Standard control transformers in 2025 set the benchmark for industrial power systems. Their technical specifications keep transformers operating with precision and safety. Manufacturers and users both rely on transformer standards to meet strict safety codes, boost efficiency, and guarantee compliance in every industrial setting. Today’s transformers must deliver reliable voltage, handle tough loads, and protect sensitive circuits. Up-to-date transformer specs play a huge role in safety, energy savings, and overall performance. The global market for transformers grows quickly, fueled by demand for better power distribution and voltage regulation.

- The industrial control transformer market continues to expand due to rising demand for efficient power distribution.

- The Asia Pacific region, especially China and India, stands out as a major market thanks to rapid industrialization.

- The market for control transformers is expected to reach $12,000 million by 2030, with a CAGR of 6.0% from 2024 to 2030.

- Growth is driven by the need for voltage regulation in many industrial applications.

Linkwell stands out as a trusted global supplier of certified transformers, supporting industries that depend on safety and reliable transformer performance. The Purpose of a Standard Control Transformer is To provide stable voltage and protect sensitive equipment, making transformers essential for modern industry. Up-to-date technical specifications in transformers ensure compliance with the latest safety standards, optimize energy use, and enhance transformer reliability. Every transformer in 2025 must meet these expectations to keep up with industry demands and deliver long-term safety.

Recommended products

Key Takeaways

- Control transformers are essential for providing stable voltage to industrial control circuits, ensuring reliable operation of automated systems.

- Linkwell transformers meet the latest safety and efficiency standards, including UL, CE, and ISO certifications, giving users confidence in their performance.

- Choosing the right transformer involves matching voltage, current, and frequency to your specific application needs for optimal safety and efficiency.

- Energy efficiency is a key feature of Linkwell transformers, helping to reduce costs and extend the lifespan of equipment in demanding industrial environments.

- Customization options are available to meet unique project requirements, ensuring that users get the perfect transformer for their specific needs.

Technical Specs for 2025 Control Transformers

Control transformers in 2025 deliver more than just power. They set the pace for industrial safety, reliability, and transformer efficiency. Linkwell’s transformers meet the latest doe efficiency standards and safety standards, making them a top choice for panel builders and industrial users. Let’s break down the specs that matter most.

Voltage and Power Ranges

Voltage is the backbone of every transformer. In 2025, manufacturers design transformers to handle a wide range of voltages and power capacities. Linkwell’s control transformers step down high input voltage to safe levels for control circuits. They support everything from low voltage panels to medium voltage industrial setups.

Here’s a quick look at standard voltage and power ranges for control transformers:

| Voltage Category | Voltage Range | Power Capacity Range |

|---|---|---|

| Low Voltage | Up to 1kV | 50 kVA – 2.5 MVA |

| Medium Voltage | 1kV – 69kV | 2.5 MVA – 25 MVA |

| High Voltage | 69kV – 230kV | 25 MVA – 100 MVA |

| Extra High Voltage | 230kV – 400kV | 100 MVA – 400 MVA |

| Ultra High Voltage | Above 400kV | 400 MVA – 1,200+ MVA |

Most industrial control transformers operate in the low voltage range, stepping down from 480V or 600V to 120V or 24V. Power ratings vary, but Linkwell offers models up to 7.5 kVA for demanding applications. The right voltage and power rating keep control circuits safe and efficient.

Frequency, Efficiency, and Insulation

Frequency plays a key role in transformer performance. Most transformers in 2025 run at 50Hz or 60Hz, depending on the region. Linkwell’s transformers support both frequencies, making them suitable for global use.

Transformer efficiency is a top priority. Manufacturers follow doe efficiency standards to reduce energy loss and cut costs. Linkwell’s transformers use copper windings and laminated cores to boost transformer efficiency. High transformer efficiency means less heat, lower bills, and longer life for equipment.

Insulation protects transformers from electrical stress. It keeps voltage stable and prevents dangerous discharges. Linkwell uses solid insulation like cellulose and epoxy resin, plus liquid insulation such as mineral oil for cooling. Some high-voltage transformers use gaseous insulation like air or SF₆. Proper insulation meets strict safety standards and helps transformers last longer.

Note: Insulation systems must comply with UL 1446, IEC 62114, IEC 60505, and IEC 61857. These standards ensure insulation can handle voltage stress and thermal loads.

Here’s a table showing common insulation materials:

| Insulation Material | Description |

|---|---|

| Solid | Cellulose, epoxy resin, pressboard; strong dielectric performance. |

| Liquid | Mineral oil, ester-based fluids; act as coolant and dielectric medium. |

| Gaseous | Air, SF₆; used in high-voltage designs for excellent dielectric performance. |

Certifications and Compliance (UL, CE, ISO)

Certifications prove a transformer meets global safety standards. Linkwell’s transformers carry UL, CE, and ISO 9001:2015 marks. These certifications show the transformer passed tough tests for safety, quality, and transformer efficiency.

| Certification | Description |

|---|---|

| UL | Essential for safety approval in the U.S. |

| CE | Mandatory for compliance in the EU. |

| ISO 9001:2015 | Recognized for quality management systems. |

Manufacturers must meet doe efficiency standards and safety standards to sell transformers worldwide. UL certification is key for U.S. installations. CE marking is required in Europe. ISO 9001:2015 shows the company follows strict quality management. Linkwell’s transformers meet all these requirements, giving users peace of mind.

- CE Marking: Required for all transformers in the EU.

- UL Certification: Needed for safety in U.S. indoor installations.

- ISO 9001:2015: Ensures quality management.

Control transformers in 2025 combine advanced voltage control, high transformer efficiency, and strong insulation. They meet doe efficiency standards and safety standards, making them reliable for every industrial application.

The Purpose of a Standard Control Transformer Is To

Safe Voltage Supply for Control Circuits

The purpose of a standard control transformer is to deliver steady voltage to control circuits in industrial environments. These transformers play a vital role in powering the brains of automated systems. When machines like CNC equipment, robotic arms, or conveyor belts need reliable operation, the transformer steps in to supply the right amount of low-voltage power. This steady voltage keeps relays, timers, and solenoids working smoothly, so machines do not act up or shut down unexpectedly.

Many industrial setups depend on transformers to regulate voltage. The purpose of a standard control transformer is to make sure control devices always get the power they need, even when the main supply fluctuates. Without this regulation, sensitive components could malfunction or wear out faster. Transformers help prevent these issues by providing a consistent and safe voltage level.

Here’s what makes these transformers so important in control circuits:

- They supply low-voltage power to control circuits, which is essential for safe machine operation.

- Transformers keep voltage stable, preventing erratic behavior in control components.

- They support reliable operation of relays, solenoids, and timers in automated machinery.

- The purpose of a standard control transformer is to maintain steady voltage, even in changing electrical environments.

- Transformers power control circuits in equipment like CNC machines, robotic systems, and conveyor belts.

Linkwell understands that the purpose of a standard control transformer is to protect both equipment and productivity. Their transformers are designed for global industrial use, offering energy efficiency and customization to fit any control panel or cabinet.

Electrical Isolation and Equipment Protection

Another key reason the purpose of a standard control transformer is to provide electrical isolation. This isolation separates the control circuit from the main power supply, which helps protect sensitive devices from electrical surges and faults. When a transformer offers electrical isolation, it shields both equipment and workers from dangerous voltage spikes.

Linkwell transformers go beyond just supplying steady voltage. They add layers of safety and reliability to every industrial application. The purpose of a standard control transformer is to ensure that control systems stay protected, even in harsh or unpredictable environments.

Take a look at how these transformers contribute to safety and reliability:

| Feature | Contribution to Safety and Reliability |

|---|---|

| Stable Voltage Output | Keeps sensitive equipment within safe limits, reducing voltage swings. |

| Electrical Isolation | Shields control devices from surges and faults, protecting both people and machines. |

| Noise Filtering | Reduces electrical noise, so control systems stay accurate and efficient. |

| Durability | Withstands tough conditions, ensuring long-term reliability. |

| Compact Design | Fits into tight spaces, making installation easier in crowded panels. |

| High Efficiency | Cuts down on energy loss, saving money and boosting system performance. |

| Short-Circuit Protection | Stops damage during faults, adding another layer of safety. |

| Versatility | Works across many types of control devices in industrial automation. |

The purpose of a standard control transformer is to combine steady voltage, electrical isolation, and robust protection in one package. Linkwell transformers use high-quality insulation and advanced design to deliver these benefits. Their transformers handle high inrush currents, filter out electrical noise, and provide reliable isolation for every control circuit.

Types and Applications of Industrial Control Transformers

Single-Phase and Three-Phase Options

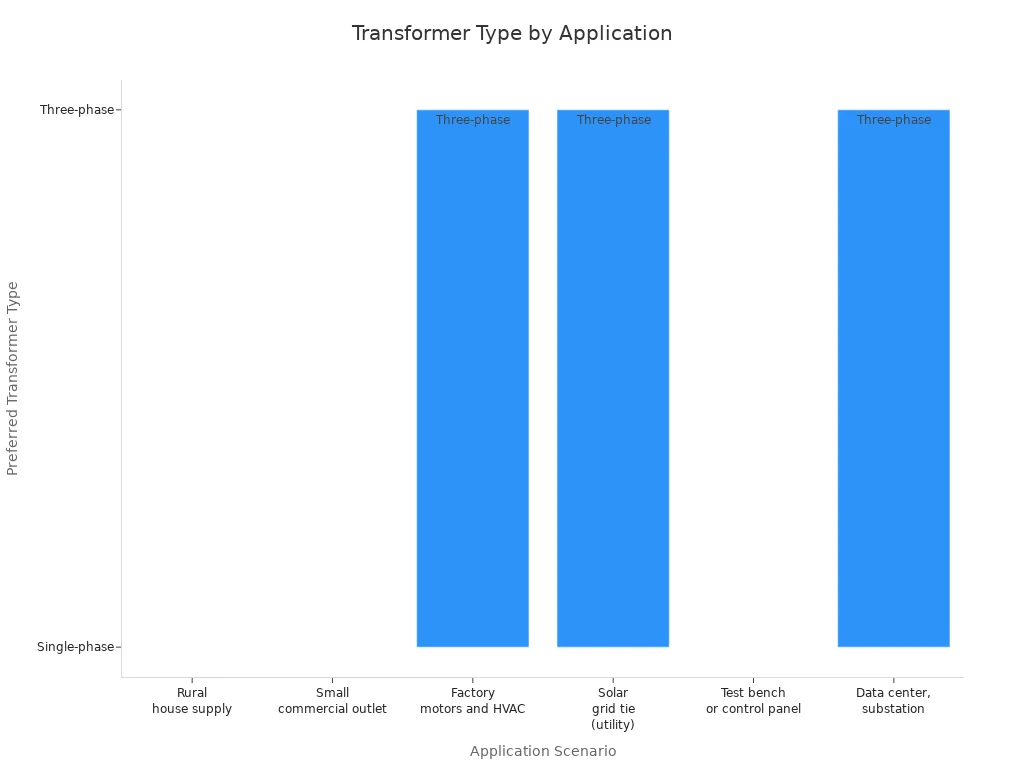

Industrial control transformers come in two main types: single-phase and three-phase. Each type serves different needs in industrial environments. Single-phase transformers work best for smaller loads or when the power demand is not balanced. Three-phase transformers handle larger, balanced loads and offer higher efficiency. The choice depends on the application and the size of the industrial system.

Here’s a quick comparison:

| Criteria | Single-Phase Transformer | Three-Phase Transformer |

|---|---|---|

| Efficiency | 92%–96% at full load | 96%–99.5% at full load |

| Load Type | Unbalanced or single-phase loads | Balanced three-phase loads |

| Size and Weight | Heavier and larger | More compact and lighter |

| Power Rating Range | Up to 250 kVA | 100 kVA to 1000+ MVA |

| Voltage Regulation | More variation under load | Tighter voltage control |

| Typical Use | Homes, control panels | Factories, power grids |

Industrial control transformers from Linkwell include both types, so users can match the right transformer to their needs. The chart below shows which transformer fits each scenario:

Typical Industrial Uses (Linkwell Examples)

Industrial control transformers power many types of equipment in factories and other industrial settings. They keep automation equipment running, supply steady voltage to instruments, and help machine tools work with precision. These transformers also support control systems that keep everything safe and efficient.

Some real-world examples from Linkwell include:

| Industry | Application Description |

|---|---|

| Manufacturing | Automates machines and controls motors for efficient production. |

| Telecommunications | Used in base station cabinets to manage backup power and cooling. |

| Water Treatment Plants | Automates pumps and sensors, ensuring smooth operations. |

Industrial control transformers also play a big role in automotive manufacturing, especially in robotic welding lines. In renewable energy, they help wind and solar farms operate smoothly.

Tip: Choosing the right transformer helps industrial systems avoid downtime and keeps sensitive equipment safe.

Control Power Transformer in Automation

A control power transformer is the heart of many automation systems. In modern factories, these transformers provide a steady power supply to control panels, relays, and timers. They help keep production lines moving without interruption. If the power supply fails, the whole process can stop, leading to costly delays.

Control power transformers support continuous operation in automation facilities. They boost efficiency and protect against power interruptions. Reliable transformers mean fewer breakdowns and more consistent output. Linkwell’s control power transformer options fit a wide range of industrial needs, from small control panels to large automated systems.

Here’s how control power transformers support automation:

- Deliver stable voltage to control circuits.

- Handle high inrush currents during equipment startup.

- Protect sensitive devices from voltage spikes.

- Ensure uninterrupted operation in critical industrial processes.

Industrial users trust Linkwell’s transformers to keep their automation systems running smoothly, no matter how tough the environment.

Key Features and Benefits of Linkwell Transformers

Energy Efficiency and Durability

Linkwell transformers stand out for their energy efficiency and long-lasting performance. Many industrial users look for a transformer that can cut down on wasted power and help with energy savings. Linkwell designs each transformer with copper windings and laminated cores. These features boost energy efficiency and keep heat levels low. A transformer that runs cooler lasts longer and needs less maintenance.

Durability matters in tough industrial settings. Linkwell transformers handle harsh conditions better than most. Take a look at how they compare to the industry average:

| Feature | Linkwell Control Transformers | Industry Average |

|---|---|---|

| Defect Rate | 0.001 | 0.003 |

| Designed for Harsh Conditions | Yes | No |

A lower defect rate means fewer breakdowns and less downtime. Linkwell transformers keep machines running and protect sensitive equipment.

Customization and Fast Delivery

Every industrial project has unique needs. Linkwell offers transformer customization for voltage, power rating, mounting style, and enclosure type. Users can request a transformer that fits their exact requirements. This flexibility helps panel builders and distributors solve problems quickly.

Fast delivery is another benefit. Linkwell keeps standard transformers in stock and ships custom orders on schedule. Industrial users get the transformer they need without long waits. Quick turnaround supports project deadlines and keeps operations moving.

Tip: Custom transformers help users avoid costly modifications and speed up installation.

Compliance with 2025 Standards

Safety and compliance matter more than ever. Linkwell transformers meet UL, CE, and ISO 9001:2015 standards. Each transformer passes strict tests for quality and safety. These certifications give users confidence that their transformer will perform reliably.

Linkwell keeps up with 2025 regulations. Their transformers support global installations and meet the latest efficiency standards. Industrial users trust Linkwell to deliver transformers that protect workers and equipment.

- UL certification for U.S. safety

- CE marking for European compliance

- ISO 9001:2015 for quality management

Linkwell transformers combine energy efficiency, durability, customization, and compliance. Industrial users get a transformer that saves energy, lasts longer, and meets every safety requirement.

Choosing the Right Control Transformer

Matching Specs to Application Needs

Selecting the right transformer starts with understanding the job it needs to do. Industrial buyers and panel builders look for a transformer that matches their system’s voltage, current, and frequency. Here’s a simple guide to help with the process:

- Voltage and Current Ratings: Pick a transformer with primary and secondary voltages that fit your equipment. Make sure the current rating supports all devices connected.

- Frequency Compatibility: Check if the transformer works with your system’s frequency, either 50 Hz or 60 Hz.

- Load Requirements: Think about both inrush VA and sealed VA. The transformer should handle startup surges and steady operation.

- Environmental Considerations: Choose a transformer rated for the temperature and conditions in your facility.

- Voltage Regulation: Find a transformer that keeps secondary voltage steady, even during peak loads.

A transformer that matches these specs will keep control circuits safe and reliable.

Sizing and Installation Tips

Sizing a transformer is more than just picking a number. Panel builders follow these steps:

- Determine Secondary Voltage: Know what voltage your control circuit needs. Common choices are 24V, 12V, or 48V.

- Calculate Power Requirements: Add up the VA ratings of all devices on the secondary side. This gives the total load.

- Consider Inrush Current: Some devices draw extra current at startup. The transformer must handle this without dropping voltage.

- Temperature and Environment: Pick a transformer rated for your location’s temperature and humidity.

- Mounting and Installation: Make sure the transformer fits in your panel and meets safety codes.

- Future Expansion: If you plan to add more devices, choose a transformer with extra capacity.

For installation, keep the area clean and dry. Double-check connections and grounding. Allow space for air to move around the transformer. Use the right wire size and follow manufacturer guidelines for mounting and ventilation.

Tip: Always turn off power before working on a transformer to stay safe.

Linkwell Support and Custom Solutions

Linkwell helps buyers find the perfect transformer for any industrial need. Their support services make the process easy:

| Support Service | Description |

|---|---|

| Product Selection Guidance | Experts help choose the right transformer for each application. |

| OEM Customization | Designs tailored to meet unique requirements. |

| Quality Inspection | Every transformer meets strict standards and certifications. |

| Fast Delivery | Quick shipping for urgent projects. |

| After-Sales Support | Ongoing help and service after purchase. |

Linkwell’s custom solutions include IoT-enabled components, predictive maintenance, real-time diagnostics, and energy-efficient designs. These features help users spot problems early, save energy, and get a transformer that fits their exact needs.

Control transformers in 2025 focus on key specs like VA rating, voltage, frequency, and temperature limits. Here’s a quick look:

| Specification | Description |

|---|---|

| Volt-Ampere (VA) Rating | Handles continuous power safely. |

| Primary Voltage Rating | Input voltage for the transformer. |

| Secondary Voltage Rating | Output voltage for control circuits. |

| Frequency Rating | Designed for 50Hz or 60Hz operation. |

| Temperature Rating | Maximum safe operating temperature. |

Linkwell stands out with 100% on-time delivery, fast response, and global certifications like UL, CE, and ISO 9001. Need expert advice or a custom solution? Contact Linkwell by email at linkwell@linkwell.org or call 0086-21 69512240. For more info, explore product documentation, catalogs, and knowledge hubs online.

FAQ

What is the main job of a control transformer?

A control transformer supplies safe, steady voltage to control circuits. It keeps machines running smoothly and protects sensitive equipment from power surges.

How long does a Linkwell control transformer last?

Most Linkwell control transformers last 10 to 15 years. Good installation and regular checks can help them last even longer.

Can Linkwell customize transformers for special projects?

Yes! Linkwell offers custom voltage, power ratings, and enclosures. Their team helps users get the perfect fit for any industrial setup.

Why do control transformers need certifications like UL or CE?

Certifications show that a transformer meets strict safety and quality rules. They help users trust that the product will work safely in their country.