If you’ve ever wondered what is machine tool control transformer, you’re in the right place. This device steps down voltage to a safe level so your machine tools run smoothly and stay protected. You count on a control transformer to keep your equipment reliable and your workspace safe. Linkwell delivers trusted solutions that meet strict industry standards. When you understand how to select, apply, and troubleshoot these transformers, you make smarter choices for your operations.

Key Takeaways

- Control transformers step down high voltages to safe levels, protecting your machines and ensuring smooth operation.

- Choose a transformer with high-quality materials and good thermal management to extend its lifespan and reduce maintenance needs.

- Look for transformers that meet industry standards for voltage regulation to keep your equipment safe and minimize downtime.

- Consider customization options to match the transformer to your specific project needs, ensuring optimal performance.

- Regular maintenance and quick troubleshooting can prevent common issues, keeping your control circuits running efficiently.

What is Machine Tool Control Transformer

Recommended products

Definition

You might ask, what is machine tool control transformer? This device is a special type of transformer that supplies power to the control circuits inside your machines. You use it to step down high voltages from the main power supply to a much safer level for your equipment’s control systems. Here’s what makes it unique:

- It powers auxiliary devices in switchgear or controlgear assemblies.

- It comes with rated primary and secondary voltages, so you know exactly what input and output to expect.

- It handles a rated burden, which means it can support the load of your control devices.

- It does not need the same accuracy as measuring transformers because its main job is to power things like solenoids, timers, and indicator lights.

When you look at automated manufacturing, you see the machine tool control transformer everywhere. It keeps your machines running safely and reliably by making sure the voltage is just right for sensitive control parts.

How It Works

Let’s break down how a machine tool control transformer does its job. You connect the transformer to your main power supply. It takes in a higher voltage—sometimes 110V, 220V, 380V, or even 690V—and steps it down to a lower, safer voltage like 6V, 12V, 24V, or 110V. This lower voltage goes straight to your control circuits.

Here’s a quick look at typical voltage ranges:

| Input Voltage (V) | Output Voltage (V) |

|---|---|

| 110 | 6, 6.3, 9, 12, 24, 48, 100, 110, 120, 220 |

| 220 | 6, 6.3, 9, 12, 24, 48, 100, 110, 120, 220 |

| 380 | 6, 6.3, 9, 12, 24, 48, 100, 110, 120, 220 |

| 690 | 6, 6.3, 9, 12, 24, 48, 100, 110, 120, 220 |

You get a few important benefits from using a control transformer:

- It steps down voltage to protect sensitive components from damage.

- It provides electrical isolation between the main power and your control circuits, so faults in one area don’t affect the other.

- It handles inrush current, keeping voltage stable even when your machines start up and draw extra power.

- It keeps your control circuits safe from power surges and fluctuations.

In automated manufacturing, the machine tool control transformer does more than just lower voltage. It also supports electromagnetic components like relays, solenoids, and contactors. Here’s a table to show you the main functions:

| Function | Description |

|---|---|

| Voltage Regulation | Provides stepped-down voltages to machine tool control devices, ensuring stable operation. |

| Surge Current Management | Maintains secondary voltage stability during high-input surge currents. |

| Support for Electromagnetic Components | Works with relays, solenoids, contactors, and magnetic motor starters. |

You rely on the machine tool control transformer to keep your equipment running smoothly. It ensures your machines get the right voltage, protects your control circuits, and helps you avoid costly downtime.

Construction & Design

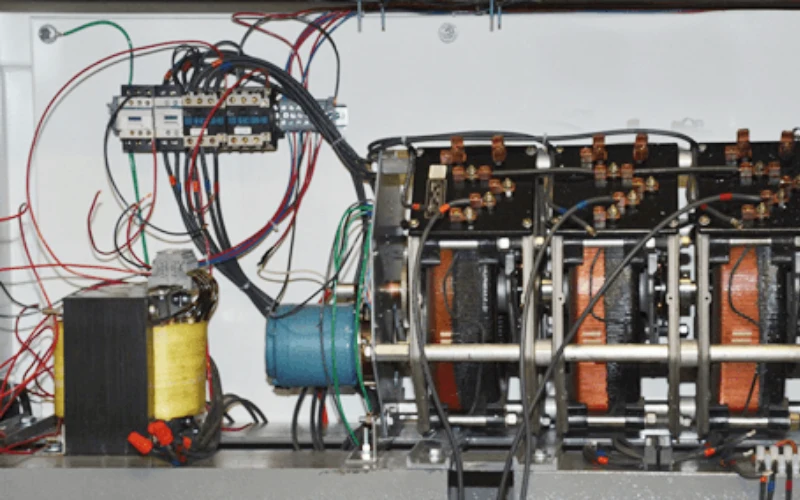

Core Components

When you look inside a machine tool control transformer, you see a few key parts that make everything work. The windings and the core do most of the heavy lifting. You usually find copper or aluminum in the windings. Copper gives you great conductivity and lasts a long time, but aluminum is lighter and costs less. The core uses silicon steel or sometimes an amorphous alloy. These materials help the transformer run efficiently and keep energy loss low.

Here’s a quick table to show you what goes into these components:

| Component | Material | Properties |

|---|---|---|

| Windings | Copper | Excellent electrical conductivity, ductility, corrosion resistance, but high cost. |

| Aluminum | Good conductor, lightweight, ductile, corrosion resistant, cost-effective alternative to copper. | |

| Core | Silicon Steel | High efficiency in electromagnetic flux induction, minimizes energy loss during magnetization. |

| Amorphous Alloy | Very low core losses, high efficiency, eco-friendly due to reduced eddy current losses. |

You want your transformer to last. Material quality matters a lot. If you choose high-quality metals and good insulation, your transformer will run longer and need less maintenance. You also need to think about cooling. Good thermal management keeps the transformer from overheating. If you match the transformer to your load requirements, you avoid stress and keep everything working smoothly. Regular checks and preventive maintenance help you spot problems early.

Here’s another table that shows what affects the lifespan of your transformer:

| Factor | Impact on Lifespan |

|---|---|

| Material Quality | High-quality materials enhance durability and reduce failure rates. |

| Thermal Management | Effective cooling systems prevent overheating and thermal stress, extending operational life. |

| Load Requirements | Understanding load characteristics helps avoid overloading and thermal degradation. |

| Environmental Conditions | Factors like humidity and temperature can degrade insulation and strain cooling systems. |

| Preventive Maintenance | Regular maintenance identifies issues early, preventing significant failures and prolonging lifespan. |

Voltage Regulation

You need a transformer that delivers stable voltage every time your machine starts or stops. Voltage regulation keeps your control circuits safe and your equipment running smoothly. If your transformer can’t handle changes in load, you might see flickering lights or even damage to sensitive parts.

Manufacturers use several methods to keep voltage steady. Tap-changing transformers let you adjust the voltage ratio when loads change. On-load tap changers work while the transformer is running, so you don’t have to shut anything down. Off-load tap changers need you to turn off the power first, which works best if your demand stays the same. Solid-state voltage regulators use electronic parts to make quick adjustments without moving anything.

Here’s a table that breaks down these methods:

| Method | Description |

|---|---|

| Tap-changing transformers | Adjust voltage ratios to respond to load variations without service disruption. |

| On-Load Tap Changers (OLTC) | Modify taps while under load for dynamic voltage management. |

| Off-Load Tap Changers | Require de-energization to change taps, suitable for stable demand conditions. |

| Solid-state voltage regulators | Use semiconductor devices for quick and reliable voltage adjustments without moving parts. |

You want your machine tool control transformer to meet industry standards. Most require output voltage regulation within ±1%. This keeps your devices safe and ensures stable voltage for every operation.

- Output Voltage Regulation: ±1% for stable device operation.

If you choose a transformer with good voltage transformation and strong regulation, you protect your equipment and keep your workspace safe. You get stable voltage, less downtime, and better performance.

Key Features of Linkwell Control Transformer

Safety & Reliability

You want your machines to run safely every day. Linkwell understands this need. Each control transformer from Linkwell comes with top safety certifications. You can trust these transformers in any industrial setting. They meet strict standards and pass tough tests before reaching you.

Here’s a quick look at the certifications you get with Linkwell:

| Certification | Description |

|---|---|

| UL | Underwriters Laboratories certification for safety standards |

| CE | Conformité Européenne marking for compliance with EU safety |

| ISO 9001 | International standard for quality management systems |

These certifications mean you get a product that keeps your equipment and team safe. You also get peace of mind knowing your control transformer meets global requirements.

Energy Efficiency

You care about saving energy and cutting costs. Linkwell designs each control transformer to use less power while delivering steady voltage. This helps your machines work better and last longer. You see lower energy bills and fewer breakdowns. The transformers handle high inrush currents, so your control circuits stay protected even during startup. You get a reliable solution that supports your business goals.

Tip: Using energy-efficient transformers can reduce your long-term operating costs and help your company meet sustainability targets.

Customization Options

Every project is different. Linkwell gives you many ways to customize your control transformer. You can choose the voltage, power capacity, enclosure type, and even add your own branding. This flexibility helps you match the transformer to your exact needs.

Here’s what you can customize:

| Customization Aspect | Description |

|---|---|

| Voltage Rating | Tailored to project requirements |

| Power Capacity | Adjusted to meet specific needs |

| Enclosure Type | Customized for application suitability |

| Branding | Options for personalized branding |

If you need special packaging or a custom logo, Linkwell can help. For orders of 500 pieces or more, you can get:

| Customization Type | Minimum Order Quantity |

|---|---|

| Customized logo | 500 pieces |

| Customized packaging | 500 pieces |

| Graphic customization | 500 pieces |

You get a partner who listens and delivers exactly what you need for your industry.

Control Transformer vs. Power Transformer

Functional Differences

You might wonder what sets a control transformer apart from a power transformer. The main difference comes down to what each one does in your system. A control transformer gives you a lower, stable voltage for your control circuits. You use it to power things like relays, contactors, and PLCs. A power transformer, on the other hand, moves large amounts of electricity from one place to another. It steps voltage up or down for transmission and distribution.

Here’s a table to help you see the differences at a glance:

| Feature | Control Transformer | Power Transformer |

|---|---|---|

| Purpose | Provides lower voltage for control circuits | Efficient transmission of bulk electrical power |

| Voltage Rating | Typically lower (e.g., 24V, 120V) | Higher (from several kilovolts to hundreds) |

| VA Rating | Low (up to around 5 kVA) | High (tens of kVA to hundreds of MVA) |

| Isolation Requirements | High isolation for safety | Isolation for efficient energy transfer |

| Construction | Compact, designed for control panels | Larger, often with cooling systems |

You can see that a control transformer focuses on safety and stable voltage for sensitive devices. Power transformers handle much bigger jobs and work with higher voltages.

Application Differences

You use a control transformer when you need to run control circuits in machines or panels. These transformers handle high inrush currents, which means they keep voltage steady even when devices like relays or contactors switch on. They also offer strong voltage regulation, so your control equipment stays protected.

Power transformers work best in places where you need to move a lot of electricity, like substations or power plants. They don’t handle high inrush currents the way control transformers do. Instead, they focus on stepping voltage up or down for efficient transmission.

Here’s another table to show how they compare in real-world use:

| Feature | Control Transformers (CPT) | Power Transformers (PT) |

|---|---|---|

| Impedance | Low impedance windings | High impedance loads |

| Voltage Regulation | High voltage regulation with compensated windings | Mainly for stepping voltages |

| Load Handling | Handles high inrush current loads | Not intended for high inrush applications |

| Application | Provides control voltage to relays, contactors, etc. | Used for metering and relaying purposes |

When you choose between these transformers, think about what your system needs. If you need to power control circuits, look for a control transformer with the right secondary voltage, VA rating, and good voltage regulation. If you need to move a lot of power over long distances, a power transformer is the way to go.

Tip: Always match the transformer type to your application. This keeps your equipment safe and your operations running smoothly.

Applications & Selection

Typical Uses

You see control circuits everywhere in modern industry. Automated assembly lines rely on control circuits to keep machines working safely and efficiently. You use a control transformer to reduce high line voltages to lower, safer levels for control circuits. This keeps your equipment protected and your workspace secure.

Here’s a table showing how control circuits benefit from control transformers in assembly lines:

| Application | Description |

|---|---|

| Voltage Reduction | Reduces high line voltages for safe control circuits operation. |

| Safety Isolation | Isolates control circuits from dangerous input voltages. |

| Surge Current Handling | Handles high inrush currents during switching in control circuits. |

You also find control circuits in telecom cabinets, electrical panels, and automation systems. Control circuits operate at lower voltages, like 24 or 120 VAC, which makes them safer for you and your team. Control circuits need isolation from high line voltages. Control circuits also require filtering of high voltage transients and noise. When you use control circuits with PLCs, you get stable power and reliable operation. Control circuits depend on voltage regulation to prevent disruptions. Control circuits stay protected from surges, which reduces downtime. Control circuits in manufacturing need accurate function, so stable power is crucial.

How to Choose

Picking the right control transformer for your control circuits can feel tricky. You want to match the voltage and power rating to your control circuits. You also need to think about the features that make your control circuits run smoothly.

Here’s a table to help you decide:

| Key Considerations | Description |

|---|---|

| Voltage Requirements | Match the transformer’s voltage to your control circuits. |

| Power Requirements | Make sure the power rating fits your control circuits’ needs. |

| Transformer Characteristics | Look for features that support your control circuits’ performance. |

If you need help, Linkwell offers expert guidance. You can reach out for advice on selecting the best transformer for your control circuits. You get support for custom solutions, so your control circuits always have the right fit.

Tip: Always check your control circuits’ voltage and power needs before ordering. This keeps your control circuits safe and your machines running.

Troubleshooting Tips

Sometimes, control circuits run into problems. You might notice overheating in your control circuits. This can happen if your control circuits face excessive load or poor cooling. Fluctuating voltage in control circuits often comes from loose connections or inconsistent power. Oil leakage affects insulation and cooling in control circuits, usually because of aging parts. Humming or vibrating control circuits may point to loose components. Insulation breakdown in control circuits can lead to short circuits, especially if moisture or chemicals are present.

Here’s a quick list of common issues with control circuits:

- Overheating in control circuits.

- Fluctuating voltage in control circuits.

- Oil leakage affecting control circuits.

- Humming or vibrating control circuits.

- Insulation breakdown in control circuits.

If you spot these problems in your control circuits, you can contact Linkwell’s support team. You get fast help and expert advice to keep your control circuits working. Regular checks and maintenance help prevent issues in your control circuits.

Note: Quick troubleshooting keeps your control circuits safe and your operations smooth.

You now know why machine tool control transformers matter for your operations. When you understand how these devices work, you keep your machines safe and efficient. Here’s what you gain:

- Control transformers protect your control panels by keeping voltage levels safe.

- They deliver steady voltage during overloads, which helps heavy machinery run smoothly.

- High-quality insulation boosts durability and reliability.

Choosing Linkwell means you get trusted performance and long-term value. Take a look:

| Feature | Benefit |

|---|---|

| High-performance magnetic core | Cuts energy use by 30% for lower costs. |

| Military-grade insulation | Keeps your system safe, certified to UL standards. |

| Lifespan | Designed for 25 years of reliable operation. |

If you want a partner who offers expert support, fast delivery, and custom solutions, Linkwell is ready to help you succeed.

FAQ

How do you pick the right control transformer for your machine?

You want to match the input and output voltage, power rating, and application type. Check your machine’s requirements. If you need help, reach out to Linkwell’s support team for expert advice.

Are Linkwell control transformers safe to use?

Yes! Linkwell transformers meet UL, CE, and ISO9001 standards. You get reliable protection against overloads, voltage spikes, and overheating. Your equipment and team stay safe.

How long does a control transformer last?

You can expect a Linkwell control transformer to last 10–15 years. With regular maintenance and proper installation, you may see even longer service life.

Can you customize a control transformer for your project?

Absolutely! Linkwell offers custom voltage, power ratings, enclosures, and branding. You get a transformer that fits your exact needs. Contact Linkwell for details and options.