In electrical distribution systems, both terminal blocks and bus bars play crucial roles in connecting and organizing wires. While they might appear similar in their function of managing electrical connections, their fundamental designs and applications differ significantly. Understanding these distinctions is key to selecting the appropriate component for specific power distribution needs.

Terminal blocks excel at routing multiple individual circuits, providing distinct, insulated connection points for specific wire pairs. Bus bars, on the other hand, are designed for power distribution, consolidating multiple connections to a single, common electrical point for high-current applications. This blog will delve into their unique characteristics, helping you differentiate between them.

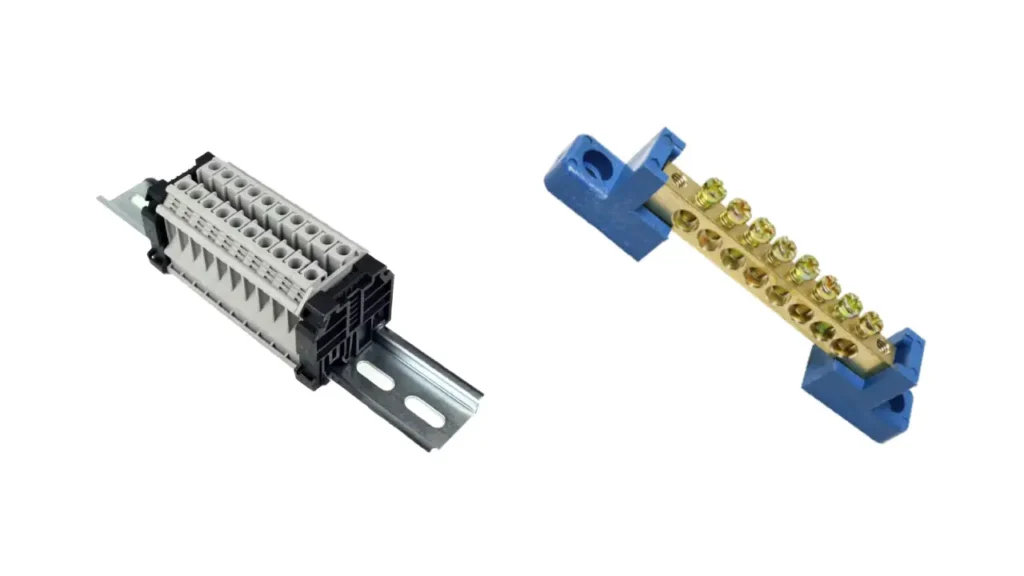

What is a Terminal Block

A terminal block is a modular, insulated electrical connector designed to secure and organize two or more wires within a circuit. It consists of an insulating body with a current-carrying element and a clamping mechanism (like a screw, spring, or push-in) to terminate wires.

Terminal blocks provide a safe, convenient, and highly organized method for connecting and disconnecting individual wires, simplifying wiring layouts, and facilitating maintenance and troubleshooting in various electrical and electronic systems.

Recommended Terminal Blocks

What is a Bus Bar

A bus bar (or busbar) is a metallic strip, bar, rod, or tube, typically made of copper or aluminum, used to conduct large amounts of electrical current and distribute power within an electrical system.

Unlike individual wires that often connect one point to another, bus bars serve as a common junction where multiple electrical circuits or components can tap into a shared power source, simplifying wiring layouts and making systems more organized and efficient, especially in high-current applications like switchgear, panel boards, and battery banks.

Terminal Block vs Bus Bar

When designing electrical systems, understanding the fundamental differences between terminal blocks and bus bars is paramount. While both components facilitate electrical connections, their distinct designs and purposes make them suitable for very different applications. Choosing the correct component ensures efficiency, safety, and optimal performance of your electrical infrastructure.

This comparison will delve into their core features, the benefits each offers, their respective pros and cons, and their typical applications, providing a comprehensive overview to help you make informed decisions for your wiring needs.

Features

Terminal blocks are modular, insulated connectors designed to secure and organize individual wires. They feature separate connection points, typically with screw, spring, or push-in clamping mechanisms, allowing for individual wire termination and isolation. This design provides a structured way to manage multiple independent circuits within a confined space.

Bus bars, on the other hand, are solid metallic strips, rods, or bars, usually made of copper or aluminum, designed for high current conduction and distribution. They serve as a single, common electrical node where multiple devices or circuits can draw power from or connect to, consolidating large current pathways without individual insulation for each connection point along their length.

Benefits

Terminal blocks excel in providing organized and flexible wiring solutions for low to medium current applications. Their modularity allows for easy addition or removal of connections, simplifying troubleshooting and maintenance tasks. They also offer excellent electrical isolation between adjacent circuits, enhancing safety and preventing accidental shorts.

Bus bars offer significant advantages in high-current power distribution due to their robust construction and low electrical resistance. They can handle substantial current loads with minimal voltage drop and heat generation, leading to greater energy efficiency. Their compact design also saves space compared to routing numerous large-gauge cables for the same power capacity.

Pros & Cons

Terminal blocks offer pros such as versatility, easy modification, and excellent individual circuit isolation. However, their cons include a lower current carrying capacity compared to bus bars and potentially higher space requirements in very high-density applications due to their individual segregated nature. They are also less ideal for consolidating extremely high currents.

Bus bars boast pros like superior high-current handling, excellent heat dissipation, and space efficiency in power distribution. Their cons, however, can include higher initial material and installation costs, less flexibility for individual circuit modification once installed, and the potential for a single point of failure if not properly designed and protected.

Applications

Terminal blocks are widely used in control panels, industrial machinery, and automation systems where individual circuit termination and organization are critical. They are ideal for routing sensor signals, control wiring, and low-power distribution, offering a clean and manageable interface for complex systems that require frequent access for testing or changes.

Bus bars are predominantly found in high-power applications such as switchgear, distribution boards, substations, and large battery banks. They are indispensable for centralizing power distribution, connecting main power feeders to multiple branch circuits, and in situations where high currents need to be efficiently and compactly routed.

Cost Considerations

The initial cost of terminal blocks is generally lower per connection point, making them a more economical choice for smaller installations or when many individual, lower-current circuits are needed. Their modular nature also allows for scalable purchasing, acquiring only what’s immediately necessary.

Bus bars typically involve a higher upfront investment due to the material cost (copper or aluminum) and specialized fabrication, especially for custom designs. However, for high-current applications, their long-term benefits in terms of efficiency, space saving, and reduced labor for managing multiple large cables can offset the initial expenditure.

Maintenance and Flexibility

Terminal blocks offer high flexibility for maintenance and modifications. Individual wires can be easily disconnected, tested, and reconnected without disturbing adjacent circuits, simplifying troubleshooting and component replacement. Their clear labeling options also contribute to faster identification of specific circuits during maintenance routines.

Bus bars, while robust, offer less flexibility for individual circuit modifications once installed, as connections are often bolted directly. Maintenance might involve de-energizing a larger section of the system. However, their simple, centralized design can reduce the number of potential points of failure compared to an equivalent number of individual large cables, leading to fewer maintenance events overall for the primary power path.

Here’s a comparison table summarizing the differences:

| Feature/Aspect | Terminal Blocks | Bus Bars |

|---|---|---|

| Primary Function | Individual wire termination, circuit organization, signal routing | High-current power distribution and consolidation |

| Current Handling | Low to medium current (typically up to ~100-200A per pole, varies by size) | High to very high current (hundreds to thousands of amperes) |

| Structure | Modular, insulated housing with separate clamping points for each wire | Solid metallic conductor (copper/aluminum) bar/strip, with connection points along its length (often bolted) |

| Insulation | Integral insulation for each connection point | Often relies on air gap, external insulators, or specialized coatings for insulation, though connections are typically uninsulated |

| Space Efficiency | Can be space-efficient for many individual, smaller wires; modularity allows dense packing | Highly space-efficient for consolidating many large-gauge power cables; reduces bulk compared to multiple large wires |

| Flexibility | High flexibility for modifications, additions, and troubleshooting of individual circuits | Lower flexibility for individual circuit changes once installed; modifications often require more significant system changes |

| Typical Use Cases | Control panels, automation, sensor wiring, signal distribution, general industrial wiring | Switchgear, main distribution boards, motor control centers, battery banks, power generation, data centers |

| Cost | Generally lower cost per individual connection point; scalable | Higher initial material and fabrication cost, but often cost-effective for high-current applications due to efficiency and reduced cable use |

| Maintenance | Easy to isolate and troubleshoot individual circuits; simple wire addition/removal | Maintenance may involve de-energizing larger sections; less straightforward for individual branch circuit changes; robustness can lead to fewer primary circuit issues |

How to Choose Terminal Block and Bus Bar

Choosing between terminal blocks and bus bars, or selecting the right type of each, depends entirely on the specific demands of your electrical project. It’s a decision driven by balancing current requirements, space limitations, safety considerations, and long-term flexibility.

- Current Capacity: For high-current distribution (hundreds to thousands of amps), bus bars are generally superior due to their low resistance and excellent heat dissipation. For individual circuit connections with lower to medium currents, terminal blocks are ideal.

- Space and Density: In applications requiring numerous individual connections in a compact space, multi-level terminal blocks can be very efficient. For consolidating high-current power in a small footprint, bus bars are often more effective.

- Flexibility and Maintenance: If frequent modifications, additions, or troubleshooting of individual circuits are anticipated, the modularity of terminal blocks offers significant advantages. Bus bars are less flexible for individual circuit changes once installed.

- Isolation and Safety: Terminal blocks inherently provide excellent insulation and isolation between individual circuits, enhancing safety. While bus bars are robust, their exposed nature for connections means additional insulation or enclosure considerations for safety.

- Cost and Application: For numerous low-current connections, terminal blocks are typically more cost-effective. For heavy-duty power distribution where efficiency and high current handling are paramount, bus bars offer long-term value despite potentially higher initial costs.

Conclusion

Understanding the distinctions between terminal blocks and bus bars is crucial for effective electrical system design. While both facilitate electrical connections, terminal blocks offer granular, insulated wire termination, ideal for organizing individual circuits and signals. Bus bars, conversely, provide high-current distribution points for multiple connections, excelling in power distribution.

The choice between them hinges on application-specific needs: terminal blocks for control wiring and diverse circuit management, and bus bars for heavy power distribution where many loads share a common power source. Optimal selection ensures system efficiency and safety.

For all your wholesale terminal block needs, engineered for diverse applications and environments, contact us. We offer robust and reliable solutions to fit all your industrial and commercial requirements in Japan.