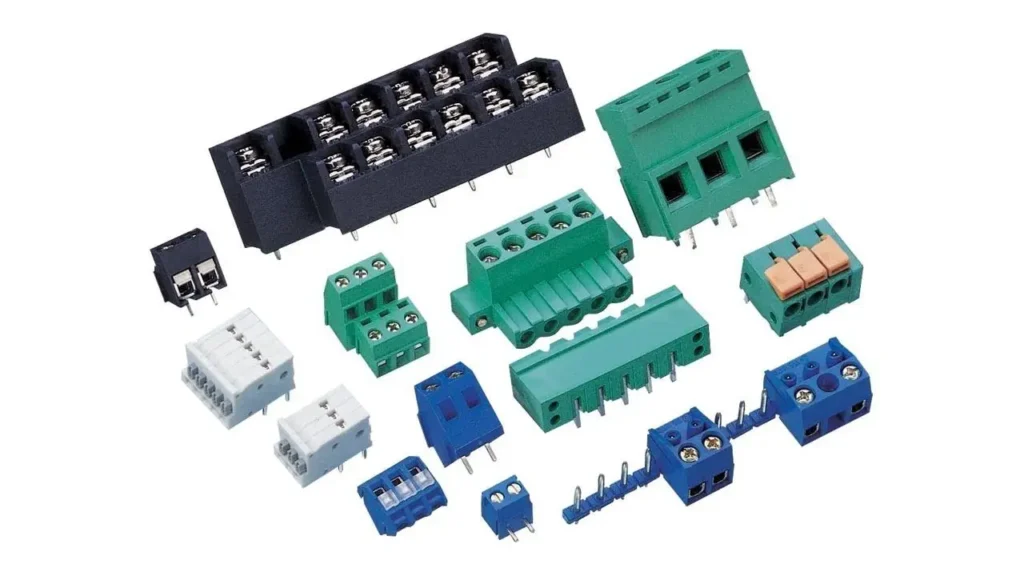

This guide dives into the essential world of terminal blocks, often unsung heroes in electrical connections. We’ll demystify these components, explaining their fundamental role in simplifying and securing wiring in countless applications.

Discover what a terminal block is, how it works, and why it’s indispensable for organized, reliable electrical systems. From their basic construction to diverse types and applications, this ultimate guide covers everything you need to know.

What is a Terminal Block?

A terminal block is a modular electrical connector designed to connect and organize two or more wires securely. It typically consists of an insulated body that houses a conductive metal strip and a clamping mechanism (like screws or springs) to hold the wires in place.

These terminal blocks provide a safe, convenient, and organized way to manage complex electrical circuits, simplifying wiring, troubleshooting, and maintenance in various applications, from industrial control panels to residential wiring.

Recommended Terminal Blocks

What Are Terminal Blocks Used For?

What is the purpose of a terminal block?

Terminal blocks serve as crucial components in a vast array of electrical systems, providing a secure and organized means of connecting wires. They are widely utilized to streamline wiring, enhance safety, and simplify maintenance across various industries and applications.

Common uses for terminal blocks include:

- Power Distribution: They act as central connection points for distributing power from a main source to multiple circuits or devices, ensuring efficient electricity flow.

- Industrial Control Systems: Essential in manufacturing and production facilities, they connect control signals, power supplies, and other electrical components within machinery and automation systems.

- Building Automation: From lighting and HVAC to security systems, terminal blocks organize and connect the numerous wires from sensors, actuators, and control devices.

- Telecommunications Equipment: Used in telephone exchanges, network cabinets, and data centers to structure and facilitate wiring connections for signal and power cables.

- Grounding and Protection: Specialized terminal blocks provide secure ground connections for electrical safety and can also integrate fuses to protect circuits from overcurrent.

- Motor Control: They are vital for securely connecting motor leads to motor starters or control centers, ensuring proper motor operation and protection.

- Sensor and Actuator Connections: In automation, they connect various input (sensors) and output (actuators) devices to control systems like PLCs.

What Do Terminal Blocks Do?

Terminal blocks primarily function to establish secure, reliable, and organized electrical connections between multiple wires. They act as intermediary connection points, enabling the seamless flow of electrical current or signals from one conductor to another. This core function is achieved by providing a housing that physically holds the wires and a conductive path that electrically links them, while simultaneously insulating adjacent connections to prevent short circuits.

Beyond basic connection, terminal blocks serve to simplify wiring layouts, making installation and maintenance more efficient. They allow for easy disconnection and reconnection of circuits, which is invaluable for troubleshooting, testing, and modifications without needing to cut or re-solder wires. Their modular design also facilitates scalability, allowing users to add or remove connections as system requirements change, ultimately enhancing the safety, reliability, and serviceability of electrical systems.

Types of Terminal Blocks

Terminal blocks are essential components in electrical systems, offering various designs to suit diverse applications, wire types, and mounting preferences. Selecting the appropriate type ensures efficient, safe, and organized electrical connections.

Screw Clamp Terminal Blocks

These are traditional and widely used, utilizing a screw to tighten a clamping plate against the stripped wire, creating a strong mechanical and electrical connection. They are known for their robustness and versatility, accommodating a wide range of wire sizes and are commonly found in industrial and power distribution applications where a secure, vibration-resistant connection is paramount.

Spring Clamp Terminal Blocks

Spring clamp terminal blocks employ a spring-loaded mechanism to secure the wire. The wire is inserted, and a spring applies constant pressure, holding it against the current bar. This design allows for quick, tool-free (or minimal tool) wiring, offers excellent vibration resistance, and provides a reliable, maintenance-free connection, making them popular in automation and control systems.

Push-in Terminal Blocks

Push-in terminal blocks enable rapid wiring by allowing solid wires or stranded wires with ferrules to be inserted directly into the connection point, where an internal spring automatically clamps the wire. They significantly reduce wiring time and are ideal for high-volume manufacturing, automated assembly, and applications requiring quick installation without specialized tools.

Plug-in Terminal Blocks

Also known as pluggable terminal blocks, these consist of two parts: a fixed base (header) and a removable plug-in connector. Wires are terminated into the plug, which then mates with the header. This design allows for quick disconnection and reconnection of entire wire bundles, simplifying maintenance, troubleshooting, and system upgrades, particularly in modular equipment.

Barrier Terminal Blocks

Barrier terminal blocks feature a series of insulated barriers between each connection point, physically separating adjacent terminals. Wires are typically secured with screws under these barriers. They are designed to prevent accidental short circuits between terminals and are often used in applications requiring clear isolation and robust connections, such as power distribution and control panels.

DIN Rail Terminal Blocks

DIN rail terminal blocks are designed to snap onto standardized metal DIN rails, commonly used in industrial control cabinets. These blocks are modular, allowing users to build customized terminal strips of various types (screw, spring, push-in, etc.) on a rail. They provide a highly organized, space-saving, and flexible wiring solution for complex electrical systems, simplifying installation and maintenance.

How Do Terminal Blocks Work?

Terminal blocks operate on a simple yet effective principle: they provide a secure and insulated housing for electrical conductors to meet and establish a connection.

At their core, they consist of a conductive metal part (often made of copper alloy for good conductivity) and an insulating body (typically plastic or ceramic). Wires are inserted into the block, and a clamping mechanism secures them against the conductive part, creating a reliable electrical path.

The specific mechanism for securing the wires can vary, but the fundamental idea remains the same:

- Screw Clamps: The most common type. Wires are inserted, and a screw is tightened, which presses a metal plate or yoke against the wire, creating a strong mechanical and electrical connection.

- Spring Clamps: These use a spring-loaded mechanism to hold the wire. The wire is either pushed directly into the opening (push-in type) or inserted after a lever or tool is used to open the spring clamp. The spring then applies continuous pressure to maintain the connection.

- Insulation Displacement (IDC): For specific applications, these blocks pierce the insulation of the wire with sharp metal contacts, making a connection without the need for stripping the wire.

These mechanisms ensure that wires are held firmly, preventing accidental disconnection and ensuring optimal electrical conductivity. The insulating body prevents current from escaping or shorting to adjacent connections, making terminal blocks a safe and efficient solution for managing electrical wiring.

How to Use a Terminal Block?

Using a terminal block effectively ensures secure and organized electrical connections. The process is straightforward, but proper technique is crucial for safety and optimal performance.

Step 1: Prepare the Wires

Before inserting wires into the terminal block, it’s essential to properly prepare them. This typically involves stripping the insulation off the end of the wire to expose the conductive metal. The length of the stripped wire should correspond to the terminal block’s specifications, usually indicated by a strip length guide on the block itself, ensuring enough bare wire for a secure connection without excess exposed conductor that could lead to short circuits.

Step 2: Insert Wires into the Terminal Block

Once the wires are prepared, they can be inserted into the appropriate clamping mechanism of the terminal block. For screw-type terminal blocks, you would loosen the screw, insert the stripped wire fully into the opening until it bottoms out, and then tighten the screw firmly to secure the connection. For spring-clamp terminal blocks, you might simply push the wire in (for push-in types) or use a tool to open the spring mechanism, insert the wire, and then release the tool or lever to allow the spring to clamp onto the wire.

Step 3: Test the Connection

After all wires are inserted and secured, it’s good practice to gently tug on each wire to confirm it is firmly held within the terminal block. A multimeter can also be used to perform a continuity test across the connected terminals to ensure a solid electrical connection. This step is vital to prevent loose connections, which can lead to intermittent operation, overheating, or even fire hazards in the long run.

Terminal Block Benefits

Terminal blocks offer a multitude of benefits that make them a preferred choice for electrical connections across various industries. Their core advantage lies in providing a highly organized and efficient method for wiring, which dramatically simplifies installation and ongoing management of electrical systems. This leads to reduced labor time and improved overall system reliability.

Furthermore, terminal blocks significantly enhance safety and flexibility within electrical circuits. They provide secure, insulated connections that mitigate risks of short circuits or accidental contact, while also allowing for easy modifications, expansions, and troubleshooting. Their robust design and wide array of types ensure they can meet diverse application requirements, from power distribution to intricate control systems.

Here are some key benefits of using terminal blocks:

- Enhanced Safety: By providing secure, insulated connections, terminal blocks reduce the risk of electrical shock, short circuits, and loose wiring. Many are designed with “finger-safe” features.

- Organized Wiring: They create neat and structured wiring layouts, especially in complex panels and systems, making it easier to manage and trace connections.

- Simplified Installation: Terminal blocks allow for quick and straightforward wire connections without the need for soldering, saving time during assembly.

- Easy Maintenance and Troubleshooting: The organized and accessible nature of terminal block connections simplifies identifying and resolving issues, reducing downtime.

- Flexibility and Modularity: Many terminal blocks are modular, allowing for easy addition, removal, or rearrangement of connections as system requirements evolve.

- Durability and Reliability: Designed to withstand mechanical stress and environmental factors, they provide robust and long-lasting connections.

- Space Saving: Multi-level terminal blocks, in particular, can significantly reduce panel space by allowing more connections in a compact footprint.

- Versatility: They accommodate a wide range of wire sizes and types and are suitable for various applications, from industrial automation to telecommunications.

How to Choose Suitable Terminal Blocks

Choosing the right terminal block is paramount for ensuring the safety, reliability, and efficiency of your electrical system. It’s not a one-size-fits-all decision, as various factors influence the optimal choice for a specific application. Careful consideration of these elements will prevent issues such as overheating, poor connections, and compliance failures.

The selection process involves evaluating both the electrical and mechanical requirements of your project, alongside environmental conditions and industry standards. Matching the terminal block’s specifications to your system’s demands will guarantee optimal performance and longevity.

Here are key factors to consider when choosing suitable terminal blocks:

- Current and Voltage Ratings: Always select a terminal block with current and voltage ratings that meet or ideally exceed the maximum expected values in your circuit. Over-rating by at least 150% is a common best practice to account for surges and ensure safety.

- Wire Size and Type Compatibility: Ensure the terminal block can accommodate the specific wire gauge (AWG or mm²) and type (solid or stranded) you plan to use. Different clamping mechanisms are better suited for different wire types.

- Connection Method: Choose between screw clamp, spring clamp, push-in, or insulation displacement (IDC) based on installation speed, vibration resistance, and ease of maintenance. Screw clamps are versatile, spring clamps offer quick connections, and push-in types are fast for solid or ferruled wires.

- Mounting Option: Consider how the terminal block will be installed. Common options include DIN rail mount (for industrial panels), PCB mount (for electronic circuits), and panel mount (for direct attachment to a surface).

- Environmental Conditions: Assess the operating environment. Factors like temperature range, humidity, dust, and vibration levels will influence the choice of material and construction (e.g., higher IP ratings for wet or dusty environments).

- Number of Poles/Circuits: Determine how many individual connections are needed. Terminal blocks come in various pole counts, and modular designs allow you to build custom lengths.

- Specialized Functions: If your application requires more than just basic wire-to-wire connections, consider specialized terminal blocks such as:

- Grounding Terminal Blocks: For creating secure earth connections.

- Fuse Terminal Blocks: To integrate circuit protection directly into the wiring.

- Disconnect Terminal Blocks: For easy circuit isolation during maintenance or testing.

- Sensor/Actuator Terminal Blocks: Designed for specific input/output device connections.

- Space Constraints and Orientation: Consider the available space in your enclosure or panel. Terminal blocks come in various profiles (single, dual, or triple level) and wire entry orientations (horizontal, vertical, 45°) to optimize space utilization and accessibility.

- Regulatory Compliance and Certifications: Verify that the chosen terminal blocks comply with relevant safety standards and certifications (e.g., UL, IEC) required for your application and region.

- Quality and Manufacturer Reputation: Opt for terminal blocks from reputable manufacturers known for producing high-quality, reliable components. This ensures consistency, performance, and adherence to specifications.

Conclusion

Terminal blocks are indispensable for safe and organized electrical connections across diverse applications. Their modularity and robust design ensure reliable circuit termination, simplifying wiring and maintenance. Understanding their types and proper usage is crucial for any electrical project.

Ultimately, terminal blocks provide a secure, efficient, and professional method for managing electrical wiring. They are fundamental components that contribute to the safety, reliability, and ease of troubleshooting in countless systems.

For all your wholesale terminal block needs, ensuring quality and competitive pricing, get wholesale terminal blocks from us.