In the world of air filtration, panel filters are a fundamental component, playing a crucial role in maintaining air quality and system efficiency. Found in countless HVAC systems, these simple yet effective devices are the first line of defense against airborne contaminants.

This ultimate guide will delve into the intricacies of panel filters, explaining what they are, how they work, and why they are indispensable. We’ll explore their various types, applications, and provide essential tips for selection and maintenance to ensure optimal performance.

What is a Panel Filter?

A panel filter is a fundamental type of air filter, primarily used in heating, ventilation, and air conditioning (HVAC) systems, as well as various industrial and commercial applications. It typically consists of a rigid frame (often made of cardboard, plastic, or metal) holding a filtration material, which can be synthetic fibers, fiberglass, or a combination.

Its main purpose is to remove airborne particles such as dust, dirt, pollen, mold spores, and other contaminants, thereby improving indoor air quality, protecting downstream equipment from damage, and ensuring the efficiency of the HVAC system.

Panel filters are often used as pre-filters in multi-stage filtration systems to capture larger particles and extend the life of more expensive, higher-efficiency filters.

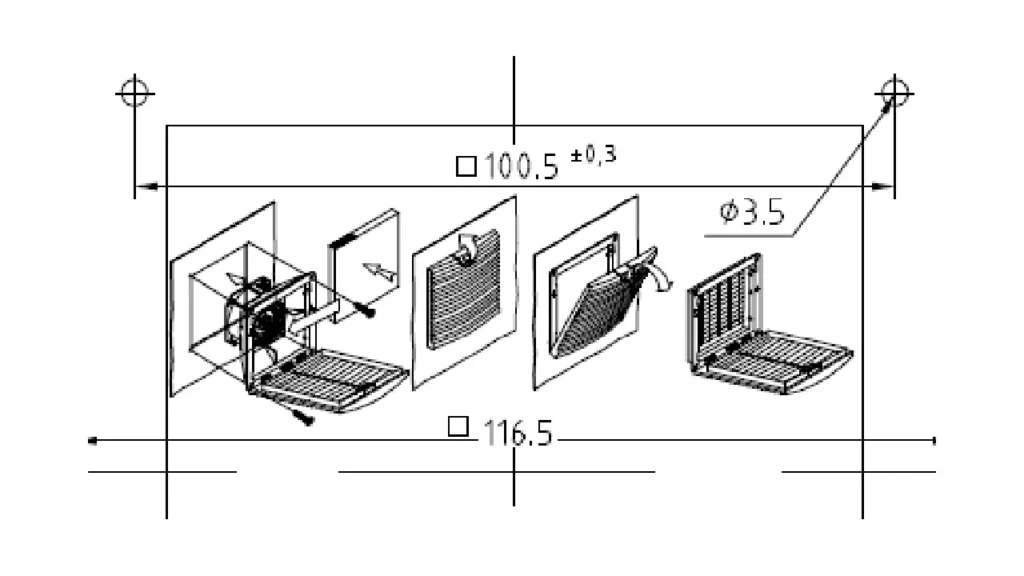

Panel Filter Structure

The structure of a panel filter is designed for straightforward air filtration, typically comprising a few key components that work together to hold the filter media securely and facilitate airflow. This simple yet effective design allows for easy installation and replacement in a wide range of HVAC systems and other air handling units.

Here are the primary components of a panel filter’s structure:

Frame:

- This is the rigid outer border that encloses the filter media. Frames are commonly made from heavy-duty cardboard (often moisture-resistant), plastic, or galvanized steel.

- The frame provides structural integrity, allowing the filter to be securely seated within an air handling unit’s filter rack and preventing air from bypassing the filtration media.

Filter Media:

- This is the heart of the filter, responsible for trapping airborne particles. The media can vary widely depending on the filter’s efficiency.

- Common materials include spun fiberglass (for lower efficiency), synthetic fibers like polyester or polypropylene (often pleated for higher efficiency), and sometimes cotton or other natural fibers.

Support Grid/Facing (Optional but common):

- Many panel filters, especially pleated ones, include a wire or expanded metal grid (often on the air-leaving side) to provide additional support to the filter media.

- This grid prevents the media from collapsing or fluttering under airflow pressure, maintaining the integrity of the pleats and ensuring consistent filtration performance.

Pleats (for pleated panel filters):

- In higher-efficiency panel filters, the filter media is often folded into a series of pleats.

- Pleating significantly increases the total surface area of the filter media within the same overall filter dimensions, allowing for greater dust-holding capacity and longer service life compared to non-pleated designs.

This increased surface area also often contributes to better filtration efficiency without excessively restricting airflow.

How Do Panel Filters Work?

Panel filters operate on a straightforward mechanical filtration principle, capturing airborne particles as air passes through their fibrous media. The filtration process primarily relies on two mechanisms:

- Impingement: Larger and heavier particles, due to their inertia, are unable to follow the airflow around the filter fibers and instead collide directly with them, becoming trapped on the surface. This is particularly effective for bigger dust particles and lint.

- Interception: Smaller particles that manage to navigate around the initial fibers may still come into contact with the fibers due to their proximity. As they pass very close, they are intercepted and adhere to the fiber surface, even if they don’t directly collide.

- Diffusion (for very small particles): For extremely tiny particles (sub-micron size), their random, chaotic motion (Brownian motion) increases the likelihood of them colliding with and attaching to the filter fibers as they travel through the media. This effect is more pronounced in higher-efficiency filters with denser media.

Over time, as particles accumulate on the filter media, the filter becomes more restrictive, reducing airflow and eventually requiring replacement to maintain system efficiency and air quality.

What are Panel Filters Used for?

Panel filters are ubiquitous in air filtration, serving a wide array of purposes across residential, commercial, and industrial settings. Their versatility stems from their ability to effectively capture a broad range of airborne contaminants, protecting both human health and mechanical equipment.

Here are the primary applications and uses for panel filters:

Residential HVAC Systems:

- Air Quality Improvement: They are the most common type of filter found in home furnaces, air conditioners, and heat pumps. Their primary role is to capture dust, pollen, pet dander, mold spores, and other allergens, significantly improving indoor air quality and reducing respiratory irritants.

- Equipment Protection: By trapping airborne debris, panel filters prevent these contaminants from entering and damaging the sensitive internal components of HVAC units, such as coils, blowers, and ductwork, extending the lifespan and efficiency of the system.

Commercial and Industrial HVAC Systems:

- General Filtration: In larger buildings like offices, schools, hospitals, and retail spaces, panel filters serve as a crucial first stage of filtration, removing general dust and particulate matter from circulated air to maintain a comfortable and healthy environment for occupants.

- Pre-filtration: They are very commonly used as pre-filters in multi-stage filtration systems. By capturing larger particles, they protect and extend the life of more expensive, higher-efficiency HEPA or activated carbon filters located downstream. This reduces overall maintenance costs and ensures the longevity of specialized filtration media.

Industrial Applications:

- Machinery Protection: In manufacturing plants, workshops, and other industrial environments, panel filters are used in air intake systems for machinery and equipment. They prevent dust, chips, and other airborne debris from entering sensitive components, which can cause wear, blockages, and operational failures.

- Paint Booths: They are often found in paint spray booths to filter incoming air, ensuring a clean, dust-free environment for painting processes and preventing defects on finished products.

- Dust Collection Systems: Panel filters are integral components of many dust collection systems, capturing particulate matter generated during industrial processes like woodworking, grinding, and sanding, improving worker safety and environmental compliance.

Specific Equipment and Appliances:

- Air Purifiers: Some standalone portable air purifiers utilize panel filters, often in conjunction with other filter types, to clean the air in smaller spaces.

- Kitchen Exhaust Hoods (certain types): While less common than mesh or baffle filters, some kitchen exhaust systems, particularly in commercial settings, might use panel filters for grease and particulate removal.

- Fan Coil Units: These individual HVAC units found in commercial and multi-unit residential buildings frequently use panel filters to filter the air being conditioned for a specific zone.

In essence, panel filters are fundamental wherever air needs to be cleaned, protecting both people and precision equipment from the detrimental effects of airborne contaminants.

When to Change Your Panel Filters

Changing your panel filters regularly is one of the simplest yet most crucial tasks for maintaining a healthy indoor environment and ensuring the efficient operation of your HVAC system. The “when” depends on a variety of factors, including the type of filter, household conditions, and system usage.

For standard low-efficiency panel filters (MERV 1-4), a general recommendation is to replace them approximately every 30 days. However, this can be a starting point, and visual inspection is always the best indicator. A dirty filter will appear visibly grey or black with accumulated dust and debris, and it may even have a noticeable layer of grime.

Here are key factors that influence how often you should change your panel filters:

Type of Filter:

- Low-Efficiency (MERV 1-4): These thin, often fiberglass filters capture larger particles but clog quickly, typically requiring replacement every 30 days to remain effective.

- Medium-Efficiency (MERV 5-8): Pleated filters with more surface area can last longer, often needing replacement every 30-90 days, offering better particle capture.

- High-Efficiency (MERV 9+): These filters trap very small particles but can also restrict airflow more, potentially requiring checks every 60-180 days, depending on system compatibility and conditions.

Household Conditions:

- Pets: Homes with furry friends introduce more dander and hair, leading to faster filter accumulation, often requiring changes every 30-60 days.

- Allergies/Asthma Sufferers: To maintain optimal indoor air quality and minimize triggers, more frequent changes (e.g., monthly) are often recommended for those with respiratory sensitivities.

- Number of Occupants: More people in a home generally means more activity and generated airborne particles, accelerating filter loading and demanding more frequent replacements.

HVAC System Usage:

- Continuous Operation: If your heating or cooling system runs frequently, especially during peak seasons or in extreme climates, the filter will accumulate particles much faster, necessitating more frequent changes.

- Intermittent Use: For systems used less often, such as in vacation homes or during mild weather, filters may last longer between replacements, though regular checks are still advisable.

Environmental Factors:

- Construction/Renovations: Nearby construction, home renovation projects, or even a dusty outdoor environment can significantly increase the airborne particulate load, requiring more frequent filter changes.

- Smoking/Candles/Fireplaces: Indoor activities like smoking, burning candles, or using a wood-burning fireplace release fine particles that quickly clog filters, demanding more frequent replacement.

Visible Signs:

- Dirty Filter: The most obvious sign is a filter that appears visibly dirty, grey, or clogged with dust, lint, and debris.

- Reduced Airflow: If you notice a weaker airflow from your vents, it’s a strong indication that the filter is blocked and restricting air movement.

- Increased Dust: A noticeable increase in dust accumulating on surfaces throughout your home suggests the filter is no longer effectively trapping particles.

- Higher Energy Bills: A clogged filter forces your HVAC system to work harder, consuming more energy and leading to an unexplained increase in your utility bills.

- Unpleasant Odors: Musty or dusty smells emanating from your vents can indicate a filter overloaded with contaminants.

Regularly checking your panel filter (at least once a month for low-efficiency types) and replacing it as needed will help ensure clean indoor air, protect your HVAC system from unnecessary strain, and maintain its energy efficiency.

How Often Should a Low-Efficiency Panel Filter Be Changed

Low-efficiency panel filters, often made of fiberglass and with a MERV rating of 1-4, are designed to capture larger particles and offer minimal airflow resistance. While they are the most affordable option, they also require the most frequent replacement to maintain decent air quality and prevent strain on your HVAC system. A general guideline is to change them monthly, but this can vary significantly based on several factors.

The frequency of changing a low-efficiency panel filter depends heavily on your specific environment and usage patterns. Neglecting timely replacement can lead to reduced airflow, decreased system efficiency, higher energy bills, and ultimately, accelerated wear and tear on your HVAC equipment.

Here are key factors influencing replacement frequency:

- Occupancy and Activity Level: Homes with more residents, especially those with active children or frequent guests, generate more dust, dander, and airborne particles, necessitating more frequent filter changes.

- Presence of Pets: Animals shed fur and dander, significantly increasing the particulate load on your filter. If you have pets, particularly those that shed heavily, expect to change your filter every 20-45 days.

- Allergies or Respiratory Issues: For individuals with allergies, asthma, or other respiratory sensitivities, maintaining cleaner air is paramount. More frequent filter changes, possibly every 30-45 days, are crucial to minimize exposure to irritants.

- HVAC System Usage: If your heating or cooling system runs continuously, such as during extreme weather, the filter will accumulate particles much faster. During peak seasons, monthly checks are highly recommended.

- Outdoor Air Quality: Living near construction sites, busy roads, or in areas with high pollen counts or industrial pollution will introduce more contaminants into your home, requiring more frequent filter replacements.

Conclusion

Panel filters are essential for clean air and efficient HVAC systems. Understanding their function, types, and maintenance ensures optimal performance and extends equipment lifespan. Regular replacement is key for sustained air quality.

For reliable, high-quality panel filters, consider Linkwell Electrics. They offer a comprehensive range of wholesale panel filters, providing durable and efficient solutions for various applications, ensuring your systems operate effectively.

Choosing the right panel filter from a trusted supplier like Linkwell Electrics ensures long-term benefits, from improved indoor environments to cost savings on energy and maintenance.