If you work with industrial automation, you know how important it is to keep wiring reliable and organized. So, what are terminal blocks used for in this field? Terminal blocks help you connect, secure, and manage wires inside control panels and machinery. In fact, almost 70% of manufacturing plants rely on advanced control systems that need high-quality terminal blocks for safe operation. Linkwell Electrics stands out among global leaders, offering terminal block solutions that support efficient, scalable automation. You get trusted products with proven quality and strong market presence.

Key Takeaways

- Terminal blocks provide reliable connections for wires, ensuring stable operation in industrial automation.

- They simplify maintenance with modular designs, allowing for quick replacements and upgrades.

- Using terminal blocks helps organize wiring, making troubleshooting easier and reducing downtime.

- High-quality terminal blocks enhance safety by protecting against electrical faults and fire risks.

- Linkwell offers customizable terminal block solutions that meet international safety standards for various industrial needs.

Terminal Block Application in Industrial Automation

What Are Terminal Blocks Used For

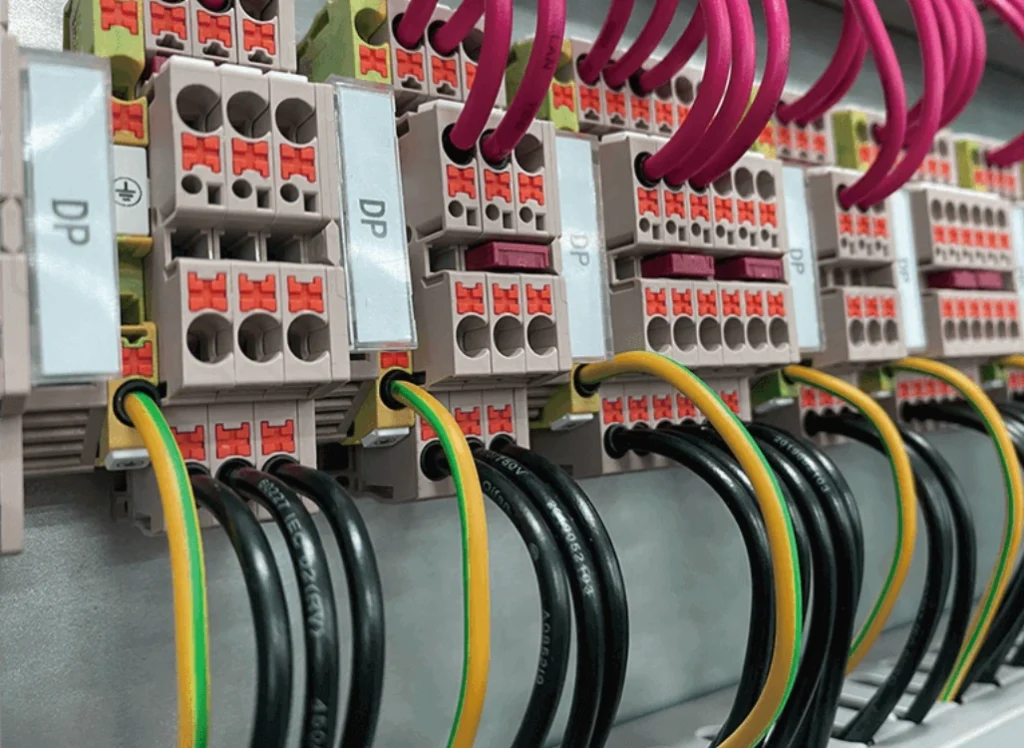

You see terminal blocks everywhere in industrial automation. They help you connect wires, organize circuits, and keep everything safe inside control panels and machinery. When you use terminal blocks, you get stable electrical connections that stand up to vibration, heat, and heavy use. This stability is key for keeping your automation systems running smoothly.

Here’s a quick look at the most common functions of terminal blocks in industrial automation:

| Function | Description |

|---|---|

| Electrical Connection Stability | Mechanically secures wires to prevent loosening caused by vibration, thermal fluctuations, or external forces. |

| Modular Design Simplifies Maintenance | Enables rapid plug-and-play replacement of terminal blocks for debugging or repairs. |

| High-Density Wiring Management | Supports dense signal line layouts in confined spaces, such as servo drive control cabinets with hundreds of connections. |

Terminal block application goes beyond just connecting wires. You also get easier maintenance and upgrades. Modular designs let you swap out blocks quickly, so you spend less time troubleshooting and more time keeping your systems productive. You can expand your control panels as your automation needs grow, thanks to the scalable nature of these blocks.

Applications of Terminal Blocks in Control Panels

You rely on terminal blocks for many applications in control panels. They help you manage complex wiring setups and keep everything organized. Here are some of the main applications:

- Industrial automation: Connect sensors, actuators, controllers, and other devices for stable operation in tough environments.

- Control panels and cabinets: Manage and organize wire and cable connections, making maintenance and upgrades simple.

- Distribution boards: Provide secure connections in electrical distribution systems.

- Control centers: Facilitate organized wiring in machine control systems.

Terminal blocks make troubleshooting easier. You can quickly identify and trace wires because the connections are clearly labeled and organized. If a wire fails, you can replace it without tearing apart the whole panel. This saves you time and reduces downtime in your automation systems.

Tip: Always check the wire gauge and torque settings during installation. This helps prevent overheating and keeps your wiring safe and reliable.

Terminal block application also solves common challenges in industrial wiring. You often work with limited space, high currents, and the need for secure connections. Terminal blocks handle these issues by offering compact layouts, strong clamps, and compatibility with different wire types.

Linkwell Terminal Block Connector for Machinery Wiring

When you need reliable wiring in industrial automation, Linkwell’s Terminal Block Connector stands out. You get a product designed for high-volume use in control cabinets, electrical enclosures, and telecom signal cabinets. Linkwell connectors keep your wires organized, preventing tangling and fraying. This boosts the reliability of your machinery wiring.

Let’s look at some real-world applications of Linkwell terminal block connectors:

| Industry | Application Example |

|---|---|

| Industrial Control Panels | Distributing power to motors and sensors |

| Data Centers | Organizing power for server racks |

| Renewable Energy | Integrating solar and wind power sources |

| Automotive Systems | Managing power for vehicle accessories |

| Commercial Buildings | Load distribution in HVAC and lighting |

You can use Linkwell connectors for power distribution, sensor and actuator connections, motor control, and grounding. These connectors withstand high temperatures, vibration, and moisture, so your automation systems stay up and running even in harsh conditions. You also get modular designs that support rapid reconfiguration and expansion. This means you can scale your control systems as your industrial projects grow.

Terminal block application with Linkwell products gives you a professional look, reliable connections, and lower installation costs. You spend less time on wiring and more time focusing on your automation goals. As the demand for industrial automation grows, modular and smart terminal blocks are becoming more popular. They offer flexibility, safety, and support for future upgrades.

You can count on Linkwell’s expertise to help you solve wiring challenges, improve safety, and keep your control systems organized. Whether you’re working in manufacturing, energy, or building automation, Linkwell terminal block connectors deliver the performance and reliability you need.

Power Distribution and Signal Transmission

Power Distribution Block in Automation Systems

You need strong and organized connections to keep your industrial control systems running smoothly. Terminal blocks play a big role in managing power inside automation systems. When you use a power distribution block from Linkwell, you can connect multiple cables securely and distribute power to different devices. This setup helps you avoid messy wiring and makes your control panels safer. You get reliable electrical connections that stand up to vibration and heat. These blocks let you manage signal and power cables with ease, so your systems stay efficient and easy to maintain.

Terminal blocks make it simple to connect, disconnect, and organize cables. You can expand your control systems without worrying about tangled wires or loose connections. This means your industrial automation projects stay flexible and ready for upgrades.

Signal Transmission with Screw Terminal Solutions

Signal transmission is key in industrial control systems. You want reliable connections that keep your automation running without interruptions. Linkwell’s screw terminal blocks give you secure wire clamping and a robust design. You can trust these connections to handle tough environments and keep your signals clear.

Here’s a quick look at the advantages of screw terminal solutions for signal transmission:

| Advantage | Description |

|---|---|

| Enhanced Cabling Efficiency | DIN rail terminal blocks make wiring faster and easier. |

| Modularity | You can add or replace modules without stopping your systems. |

| Reliability and Safety | Secure mounting keeps connections stable, even with vibration. |

| Long-term Cost Reductions | Fewer maintenance calls mean lower costs over time. |

| Simplified Maintenance | Modular design lets you swap out parts quickly and keep your control systems running. |

You can use spring terminal blocks and din rail terminal blocks for different types of cables. These options help you build industrial control systems that are both reliable and easy to maintain.

Reliable Connections for Sensors and Actuators

Sensors and actuators need reliable connections to work well in industrial control systems. Terminal blocks simplify wiring and keep everything organized. You can combine signals from many field devices and send them to your control systems. This setup saves space in your control cabinets and makes layouts clearer.

- Terminal blocks help you manage multiple cables for sensors and actuators.

- You spend less time installing and more time running your automation systems.

- PCB terminal blocks give you secure connections, which means accurate measurement and control.

When you use Linkwell’s screw terminal blocks and spring terminal blocks, you get dependable wiring for all your industrial automation needs. Your systems stay reliable, organized, and ready for future growth.

Benefits of Using Terminal Blocks

Safety and Organization in Automation

You want your industrial systems to run smoothly and safely. Terminal blocks help you achieve this by providing secure connection points for all your electrical wiring systems. These blocks keep your wiring organized, which means you can easily trace connections and avoid confusion during maintenance. You also get protection against fire and electrical faults. High-quality terminal blocks meet strict safety standards, including fire protection on railway vehicles, flammability testing, and halogen-free flame resistance.

| Standard | Description |

|---|---|

| Fire protection on railway vehicles (EN 45545-2) | Addresses smoke gas development and toxicity in fire scenarios. |

| Flammability testing of plastics | Includes vertical and horizontal small flames tests (UL 94 and EN 60695-11-10). |

| Halogen-free flame resistant | Ensures materials do not release harmful gases when burned (DIN EN ISO 1043-4). |

You get peace of mind knowing your systems have safe wiring and reliable protection. Organized wiring also reduces the risk of errors and makes troubleshooting much easier.

Flexibility and Maintenance Advantages

How do terminal blocks work to make your life easier? Their modular design lets you expand or modify your systems without hassle. You can add new connections or upgrade your automation projects quickly. This flexibility is a huge advantage, especially when you need to adapt to changing industrial requirements.

- Fault resolution time drops from 52 minutes to just 18 minutes with plug-in systems.

- You need 92% fewer special tools for maintenance.

- Push-in terminal blocks offer over 50% time savings compared to older models.

- Modular designs allow for 85% faster fault resolution and a 60% improvement in mean time to repair.

You spend less time on wiring and more time keeping your systems productive. The advantages of using terminal blocks include faster installation, easier upgrades, and reduced downtime.

Linkwell Quality and Customization

You want high-quality terminal blocks that meet international standards. Linkwell delivers products with UL, CE, CCC, and ROHS certifications. The KDB Series uses eco-friendly flame-retardant nylon housing for extra protection. Linkwell customizes terminal block solutions to fit your specific needs, offering options for voltage, current ratings, material quality, and installation type.

| Specification | Details |

|---|---|

| Voltage & Current Ratings | Supports up to 1000V and 30A–150A |

| Compliance Standards | CE, RoHS, REACH, IEC 61910 |

| Material Quality | Tin-plated copper or brass |

| Installation Type | DIN rail, screw terminal, push-in variants |

| Compatibility | Compatible with wire gauges (e.g., 2.5mm²) |

| Environmental Resistance | Models rated for IP65 or higher |

| Operational Safety Compliance | Built-in insulation barriers and arc-resistant housing |

You get reliable connection, strong protection, and support for all your industrial electrical wiring systems. Linkwell stands by you with fast delivery, customization, and ongoing support, so your systems stay safe and efficient.

Conclusion

You now know why terminal blocks matter so much in industrial automation. These small but mighty components help you connect, organize, and protect your wiring. When you use terminal blocks, you make your control panels safer and your systems easier to manage. You also save time during installation and maintenance. That means less downtime and more productivity for your projects.

Let’s recap the main reasons you should use terminal blocks in your automation setup:

- Reliable Connections: Terminal blocks keep your wires secure, even in tough environments.

- Easy Organization: You can label and arrange wires neatly, which makes troubleshooting simple.

- Flexible Upgrades: Modular designs let you expand or change your system as your needs grow.

- Safety First: High-quality terminal blocks protect against electrical faults and fire risks.

Tip: If you want to future-proof your automation systems, choose terminal blocks that meet international safety standards and offer customization options.

Linkwell stands out as a trusted partner in this field. You get products that meet strict quality standards, with fast delivery and support whenever you need it. Linkwell’s terminal block solutions help you build safer, smarter, and more efficient automation systems. You can count on their expertise, whether you work in manufacturing, energy, or any other industry that relies on reliable wiring.

Ready to upgrade your control panels or start a new project? Explore Linkwell’s full range of terminal blocks and accessories. You’ll find the right solution for every industrial automation challenge.

You see terminal blocks making your automation projects safer, more organized, and easier to maintain. They boost precision, flexibility, and support smart devices. Here’s a quick look at the benefits:

| Benefit | Description |

|---|---|

| Enhanced Precision | Accurate, reliable connections for complex control systems |

| Increased Flexibility | Easy integration with new devices and changing needs |

| Smart Device Support | Ready for IoT and advanced monitoring |

Linkwell’s terminal blocks give you reliable connections, quick installation, and strong protection. Ready to upgrade your system? Explore Linkwell’s range for your next industrial project.

FAQ

What are terminal blocks used for in industrial automation?

You use terminal blocks to connect, organize, and secure wires in control panels and machinery. They help you manage wiring, improve safety, and make maintenance easier in your automation systems.

How do I choose the right terminal block for my project?

You should check the current and voltage ratings, wire size, and installation method. Think about your environment and if you need special features like modularity or color coding.

Can I use terminal blocks for both power and signal wiring?

Yes! You can use terminal blocks for power distribution and signal transmission. Just pick the right type for your voltage and current needs.

Why should I choose Linkwell terminal blocks?

Linkwell gives you high-quality, certified products with fast delivery and customization. You get reliable connections, strong support, and solutions trusted by top brands worldwide.