tightly to keep out dust and moisture.

- Keep records of every inspection and fix problems right away.

Routine inspections help you catch problems early. You avoid electric failures, reduce downtime, and keep your team safe. Linkwell’s products, with their strong enclosures and organized cable management, make it easier to maintain your electrical system and follow industry standards.

You now know why identifying line and load wires matters so much in industrial electrical systems. Using Linkwell’s electrical power distribution box helps you meet strict safety standards, thanks to its tough, weatherproof design and built-in protection devices. Always choose high-quality equipment, follow safety codes, and let certified electricians handle complex wiring. Regular inspections and clear labeling keep your system safe and efficient for everyone.

FAQ

How do you tell the difference between line and load wires?

You can check labels, color codes, or use a voltage tester. Line wires connect to the power source and usually stay live. Load wires run to your devices and only carry current when equipment is on.

What happens if you mix up line and load wires?

If you swap them, your equipment may not work right. You could lose safety features or even cause a short circuit. Always double-check before connecting anything.

Are there standard colors for line and load wires?

Yes! Most systems use brown, black, or red for line wires. Load wires often match the device’s wiring. Always follow your local code and check the labels in your Linkwell distribution box.

Can you use Linkwell’s distribution box outdoors?

Absolutely! Linkwell’s boxes have IP65/IP66 ratings. They keep out dust and water, so you can use them indoors or outdoors without worry.

Do you need a professional to install line and load wires?

You should call a licensed electrician for complex jobs. If you’re not sure about wiring, it’s safer to get expert help. Mistakes can lead to shocks or fires.