This blog delves into the distinctions between shorting blocks and terminal blocks, two common components in electrical wiring. While both facilitate connections, their fundamental purposes and functionalities differ significantly. Electrical Enclosure and industrial machinery are the most common application scenarios

Understanding these differences is crucial for proper circuit design and maintenance. We’ll explore their unique features, applications, and how to choose the right component for your specific electrical needs.

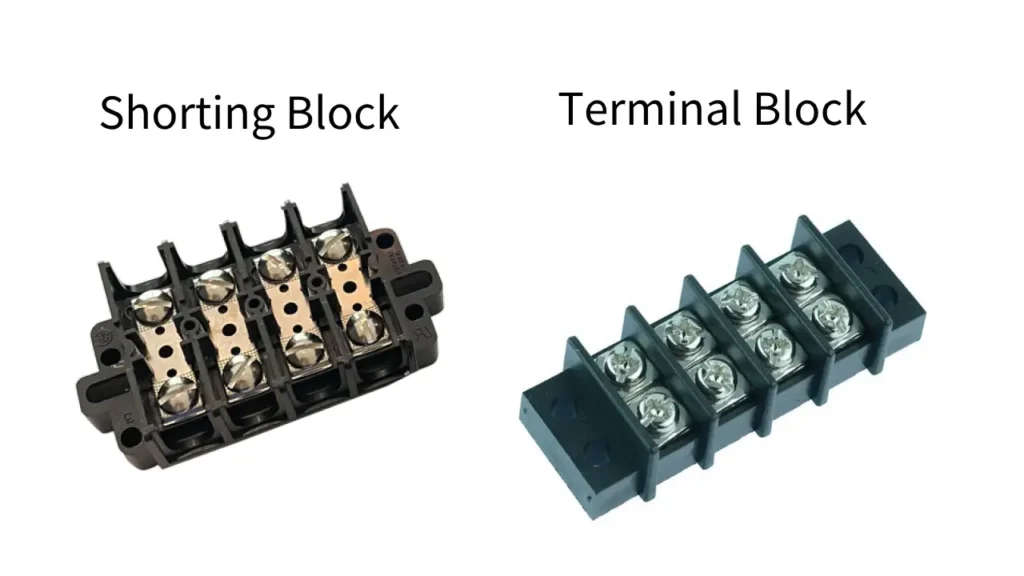

What is a Shorting Block?

A shorting block is a mechanical device designed to intentionally create a temporary or permanent short circuit between one or more electrical points in a circuit. These blocks are commonly used in electronic testing, diagnostic environments, and in applications involving current transformers (CTs), where they safely bypass the CT during maintenance or testing to prevent dangerous high voltages from forming.

They typically consist of a conductive material with terminals that can be easily connected or disconnected to bridge circuits, facilitating quick and safe electrical modifications for troubleshooting or system adjustments.

What is a Terminal Block?

Recommended Terminal Blocks

A terminal block is an electrical connector that provides a secure, organized, and insulated point for connecting two or more wires. It consists of a modular housing, typically made of plastic or ceramic, which contains a conductive metal strip with connection points, often screw terminals or spring clamps.

Terminal blocks are widely used in industrial, commercial, and residential electrical systems to simplify wiring, improve safety by preventing exposed wires, and facilitate easier maintenance and troubleshooting of electrical circuits. They allow for the efficient routing and distribution of power and signals within a control panel or system.

Shorting Block vs Terminal Block

Shorting blocks and terminal blocks are fundamental components in electrical systems, each serving distinct roles in managing connections. Understanding their differences is crucial for proper circuit design and maintenance. This comparison highlights their unique characteristics and applications.

Functionality

Shorting blocks are specifically designed to create a temporary or permanent electrical connection, effectively “shorting” two or more points in a circuit. Their primary purpose is to bypass or bridge specific circuit paths, often for testing, calibration, or reconfiguring a system without disconnecting individual wires. They act as a switchable link.

In contrast, terminal blocks are designed for the secure termination and organization of individual wires. They provide a fixed point where wires can be connected and disconnected reliably, serving as a clean interface between different parts of an electrical system or between equipment and field wiring. Their main function is to simplify wiring, improve safety, and facilitate maintenance.

Application

Shorting blocks are frequently found in environments requiring circuit isolation or bypassing, such as in current transformer (CT) circuits for metering and protection. They allow technicians to safely short the CT secondary during maintenance, preventing dangerous high voltages. They are also used in test setups where temporary connections are needed for diagnostics.

Terminal blocks are ubiquitous in control panels, distribution boards, and various industrial and commercial electrical installations. They are used for power distribution, signal wiring, and connecting field devices to control systems, providing a neat and easily identifiable method for wire management.

Design

Shorting blocks typically feature a mechanism that allows for the easy insertion or removal of a conductive link or screw to establish or break the short. Their design emphasizes the ability to quickly create or remove a connection between specific terminals, often with visual indicators for the shorted state.

Terminal blocks, on the other hand, are built with insulated housing and robust clamping mechanisms (like screws or springs) to securely hold individual wires. They are designed for long-term, stable connections and often feature modular designs that can be assembled into strips to accommodate many connections.

Connectivity

The operation of a shorting block involves manipulating a conductive element to bridge terminals, thereby creating a direct electrical path. This action effectively connects points that are otherwise isolated, allowing current to flow between them in a controlled manner.

Terminal blocks establish point-to-point connections where each wire is securely fastened to its designated terminal. They do not inherently create a short circuit; rather, they provide a safe and organized way to connect wires, ensuring electrical isolation between adjacent connections.

Safety Considerations

When using shorting blocks, significant safety precautions are paramount, especially in high-voltage or high-current applications. Improper use can lead to dangerous short circuits, arc flashes, or damage to equipment. They are tools for specific, controlled bypass operations.

Terminal blocks enhance safety by providing insulated enclosures for wire connections, reducing the risk of accidental contact or short circuits. They help maintain an organized wiring layout, which is crucial for preventing errors during installation and maintenance, thereby contributing to overall system safety.

Here is a table showing you the differences between shorting blocks and terminal blocks:

| Feature | Shorting Block | Terminal Block |

|---|---|---|

| Purpose | Create temporary/permanent short circuits | Securely terminate and organize individual wires |

| Function | Bypass, bridge, test circuits | Connect, distribute, and consolidate wires |

| Application | CT circuits, testing, circuit isolation | Control panels, distribution, general wiring |

| Design | Features a removable/insertable conductive link | Insulated housing with fixed wire clamping points |

| Connectivity | Creates a direct electrical path (short) | Provides secure, insulated point-to-point connection |

| Safety Role | Used for controlled bypass (requires caution) | Enhances safety by insulating connections |

How to Choose Shorting Blocks and Terminal Blocks

Choosing the right shorting blocks and terminal blocks requires careful consideration of several factors to ensure optimal performance, safety, and compatibility with your specific application.

- Current and Voltage Ratings: Always match the block’s current and voltage ratings to your circuit’s maximum operating parameters. Exceeding these limits can lead to overheating, component failure, or hazardous conditions, ensuring safe and reliable operation.

- Wire Gauge and Type: Select blocks compatible with the specific wire gauges (AWG/mm²) and types (solid, stranded) you will be using. Improper wire fit can cause loose connections, arcing, and unreliable electrical performance, impacting system integrity.

- Mounting Method: Consider the desired mounting method, such as DIN rail, panel mount, or PCB mount, to ensure easy installation and integration into your enclosure or system. Proper mounting ensures stability and accessibility for maintenance.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals or vibrations. Choose blocks made from materials resistant to these conditions for long-term durability and consistent performance.

- Specific Functionality: For shorting blocks, assess if you need features like disconnect options or visual indicators for the shorted state. For terminal blocks, consider features like fuse holders, disconnect levers, or integrated components to simplify wiring. Choosing the right shorting blocks and terminal blocks is critical for electrical system performance and safety. Key factors to consider include the specific application’s electrical requirements, environmental conditions, and desired connectivity, ensuring the selected components meet both current and future operational needs.

- Electrical Ratings: Always match the component’s voltage and current ratings to your circuit’s maximum demands. Over-specifying provides a safety margin for surges, preventing overheating and potential failures, ensuring long-term reliability and safety.

- Wire Compatibility: Verify that the block’s wire range (gauge/mm²) and type (solid/stranded) perfectly accommodate your wiring. Proper wire fit is crucial for a secure connection, preventing loose contacts, excessive resistance, or accidental disconnections, thus ensuring stable performance.

- Environmental Conditions: Consider the operating environment’s temperature, humidity, and exposure to dust or chemicals. Selecting blocks with appropriate IP ratings or material compositions ensures durability and reliable performance in harsh conditions, preventing premature degradation.

- Mounting and Space: Evaluate the available space and desired mounting method (e.g., DIN rail, PCB, panel mount). Choosing a compatible mounting type and an appropriately sized block ensures proper installation and ease of access for wiring and maintenance within your enclosure.

- Connection Method & Features: Decide between screw clamp, spring clamp, or push-in connections based on ease of use, vibration resistance, and wiring speed. Consider additional features like test points, fusing capabilities, or multi-level designs for enhanced functionality and simplified troubleshooting.

Conclusion

Shorting blocks and terminal blocks serve distinct purposes in electrical wiring.

Shorting blocks facilitate temporary or permanent connections between circuits, often for testing or configuration changes, while terminal blocks provide secure, organized points for connecting and terminating individual wires. Their primary difference lies in functionality: one enables selective bridging, the other fixed termination.

Choosing the right block depends entirely on the specific application’s needs for connectivity and circuit management. For all your wholesale terminal block requirements, consider sourcing from us.