If you’ve ever wondered what is a fan filter unit, you’re in the right place. A fan filter unit is a device you install in control cabinets or cleanrooms to pull in fresh air, filter out dust, and keep equipment cool. You get cleaner air and longer-lasting electronics. The global market for these units is growing fast, especially in Asia-Pacific and North America:

| Year | Market Size (USD Billion) | Projected Growth Rate (%) |

|---|---|---|

| 2025 | 1.2 | — |

| 2033 | 2.5 | 9.2 (2026-2033) |

When you choose a Linkewell fan filter unit, you get trusted quality and easy installation.

Key Takeaways

- A fan filter unit cleans and cools air in control cabinets and cleanrooms to protect sensitive equipment from dust and overheating.

- The main parts include a fan that moves air, a HEPA or ULPA filter that traps tiny particles, a strong housing, and a controller to adjust airflow.

- Fan filter units work by pulling air through filters to remove contaminants, then pushing clean air back to keep environments safe and equipment running longer.

- These units save energy, reduce maintenance costs, and help meet strict air quality standards in industries like healthcare, food processing, and electronics.

- Regular filter checks and replacements, along with proper installation, keep fan filter units efficient and extend their lifespan.

What Is a Fan Filter Unit

Fan Filter Unit Overview

If you want to know what is a fan filter unit, think of it as an air cleaning device that keeps your electrical cabinets, cleanrooms, and industrial spaces safe and dust-free. This air filtration device pulls in outside air, removes contamination, and pushes out clean air to protect sensitive equipment. You often see fan filter units in places where even a small amount of dust or moisture can cause big problems, like in a cleanroom or inside a control cabinet.

A fan filter unit works as both an air purification device and a cooling system. You get a steady flow of filtered air, which helps prevent overheating and keeps electronics running longer. In cleanroom environments, these units play a huge role in keeping the air free from particles that could ruin products or disrupt experiments.

When you choose a fan filter unit, you want something that delivers consistent quality and reliability. That’s where Linkewell comes in. Linkewell stands out as a global supplier of high-quality fan filter units. Their products meet strict international standards, including CE and RoHS certifications, and they have an IP54 rating for dust and water protection. You can trust Linkewell to deliver fan filter units that last, thanks to their years of experience and commitment to quality.

Main Components

You might wonder about the fan filter unit structure and what makes these devices so effective. Let’s break down the main components of fan filter units and see how each part works together:

- Fan: This is the heart of the unit. The fan draws air into the system and pushes it through the filter. You can find fans powered by either AC or DC motors, depending on your needs. The motor inside the fan often lasts between 40,000 and 100,000 hours, so you get years of continuous operation.

- Filter: The filter is the key to keeping out dust, dirt, and other particles. Most fan filter units use a HEPA filter or another high-efficiency filter. The HEPA filter can trap at least 99.97% of particles as small as 0.3 micrometers. This makes it perfect for cleanroom applications where even tiny particles matter. You should replace the filter regularly to keep the filtration process working at its best.

- Housing: The housing holds everything together. It’s usually made from strong materials like aluminum or steel, so it can handle tough industrial environments. The housing also protects the fan and filter from damage.

- Controller Switch: Many fan filter units come with a controller switch. This lets you adjust the fan speed or turn the unit on and off. You can set the airflow to low, medium, or high, depending on what your equipment needs.

- Thermostat: In control cabinets, thermostats regulate cooling fans to maintain optimal temperatures. When internal temperatures exceed the set threshold, the thermostat activates the exhaust fan (typically top-mounted) to dissipate heat. For precision control:

- Axial fans (24V/110V) pair with digital thermostats for variable speed

- Thermostat probes monitor hotspot temperatures

- IP54-rated fans ensure dust/water resistance

- Fail-safe modes trigger fans if thermostat fails

- Proper wiring (using C/Y1/W terminals) ensures synchronized operation between the thermostat and cooling system.

Tip: If you want to keep your fan filter unit running smoothly, check the filter often and replace it when it gets dirty. This simple step helps your air cleaning device work better and last longer.

The components of fan filter unit design work together to create a powerful barrier against contamination. The fan pulls in air, the filter removes harmful particles, and the housing keeps everything safe and secure. With a controller switch, you get more control over airflow and energy use.

When you look at the fan filter unit structure, you see how each part plays a role in making this device a must-have for cleanroom and industrial settings. Linkewell’s fan filter units combine all these features with top-notch quality, so you get peace of mind and reliable performance.

Fan Filter Unit Working Principle

How Does Fan Filter Unit Work

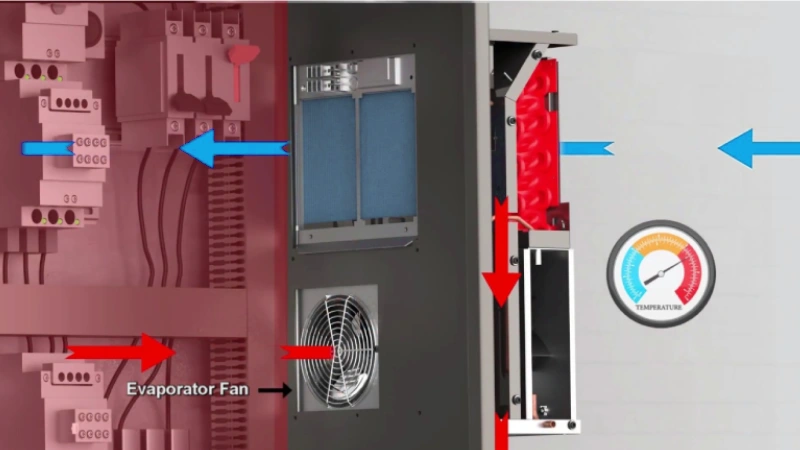

You might wonder, how does a fan filter unit work to keep your equipment safe and your air clean? The answer is simple but powerful. When you install a fan filter unit in your control cabinet or cleanroom, it acts as an air cleaning device that pulls in air from the outside environment. The fan inside the unit draws this air through a series of filters, starting with a pre-filter that catches larger dust and debris. Next, the air passes through a HEPA filter, which removes tiny airborne particles and even microorganisms.

The fan filter unit working principle relies on steady airflow and strong filtration. The fan keeps the air moving, even as the filters collect more particles over time. This means you always get filtered air, which helps prevent contamination and keeps your electronics cool. The unit then pushes the clean air back into your cabinet or room, creating a safe space for sensitive equipment.

Linkewell’s fan filter units stand out because they combine energy efficiency, low noise, and easy maintenance. You get a unit that uses less power—some models consume as little as 0.35 watts per cubic foot per minute (W/CFM)—and operates quietly, often below 60 decibels. You can also replace the filters quickly, so you spend less time on upkeep and more time focusing on your work.

Tip: If you want to save energy and reduce costs, choose a fan filter unit with advanced fan technology and easy-to-replace filters. This helps you keep your system running smoothly and efficiently.

Airflow and Filtration Process

Let’s break down the airflow and filtration process step by step, so you can see exactly how fan filter units protect your equipment:

- The fan filter unit draws in air from the surrounding environment.

- Air first passes through a pre-filter, which captures larger particles like dust and lint.

- The air then moves through a HEPA filter, which removes over 99% of fine particles, including bacteria and tiny contaminants.

- The integrated fan maintains steady airflow, even as the filters collect more debris.

- Finally, the unit distributes the clean air in a smooth, laminar flow, reducing turbulence and the risk of contamination.

This process is what makes localized air filtration so effective in industrial and electrical settings. The combination of pre-filter and HEPA filter ensures that even the smallest airborne particles are removed. You get clean air that keeps your equipment safe and your workspace healthy.

Standard fan filter units in industrial settings usually operate at airflow velocities around 0.45 meters per second. The filtration efficiency of a HEPA filter in these units is typically above 99%, which meets the strict requirements for cleanrooms and sensitive environments. Some units even use ULPA filters for even higher filtration performance.

| Metric | Industry Standard | Premium Performance |

|---|---|---|

| Energy Efficiency | Below 0.55 W/CFM | As low as 0.35 W/CFM |

| Power Consumption | 200-600 watts typical | — |

| Noise Level | 55-65 dBA | Below 50-60 dBA |

You might notice that fan filter units not only provide excellent filtration but also help you save energy. Features like diagonal fan technology and tool-free assembly make maintenance quick and easy. This means you can replace filters without special tools, reducing downtime and keeping your system efficient.

Localized air filtration with a fan filter unit also supports your environmental goals. By optimizing airflow and reducing energy use, you help lower emissions and support a cleaner, greener workplace. Stable airflow and laminar flow keep contamination risks low, so your equipment stays protected.

Note: Regularly check and replace your filters to maintain high filtration efficiency and keep your fan filter unit working at its best.

Fan Filter Unit Applications

Where Fan Filter Units Are Used

You might be surprised by how many places rely on a fan filter unit to keep things running smoothly. These units show up in all sorts of industries and settings where clean air and safety matter most. Here are some of the most common applications:

- Control cabinets and electrical panels: You find fan filter units here to protect sensitive electronics from dust and overheating.

- Telecom enclosures: These units help keep communication equipment safe and reliable.

- Cleanroom environments: Cleanrooms in pharmaceuticals, biotechnology, and microelectronics use fan filter units to maintain contamination-free environments.

- Food processing plants: You see these units working hard to keep airborne contamination away from food products.

- Healthcare facilities: Hospitals and labs use fan filter units to meet strict air quality standards and protect both patients and staff.

Recommended products

You also see fan filter units in places like semiconductor factories, energy storage systems, and automated robotics. Their modular design makes them easy to install and expand as your needs grow.

Benefits for Industrial and Electrical Systems

When you use a fan filter unit, you get more than just clean air. You gain real advantages that help your business and your team. Here are some of the top benefits:

- Reduced downtime: You can service or replace individual units without shutting down your whole system. This keeps your operations running and saves time.

- Lower maintenance costs: Easy filter changes and tool-free access mean you spend less on upkeep.

- Long service life: Many fan filter units last over 60,000 hours, so you don’t have to replace them often.

- Energy efficiency: These units use less power than traditional systems, which helps you save on energy bills.

- Compliance with regulations: Fan filter units help you meet strict air quality standards in industries like pharmaceuticals, healthcare, and food processing. They support safety and quality by keeping your controlled environment free from airborne contamination.

- Flexibility and scalability: You can add or move units as your facility changes, making them a smart choice for growing businesses.

Tip: The advantages of fan filter unit design include easy installation, modular expansion, and reliable safety for your equipment and staff.

You can trust Linkewell to deliver high-quality fan filter units that support automation, energy, and infrastructure projects. Their products help you create a safer, cleaner, and more efficient workplace.

Fan Filter Unit Types and Specifications

Recommended products

Fan Filter Unit Options

When you look for a fan filter unit, you’ll find several types designed for different needs. Each one helps you keep your equipment safe and your air clean. Here are the main options you’ll see:

- Positive Pressure Units: These push clean, filtered air into your space. You often use them in cleanroom environments, especially where you need strict air quality, like in pharmaceuticals or semiconductor manufacturing.

- Negative Pressure Units: These pull air out, capturing contaminants before they escape. You’ll see these in hazardous labs or places where you want to protect operators from dangerous particles.

- HEPA Filter Units: These remove 99.97% of particles as small as 0.3 microns. They’re perfect for hospitals, labs, and any place that needs high filtration.

- ULPA Filter Units: These go even further, trapping 99.999% of particles down to 0.12 microns. You’ll find them in ultra-sensitive areas like nanotechnology or microchip production.

Here’s a quick table to help you compare:

| Specification Aspect | Details / Range |

|---|---|

| Size | 16″x48″ up to 1175x575x300mm |

| Airflow Capacity | 600 to 1200 m³/h |

| Power Consumption | 100 to 350 watts |

| Noise Level | 50 to 60 dB |

| Filter Type & Efficiency | HEPA (99.97%), ULPA (99.999%) |

| Weight | 28 to 50 pounds |

| Voltage Options | 110V, 220V, 240V |

Tip: Higher airflow means better air changes in your cleanroom. Lower noise levels make your workspace more comfortable.

Customization and Selection Tips

You want your fan filter unit to fit your exact needs. Luckily, you can customize almost every part. You can pick from different voltages, sizes, and filter types. Some units come with special features like remote speed control, indicator lights, or even ion bars to reduce static. You can also choose room-side replaceable filters, which make maintenance much easier.

When you select a unit, think about these factors:

- Motor Type: ECM motors save energy and let you adjust speed. PSC motors run at a constant speed.

- Ductwork and Layout: Match your fan filter unit to your cleanroom layouts. Some units work best with ducted systems, while others fit open plenums.

- Performance Needs: Check filtration efficiency, airflow, and noise. Make sure the unit meets your air quality standards.

- Installation and Maintenance: Look for easy filter replacement and good after-sales support.

- Special Requirements: Some spaces need anti-static features, temperature control, or extra-quiet operation.

Note: Custom units can be made for unique ceiling grids or harsh environments. You can even get units with smart sensors for real-time monitoring and predictive maintenance.

Choosing the right fan filter unit helps you protect your equipment, meet industry standards, and create a safe, comfortable workspace. With so many options and custom features, you can always find a solution that delivers the quality you expect.

What is a Fan Filter Unit Installation and Maintenance

Basic Installation Steps

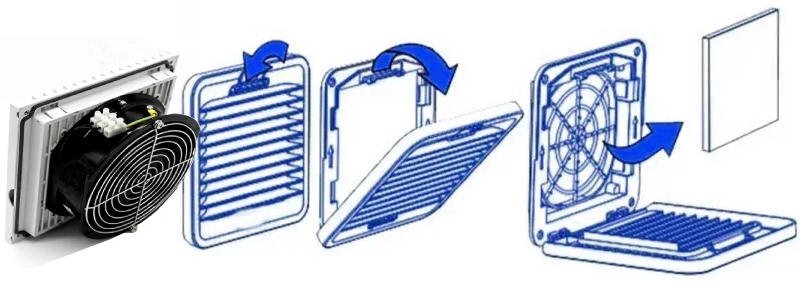

Getting your fan filter unit up and running is easier than you might think. You just need to follow a few clear steps to make sure everything works smoothly and safely:

- Choose the Right Location

Pick a spot with enough space for airflow and easy access for future maintenance. Make sure the area is free from obstructions and meets any regulatory requirements for your industry. - Prepare the Mounting Surface

Use the template provided to mark where you’ll install the unit. Drill holes and attach mounting gaskets to prevent leaks. - Install the Fan Filter Unit

Secure the unit to the surface using screws. Double-check that the housing is tight and level. If you’re working in a cleanroom or tight space, modular designs can help you fit the unit without hassle. - Connect Power and Controls

Wire the fan filter unit to your power supply. If your unit has a controller or thermostat, connect these as well. For advanced setups, link the unit to your building management system to monitor performance and prevent outages. - Test and Balance Airflow

Turn on the unit and check for steady airflow. Monitor static pressure and make adjustments if needed. If you use electronically commutated motors, make sure the pressure is balanced to avoid motor stalls.

Tip: Always follow manufacturer instructions and local codes for installation. If you’re in a hazardous environment, choose intrinsically safe units to protect against ignition risks.

Common installation challenges include fitting the unit into tight spaces, meeting regulatory standards, and ensuring energy efficiency. You can overcome these by using modular products, working with expert teams, and integrating controls with your facility’s systems.

Maintenance Best Practices

Keeping your fan filter unit in top shape doesn’t have to be complicated. Regular care helps you avoid downtime and keeps your equipment running longer. Here’s what you should do:

- Weekly:

Look over the unit for any signs of damage, odd noises, or vibrations. - Monthly:

Wipe down the exterior with a soft, non-abrasive cloth. Clean surfaces help maintain airflow and prevent dust buildup. - Quarterly:

Check the filter media for clogs or damage. Replace pre-filters every six months, especially in high-dust areas. - Annually:

Test the motor, check electrical connections, and lubricate moving parts if needed. Replace HEPA filters every 6 to 12 months and ULPA filters every 3 to 6 months, or sooner if pressure drops double from the original value.

| Filter Type | Recommended Replacement Frequency |

|---|---|

| Pre-filter | Every 6 months |

| HEPA | Every 6–12 months |

| ULPA | Every 3–6 months |

- Monitor Performance:

Use sensors to track vibration, temperature, and pressure. Early detection of issues like bearing wear or blockages can save you from bigger problems later. - Follow Manufacturer Guidelines:

Stick to the recommended schedule for inspections and replacements. This helps you maintain air quality and extend the life of your fan filter unit.

Note: Good maintenance not only boosts performance but also supports safety by preventing failures and keeping your environment clean.

When you choose a fan filter unit, you get a device that combines a powerful fan with a HEPA or ULPA filter to deliver clean, steady airflow. You protect your equipment from dust and overheating while saving on energy and maintenance. Linkewell stands out with trusted certifications, easy installation, and proven results in labs, data centers, and food plants. Many customers report fewer failures and lower costs. If you want reliable air filtration for your industrial needs, Linkewell has you covered.

FAQ

How often should you replace the filter in a fan filter unit?

You should check your filter every few months. In clean areas, swap it out every 4–6 months. In dusty or outdoor spots, change it every 1–3 months for best performance.

Can you install a fan filter unit by yourself?

Yes, you can! Most units come with clear instructions and mounting templates. You just need basic tools. If you follow the steps, you’ll have it running in no time.

What size fan filter unit do you need?

Pick a size based on your cabinet or room. Measure the space and check the airflow requirements. If you’re not sure, ask Linkewell’s support team for help.

Are Linkewell fan filter units energy efficient?

Absolutely! Linkewell designs its units to use less power while delivering strong airflow. You save on energy bills and keep your equipment cool at the same time.

Conclusion

A fan filter unit is a smart investment for any cleanroom or control cabinet. It combines powerful airflow with high-efficiency filtration to protect sensitive equipment from dust, heat, and contaminants. With proper installation and regular maintenance, these units improve air quality, reduce energy costs, and extend equipment life. Linkewell’s fan filter units offer trusted performance, global certifications, and easy customization for your specific needs.

Whether you’re working in healthcare, electronics, or industrial automation, fan filter units ensure a cleaner, safer environment. Choose Linkewell for dependable protection and proven results—because your equipment deserves nothing less.