Ever wondered why do transformers blow? Most times, it happens because of electrical faults, insulation breakdown, overload, or even harsh weather. High-voltage transformers can fail in a big way, but you usually do not see that with low-voltage ones.

You get extra peace of mind with Linkwell’s low-voltage and control transformers. Thanks to patented safety technology, these units stay safe and reliable—no fire, no explosion. Understanding transformer blowouts keeps you and your equipment safe.

Key Takeaways

- Transformers can blow due to electrical faults, overload, insulation failure, and environmental factors. Understanding these causes helps prevent failures.

- Regular maintenance is crucial. Inspect transformers monthly for leaks and overheating. Schedule yearly inspections to catch problems early.

- Linkwell transformers use patented safety technology to prevent fire and explosions. They are designed for reliability, even in tough conditions.

- Look for warning signs of transformer failure, such as strange noises or flickering lights. Acting quickly can prevent serious damage.

- Choose trusted brands like Linkwell for peace of mind. Their transformers meet strict safety standards and handle power surges effectively.

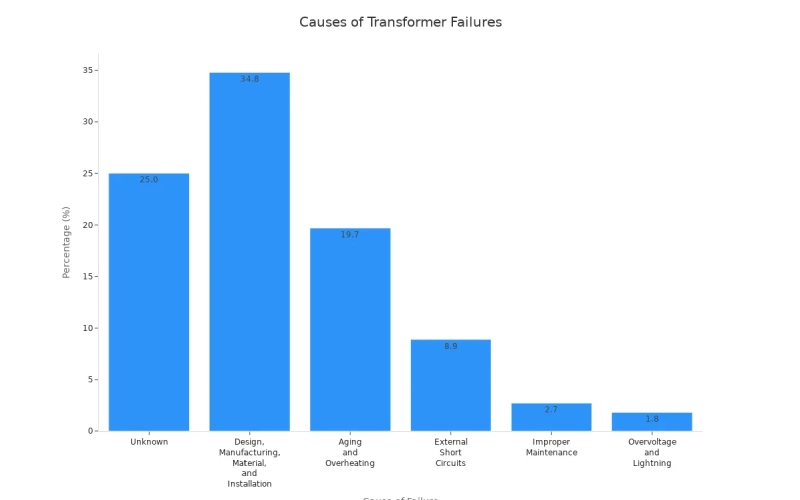

Causes of Transformer Blow

Transformers play a huge role in keeping your power running smoothly, but sometimes things go wrong. You might wonder, why do transformers blow? Let’s break down the most common causes and see how you can spot trouble before it leads to a transformer explosion.

Electrical Faults and Overload

You often hear about transformers blowing up because of electrical faults. These faults can happen inside the transformer or come from outside sources. Here are some of the main electrical issues that lead to transformer failure:

- Overvoltage conditions, like lightning strikes or sudden grid changes, can push the transformer past its limits. This can break down insulation and cause a transformer explosion.

- Short circuits and ground faults send too much current through the windings. This heats up the transformer and damages the insulation, making it more likely to fail.

- Harmonics and transients from industrial machines can stress the windings, causing extra heat and wear.

Overloading is another big reason why transformers blow. When you connect too many devices or draw more power than the transformer can handle, it gets hot fast. Studies show that overloading causes the transformer to explode in about 16% to 29% of all cases. If you keep pushing a transformer past its rated capacity, you risk a transformer explosion and a total power outage.

Tip: Always check the load on your power transformer. If you notice flickering lights or warm panels, you might be overloading the system.

Linkwell’s low-voltage, power, and control transformers use patented safety technology to prevent these problems. Our transformers handle inrush current and overloads without catching fire or exploding. You get peace of mind, even during a power surge.

Insulation Failure and Short Circuits

Insulation keeps the electrical parts inside a transformer separated and safe. When insulation breaks down, you get a direct path for electricity to jump across, which is why does a transformer blow so suddenly. Insulation failure leads to transformer blows in dramatic ways, often with sparks or even fire.

| Degradation Agent | Resulting Condition |

|---|---|

| Humidity | Breaks down insulation faster than time |

| Heat and oxidation | Reduced dielectric strength leading to failure |

| Moisture contamination | Causes partial discharge and arc inception |

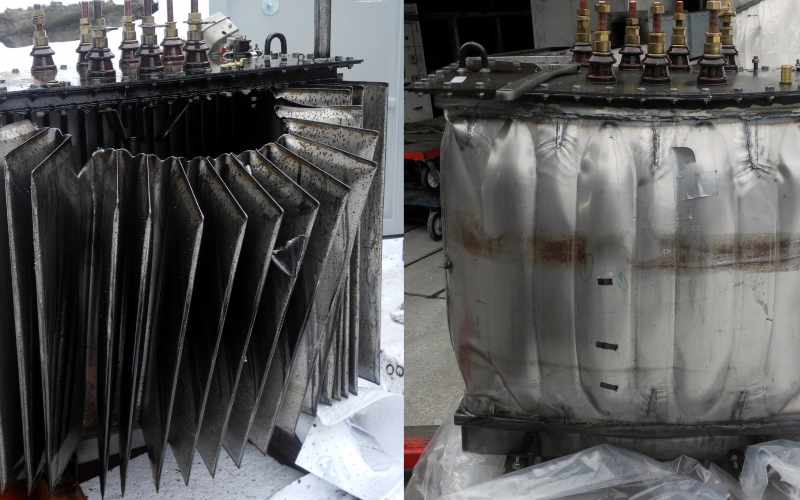

You might see insulation failure from heat, moisture, or just old age. Aging insulation, especially in older power transformer units, can crack and lose strength. When this happens, short circuits cause transformers to explode. You’ll often hear a loud bang or see smoke if insulation failure leads to transformer blows.

Short circuits are another common cause. If a wire inside the transformer touches where it shouldn’t, or if water gets inside, short circuits cause transformers to explode almost instantly. That’s why regular checks and good maintenance matter so much.

Linkwell transformers use high-grade insulation and advanced sealing. Our patented designs keep moisture and heat out, so you don’t have to worry about insulation failure leading to transformer blows.

Environmental and External Factors

Sometimes, the environment itself answers the question: why do transformers blow? Weather and outside events can hit transformers hard.

| Weather Condition | Impact on Transformer Reliability | Preventative Measures |

|---|---|---|

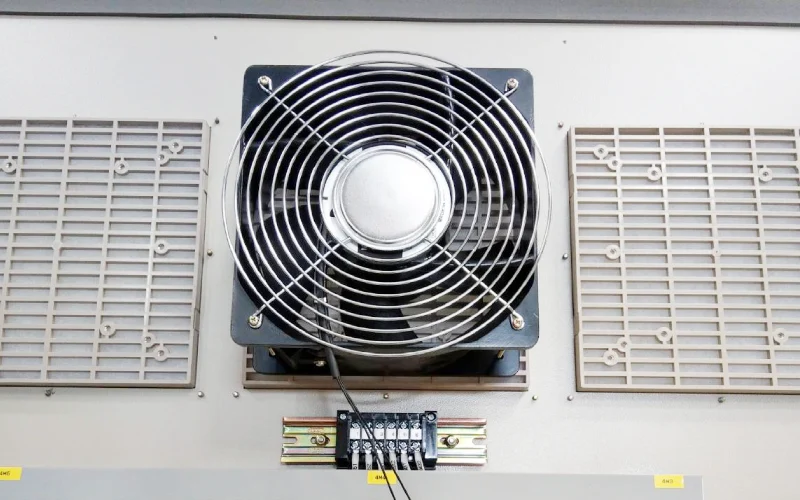

| High Temperatures | Overheating, degrading insulation, increased fire risk | Cooling systems, heat-reflective coatings |

| Low Temperatures | Oil thickening, brittle materials, moisture condensation | Synthetic oils, oil heaters |

| Humidity and Rain | Insulation breakdown, increased discharge activity | Moisture-absorbing breathers, oil sampling |

| Flooding | Short-circuits, corrosion, insulation problems | Raised installation, weather-resistant enclosures |

| Wind | Damage to connections and cooling fins | Structural reinforcement |

| Lightning | Insulation breakdown, surge damage, arc flash events | Grounding, surge arresters, lightning rods |

Lightning strikes and power surges can send a huge jolt through the transformer. Direct strikes or even nearby lightning can cause overvoltage, leading to insulation flashover and sometimes a transformer explosion. Switching surges from the grid can also damage winding insulation.

Note: Proper protection, like surge arresters and grounding, helps keep your transformer safe from these threats.

Flooding, high winds, and extreme temperatures also put stress on transformers. Humidity and rain speed up insulation breakdown, while heat can warp components. These are all common causes of transformer failure in outdoor installations.

But here’s the good news: Linkwell’s low-voltage, power, and control transformers are built to handle tough environments. Our patented technology and strict quality controls mean you won’t see a transformer explosion or fire, even when the weather turns bad.

High-Voltage vs. Low-Voltage Transformer Risks

You might ask, why do transformers blow more often at high voltages? High-voltage transformers face bigger risks from surges, insulation breakdown, and short circuits. When a high-voltage transformer fails, the results can be dramatic—loud explosions, fire, and widespread outages.

Low-voltage transformers, like those from Linkwell, are much safer. Our control transformers and step-down transformers use advanced protection features. You get reliable performance without the risk of fire or explosion. That’s why so many industries trust Linkwell for safe, dependable power transformer solutions.

Why Does a Transformer Blow? Signs and Consequences

Physical and Audible Signs

You might notice some clear signs before transformers blow. When a transformer failure is about to happen, you often hear a loud bang or popping sound. Sometimes, you see sparks, smoke, or even flames. The smell of burning insulation or oil can fill the air. Lights may flicker or go out. If you stand near a power transformer, you might feel the ground shake during a transformer explosion. These signs tell you what happens when a transformer blows and help you act fast.

Power Outages and Hazards

When transformers blow up, the impact can be huge. You can lose power for hours, days, or even longer. The risk of transformer damage changes by location. Some counties in the US face a risk 1000 times higher than others. The corridor between Washington DC and New York sees the highest risk. In rare cases, like a Carrington-level geomagnetic storm, outages could last 1 to 2 years and affect up to 40 million people.

Power surges cause exploding electrical transformer events, leading to widespread outages and hazards. Always make sure your system has proper protection.

Here’s a quick look at the hazards linked to transformer failure:

| Hazard Type | Description |

|---|---|

| Human Safety | Injuries or fatalities of personnel and release of toxic gases posing health threats. |

| Power Outages | Disruption of operations in facilities leading to production and revenue loss. |

| Property Damage | Extensive damage to transformers and nearby equipment resulting in high repair costs. |

| Environmental Impact | Contamination of soil and water bodies due to the release of oil and toxic gases during fires. |

The International Council on Large Electrical Systems (CIGRE) stresses the need for fire protection and safety guidelines to reduce these risks.

Impact on Equipment and Safety

What happens when a transformer blows? The damage spreads fast. Power transformer blowouts can trip circuit breakers, stress busbars, and burn cables. CT/PT equipment may lose insulation and fail to work right.

| Component | Possible Reaction Post-Blowout |

|---|---|

| Circuit breakers | Trip on fault current surge |

| Busbars | Experience mechanical stress |

| Cables | Burn or melt from arc proximity |

| CT/PT equipment | Lose insulation, fail accuracy |

Short circuits and surges can damage everything connected to the power transformer. You risk losing expensive equipment and facing safety threats. Power surges cause exploding electrical transformer incidents, but with Linkwell’s patented technology, you avoid fire and explosion. Our low-voltage, power, and control transformers offer advanced protection, keeping your facility and people safe.

Recognizing Transformer Failure

Warning Signs Before a Blow

You can often spot trouble before a transformer failure happens. Look for early warning signs, like strange noises, overheating, or a sudden drop in performance. Maintenance records show that continuous hydrogen monitoring is one of the most reliable ways to catch problems early. Hydrogen is the first gas released when insulation breaks down or overheating starts inside a power transformer.

| Early Warning Sign | Description |

|---|---|

| Continuous Hydrogen Monitoring | Indicates developing problems, especially from overheating or insulation breakdown. Hydrogen is the first fault gas released during incipient faults. |

You might also notice oil leaks, discoloration, or a burning smell. Predictive maintenance technologies help you stay ahead of transformer failure. These tools use advanced monitoring to catch issues before they become dangerous.

| Technique | Description |

|---|---|

| Dissolved Gas Analysis (DGA) | Checks gases in transformer oil to spot overheating and insulation problems. |

| Partial Discharge Monitoring | Finds insulation breakdowns before they cause failure. |

| Temperature Monitoring | Tracks heat changes to prevent overheating. |

| Vibration Analysis | Detects mechanical issues that could lead to transformer failure. |

| Moisture Content Analysis | Watches for moisture in insulation to avoid breakdowns. |

Predictive maintenance makes it much easier to identify transformers at risk of blowing. You get early alerts and can act before a power transformer fails.

What Happens During a Transformer Blow

When a power transformer blows, you see and hear it right away. You might hear a loud bang or see sparks and smoke. Sometimes, flames shoot out, and the area fills with the smell of burning oil or insulation. Short circuits or overloading can trigger these events. Surges or sudden spikes in current often make things worse. The explosion can damage nearby equipment and create a serious safety hazard.

If you use Linkwell’s low-voltage, power, or control transformers, you do not have to worry about fire or explosion. Our patented technology gives you extra protection and peace of mind.

Recommended products

Immediate Steps to Take

If you suspect a transformer failure or see a power transformer blow, act fast to stay safe. Here’s what safety authorities recommend:

| Step | Action |

|---|---|

| 1 | Isolate the transformer from all power sources |

| 2 | Activate emergency response protocols |

| 3 | Secure the site with hazard signage |

| 4 | Notify the control center and safety team |

| 5 | Assess for fire or oil leaks |

| 6 | Prevent public or staff access |

- Stay clear of the area right away.

- Avoid downed power lines at all costs.

Quick action and proper protection can prevent injuries and further damage. Always trust certified transformers with advanced safety features, like those from Linkwell, to reduce your risk.

Preventing Transformers Blow with Linkwell Solutions

Linkwell Control Transformer Safety

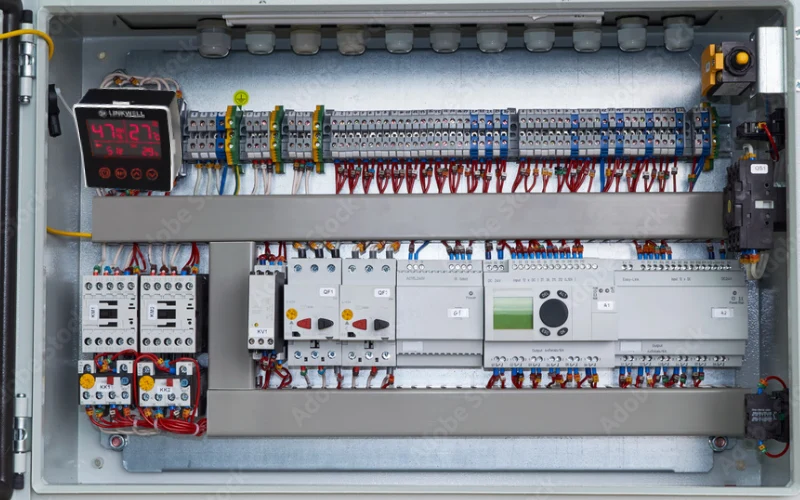

You want transformer safety you can trust. Linkwell’s control transformers stand out because they use patented safety technology that keeps your equipment safe from fire risks and explosions. These transformers are built with military-grade insulation and advanced thermal management. That means you get strong protection against electrical failure, overloading, and surges. You never have to worry about manufacturing defects cause transformers blowing up—Linkwell’s strict quality control and certifications like UL and CE keep you covered.

Linkwell’s low-voltage, power, and control transformers are designed not to catch fire or explode. This unique safety feature gives you peace of mind, even in tough environments.

Step Down Transformer Reliability

When you choose a step down transformer, you want it to last. Linkwell’s step down transformers use high-quality materials and a high-performance magnetic core. This design cuts energy use by 30% and keeps your system running for up to 25 years. You get fewer breakdowns and lower costs compared to other brands. Here’s how Linkwell compares:

| Feature | Benefit |

|---|---|

| High-performance magnetic core | Cuts energy use by 30% |

| Military-grade insulation | Certified to UL standards for safety |

| Lifespan | Designed for 25 years of operation |

You also get strong protection against fire risks and electrical failure. Linkwell’s transformers handle current spikes and overloading without trouble. You avoid the worry of how do we deal with transformer explosions because these units are built to prevent them.

Maintenance and Best Practices

You can boost transformer safety and reliability with regular care. Here’s a simple checklist to help you prevent problems:

- Inspect your transformer every month for leaks, overheating, or strange noises.

- Check oil levels and cooling systems.

- Test alarms and protection devices each quarter.

- Schedule a full inspection and dissolved gas analysis every year.

- Every three to five years, run advanced tests like winding resistance and oil quality checks.

Regular maintenance helps you spot issues early, so you never have to ask how can we prevent transformer explosions or how do we deal with transformer explosions. Always choose a trusted brand with proven safety features and strong transformer protection. Linkwell’s transformers give you the protection you need, so you can focus on your business—not on fire risks or electrical failure.

You’ve seen why transformers blow—electrical failures, poor maintenance, wiring issues, and sudden power surges top the list. High-voltage units face bigger risks, but Linkwell’s low-voltage, power, and control transformers use patented technology to prevent fire and explosion.

| Safety Step | Why It Matters |

|---|---|

| Routine inspection | Catches problems early |

| Training programs | Keeps your team safe |

| Grounding and PPE | Protects against accidents |

Choose Linkwell for peace of mind. Always follow safety steps and call a professional if you spot trouble.

FAQ

What causes a transformer to blow?

You usually see transformers blow because of electrical faults, overload, or insulation breakdown. Weather can also play a role. High-voltage units face bigger risks. Linkwell’s low-voltage transformers use patented safety technology, so you avoid fire or explosion.

How can I tell if my transformer is failing?

You might hear strange noises, see smoke, or notice flickering lights. Sometimes, you smell burning insulation. If you spot these signs, act fast. Linkwell transformers rarely show these issues thanks to advanced protection.

Are Linkwell transformers safe for my facility?

Absolutely! Linkwell’s low-voltage, power, and control transformers use patented technology. You never have to worry about fire or explosion. These units meet strict UL and CE standards for safety.

What maintenance should I do to prevent transformer failure?

Check your transformer every month for leaks, overheating, or odd sounds. Test alarms and protection devices. Schedule yearly inspections. Regular care helps you catch problems early and keeps your system safe.

Can Linkwell transformers handle power surges?

Yes! Linkwell transformers are built to handle surges and overloads. Patented safety features protect your equipment. You get reliable performance without the risk of fire or explosion.

Conclusion

Understanding Why Do Transformers Blow is essential for ensuring stable industrial operations and avoiding costly downtime. By choosing certified, high-quality transformers and proper installation, you can prevent failures and extend service life.

We at Linkwellelectrics provide reliable transformer solutions, expert guidance, and customization services for wholesalers and industrial clients. Contact us today to secure your power systems with proven performance and fast delivery tailored to your business needs.