If you have ever wondered what is a control power transformer, you are not alone. A control power transformer is a special type of transformer that gives your control circuits the safe, steady voltage they need to work properly. You use a control power transformer to power things like relays or timers in electrical panels.

When you ask, what is a control power transformer, think of it as the reliable middleman that keeps your equipment running smoothly. Linkwell stands out as a trusted provider, known worldwide for quality and competitive pricing. Many industries choose a Linkwell transformer because the company ranks among the top 25 manufacturers and delivers dependable performance.

Key Takeaways

- A control power transformer lowers high voltage to a safe, steady voltage for control circuits like relays and timers.

- These transformers protect your system by isolating control circuits and providing stable voltage to prevent equipment issues.

- Linkwell transformers offer certified quality, flexible options, and reliable performance for various industrial needs.

- Choosing the right transformer means matching voltage, power needs, and safety standards to avoid failures and save energy.

- Regular maintenance, like cleaning and checking connections, helps your transformer last longer and keeps your system running smoothly.

- Linkwell transformers are engineered for energy efficiency, using optimized core materials to minimize power loss and cut operational costs.

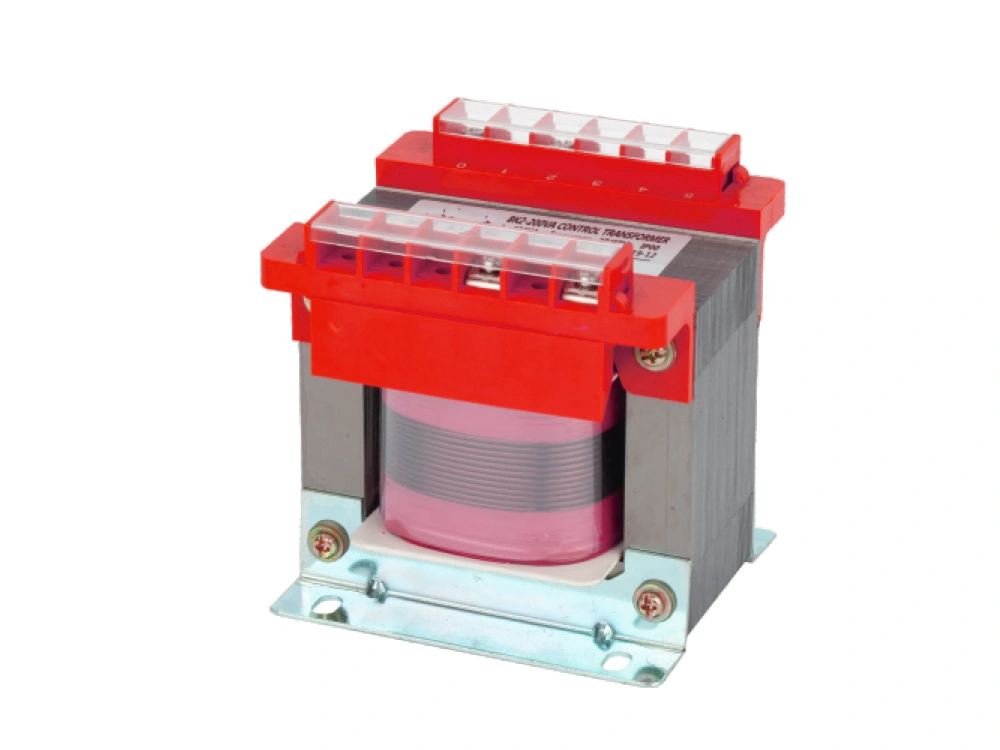

what is a control power transformer

Recommended products

Basic Function

You might ask, what is a control power transformer and why does it matter in your electrical system? The answer is simple. A control power transformer steps down high voltage from the main supply to a lower, safer voltage for your control circuits. You use it to power devices like relays, timers, and contactors inside control panels. This transformer keeps your equipment running smoothly by delivering a steady and reliable control voltage.

Here’s what you get from a control transformer in your automation or control circuits:

- Voltage conversion: It changes high voltage to a lower voltage, such as 24V or 12V, which is perfect for control devices.

- Electrical isolation: It separates the control circuit from the main power circuit, keeping your system safe.

- Stable output: It maintains a consistent voltage so your control devices work without interruption.

- Load handling: It manages the lower power needs of control circuits, making sure everything operates efficiently.

- Protection: It offers built-in safeguards against overloads and short circuits.

- Noise reduction: Advanced designs filter out electrical noise, ensuring smooth operation of sensitive devices like PLCs and instrumentation.

When you choose a Linkwell control power transformer, you get more than just basic function. Linkwell’s transformers come with UL and CE certifications, so you know they meet strict safety standards. The company has a supplier rating of 5.0 out of 5.0 and a 100% on-time delivery rate. You can count on fast responses and reliable service every time.

How It Works

Let’s break down how a control transformer actually works. You connect the primary side of the transformer to your main power source. The transformer uses coils of wire to create a magnetic field. This field transfers energy to the secondary side, which delivers a lower control voltage to your devices.

You’ll find control power transformers in many industrial settings. They often handle primary voltages from 1 kV up to 35 kV and step them down to secondary voltages like 415V or 6.6 kV, depending on your needs. In heavy-duty environments, three-phase transformers are common because they handle larger loads and keep power delivery stable.

Here’s a quick look at typical ratings for industrial transformers:

| Voltage Class | Typical Voltage Range | Typical Power Capacity Range | Typical Use Case / Application |

|---|---|---|---|

| Medium Voltage (MV) | 1 kV – 35 kV | 50 kVA – 5 MVA | Distribution, industrial service, control power |

| Example Industrial Transformer Ratings | Primary: 33 kV, Secondary: 6.6 kV | Around 5 MVA | Industrial plants, manufacturing facilities |

You also need to think about certifications. In the US and Canada, UL and CSA certifications are required. In Europe, you look for the CE mark. These certifications mean your control transformer meets strict safety and performance standards. Linkwell transformers carry these marks, so you know you’re getting a product that’s safe and reliable.

If you want a transformer that delivers consistent performance and meets global standards, Linkwell is a smart choice. The company’s control voltage transformer options fit a wide range of applications, from telecom cabinets to industrial automation. You get peace of mind knowing your system is protected and your equipment gets the power it needs.

Example: A transformer with Primary: 33 kV and Secondary: 6.6 kV at around 5 MVA is widely used in large manufacturing plants.

You also need to think about certifications. In the US and Canada, UL and CSA certifications are required. In Europe, you look for the CE mark. These certifications mean your control transformer meets strict safety and performance standards. Linkwell transformers carry these marks, so you know you’re getting a product that’s safe and reliable.

In addition, Linkwell can customize transformers for different global markets, meeting IEC, ANSI, or other regional standards so your system stays compliant wherever you operate.

Control Transformer Features

Key Benefits

When you look at a control transformer, you see more than just a piece of hardware. This transformer gives your control circuits a high degree of secondary voltage stability, even when loads change or power surges happen. You get steady, precise voltage for your relays, timers, and contactors. That means your equipment runs without hiccups.

Here are some reasons why you want a control transformer in your system:

- You get consistent voltage output, so your control devices work smoothly.

- The transformer handles inrush currents and momentary overloads, protecting sensitive components.

- You benefit from electrical isolation, which keeps your control circuits safe from interference.

- The transformer uses high-quality insulation and laminated steel cores for reliable operation.

- You avoid equipment malfunctions because the transformer maintains optimal voltage levels.

- The transformer reduces electrical noise, which helps with precision in industrial machinery.

- Rugged design ensures durability in harsh environments such as mining, oil & gas, and outdoor telecom cabinets.

- Complies with RoHS and eco-design directives, supporting your sustainability goals without sacrificing performance.

If you need a control voltage transformer for demanding environments, you can count on these features to keep your system running.

Linkwell Power Transformer Advantages

You want a power transformer that fits your needs and lasts a long time. Linkwell gives you options and flexibility. You can choose from different mounting styles and enclosure types. The transformers come with UL and CE certifications, so you know they meet global safety standards.

Here’s a quick look at what Linkwell offers:

| Mounting/Enclosure Type | Description | Key Features | Typical Applications |

|---|---|---|---|

| Enclosed Control Transformers | Protective enclosure shields against dust, moisture, and damage | Enhanced safety, corrosion resistance, noise reduction | Industrial control panels, machinery in harsh environments |

| Open Core & Coil Transformers | Unencapsulated design, epoxy-encapsulated for corrosion resistance | Compact, cost-effective, flexible mounting | HVAC systems, control cabinets, conveyor systems |

You also get customization options. Linkwell lets you pick mounting footprints, bracket designs, and termination styles. You can select screw terminals, quick-connects, or lead wires. The transformers offer various primary and secondary voltage combinations, including multi-tap options for flexibility. You can match the VA rating to your system’s needs, so you never worry about voltage drop during inrush currents.

Linkwell power transformer models include integrated fusing for extra protection. You get a durable product that works in tough environments. If you need a transformer for telecom cabinets, automation, or industrial machinery, Linkwell has a solution for you.

Linkwell also offers extended warranty and global technical support, giving you confidence that your investment is protected long after installation.

Control Power Transformer Types and Applications

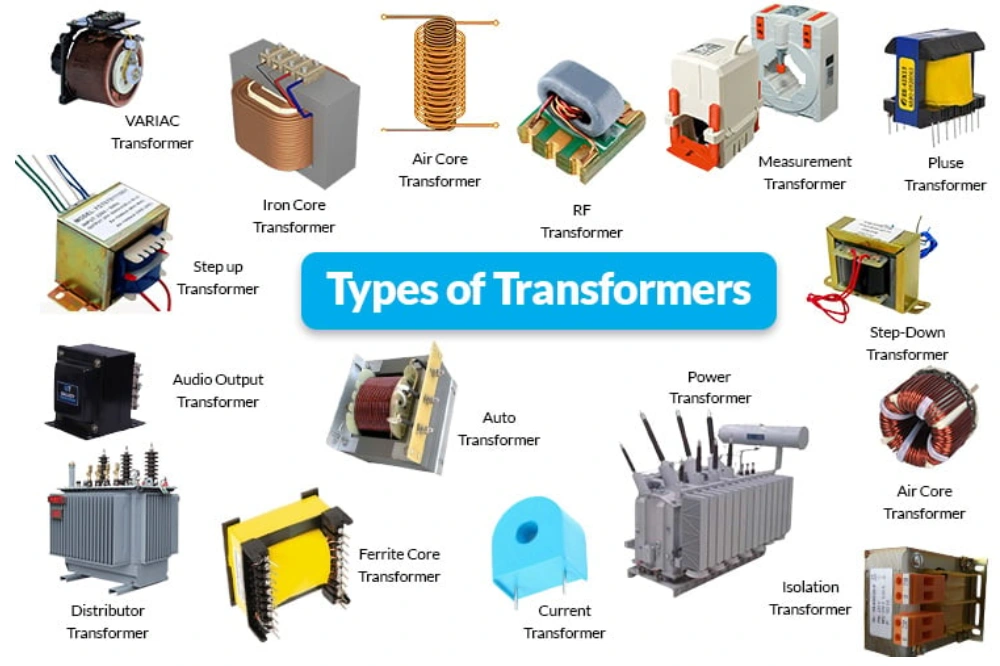

Single-Phase and Multi-Phase

When you look at control transformers, you’ll notice two main types: single-phase and multi-phase. Single-phase transformers work best for smaller loads and simple control circuits. You’ll often see them in basic control panels or small machines. Multi-phase transformers, like three-phase models, handle bigger jobs. They power large equipment, automation lines, and heavy-duty industrial systems.

Single-phase transformers give you a straightforward way to step down voltage for things like relays or timers. Multi-phase transformers, on the other hand, keep power balanced and steady across more demanding setups. If you run a factory or manage big machines, you’ll likely use a three-phase transformer to keep everything running smoothly.

Industrial Uses

You’ll find control transformers in almost every industrial setting. Here are some common ways you might use them:

- Powering automation equipment and control panels for reliable operation.

- Supplying stable voltage to electrical instruments for accurate readings.

- Running machine tools with precise voltage for exact processing.

- Supporting industrial control systems to keep everything safe and efficient.

- Case Study: Automotive manufacturers use Linkwell transformers in robotic welding lines, ensuring stable power for precise automation.

- In renewable energy, Linkwell control transformers support wind and solar farms by delivering reliable voltage for monitoring and control equipment.

A control transformer helps prevent power surges and keeps your equipment safe. It also makes sure your machines don’t shut down unexpectedly. If you use an industrial control transformer, you get better efficiency and longer machine life.

Tip: Using the right transformer can save you money on repairs and downtime.

Linkwell Solutions

Linkwell gives you a full range of transformer options for every need. You can choose from single-phase (like JBK5, JBK6) or three-phase (SG, JSG, SGC) models. If you need DC power, Linkwell has DZD and JSZ transformers too. Each transformer comes with all-copper windings for stable quality and long life.

| Control Panel Type | Role in Automation/Robotics | Industrial Applications & Benefits |

|---|---|---|

| Motor Control Centers | Central control for motors, conveyor belts, robots | Manufacturing, oil & gas, food processing; boosts safety |

| Automation Panels (PLC/SCADA) | Real-time decisions, process monitoring | Factory lines, energy management; fast control |

| VFD Panels | Adjusts motor speed for energy savings | HVAC, water treatment; precise control |

| Custom Control Panels | Tailored for unique needs, safety features | Hazardous sites, special machinery; flexible solutions |

You can customize voltage, mounting, and even the size of your transformer. Linkwell’s industrial control transformers meet global standards and fit right into your control cabinets, automation systems, or factory floors. If you want reliable performance and easy integration, Linkwell has you covered.

Choosing a Control Transformer

Selection Tips

Picking the right transformer for your control system can feel overwhelming, but you can break it down into a few simple steps. Here’s a quick checklist to help you make the best choice:

- Figure out your primary and secondary voltage needs. Check what voltage your supply gives and what your control circuit requires.

- Add up the total VA (volt-amperes) for all devices in your control circuit. Don’t forget to include relays, timers, and anything else that draws power.

- Think about inrush current. Some devices, like motors, pull extra power when they start. Make sure your transformer can handle these spikes.

- Look at the temperature rating. Choose a transformer that can handle the heat in your environment.

- Check the size and mounting style. Make sure the transformer fits your panel and matches your installation needs.

- Confirm that the transformer meets safety and efficiency standards like UL, CE, and RoHS.

Tip: Avoid common mistakes like underestimating your load or ignoring inrush current. Oversizing or undersizing can lead to wasted energy or early failure.

Linkwell makes this process easier for you. Their team helps you calculate your VA needs, select the right voltage, and even customize the transformer for your application. You get support before, during, and after your purchase. Plus, every Linkwell transformer meets strict global standards, so you know you’re getting a safe and reliable product.

Maintenance Basics

If you want your transformer to last, regular maintenance is key. Here are some basics you should follow:

- Inspect your transformer for dust, dirt, or signs of overheating.

- Tighten all electrical connections to prevent arcing or hot spots.

- Monitor the load to avoid overloading the transformer.

- Check for any oil leaks or damaged insulation if your transformer uses oil.

- Keep the area around your transformer clean and free from debris.

You can expect a well-maintained transformer to last 20 to 30 years, sometimes even longer. Regular checks and cleaning help prevent unexpected breakdowns and keep your system running smoothly. Linkwell transformers are built for durability, but a little care goes a long way in extending their service life.

You want your control circuits to run safely and smoothly. Control power transformers help you achieve that by providing stable voltage, boosting safety, and extending equipment life. Take a look at the main benefits:

| Benefit | Explanation |

|---|---|

| Enhanced System Stability | Provides stable voltage to control circuits, ensuring smooth and reliable operation of systems. |

| Increased Safety | Electrical isolation protects equipment and personnel by separating high and low voltage circuits, reducing shock risk. |

| Prolonged Equipment Lifespan | Reduces electrical interference and noise, preventing premature wear and damage to control components. |

| Improved Efficiency | High-efficiency transformers reduce power loss, saving energy and lowering operational costs. |

| Noise Reduction | Filters out harmful electrical noise, protecting sensitive control equipment from damage. |

Linkwell stands out with top customer ratings, fast delivery, and strong warranties. You get reliable support and proven quality. If you want peace of mind and dependable performance, Linkwell is ready to help you succeed.

FAQ

What does a control power transformer actually do?

You use a control power transformer to change high voltage into a lower, safer voltage for your control circuits. It keeps your relays, timers, and contactors working smoothly and safely.

How do you pick the right size transformer?

First, add up the total VA (volt-ampere) rating of all your control devices. Then, choose a transformer with a slightly higher VA rating. This helps you handle inrush currents and keeps your system safe.

Can you use a Linkwell control transformer outdoors?

Most Linkwell control transformers work best indoors. If you need one for outdoor use, ask for a model with a weatherproof enclosure, like IP65 or NEMA 4. Linkwell can customize it for you.

Why should you choose Linkwell for control transformers?

You get certified quality, fast delivery, and expert support. Linkwell offers UL and CE certified transformers, flexible mounting options, and custom solutions. Many global brands trust Linkwell for reliable performance.

On top of that, you benefit from global after-sales support, extended warranties, and eco-compliant designs that make your system safer and greener.