You rely on a limit switch in an electrical cabinet to keep your system safe and efficient. When you open a cabinet door, the limit switch reacts instantly. It can cut power or trigger an alert, stopping unwanted access and reducing risk.

This simple device lets you automate tasks and maintain control over your setup. In Linkewell cabinets, a limit switch boosts safety, supports automation, and gives you reliable control. If you ever wondered, “What is a Limit Switch: Application of Electrical Cabinets,” you see its value every time you interact with your panel.

Limit Switch Key Takeaways

- Limit switches detect movement or position changes in electrical cabinets to keep systems safe and efficient.

- They cut power or send signals instantly to prevent accidents and protect equipment when doors or panels open.

- Different types like plunger, roller, lever, and rotary switches fit various applications for precise and reliable control.

- Proper installation, wiring, and regular testing ensure limit switches work correctly and maintain safety.

- Routine maintenance and cleaning prevent common problems and extend the life of limit switches in tough environments.

What Is a Limit Switch: Application of Electrical Cabinets

Definition

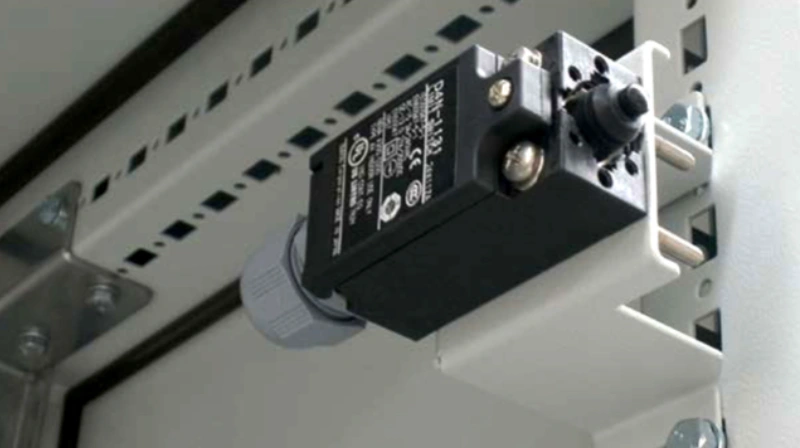

When you ask, “what is a limit switch: application of electrical cabinets,” you want a clear answer. A limit switch is an electro-mechanical device that reacts to physical movement. You find it inside electrical cabinets, where it connects to an actuator. When something moves or touches the actuator, the switch changes the state of an electrical circuit. This action can turn power on or off, send a signal, or trigger an alarm. In Linkewell’s electrical control panels and power distribution boxes, you see limit switches near cabinet doors. When you open the door, the switch disconnects power, keeping you safe and protecting the equipment. This simple device acts as a safety device, making sure you do not get shocked or damage the system.

A limit switch does more than just turn things on or off. It can detect the presence of objects or sense when something reaches a certain position. The switch uses a snap-action mechanism, so it responds quickly and reliably. You can trust it to work even in tough environments, like factories or outdoor electrical boxes. The rugged design means it can handle high currents and keep working for years. When you think about what is a limit switch: application of electrical cabinets, remember that it is there to keep you and your machines safe.

Main Uses

You use a limit switch in electrical cabinets for many reasons. The main job is to detect the presence of objects or sense when a door or panel moves. When you open a Linkewell electrical control panel, the limit switch can cut off power right away. This protects you from electrical shock and prevents accidents. You also use limit switches to control machines. For example, if a machine part moves too far, the switch stops it before it causes damage. This is important for machine safety and helps avoid costly repairs.

Here are some ways you use limit switches in electrical cabinets:

- You detect the presence or absence of objects, like a door being open or closed.

- You use them as safety devices to stop machines if something goes wrong.

- You control the sequence of operations, making sure machines only run when it is safe.

- You send signals to alarms or lights, letting you know if there is a problem.

- You help with energy savings by shutting down equipment when not needed.

Tip: In Linkewell’s power distribution boxes, you can customize the setup. You choose the type of limit switch that fits your application, whether you need a plunger, lever, or rotary style. This flexibility helps you meet strict safety standards and keep your operations running smoothly.

Limit switches play a big role in industrial automation. You find them in conveyor systems, elevators, and packaging machines. They prevent overtravel, improve accuracy, and boost safety. When you use a Linkewell electrical cabinet, you get reliable limit switches that help you control your system and protect everyone around it. So, when you think about what is a limit switch: application of electrical cabinets, remember that these switches are essential for safety, control, and smooth operation.

Limit Switch Operation

Mechanical Action

When you open an electrical cabinet, you might notice a small device near the door. That’s the limit switch. It works by using a mechanical actuator, like a lever or a plunger. When you move the door, it pushes against the actuator. This movement travels a short distance, called pre-travel, until it reaches a point where the internal contacts inside the switch snap into a new position. You get a clear on/off signal every time the actuator moves past this point.

In Linkewell cabinets, you see this in action when the door opens or closes. The limit switch detects the exact position of the door. It doesn’t matter if you use a lever, roller, or plunger style. The switch responds to direct mechanical contact, so you always get precise and repeatable results. This rugged design stands up to tough environments, making it perfect for industrial electrical cabinets.

Note: The mechanical action of a limit switch gives you reliable feedback about moving parts. You can trust it to detect the presence or absence of a door, panel, or machine part every time.

Electrical Switching

Once the actuator moves, the limit switch changes the state of its electrical contacts. You might hear a click as the contacts snap from one position to another. This action either opens or closes the electrical circuit inside your cabinet. When you use a Linkewell electrical control panel, the limit switch can cut power to certain sections or send a signal to your control circuits. This helps you automate processes and keep your equipment safe.

You can use limit switches to start or stop machines, turn on indicator lights, or even trigger safety alarms. The electrical switching happens instantly, so you get immediate feedback. You don’t have to worry about delays or missed signals. The switch handles high currents and keeps working even after thousands of cycles.

Here’s a quick look at what happens inside the switch:

| Action | Result in Electrical Cabinet |

|---|---|

| Actuator pressed | Circuit opens or closes |

| Contacts snap | Signal sent to control circuits |

| Power interrupted | Equipment protected for safety |

Safety Interlock

You want your electrical cabinet to be as safe as possible. That’s where safety interlocks come in. A limit switch acts as a safety interlock by making sure certain actions can’t happen unless conditions are right. For example, if you open the door of a Linkewell power distribution box, the limit switch can disconnect power before you reach inside. This protects you from electrical shock and keeps your team safe.

Safety interlocks also prevent machines from running when a guard or panel is open. You can use multiple limit switches to create a chain of safety interlocks. This setup ensures that your system only operates when everything is secure. If something goes wrong, the switch can trigger safety alarms or shut down the equipment right away.

Tip: Always check your safety interlocks during routine maintenance. A working limit switch is your first line of defense against accidents in electrical cabinets.

You see how limit switches combine mechanical action, electrical switching, and safety interlocks to give you full control over your electrical systems. In Linkewell cabinets, these switches help you meet strict safety standards and keep your operations running smoothly.

Types of Limit Switches

Plunger and Roller

You often see plunger and roller types when you open an electrical cabinet. A plunger limit switch works by pressing a button or rod straight in. When a door closes or a part moves into place, it pushes the plunger. This gives you a clear on/off signal. Plunger switches are great for detecting short, precise movements. You get reliable results every time.

A roller limit switch uses a small wheel on a lever. When something slides or rolls by, the roller moves the lever and triggers the switch. This design reduces friction and wear, making it perfect for parts that move often or for sliding doors. You can use roller switches for both straight and rotary motion. Here’s a quick comparison:

| Feature | Plunger Type | Roller Type |

|---|---|---|

| Actuator Mechanism | Direct press | Lever with roller |

| Best For | Short, precise movement | Sliding or rolling motion |

| Advantage | High accuracy | Less wear, smooth operation |

Both types help you control power, trigger alarms, or stop machines when something reaches its movement limits.

Lever and Rotary

Lever limit switches look like sturdy toggle switches. You push the lever with a moving part, and the switch reacts. Sometimes, the lever has a roller tip to make movement smoother. Lever switches work well for detecting the position of doors, panels, or machine arms. You get fast response and easy adjustment.

Rotary limit switches sense rotation instead of straight movement. They can use a spinning cam, a wheel, or even magnetic or optical sensors. When a shaft turns to a certain point, the rotary switch activates. This is useful for tracking the position of motors or gears. You don’t need direct contact, so rotary switches last longer in some setups.

Tip: Lever switches need direct contact, while rotary switches can sense motion without touching the moving part.

Application Examples

You find limit switches in many real-world applications inside Linkewell electrical control panels and power distribution boxes. Here are some common uses:

- Plunger switches detect when a cabinet door closes, cutting power for safety.

- Roller switches control conveyor belts or automated gates, reacting to moving parts.

- Lever switches track the position of robotic arms or lifts.

- Rotary switches monitor the rotation of motors or gears.

- Micro switches provide emergency stops or trigger alarms in control panels.

These switches help you automate tasks, protect equipment, and keep people safe. You can choose the right type for your needs, knowing each one offers reliable performance in tough environments.

Installation and Wiring

Step-by-Step Guide

You want your electrical cabinet to work safely and reliably. Installing a limit switch the right way makes a big difference. Here’s how you can do it:

- Plan the Location: Pick a spot inside your electrical control panel or power distribution box where the moving part will hit the actuator every time. Make sure nothing blocks the switch.

- Mount the Switch: Use screws or mounting brackets to secure the limit switch. Keep it steady so it doesn’t move when the door or panel moves.

- Wire the Switch:

- Use the correct wire size for your electrical load.

- Strip the wire ends and insert them into the terminals. Tighten the screws, but don’t force extra wires into one terminal.

- Use crimped or bootlace ferrules for a strong connection. Avoid solder unless the terminal is made for it.

- Route grounding wires away from power cables. Connect them to a dedicated grounding busbar.

- Label all wires and use color codes for easy identification.

- Organize the Cables: Place wires in cable trays or ducts. Leave a little slack for future changes, but avoid tangles.

- Check Everything: Double-check your connections. Make sure the switch moves freely and nothing rubs or pulls on the wires.

Tip: Always wire safety components like limit switches in series. If any switch opens, the whole circuit stops, keeping your electrical system safe.

Adjustment and Testing

After you install the limit switch, you need to adjust and test it. Here’s what you should do:

- Disconnect power before you start.

- For plunger switches, set the depression to the right depth. Test by opening and closing the door several times.

- For lever or roller switches, line up the actuator with the moving part. Adjust the angle so it triggers smoothly.

- For rotary switches, match the rotation arc to the machine’s movement. Make sure it clicks at the right spot.

- Inspect the switch for damage or dirt.

- Use a multimeter to check resistance or continuity. You should hear a beep or see near-zero resistance when the switch works.

- If the switch doesn’t work, adjust its position or replace it if needed.

- Always follow safety rules to avoid shocks.

Note: Keep switching frequency below two cycles per second. Too much movement can wear out the switch or cause errors.

A well-installed and tested limit switch keeps your electrical cabinet safe and your equipment running smoothly.

Troubleshooting and Maintenance

Common Issues

You might run into a few problems with your limit switch in an electrical cabinet. Knowing what to look for helps you keep your system safe and reliable. Here are some of the most common issues:

- Mechanical wear: Over time, moving parts can loosen or wear out, causing the switch to fail or arc.

- High temperatures: Heat inside the cabinet can damage springs and contacts, leading to malfunction.

- Dirt and debris: Dust can build up and block the movement of the switch, making it stick or miss signals.

- Electrical arcing: High loads can cause arcing, which erodes contacts and makes the switch unreliable.

- Improper installation or alignment: If the switch isn’t lined up right, it might not trigger when you open the door or move a safety guard.

- Vibration and shock: Constant shaking can loosen wires or parts, causing the switch to work inconsistently.

- Overloading: If you run too much current through the switch, it can overheat and burn out.

When these problems happen, you might notice equipment running longer than it should, unexpected downtime, or even trouble finding the real cause of a failure. Sometimes, a faulty limit switch can lead to bigger issues, like product defects or higher maintenance costs. In automated systems, you could even lose control or data if the switch fails.

Tip: If you see discoloration, cracking, or signs of overheating on your switch, replace it right away to keep your safety systems working.

Preventive Care

You can avoid most problems with a little preventive care. Here’s how you keep your limit switch and cabinet in top shape:

- Set up a regular maintenance schedule. Clean, inspect, and replace worn parts before they fail.

- Check for dirt and dust. Wipe down the switch and keep the area clean so nothing blocks movement.

- Monitor temperature inside the cabinet. Use a thermal camera or thermometer to spot overheating early.

- Inspect for loose wires, broken insulation, or strange noises. Tighten connections and fix damage right away.

- Make sure air filters and vents stay clear. Good airflow keeps the switch cool and prevents heat buildup.

- Test the switch by opening and closing the door or moving the safety guard. Listen for a solid click and check for smooth action.

- Follow the manufacturer’s guidelines for inspections and replacement. In busy environments, check switches more often.

Note: Humidity and temperature swings can shorten the life of your switch. Use cooling fans, humidity sensors, or sealed enclosures to protect your equipment.

A little attention goes a long way. Regular checks and cleaning help you avoid downtime, keep your safety features strong, and make sure your electrical cabinet runs smoothly.

You play a key role in keeping your electrical cabinets safe and efficient. When you choose a Linkewell solution, you get reliable protection and smooth automation. Always look at factors like stroke, electrical ratings, IP rating, and certifications before picking a switch. Follow NEC and NFPA 70B guidelines for installation and maintenance. Regular checks and proper grounding help you avoid problems and keep your system running strong.

Remember: A little attention to detail goes a long way in boosting safety and reliability.

FAQ

How do you know if a limit switch in your cabinet needs replacing?

If you notice the switch feels loose, fails to click, or your equipment does not respond, it is time to check or replace it. Burn marks or visible damage are also clear signs.

Tip: Test the switch with a multimeter for continuity.

Can you install a limit switch yourself?

Yes, you can install one if you follow the wiring diagram and safety instructions. Always disconnect power first. If you feel unsure, ask a qualified electrician for help.

What type of limit switch works best for cabinet doors?

A plunger or lever type usually works best for cabinet doors. These types give you reliable detection when the door opens or closes. You get quick feedback and easy installation.

| Switch Type | Best Use |

|---|---|

| Plunger | Door detection |

| Lever | Panel movement |

How often should you check limit switches in electrical cabinets?

You should check them every six months. Regular checks help you spot wear, dirt, or loose wires before they cause problems. In busy environments, inspect them more often.

Conclusion

What Is a Limit Switch? It’s a mechanical device used in electrical cabinets to detect movement, control power, and enhance safety. When activated by a door or part, it changes electrical signals instantly. Found in Linkewell control panels, it helps automate processes, prevent accidents, and reduce downtime. From plunger to rotary types, proper installation and maintenance ensure precise control, long life, and compliance with safety standards.