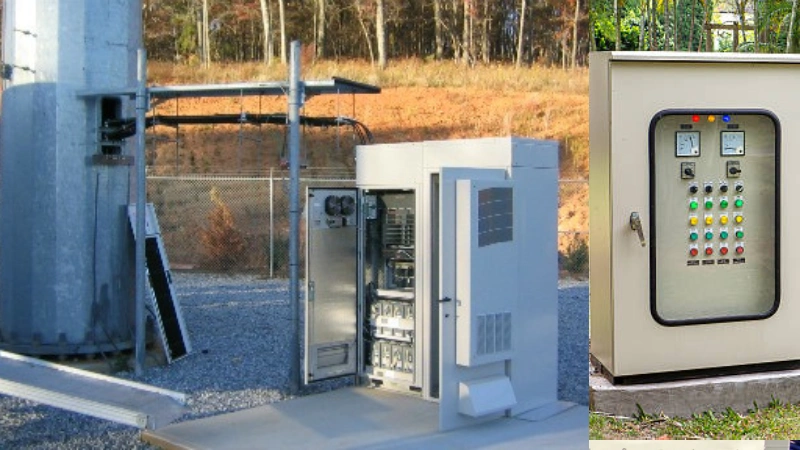

When it comes to deploying an Outdoor Telecom Cabinet, protection against weather, dust, and heat is vital. Choosing the right IP protection class ensures long-term reliability, reduced failures, and minimal maintenance costs.

Outdoor Telecom Cabinet: What IP Protection Class Necessary

When it comes to outdoor telecom cabinets, your IP (Ingress Protection) rating isn’t just a badge—it’s a survival guarantee. We’ve engineered, tested, and deployed hundreds of outdoor telecom cabinets equipped with customized fans, filters, and air-conditioning units, and our real-world experience shows that choosing the right IP rating can mean the difference between smooth operation and catastrophic failure. Let’s dive deep into why IP matters, how to pick the right class, and how our specialized manufacturing approach ensures both weather sealing and internal airflow—without compromise.

Why IP Ratings Matter for Outdoor Telecom Cabinets

Imagine this: your critical telecom gear is mounted in a cabinet outside, smack in the middle of a sudden downpour or a dust storm. What do you want? A weatherproof Telecom Shelter or a sieve?

IP ratings define how well a cabinet resists dust and water ingress. But in practical terms, it’s about uptime, safety, and total cost of ownership. One of our distributor partners recently shared a truth borne from field data:

“Ever since switching to your IP66-rated cabinets, our field-related returns dropped by nearly 70%. That’s not hype—it’s hard numbers on improved reliability and service efficiency.”

We’re not surprised. With subpar protection, moisture and particulate can corrode connectors, short circuits, or degrade wireless transmissions. Worse yet, on-site technicians risk electric shock during routine inspections.

We also get praise from end-users:

“After four hurricanes, not a drop of water inside. And the fans kept everything cool. I’ve got to say: this is rock-solid engineering.”

That feedback comes from a telecom tower operator in coastal Florida, one of the harshest environments imaginable. Our designs combine well-engineered IP sealing with active fan/heater/AC modules to maintain a stable internal climate. That’s how we balance seal and breathability—a core philosophy at our manufacturing operation.

Demystifying the IP Code – It’s Not Just Numbers

Let’s decode “IP66”. According to IEC 60529 / EN 60529, the first numeral refers to protection against solids (dust), the second to liquids (water)—but the real world demands practical interpretation.

First digit:

- 0 – No protection

- 4 – Protected against objects larger than 1 mm (wires, screws)

- 5 – Limited dust ingress permitted; sufficient to avoid impairing equipment

- 6 – Dust-tight; complete protection

Second digit:

- 5 – Protection from low-pressure jets (≥6.3 L/min at 30 kPa)

- 6 – Protection from high-pressure jets (≥12.5 L/min at 100 kPa)

- 7 – Temporary immersion to 1 m

- 9K – High-temperature, high-pressure water jets

Telecom infrastructure often cites NEMA ratings too (like NEMA 4, 4X). Roughly, NEMA 4X equates to IP66, including corrosion resistance. But since global deployments rely on IEC, we refer to IP ratings primarily—and test accordingly through certified labs like Intertek and UL.

In short:

- IP55 = light dust + low-pressure water jets

- IP56 = light to moderate dust + high-pressure water jets

- IP66 = completely dust-tight + high-pressure water jets

- IP67 = fully dust-tight + temporary water immersion

- IP69K = dust-tight + high-temperature, high-pressure cleaning

Selecting IP isn’t about chasing the highest digit—it’s about matching environmental risks with protection levels.

Matching IP Ratings to Environments

Experience teaches what theory can’t. Here’s how we’ve matched IP classes to real-world conditions:

Urban and Suburban Sites (Light Dust, Splash)

For rooftop pods or street-side cabinets in cities, IP55 is often sufficient. It wards off most dust and stands up to rain or occasional cleaning jets. Longevity remains uncompromised, and cost stays reasonable.

Coastal or Industrial Zones (Heavy Dust, Salt, High-Pressure Wash-downs)

Here, debris, salt corrosion, and routine wash-downs are par for the course. We recommend IP56 or IP66:

- IP56: High dust protection and robust water jet resistance.

- IP66: Adds full dust-tight performance—useful if the equipment inside is highly sensitive.

A recent project at a chemical plant used IP66 cabinets; after a year, engineers confirmed zero particle ingress or board corrosion.

Flood-Prone or Immersion Risk Areas

Near coastlines or flood zones, occasional submersion is possible. IP67 cabinets give you peace of mind—and often preserve electronics even after standing in water for a few inches.

Industrial Hygiene or Food-grade Wash Environments

Food plants or hospitals need high-pressure, hot-water cleaning. That demands IP69K rated enclosures—a rare but viable requirement we can custom-build.

Extreme Environments (Deserts, Arctic, Broadcast Towers)

Here, specifics matter: fine dust, extreme temperature swings, wind-driven sand, ice:

- IP66 or IP67 tend to be the base.

- Add thermal insulation, heater pads, humidity sensors, and servo-controlled fans to maintain internal conditions.

Remember: more isn’t always better. For example, in humid tropics, a fully sealed IP67 cabinet without moisture escape strategies can trap condensation. That’s why our designs include breathable filters, silica cartridges, drain channels—even hydrophobic valves to vent humidity while keeping dust and water out.

Balancing Ventilation and Sealing – Our Specialty

IP sealing alone might protect, but without active thermal control, internal moisture and heat can cripple operations. That’s where our expertise lies: stacking air-flow intelligence with sealing robustness.

Fan-Driven Filtered Ventilation

Recommended products

Each cabinet features multi-stage filters (pre-filter + HEPA or ULPA optional) funneling fresh air without letting in contaminants. Fans are sized to match cooling needs—typically 10 CFM per watt of heat dissipation.

Thermostatically-Controlled Air-Conditioning

Recommended products

Our AC modules are IEC and UL certified, ranging from 500 W to 1500 W output. They maintain internal temperatures within ±2 °C. Plus, auto condensate evacuation prevents pooling.

Humidity Management

We incorporate:

- Drains on cabinet floors

- Hydrophobic vent valves to equalize pressure while shedding moisture

- Desiccant or silica packs for sensitive electronics

- Humidity sensors paired with fan speed modulation

Heat vs Seal Balance

A real-world campaign in Arizona showed a sealed IP66 cabinet with no airflow cooked to 70 °C inside. We retrofitted it with filtered fans and AC—it dropped internal temperature by 25 °C, doubling component life expectancy.

That’s why we’re fan-cooled AND sealed—keeping dust out while breathing right.

Standards & Certifications Backing Our Products

We don’t chase fancy IP labels; we earn them through certified testing:

- IEC 60529 / EN 60529 – IP test standard conducted via certified labs.

- NEBS GR-78 – telecom-grade testing for vibration, fire, and durability.

- ANSI/TIA‑942‑A – commercial telecommunications cabling standard.

- NEMA 4X compliance – moisture and corrosion resistance.

- UL / CE approval on AC units; fans meet RoHS/CE/EMC/FCC standards.

- Intertek / ISO independent validation of environmental protection ratings.

Clients receive Certificates of Conformance, Test Reports, and Serial-Number Traceability. That transparency is a big differentiator in regulated or mission-critical projects.

Customer Testimonials & Wholesale Feedback

We’re proud when clients speak out—that feedback is real-world proof:

- Wholesale Partner (North America) “We used to get field failure rates near 15%. After switching to your IP66 cabinets, we’re down to 5%, even with fewer service calls. Plus, techs love how quickly they can change filters or fans.”

- Coastal Telecom Tower (Florida) “After four consecutive storms, zero water ingress. Cabinet stayed below 45 °C inside in mid-summer—our previous units peaked at 65 °C. We were seriously impressed.”

- Industrial Data Integrator (Midwest) “Your modular fan/AC combo is a game-changer. We no longer mount rooftop units. Downtime dropped by 30%—and so did energy costs.”

- Global Defense Contractor “Certification documentation was on point. We plugged your test data directly into our compliance package—saved us weeks.”

Shipping hundreds of units annually to wholesalers and end-users, this feedback consistently drives repeat business and referrals.

Common Misconceptions – Busted

“Higher IP is Always the Answer”

It’s tempting to say IP67 or IP69K all the way, but that’s like using a chainsaw to slice bread. Overspecing can make cabinets too sealed—leading to heat stress and condensation issues, unless you pair them with smart ventilation systems.

“Waterproof Means Floodproof”

An IP67 label says “temporary submersion up to 1 m.” That doesn’t mean long-term flood protection or wave impact. For sustained immersion, you need custom gasket seals, potting compounds, or connectors designed for underwater use.

“Seal Will Keep Moisture Out”

Seals prevent wetting in, but they also keep moisture in. That’s why we engineer humidity escape—and monitor conditions internally. A sealed but humid internals can corrode connectors faster than rain ever could.

How to Choose the Right IP Class for Your Cabinet

Here’s a step-by-step checklist we’ve refined over thousands of installations:

- Site/Risk Assessment

- Rain? Flood risk? Dust? Wildlife intrusion?

- For light rain + dust: IP55 or IP56.

- For salt air, spray, or wash-downs: IP56/IP66.

- For immersion possibility: IP67 (+ extra sealing).

- For food-grade/hygiene: IP69K.

- Equipment Inside

- Heat-generating radios/servers = AC + fan.

- Humidity-sensitive parts = humidity control modules.

- Maintenance Frequency

- Frequent access? Consider lower IP with easy gasket replacement.

- Rare access? Install high IP with integrated filters.

- Budget Considerations

- IP55 cabinets cost 20–30% less than IP66, but long-term failure cost may exceed savings.

- Filter/fan/AC modules pay for themselves via reduced service calls.

- Future-Proofing

- Plan for environmental changes—construction, new dust sources, new gear.

Example outcome:

For a coastal telecom base station, we specified:

- IP66 rating

- RC-rated stainless steel filter box with HVAC

- Drift-resistant fan module

- Humidity sensors + hydrophobic vents

This setup operated flawlessly for three years without a service call.

Why Choose Us: Voice of the Expert Manufacturer

Deep Component Expertise

We don’t just slap on off-the-shelf fans. We engineer fan units, filters, and AC modules for IP cabinet use. We’ve tested hundreds of permutations to optimize airflow vs. power draw vs. seal effectiveness.

Modular, Serviceable Design

Our side-hinged panels, removable fan/filter trays, and external drip guards make field servicing easy—without risking seal damage. Replacement parts (gaskets, fan assemblies) are stocked worldwide.

Proven Innovation Pipeline

We’re currently developing:

- Auto-adjusting vents responding to internal humidity and pressure

- Smart telemetry suites for remote monitoring of cabinet conditions

- Eco-mode AC units with solar or DC integration for green deployments

Summary & Call to Action

Choosing the right IP-rated cabinet is more than ticking specs—it’s about ensuring proven reliability, maintaining airflow and cooling, and delivering real-world performance. Here’s what to do next:

- Bookmark this guide for design or procurement discussions

- Share it with your team or colleagues who face field failures

- Let’s talk—we’ll review your site, calibration needs, gear inside—and propose a turnkey solution, down to the fan, filter, AC combo.

Remember: rain, dust, heat, and corrosion aren’t just nuisances. They’re threats. Protecting your telecom assets means taking proactive, engineered measures—not hoping that IP numbers alone will do the job.

FAQ

What IP rating do I need for a telecom cabinet in a rainy urban area?

Typically IP55 or IP56. Offers sufficient dust and rain defense. Prefer IP56 if frequent wash-down or hose cleaning occurs.

Is IP67 necessary for rooftop telecom boxes?

Not usually. Only opt for IP67 if there’s actual risk of flooding or immersion. Otherwise, IP66 is sufficient and easier to ventilate.

Can a high IP rating cause overheating?

Yes. If the cabinet is too sealed, heat and humidity accumulate. Our design includes filtered fans, AC modules, and humidity relief valve to prevent internal stress.

Do you provide IP69K-grade cabinets?

Yes, on request. We build them per NEMA 4X/IP69K standards—suitable for food processing or clean-room wash-downs.

Are your cabinets NEBS-compliant?

Absolutely. We meet NEBS GR‑78, NEBS Input Criteria, and ANSI/TIA‑942‑A for telecommunications infrastructure.

How often should I service the seals?

Inspect annually. In harsh environments, gaskets last ~5 years. We provide offline gasket kits and instructions to keep local technicians efficient.

Conclusion

This isn’t just a guide—it’s your field-tested blueprint. Selecting the right IP rating for your outdoor telecom cabinet isn’t about chasing the highest number; it’s about understanding your environment, your equipment needs, and how to maintain seal + circulation synergy. When you combine that with proven manufacturing, global certifications, modular service design, and real-world performance data—you don’t get just a cabinet. You get peace of mind.

If you’re working on a deployment—rainy streets, offshore towers, desert hubs—bookmark this, share with your team, and let’s collaborate. We’ll design, certify, and deliver a tailored outdoor cabinet that stands up to whatever your site throws at it.