A Motor Control Centre (MCC) is a centralized system designed to manage and protect multiple motors from a single location. So, what is Motor Control Centre exactly? It plays a crucial role in industrial and commercial settings by enhancing efficiency, safety, and energy savings.

MCCs are commonly integrated into electrical control panels. Linkewell provides reliable Motor Control Centre solutions globally.

Motor Control Centre Key Takeaways

- Motor Control Centres let you control and protect many motors from one place, making your operations safer and easier to manage.

- MCCs improve energy use and reduce downtime by monitoring motor health and adjusting motor speed to match demand.

- Linkewell offers reliable, customizable MCCs with strong safety features and cooling solutions to keep your system efficient and long-lasting.

What is Motor Control Centre

MCC Definition

So, what is motor control centre? You can think of it as the heart of your facility’s motor management. An MCC is a centralized system that lets you control, protect, and monitor several electric motors from one spot. If you work in an industrial or commercial setting, you know how important it is to keep motors running smoothly. The MCC brings all your motor controls together, making your job easier and safer.

When you ask, “what is motor control centre,” you’re really asking about a solution that handles everything from starting and stopping motors to protecting them from overloads. MCCs often sit inside electrical control panels, which act as the main hub for your power and automation needs. These panels organize all the wiring, switches, and safety devices you need for reliable operation.

Linkewell stands out as a global supplier of MCCs and electrical control panels. You get products that meet strict quality and safety standards, including UL, CE, and IEC certifications. This means you can trust your MCC to perform well and comply with regulations, no matter where your project is located.

Tip: Always check for certifications like UL, CE, and IEC when choosing an MCC. These show that the product meets international safety and performance standards.

Core Functions

You might wonder what makes an MCC so valuable in your daily operations. Here’s what you can expect from a modern motor control center:

- Centralized control of multiple motors, so you can manage everything from one place.

- Real-time monitoring of motor status, energy use, and faults, helping you spot issues before they become problems.

- Integration with automation systems like PLCs and SCADA, giving you remote access and advanced control features.

- Enhanced safety with built-in circuit breakers, overload relays, and fault detection to protect both people and equipment.

- Energy efficiency improvements using devices like Variable Frequency Drives (VFDs) that adjust motor speed to match demand.

- Modular design for easy expansion, so you can add or change motor setups as your needs grow.

- Predictive maintenance tools that use sensors and data analytics to catch problems early and reduce downtime.

- Reliable power distribution through busbars and Power Distribution Units (PDUs), keeping your motors supplied with balanced power.

Here’s a quick look at some key certifications you might see on a motor control centre:

| Certification/Standard Type | Examples/Details |

|---|---|

| North American Safety Standards | UL 1004 Series, CAN/CSA C22.2 No. 25, 30, 77, 100, 145, 213 |

| International Electrotechnical Commission (IEC) Standards | IEC 60034-5, IEC 60079-15, IEC 80079-36, IEC 80079-37 |

| Energy Efficiency Certifications | U.S. DOE, NRCan, CAN/CSA C390-10, IEEE 112-2004 |

| Hazardous Location Standards | UL/ISA/CSA C22.2 No. 60079-1, IEC 60079 series |

| Testing and Certification Bodies | CSA Group, UL Solutions, Intertek, TÜV SÜD |

You’ll find that modern MCCs do more than just switch motors on and off. They connect with your automation systems using communication protocols like Ethernet, Modbus, or Profibus. This means you can monitor and control your motors from a central computer or even remotely. Advanced MCCs also collect real-time data, so you always know how your motors are performing.

If you choose Linkewell, you get MCCs and electrical control panels that are ready for the latest industrial automation trends. You can count on their products for reliable power distribution, advanced monitoring, and easy integration with your existing systems. Whether you run a factory, a data center, or a commercial building, a well-designed MCC keeps your operations safe, efficient, and future-ready.

Motor Control Center Structure and Components

Key MCC Parts

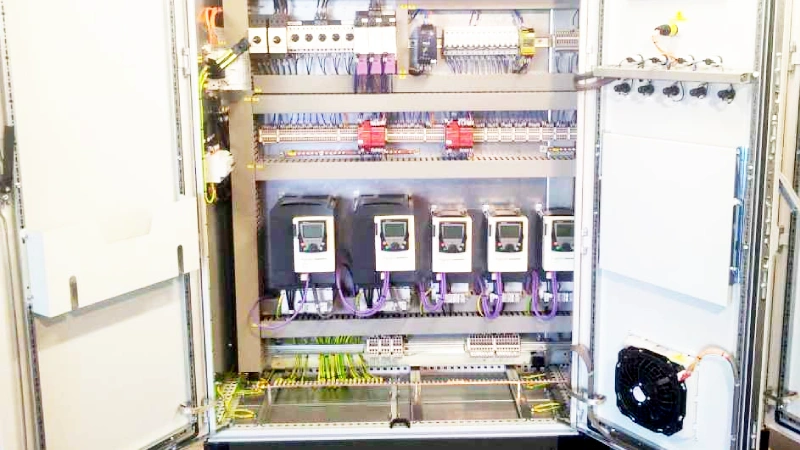

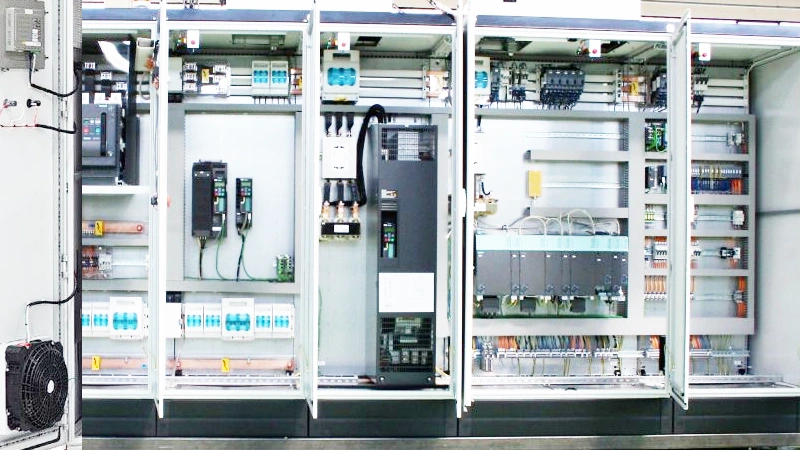

When you look inside a motor control center, you’ll see several important MCC components working together to keep your motors running safely and efficiently. Here’s what you’ll typically find:

- Motor control units: These include switches, relays, contactors, and starters. You use them to start, stop, and monitor each motor.

- Horizontal bus: This part carries the main power across the MCC, feeding electricity to all the vertical sections.

- Vertical bus: It connects the power from the horizontal bus to each starter unit, making sure every motor gets the right amount of power.

- Control and monitoring systems: These systems use PLCs, VFDs, and network connections for remote operation, diagnostics, and energy efficiency.

- Protection devices: You’ll find overload relays, circuit breakers, and disconnect switches. These protect your motors from short circuits, overheating, and other risks.

- Control circuitry: Push buttons, indicator lights, and wiring let you operate and monitor the MCC easily.

- Cooling and heating systems:Cooling and heating systems Fans and cabinet air conditioners as well as enclosure heating are key to ensuring component ventilation

All these MCC components come together in a cabinet, giving you centralized control, protection, and monitoring for your entire power distribution system.

Linkewell Electrical Control Panel Integration

You want your MCC to be reliable and easy to manage. Linkewell’s electrical control panels make that possible. These panels organize all your MCC components in a neat, accessible way. You get clear labeling, modular layouts, and smart monitoring features. This setup helps you spot issues quickly and keep your power flowing smoothly.

Linkewell panels meet strict UL, CE, and IEC standards. You can customize them for your industry, whether you need extra space for future expansion or advanced automation features. The modular design means you can add new motor starters or upgrade your system without major downtime. This flexibility keeps your power distribution systems ready for whatever comes next.

Tip: Customization options include special enclosures, advanced monitoring, and integration with your existing automation systems.

Cabinet Air Conditioner for MCCs

Heat and moisture can damage sensitive MCC components. That’s where a cabinet air conditioner comes in. Linkewell’s cabinet air conditioners keep your MCC at the right temperature and humidity. They use refrigerant-based cooling to move heat out and maintain a sealed environment. This protects your equipment from overheating, condensation, and corrosion.

| Function Aspect | Description |

|---|---|

| Temperature Control | Keeps MCC components cool, even in hot environments. |

| Humidity Control | Reduces moisture to prevent rust and electrical faults. |

| Environmental Suitability | Works in dusty, wet, or corrosive areas. |

| Maintenance | Needs regular filter cleaning and refrigerant checks. |

| Impact on Longevity | Extends the life of your MCC by protecting against heat and moisture damage. |

With Linkewell’s cooling solutions, you get reliable performance and longer equipment life for your motor control center.

MCC Benefits and Applications

Centralized Control

When you use an MCC in your industrial or commercial facility, you get centralized control over all your motors. This means you can manage, monitor, and adjust everything from one spot. Here’s how this helps you:

- You can regulate motor speed, torque, and direction with precision.

- Real-time monitoring and diagnostics let you spot problems before they cause downtime.

- Smart devices inside the MCC give you instant data, so you can make quick decisions.

- Modular designs let you expand or change your setup as your needs grow.

With centralized control, you reduce installation time, lower maintenance costs, and keep your power distribution organized. This setup leads to fewer interruptions and smoother operations.

Safety and Efficiency

MCCs bring improved safety to your workplace. Intelligent systems detect hazards like overheating or electrical faults, so you don’t have to send workers into risky areas. Built-in protection devices, such as overload relays and circuit breakers, help prevent accidents and equipment damage. Remote monitoring means you can troubleshoot issues without being on-site, which keeps everyone safer.

You also get enhanced efficiency. MCCs use advanced automation and monitoring to optimize motor performance. Variable Frequency Drives (VFDs) adjust motor speed to match demand, cutting down on wasted energy. Predictive maintenance tools use real-time data to schedule repairs only when needed, saving you time and money.

Linkewell Industry Solutions

You’ll find Linkewell MCCs and electrical control panels in many industrial and commercial settings. These include manufacturing plants, energy facilities, infrastructure projects, and data centers. Linkewell’s solutions support reliable power distribution and advanced monitoring, helping you meet strict safety and environmental standards. You can count on rapid delivery, full customization, and 24/7 support for every project. Linkewell’s commitment to quality ensures your operations stay efficient, safe, and future-ready.

- You get centralized control and protection for all your motors, making your industrial operations safer and more efficient.

- Linkewell’s panels offer easy maintenance, strong safety features, and room for future growth.

- Trust Linkewell for reliable MCC solutions that keep your business running smoothly.

FAQ

What is the main difference between an MCC and a regular electrical panel?

You use an MCC to control and protect motors. A regular panel manages general electrical circuits, not just motors.

How do you keep an MCC cool in a hot environment?

You install a cabinet air conditioner. This keeps your MCC at a safe temperature and helps prevent overheating.

Can you customize Linkewell MCCs for your project?

Yes! You can request custom sizes, layouts, and features. Linkewell builds MCCs to fit your exact needs.

Conclusion

What is Motor Control Centre? It’s the heart of efficient, safe motor management across industrial and commercial systems. MCCs combine smart monitoring, automation, and protection in a single unit. With customizable options, remote access, and modular design, MCCs improve uptime, safety, and energy use.

At Linkewell, we deliver globally certified MCCs ready for your automation and power needs. Whether you’re upgrading or building new, trust us to power your operations with confidence. Contact our team today to get started.