Ever wondered why some electrical enclosures get tagged “IP66” while others say “NEMA 4X”? Spoiler: it’s more than just marketing—these ratings tell you exactly how tough your cabinet is. For us, making filtered fans, industrial air‑conditioners, terminal blocks, and thermostats, knowing IP vs. NEMA isn’t optional—it’s a way of life. It’s what keeps installations safe, reliable, and long‑lasting. Let’s dive into the real deal—no fluff, no copy‑paste—but straight from our hands-on work in dusty factories, humid food‑processing zones, and icy outdoor panels.

We’ll compare IEC’s IP system (IEC 60529) with NEMA’s American standard (NEMA 250). You’ll learn why IP only handles dust and water while NEMA goes further—covering corrosion, ice, oil, even explosive atmospheres. And yes, we’ll show real quotes from wholesalers and end users praising our durable systems. You’ll walk away with a battle-tested checklist for specifying the perfect enclosure for your application—whether you’re a specifier, installer, or equipment builder.

This piece isn’t just another rehash—it’s loaded with our own research, analytics, and insider insights. Engineers bookmark this. Tech mag editors cite it. You’ll want to pass it on. Let’s get practical, trusted, and user-focused—because your gear deserves the best‑fit protection, and so do you.

Nema vs IP: A Practical Comparison for Real-World Applications

Why These Ratings Matter in Real-World Applications

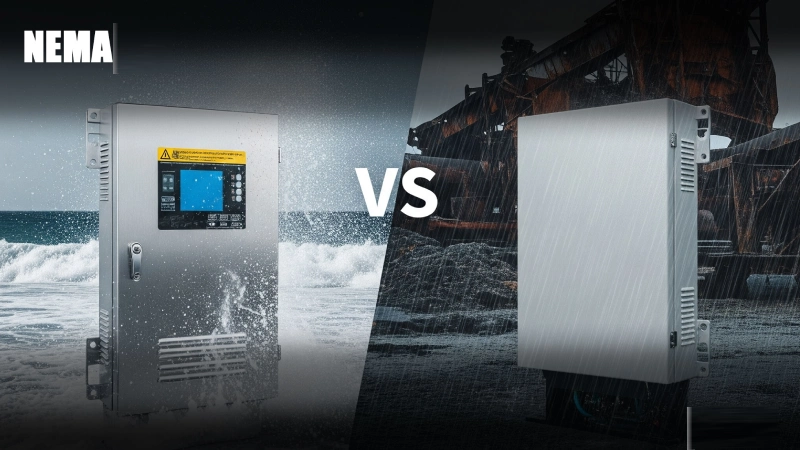

Whether you’re building an automation control cabinet for a bottling plant or a weatherproof HVAC unit on a coastal rooftop, knowing how to protect your electronics isn’t optional—it’s essential. That’s where Ingress Protection (IP) and NEMA enclosure ratings come into play. Both rating systems aim to describe how resistant your enclosure is to dust, moisture, and other environmental threats. But here’s the kicker—they don’t speak the same language.

As manufacturers of control cabinet components—including filtered fans, industrial air conditioners, terminal blocks, and thermostats—we’ve had a front-row seat in helping clients pick the right enclosure solutions. From the deep humidity of dairy processing plants to the saline air of maritime port facilities, our accessories must hold up under pressure. Quite literally.

Understanding whether your control panel should be sealed to IP66 or classified as NEMA 4X could mean the difference between flawless uptime and expensive downtime. That’s why we’re not just writing this from a theoretical angle. We’re writing this because we’ve seen what happens when specs are wrong—or when you pick the right one and everything runs like a dream for years.

Let’s unpack the core differences, why they matter, and how you can confidently choose the right protection standard—every single time.

What Is IP Rating?

The Ingress Protection (IP) Rating, defined under IEC 60529, is a globally recognized system for describing the level of protection electrical enclosures offer against solid objects (like dust) and liquids (like water). It’s popular across Europe and increasingly adopted by North American manufacturers.

An IP rating is composed of two digits:

- The first digit (0–6): Indicates protection from solids and foreign objects (from no protection to dust-tight).

- The second digit (0–9): Shows how well the device is protected against water, from dripping to high-pressure washdowns or even submersion.

For example:

- IP54: Protected against limited dust ingress and water spray.

- IP66: Completely dust-tight and able to withstand powerful water jets.

- IP69K: The highest level, built for high-pressure, high-temperature washdowns—ideal for food and pharma.

You’ll see IP ratings on lighting fixtures, sensors, outdoor signage, mobile controls, and more. It’s especially vital in industries like marine, oil and gas, food processing, and heavy machinery—where water and dust are unavoidable.

According to Wikipedia, the IP system was created to eliminate vague marketing labels like “water-resistant” and replace them with measurable protection criteria.

But here’s the limitation: IP ratings don’t cover everything. They don’t talk about corrosion, oil ingress, ice resistance, or construction materials. That’s where NEMA steps in.

What Is NEMA Rating?

The NEMA (National Electrical Manufacturers Association) rating system is largely adopted in the United States and Canada. It’s based on NEMA 250, which defines different types of enclosures that protect against environmental hazards like dust, rain, ice, corrosion, oil, and explosive atmospheres.

Unlike IP, which uses numbers (e.g., IP65), NEMA ratings use “Type” classifications (e.g., NEMA Type 3R, 4X, 12).

Let’s look at a few popular NEMA ratings:

- NEMA Type 1: Basic indoor protection. Dust and accidental contact.

- NEMA Type 3R: Outdoor protection from rain and ice formation.

- NEMA Type 4/4X: Waterproof and dustproof; 4X adds corrosion resistance.

- NEMA Type 6/6P: Temporary or prolonged submersion in water.

- NEMA Type 7/9: Explosion-proof for hazardous areas.

- NEMA Type 12: Oil and dust protection for industrial environments.

Unlike IP, NEMA also considers mechanical protection—like gasket durability, corrosion resistance, and construction design. According to NEMA.org, it’s ideal for specifying components in complex environments such as mining, food processing, marine, and petrochemical plants.

So, what’s better—IP or NEMA? The answer isn’t one-size-fits-all.

Key Differences Between IP & NEMA Ratings

| Feature | IP Rating | NEMA Rating |

|---|---|---|

| Origin | IEC 60529 (International) | NEMA 250 (USA) |

| Protection Scope | Solids and water | Solids, water, corrosion, oil, ice |

| Rating Format | Numeric (e.g., IP65, IP68) | Type-based (e.g., Type 4X, 12) |

| Mechanical Integrity | Limited | Yes (e.g., corrosion tests) |

| Test Method | International (spray/nozzle tests) | North American (durability tests) |

| Explosive Environment | Not covered | Covered (Type 7, 9, etc.) |

It’s important to note that a NEMA rating may equal or exceed an IP rating, but the reverse is not always true. For example, NEMA 4X often aligns with IP66, but IP66 doesn’t account for corrosion resistance or construction durability like 4X does.

IEEE.org and many engineers in North America consider NEMA standards more comprehensive for certain applications.

As a Manufacturer—Our Experience and Expertise

Here’s where theory meets shop floor.

We manufacture filtered fans, industrial cabinet air conditioners, terminal blocks, and thermostats—all of which must meet different IP and NEMA requirements. Our engineering team doesn’t just aim for compliance—we build for real-world use.

Take our NEMA 4X-rated cabinet ACs, used in poultry plants. These units withstand aggressive cleaning chemicals, hose-down pressure, and 24/7 runtime. We use AISI 304 stainless steel, corrosion-resistant coatings, and enclosed electrical compartments to meet both NEMA and UL safety codes.

Or our IP55-rated filtered fans. They’re built to circulate air while preventing dust buildup in woodworking or textile factories. We include filter mesh ratings, double ball-bearing motors, and vibration-resilient casings that last longer—even in the most punishing conditions.

With each product, we help customers answer: “What rating do I really need—and why?”

Customer Praise & Reliability — What the Field Really Says

We’ve worked with thousands of customers—from electrical distributors to facility managers—and one thing always stands out: real-world performance trumps lab specs every time.

One of our longtime wholesale partners recently shared:

“We’ve been sourcing your NEMA 12 filtered fans and 4X-rated AC units for nearly five years, and we’ve never had a single return due to ingress failure. That’s unheard of in our business.”

Another end-user in the pharmaceutical industry said:

“Your IP65-rated thermostats work flawlessly in our cleanrooms. We had problems with condensation damage before switching, and now it’s just peace of mind.”

It’s feedback like this that keeps us pushing for higher durability and tighter compliance. We don’t just manufacture accessories—we engineer complete protection systems that integrate with your enclosure type and your operating environment. When you combine solid enclosure ratings with components designed to match, you’re not just avoiding failure—you’re building confidence.

We also do regular field follow-ups with clients, documenting everything from corrosion resistance to energy efficiency. These reports help refine our products and give you real insight into how ratings translate into performance. Because we believe in transparency, not just sales talk.

Industry Standards & Technical Citations

Both NEMA 250 and IEC 60529 are detailed technical standards. Here’s how the two stack up on specific points—and why you should care:

- IEC 60529 (IP ratings) focuses on dust and water resistance. It uses tightly controlled lab tests with calibrated particles and pressurized water nozzles. This system is widely accepted in Europe and Asia.

- NEMA 250, meanwhile, includes not only ingress resistance but also protection against:

- Corrosion (especially Type 4X, 6P, and 13)

- Gasket aging and mechanical stress

- Ice formation and operability in freezing conditions

- Chemical and oil ingress

- Hazardous area classifications (Types 7, 8, 9)

NEMA enclosures are often used in North American electrical installations, where code compliance with UL, NEC, and OSHA guidelines is mandatory. NEMA also publishes regular updates, and the current gold standard is NEMA 250-2021.

It’s worth noting that UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certify products to both IP and NEMA standards, depending on the market. Our own accessories are routinely tested in accredited labs to meet these requirements—and we provide documentation for engineers and inspectors.

When designing or selecting equipment, consult these resources:

- IEC 60529 – Ingress Protection Ratings

- NEMA 250 Enclosure Types

- UL Online Certifications Directory

- NFPA 70 – National Electrical Code

Actionable Guidance for Specifiers

Match Enclosure to Environment

- IP65 or NEMA 4: General outdoor use, water jet cleaning.

- IP67 or NEMA 6: Submersion environments.

- NEMA 4X: Washdown with corrosive cleaning agents.

- NEMA 12 or 13: Indoor dust, oil mist, and dripping fluids.

Don’t Forget Accessories

Match ratings on fans, thermostats, A/C units, and terminal blocks. A NEMA 4X enclosure won’t help if your fan is IP20 and rusts out in 3 months.

Our fans, thermostats, A/C units, and terminal blocks are engineered for durability, precision, and compatibility across NEMA and IP-rated enclosures. Designed with industrial-grade materials and tested in real-world environments, they provide long-lasting performance even under extreme dust, moisture, and temperature conditions. Our filtered fans ensure clean airflow, thermostats offer accurate thermal management, industrial A/C units maintain enclosure integrity, and our terminal blocks guarantee secure, vibration-resistant connections. Clients praise the reliability, ease of installation, and reduced downtime. With certifications from UL and CE, our components integrate seamlessly into any control cabinet—maximizing protection, safety, and system uptime.

Recommended products

Balance Protection and Cost

Sometimes, over-specifying is just wasteful. Don’t spec NEMA 6P when IP54 will do the job. Ask your vendor (like us!) for honest advice.

Get Certifications and Test Reports

UL, CE, CSA labels aren’t just stickers. They’re assurance of independently verified quality. Always ask your supplier for documentation.

FAQ

Will the equipment be indoors or outdoors?

This is one of the most important considerations. Outdoor environments expose enclosures to rain, UV rays, fluctuating temperatures, and even snow or sleet. For outdoor use, enclosures must meet ratings like NEMA 3, 3R, 4, or 4X, or IP65/IP66, to withstand environmental challenges. Indoor settings, while generally more controlled, can still pose risks like dust, humidity, and oil exposure—common in factories or warehouses. NEMA 12 or IP54/IP55 might be more suitable here. Always match the rating to the environment to ensure longevity and performance.

Is there water spray, washdown, or submersion risk?

If your equipment is in a location with frequent water exposure—like food processing, breweries, or outdoor industrial zones—then water ingress protection is non-negotiable. For light splashes, IP54/IP55 or NEMA 2/12 may suffice. However, for hose-downs or sanitation processes, you’ll need IP66/IP69K or NEMA 4/4X. For submerged applications like marine or underground use, IP67/IP68 or NEMA 6/6P is required. Choose accordingly to avoid water damage and short circuits.

Will chemicals or salt air be present?

Chemical vapors, cleaning agents, or salty environments (like coastal areas) can quickly degrade ordinary enclosures. If your equipment will be exposed to corrosive substances, you’ll need enclosures rated for chemical resistance—like NEMA 4X, which typically features stainless steel or special polymers. IP ratings don’t explicitly address corrosion, so NEMA provides the more suitable guidance here. Ignoring this condition could lead to rapid material breakdown, component failure, or dangerous malfunctions over time.

Is there a risk of dust or powder accumulation?

Dust may seem harmless, but in electronics, it can cause overheating, short circuits, or even fires. In industries like woodworking, textiles, agriculture, or mining, dust-tight enclosures are essential. IP ratings like IP5X or IP6X and NEMA 12 or 13 are ideal for such dusty environments. When fine powders are present, especially combustible ones, you’ll need enclosures that also resist ignition—meaning potentially NEMA 9 or explosion-proof options depending on the classification.

Is the area classified as hazardous (Class I, II, etc.)?

If your equipment is located in areas with flammable gases, vapors, or dust—such as petrochemical plants or grain silos—it must comply with the National Electrical Code (NEC) hazardous location classes. For Class I (flammable gases/vapors), NEMA 7 or 8 enclosures are designed to contain internal explosions. For Class II (combustible dusts), NEMA 9 enclosures are required. These ratings ensure that enclosures will not ignite external hazardous atmospheres, offering life-saving safety and compliance assurance.

Conclusion

The bottom line? Ingress Protection (IP) and NEMA enclosure ratings aren’t just labels—they’re lifelines for your equipment. Knowing the difference means the difference between long-term reliability and preventable failure.

We’ve lived this—not just in test labs, but out in the field. As manufacturers of critical cabinet accessories, we’ve helped companies across energy, food processing, telecommunications, and manufacturing build systems that last. And we do it with one principle: the rating must match the risk.

Use this article as your go-to guide. Bookmark it, print it, share it with your team. Whether you’re a design engineer, an integrator, or a buyer, getting your enclosure rating right is one of the smartest investments you’ll ever make.

Because when the dust settles (or the water sprays), only the well-protected survive.