Understanding terminal blocks is essential for electrical design, and the concept of a “pole” is fundamental. This blog post will demystify what a terminal block pole is, how it functions within a terminal block, and why this seemingly simple characteristic is crucial for effective electrical connections.

We’ll delve into the mechanics of how each pole facilitates the connection of individual wires, ensuring electrical continuity and isolation. Grasping this core concept is key to selecting the right terminal blocks for your specific application, optimizing both efficiency and safety.

What is a Terminal Block Pole

In the terminal of terminal blocks, a “pole” refers to a single, individual electrical connection point or circuit path within the block. Each pole consists of a conductive metal part (often copper alloy) housed within an insulating body, designed to securely terminate and connect one or more wires.

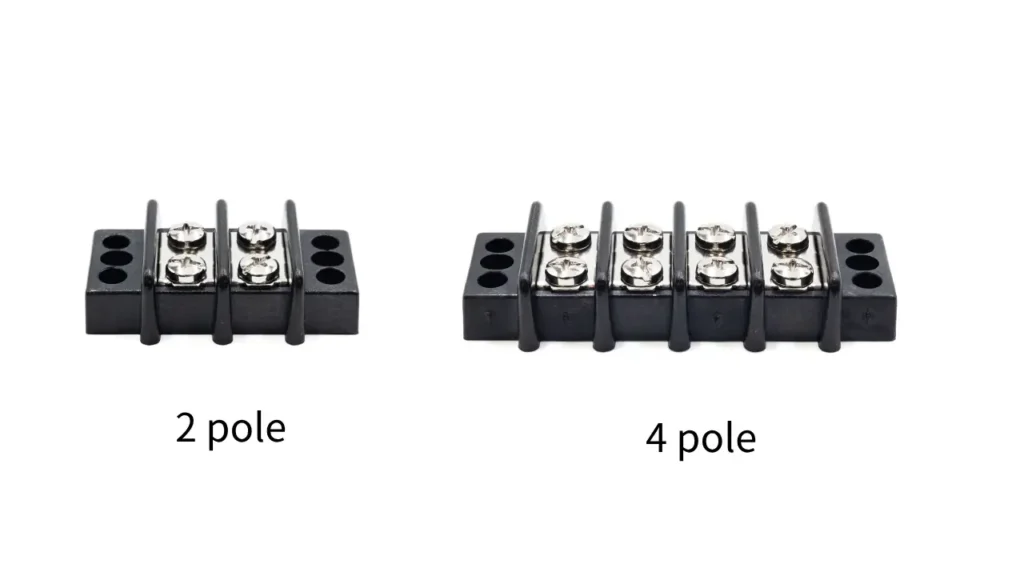

When a terminal block is described as “2-pole,” “3-pole,” or “multi-pole,” it indicates the number of distinct, isolated electrical circuits that the single block unit can manage. This allows for organized wiring and clear separation of different circuits within a compact space, enhancing both safety and ease of maintenance.

How Many Poles Do Terminal Blocks Have?

Recommended Terminal Blocks

Terminal blocks are designed with varying numbers of poles to accommodate diverse wiring needs, ranging from simple single connections to complex multi-circuit setups. The number of poles directly corresponds to how many individual wires or circuits a single terminal block unit can manage.

Single Pole Terminal Blocks

A single-pole terminal block provides one individual connection point. These are essentially modular units that can be combined to form a longer strip of connections. They are highly flexible, allowing users to create custom pole counts by snapping together as many single-pole blocks as needed for a specific application. This modularity is particularly useful for managing complex wiring layouts where precise numbers of connections are required.

Multi-Pole Terminal Blocks

Multi-pole terminal blocks come as a single, integrated unit with two or more connection points. These blocks are manufactured with a fixed number of poles, commonly seen in configurations like 2-pole, 3-pole, 4-pole, and often extending up to 12 or more poles in a single housing. They offer a compact solution for connecting multiple circuits in a single device, simplifying installation and providing a neat appearance for systems with recurring connection patterns.

Specialized Pole Configurations

Beyond standard single and multi-pole designs, terminal blocks can feature specialized pole configurations to address specific electrical functions. This includes multi-level terminal blocks, which stack multiple connection layers vertically to save space, and distribution blocks, which might have one input pole splitting into multiple output poles. These specialized designs offer enhanced functionality, such as power distribution, fusing, or switching, all within the integrated terminal block form factor.

| Pole Count | Description | Typical Applications |

| 1-pole | Single, individual connection point | Custom assembly of desired pole counts, grounding connections |

| 2-pole | Two individual connection points in one unit | Single-phase power connections (Line, Neutral) |

| 3-pole | Three individual connection points in one unit | Three-phase power systems (L1, L2, L3), motor connections |

| 4-pole | Four individual connection points in one unit | Three-phase with neutral (L1, L2, L3, N) |

| Multi-pole | More than four individual connection points | Complex control panels, large distribution systems |

Terminal Block Pole Functions

Each pole within a terminal block serves specific functions, contributing to the overall integrity and versatility of electrical connections. While the primary role of every pole is to provide a secure and insulated point for wire termination, different types of poles offer specialized capabilities that enhance safety, organization, and troubleshooting in electrical systems.

- Connection Point: The most fundamental function of a pole is to provide a secure and reliable point for joining two or more wires electrically. This ensures continuous current flow and mechanical stability for the connected conductors.

- Insulation and Isolation: Each pole is individually insulated from adjacent poles, preventing short circuits and electrical interference between different circuits. This isolation enhances the safety and reliability of the overall wiring system.

- Circuit Organization: Poles help in systematically organizing complex wiring by providing designated termination points for specific circuits or phases. This systematic arrangement simplifies installation and makes future modifications or troubleshooting much clearer.

- Testing and Troubleshooting Access: Many terminal block poles are designed with integrated test points, allowing electricians to easily and safely test circuit continuity, voltage, or current without disconnecting wires. This significantly speeds up diagnostics.

- Protection (for specialized poles): Certain specialized poles integrate protective devices like fuses or disconnect mechanisms directly. This provides overcurrent protection or allows for quick circuit isolation for maintenance, enhancing system safety and simplifying design by combining functions.

How to Select the Best Terminal Blocks?

Selecting the best terminal blocks, particularly concerning their pole configurations, is paramount for optimizing the performance, safety, and efficiency of your electrical system. The number and type of poles directly dictate how effectively wires are organized, circuits are isolated, and maintenance is simplified. An informed decision based on your specific application requirements will prevent wiring complexity, potential faults, and unnecessary downtime.

To ensure you choose the best terminal blocks tailored to your project’s pole-related needs, consider these critical aspects:

Determine Required Pole Count:

- Number of Circuits: Accurately count the distinct electrical circuits you need to connect at a specific point. For simple power or control lines, a 2-pole or 3-pole block might suffice.

- Future Expansion: Anticipate any potential future additions or modifications to your system. Selecting terminal blocks with a slightly higher pole count than immediately necessary can provide flexibility for future expansion without needing to replace entire blocks.

- Modularity vs. Fixed Blocks: Decide if you prefer the flexibility of single-pole modular blocks (snapping together to achieve any pole count) or the compactness of fixed multi-pole blocks (e.g., 2-pole, 3-pole units), which are often better for recurring connection patterns.

Consider Pole Functionality:

- Standard Feed-Through: For basic wire-to-wire connections, standard feed-through poles are ideal. They simply pass the electrical signal through the block.

- Grounding Poles: For safety, ensure you have dedicated grounding poles (often green/yellow) for connecting protective earth conductors. These are designed to provide a secure and reliable ground path.

- Specialized Poles (Fuse, Disconnect, Diode): If your application requires integrated protection or switching, consider terminal blocks with poles that incorporate fuses, disconnect levers, or diodes. This saves space and simplifies wiring compared to external components.

- Test Point Poles: For ease of troubleshooting and maintenance, look for poles that include built-in test points, allowing for voltage or current measurements without disturbing the wiring.

Space Optimization and Wiring Density:

- Multi-Level Poles: For applications with limited panel space but numerous connections, multi-level (two-tier, three-tier) terminal blocks maximize wiring density by stacking connection points vertically within a single block footprint.

- Compact Design: Compare the physical dimensions of different terminal blocks. Some manufacturers offer ultra-slim designs for high-density applications where every millimeter counts.

Connection Technology Per Pole:

- Wire Type and Gauge: The chosen connection technology for each pole (screw, push-in, spring-clamp) should match the wire types (solid, stranded, ferruled) and gauges you are using. Push-in connections are excellent for speed with solid/ferruled wires, while screw clamps offer strong, versatile connections.

- Vibration Resistance: For environments with high vibration, ensure the connection technology of the poles provides superior wire retention (e.g., spring-based technologies).

Conclusion

This discussion on terminal block poles underscores their fundamental role in defining connection capacity and circuit isolation within electrical systems. Understanding what a “pole” signifies—each individual conducting path—is crucial for designing efficient and safe wiring configurations. The versatility offered by single, multi-pole, and specialized terminal blocks allows for precise circuit organization tailored to diverse application needs.

The effective utilization of terminal block poles directly contributes to streamlined installations, simplified troubleshooting, and enhanced system reliability. By carefully selecting the appropriate number and arrangement of poles, engineers and technicians can optimize space, reduce wiring complexity, and ensure robust electrical connections, ultimately improving overall operational safety and efficiency.

For projects requiring high-quality, wholesale terminal blocks with reliable pole configurations, consider Linkwell Electrics. Their extensive range and commitment to precision engineering provide dependable solutions for managing electrical connections effectively across various industrial and commercial applications.