If you want wiring that’s safe and hassle-free, nylon cable glands are your go-to solution. You get waterproof protection, flexibility, and solid cable security in one simple device. Whether you’re working inside your home or outdoors, nylon cable glands keep your connections protected from dust, water, and chemicals. Check out the most popular features below:

| Feature | Description |

|---|---|

| Cost-Effective | Saves money compared to metal alternatives |

| Lightweight | Installs easily, less effort |

| UV Resistance | Works well in direct sunlight |

| Chemical Resistance | Stands up to harsh environments |

Key Takeaways

- Nylon cable glands provide waterproof and dustproof protection, ensuring your wiring lasts longer in harsh environments.

- These glands are lightweight and easy to install, making them suitable for both beginners and experienced users.

- Nylon cable glands resist corrosion and chemicals, offering a cost-effective solution that saves money over time.

- They feature strong strain relief and anti-vibration locks, keeping cables secure and preventing damage from movement.

- Choosing the right size and type of nylon cable gland is crucial for achieving a tight, waterproof seal in your wiring projects.

What are nylon cable glands?

Definition and function

You might wonder what makes nylon cable glands so important in wiring projects. These small devices play a big role in keeping your cables safe and organized. When you use a nylon cable gland, you attach and seal a cable to a piece of equipment. This helps protect your wiring from dust, dirt, and moisture. You also keep your enclosure airtight and your cables secure.

- A nylon cable gland acts as a mechanical entry point for cables in electrical systems.

- It seals and terminates cables, which protects your equipment from outside elements.

- You prevent sensitive wires from getting damaged by dirt or water.

- The gland holds cables firmly in place, so you avoid loose connections.

Tip: Using nylon cable glands means you get a simple way to boost safety and reliability in your electrical setups.

Application areas

You can use nylon cable glands in many different places. They work well in both home and industrial settings. Here are some of the most common areas where you might find them:

| Industry/Environment | Main Reasons for Selection |

|---|---|

| Telecommunications | Flexibility and cost-effectiveness |

| Consumer Electronics | Lightweight and cost-effective |

| Renewable Energy (Solar and Wind) | Resistance to chemicals and UV rays |

| Automotive and Electric Vehicles (EVs) | Cost savings and flexibility |

| HVAC and Building Automation Systems | Lightweight and resistance to environmental factors |

| Automation and Robotics | Cost-effective and suitable for indoor use |

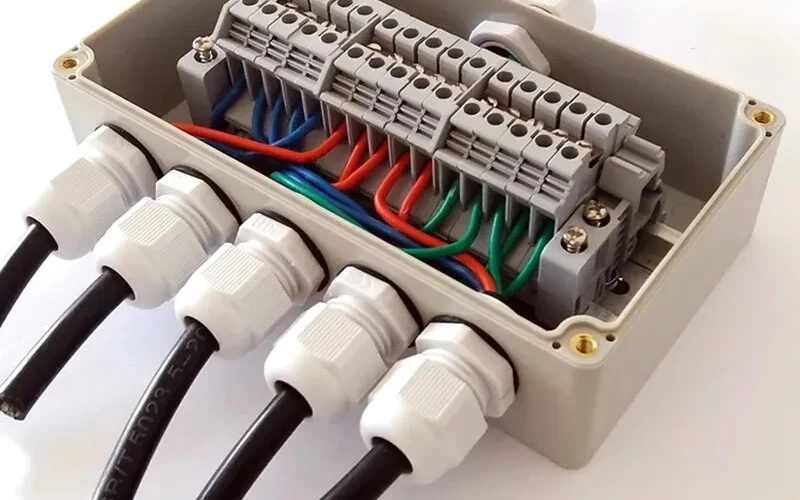

You will also see nylon cable glands in electrical panels, control systems, automation equipment, lighting installations, and outdoor junction boxes. They help manage power and control cables in machinery, making sure everything stays safe and organized.

If you work with wiring in any of these areas, nylon cable glands give you a reliable and easy-to-use solution.

Safety benefits of nylon cable glands

Waterproof and dustproof protection

You want your wiring to stay safe from water and dust. Nylon cable glands give you that peace of mind. These glands seal out moisture and dirt, so your cables last longer and work better. You can use them in wet or dusty places, like outdoor control boxes or factory floors. Many nylon cable glands come with an IP68 rating, which means they keep out water and dust even in tough conditions.

Tip: If you install wiring outdoors or in a workshop, choose cable glands with a high waterproof rating for extra protection.

Check out how nylon cable glands compare to other materials in terms of tensile strength:

| Material | Tensile Strength (N) |

|---|---|

| Polyamide | 150 |

| Brass | 200 |

| Stainless Steel | 250 |

| Aluminum | 180 |

Nylon cable glands offer strong protection and flexibility, making them a smart choice for many environments.

Strain relief and cable security

Cables can get pulled, twisted, or shaken, especially in places with lots of movement. Nylon cable glands help keep your cables secure. They use special features to stop cables from getting damaged or coming loose. You get strong strain relief, anti-vibration locks, and spiral protective springs. These features keep your wiring safe, even if your equipment moves or vibrates a lot.

Here’s how these design features work for you:

| Design Feature | Function |

|---|---|

| Strong strain relief mechanisms | Provides support to prevent cable damage from tension and movement. |

| Anti-vibration locks | Ensures that the cable remains securely in place, preventing loosening due to vibrations. |

| Spiral protective spring | Limits cable bending and twisting, reducing the risk of breakage and electric leakage. |

If you work in factories, vehicles, or anywhere with moving parts, nylon cable glands help you avoid cable failures.

Electrical insulation

You want to prevent short circuits and keep your wiring safe. Nylon cable glands do not conduct electricity, so they act as a barrier between your cables and the outside world. This non-conductive nature helps stop electrical accidents. The sealing capabilities also keep out dust and moisture, which can cause problems with your wiring. Nylon cable glands resist corrosion, so they last longer than metal ones in many situations.

Take a look at the features that make nylon cable glands great for electrical insulation:

| Feature | Description |

|---|---|

| Non-conductive nature | Nylon does not conduct electricity, making it ideal for electrical insulation. |

| Sealing capabilities | Prevents dust, dirt, and moisture penetration, which helps in maintaining electrical integrity. |

| Corrosion resistance | Unlike metal glands, nylon does not rust, ensuring longevity in various environments. |

| IP68 rating | Essential for marine, outdoor, or industrial installations, providing high-level protection. |

Note: If you need wiring for outdoor lighting or marine equipment, nylon cable glands help keep your system safe and reliable.

Compliance with standards

Safety standards matter when you choose wiring products. Nylon cable glands meet many international and national certifications. You can trust them for use in hazardous areas, explosive atmospheres, and places where safety is critical. These glands comply with ATEX, IECEx, UL, IP68, SGS, CE, ROHS, and REACH standards. That means you get products that meet strict safety and quality requirements.

Here are some of the certifications you might see:

| Certification | Compliance Details |

|---|---|

| ATEX | Ensures compliance with safety standards for hazardous areas. |

| IECEx | Certifies equipment for use in explosive atmospheres. |

| UL | Complies with UL 514B, ensuring safety for North American and European markets. |

| IP68 | Indicates protection against dust and water ingress. |

| SGS | Certifies compliance with safety and quality standards. |

| CE | Indicates conformity with health, safety, and environmental protection standards. |

| ROHS | Restricts the use of specific hazardous materials. |

| REACH | Addresses the production and use of chemical substances. |

You can feel confident using nylon cable glands in your projects, knowing they meet top safety standards.

Ease of use and installation

Quick installation steps

You want wiring projects to go smoothly, right? Nylon cable glands make installation fast and simple. You don’t need special tools or advanced skills. Most of the time, you just follow a few easy steps:

- Choose the right size for your cable.

- Insert the cable through the gland body.

- Tighten the clamping nut by hand or with a wrench.

- Check the seal to make sure it’s snug and secure.

You save time and avoid frustration. The user-friendly design helps you get a tight fit without much effort. If you’re working on a control box, panel, or outdoor appliance, you’ll appreciate how quickly you can finish the job.

Tip: Always double-check the seal after installation. A secure fit keeps water and dust out.

Flexibility for different cables

You might have cables of all shapes and sizes. Nylon cable glands handle this challenge with ease. Their adjustable clamping mechanism lets you fit a wide range of cable diameters and types. You don’t have to worry about mismatched parts or complicated adapters.

Here’s a look at what makes them so versatile:

| Feature | Description |

|---|---|

| Adjustable Clamping Mechanism | Allows for easy customization to fit different cable diameters and types, enhancing versatility. |

| User-Friendly Installation | Simplifies the process of cable entry and termination, saving time and effort for users. |

You can use nylon cable glands for round cables, flat cables, and even multi-core wires. This flexibility means you only need one product for many different jobs. If you’re working on a project with mixed cable types, you’ll find these glands save you time and reduce clutter.

Maintenance advantages

You want your wiring to last and stay safe. Nylon cable glands offer big advantages when it comes to maintenance. They resist corrosion, so you don’t have to worry about rust or damage from moisture. Their lightweight design makes inspection and replacement easy. You spend less time checking for problems and more time focusing on your work.

Take a look at how nylon cable glands compare to metal and brass alternatives:

| Advantage | Nylon Cable Glands | Metal/Brass Alternatives |

|---|---|---|

| Corrosion Resistance | Excellent (cannot corrode) | Prone to corrosion |

| Weight | Lighter weight | Heavier |

| Cost | Significantly lower cost | Higher cost |

| Moisture Handling | Excellent moisture handling capabilities | Limited moisture handling |

| Longevity | Suitable for various environments | Requires more frequent inspections |

You’ll notice that nylon cable glands last longer in tough environments. They stand up to extreme temperatures, moisture, UV rays, and chemicals. This durability means you replace them less often, which saves you money over time. Their insulation properties help prevent electrical failures, so you don’t have to deal with short circuits or hazards. The easy installation also cuts down on labor costs and makes future inspections a breeze.

Note: Choosing nylon cable glands helps you keep maintenance costs low and your wiring safe for years to come.

Nylon cable glands vs. other materials

Safety comparison

When you look at wiring safety, the material of your cable gland makes a big difference. Nylon cable glands stand out because they don’t corrode or rust, even after years of water contact. You get peace of mind knowing your connections stay secure in wet or humid environments. Nylon also provides strong electrical insulation, so you avoid unwanted electrical paths or ground loops. This feature helps protect your equipment from short circuits and electrical faults.

Take a look at how nylon compares to other materials:

| Feature | Nylon Cable Glands | Other Materials (e.g., Brass, Stainless Steel) |

|---|---|---|

| Corrosion Resistance | No corrosion, no rust | Prone to corrosion in certain environments |

| Temperature Adaptability | -40° to 135° | Limited range depending on material |

| Impact Resistance | Strong impact resistance | Varies by material, generally lower than nylon |

| Leakage Resistance | Good leakage resistance | Varies, often less effective than nylon |

| Toxicity | No toxicity | Varies, some metals can leach harmful substances |

You can see that nylon cable glands offer reliable protection in harsh conditions. They don’t leach harmful substances, which makes them safer for sensitive electronics and control panels.

Usability comparison

You want installation to be quick and easy. Nylon cable glands make your job simpler because they’re lightweight and tough. You don’t need heavy tools or extra support for mounting. The flexible design adapts to different cable sizes, so you spend less time searching for the right fit.

Here are some reasons nylon cable glands are easier to use:

- You can install them without worrying about corrosion or rust.

- They work well in a wide temperature range, from freezing cold to hot summer days.

- You get strong impact resistance, so they won’t crack or break easily.

- Nylon doesn’t age or break down when exposed to water.

If you need a solution that saves time and effort, nylon cable glands help you finish your wiring projects faster and with fewer headaches.

Choosing nylon cable glands

Key selection factors

When you pick nylon cable glands, you want to make sure they fit your needs. Start by looking at the cable diameter and the hole size. If the gland is too loose or too tight, you won’t get a good seal. Think about the environment. If you work indoors, plastic works well. For outdoor jobs, you might need extra protection. Check the waterproof rating and certifications like IP68 or UL. Some glands offer special features, like shielding or high-temperature resistance. Always look for products that meet international standards, such as EN50262 or IEC60529.

Tip: Choose a gland with the right protection level for your project. If you need extra safety, look for explosion-proof or corrosion-resistant options.

Sizing and compatibility

Getting the right size matters. Measure the outer diameter of your cable with a caliper or micrometer. Count the number of cores inside the cable. Use a sizing chart to match your cable to the correct gland. Make sure the gland fits your cable type, whether it’s round, flat, or multi-core. Check if the gland can handle the operating temperature and pressure in your environment.

| Feature | Benefit |

|---|---|

| Waterproof Performance | Protects cables and connectors from humid environments, ensuring reliability. |

| Mechanical Strength | High resistance to stretching and compression, ensuring durability in various environments. |

| Chemical Resistance | Protects against corrosive substances, extending the lifespan of the cable gland. |

| UV Resistance | Ensures long-term use in harsh outdoor conditions. |

| Dust and Debris Protection | Prevents contaminants from entering, maintaining the integrity of the cable connections. |

Application tips

You have many options when it comes to types. NPT glands work well in the United States and have tapered threads. Metric glands follow the ISO system and fit IEC standards. Multi-hole glands let you run several cables through one entry. If you need to protect data cables from interference, EMC-compatible glands are a smart choice. Nylon A-type divided body glands seal joints and keep out moisture and dust. Use these in control boxes, panels, and appliances for the best results.

- Pick the right thread type for your region.

- Use multi-hole glands for projects with several cables.

- Always check compatibility with your equipment before installation.

Note: Nylon cable glands give you flexibility, waterproof protection, and easy installation. You can use them in control boxes, panels, and appliances for safe and reliable wiring.

Installation guide for nylon cable glands

Preparation and tools

Before you start, make sure you have everything ready. You want the right size gland for your cable, so measure the cable’s outer diameter first. Check if your cable is armored, non-armored, or shielded. Think about where you’ll install it—indoors, outdoors, or in a wet area. For most jobs, you’ll need a wrench, a drill with the correct bit, a deburring tool, and maybe a tap and die set if you need to thread the hole. Always clean the cable and the entry point to remove dust or grease. Double-check that all gland parts, like the sealing ring and locknut, are in good shape.

Tip: Choosing the correct size and type of gland helps you get a tight, waterproof seal.

Step-by-step process

Follow these steps to install nylon cable glands and get a secure, waterproof connection:

- Mark the spot for the hole and use a punch tool to guide your drill.

- Drill the hole, adding cutting oil if needed. Use masking tape on the bit to avoid making the hole too big.

- Remove any sharp edges with a deburring tool.

- If your gland needs threads, use a tap and die set to create them.

- Disassemble the gland and check all parts for damage.

- Pass the cable through the gland body, making sure it fills the sealing area.

- Tighten the compression nut by hand, then finish with a wrench. Don’t overtighten.

- Check for gaps between the locknut and compression nut. Test for leaks if you’re working outdoors.

Note: A proper seal keeps water and dust out, protecting your wiring for years.

Mistakes to avoid

You want your installation to last, so watch out for these common mistakes:

- Picking the wrong gland size for your cable.

- Not tightening the gland enough, which can let water in.

- Overtightening and crushing the cable jacket.

- Using old or damaged sealing inserts.

- Ignoring the manufacturer’s instructions.

- Exposing armored cable, which can cause grounding problems.

If you avoid these errors, your nylon cable glands will keep your wiring safe and secure.

You want wiring that’s safe, simple, and built to last. Nylon cable glands deliver on all fronts. They keep out water and dust, stay strong without rusting, and make installation a breeze. Here’s why you should make them your first choice:

- Lightweight design means less effort for you.

- Cost-effective and corrosion-free for long-term safety.

- Easy to install, even if you’re new to wiring.

Tip: Always pick the right size and tighten the gland securely for the best protection.

FAQ

How do I choose the right size nylon cable gland?

Measure your cable’s outer diameter. Check the product’s sizing chart. Pick a gland that fits snugly but doesn’t crush the cable. If you’re unsure, ask your supplier for help.

Can I use nylon cable glands outdoors?

Yes, you can use them outdoors. Nylon cable glands resist UV rays, water, and chemicals. Look for an IP68 rating for the best waterproof protection.

Do I need special tools to install nylon cable glands?

You don’t need special tools. Most installations only require a wrench and a drill. Always check the manufacturer’s instructions before you start.

What types of cables work with nylon cable glands?

You can use nylon cable glands with round, flat, and multi-core cables. They fit many cable types in control boxes, panels, and appliances.

How do I know if my installation is waterproof?

Check the seal after tightening the gland. Make sure there are no gaps. If you see moisture inside, retighten or replace the gland. Always use glands with a high waterproof rating.