You might wonder what is water to air heat exchanger. It’s a device that moves heat from water to air, helping you keep things cool and safe. You’ll find it especially useful if you want to protect sensitive electronics or boost energy efficiency in your systems. With the global market for these devices growing fast and more industries choosing them for energy-saving goals, it’s clear they make a difference. Linkwell offers advanced water to air heat exchanger solutions to fit your needs.

Key Takeaways

- A water to air heat exchanger transfers heat from water to air, keeping sensitive electronics cool and safe.

- These devices are essential for managing heat in control cabinets, telecom cabinets, and other enclosed spaces.

- Linkwell offers customizable heat exchangers that fit various applications, ensuring efficient cooling in tough environments.

- Using a water to air heat exchanger can significantly reduce energy costs and greenhouse gas emissions, benefiting both your budget and the environment.

- Regular maintenance and proper installation are key to maximizing the lifespan and efficiency of your heat exchanger.

What is Water to Air Heat Exchanger

Simple Definition

If you have ever wondered what is water to air heat exchanger, you are not alone. Many people ask this question when they want to keep their equipment cool and safe. In simple terms, a water to air heat exchanger is a device that moves heat from water to air. You can think of it as a bridge that lets heat travel from one place to another without mixing the water and air together.

In engineering, experts describe a heat exchanger as a device that transfers thermal energy between two fluids. One fluid gets warmer while the other cools down. This happens without the fluids mixing or changing into steam or liquid. When you use a water to air heat exchanger, water flows through special tubes inside the device. Air passes over these tubes, and the heat from the water moves into the air. This process helps lower the temperature of the water and warms up the air.

You might also hear people call this device a liquid-to-air heat exchanger. Both names mean the same thing. They both describe a tool that helps you control temperatures by moving heat from water (or another liquid) to air.

Linkwell offers high-quality water to air heat exchangers for many industries. If you need a reliable way to manage heat in your control cabinets or electrical enclosures, Linkwell has solutions that fit your needs.

Main Purpose

Now that you know what is water to air heat exchanger, let’s talk about why you might need one. The main purpose of a water to air heat exchanger is to keep things cool and running smoothly. You use it when you want to remove heat from a closed space, like an electrical cabinet, and send that heat into the air outside.

Here’s a quick look at how a water to air heat exchanger works and what it does for you:

| Function/Component | Description |

|---|---|

| Water Source and Circulation | A pump moves heated water through tubes, keeping the system efficient and closed. |

| Heat Transfer Coil | Coils made of aluminum or copper heat up quickly as water flows through them. |

| Forced Air Distribution | A fan or blower pulls cooler air over the hot coils, warming the air before it leaves. |

| Energy Transfer Completed | Warm air is sent out, and the cooled water goes back to be reheated, starting the cycle again. |

| Applications | Used in control cabinets, air handlers, greenhouses, telecom cabinets, and more. |

You will find that a water to air heat exchanger is different from other types of heat exchangers. For example, water-to-water heat exchangers move heat between two water sources, while air-to-air types move heat between two air streams. The water to air heat exchanger stands out because it uses water to collect heat and air to release it. This makes it perfect for places where you need to keep electronics cool and dry.

If you want a device that protects your sensitive equipment from overheating, dust, and moisture, a water to air heat exchanger is a smart choice. Linkwell designs these devices to work in tough environments, so you can trust them to keep your systems safe and efficient.

Tip: When you see the term “liquid-to-air heat exchanger,” remember it means the same thing as water to air heat exchanger. Both help you manage heat in a simple, effective way.

How Heat Transfer Works

Step-by-Step Process

Let’s break down how a water to air heat exchanger moves heat from one place to another. Imagine you have a control cabinet that gets warm inside. You want to keep your electronics safe, so you use a water to air heat exchanger. Here’s what happens:

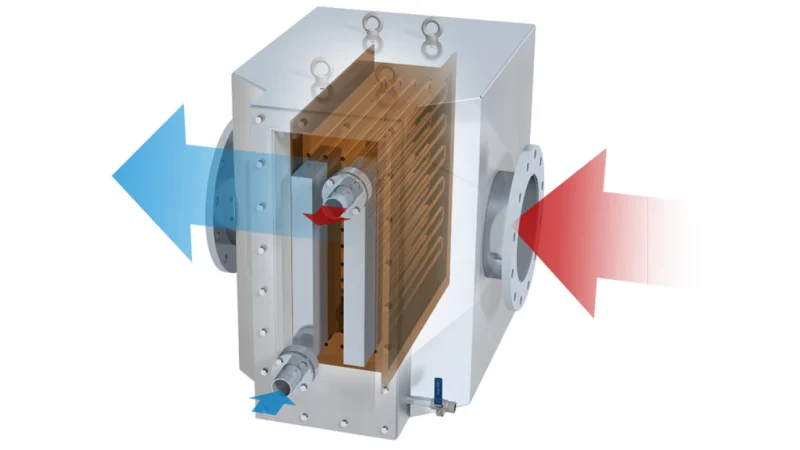

- Warm water flows through special tubes inside the heat exchanger.

- A fan pulls cooler air from outside and blows it over these tubes.

- The heat from the water moves into the air as they pass by each other.

- The now-cooled water goes back into your system to pick up more heat.

- The warmed air gets pushed out, keeping your cabinet at a safe temperature.

You can picture this like blowing on a hot cup of cocoa. Your breath (air) cools the cocoa (water) by carrying away the heat. The process repeats, so your equipment stays cool and protected.

Linkwell designs its water to air heat exchangers to make this process as smooth as possible. The aluminum fin-and-tube core helps move heat quickly, and the fan ensures steady airflow. This design gives you reliable heat transfer every time.

Key Principles

Three main principles make heat transfer possible in these devices. Here’s a quick look:

| Method | Description |

|---|---|

| Conduction | Heat moves when two materials touch. In the heat exchanger, heat travels from the water through the metal tubes. |

| Convection | Heat moves when fluids like air or water flow. The fan helps air carry heat away from the tubes. |

| Radiation | Heat can also move as energy waves, but this plays a small role here. |

You get the best results when all these methods work together. Linkwell’s design focuses on conduction and convection to boost heat transfer performance. The materials and layout help you get the most out of every cooling cycle.

Tip: If you want your equipment to last longer, pay attention to how well your system manages heat transfer. Good design means better protection and less downtime.

Linkwell Water to Air Heat Exchanger Features

Main Components

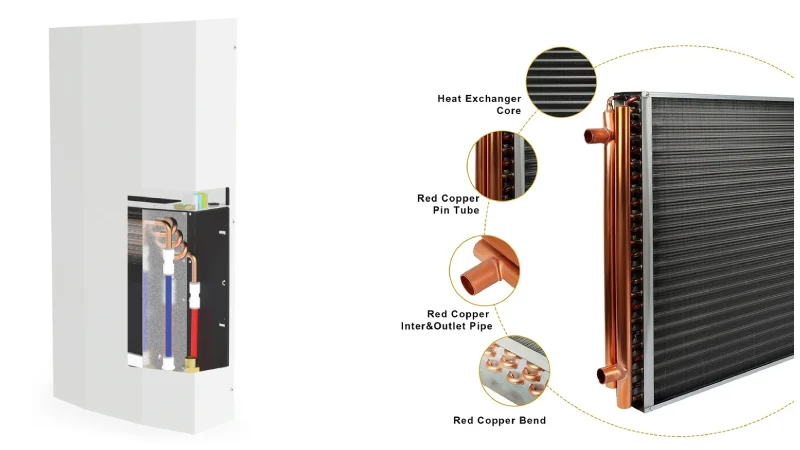

When you look inside a Linkwell heat exchanger system, you’ll notice several important parts working together to keep your equipment cool. Here’s what you’ll find:

- Aluminum fin-and-tube core: This is the heart of the heat exchanger system. Aluminum is lightweight and has great thermal conductivity, so it moves heat quickly from water to air.

- Fans or blowers: These help push air across the fins and tubes, making sure you get efficient heat dissipation.

- Sealed housing: The outer shell keeps dust and moisture out, protecting the inside parts.

- Control options: You can add thermostatic valves or pump controllers to fine-tune how your system works.

- Flexible mounting brackets: These let you install the unit on the side, top, or back of your cabinet.

You can see how each part plays a role in moving heat away from sensitive electronics. The design makes it easy to fit the heat exchanger system into different cabinet sizes and shapes.

Protection and Durability

You want your cooling solution to last, especially in tough environments. Linkwell builds its water to air heat exchangers with durability in mind. The materials used are chosen for their strength and resistance to corrosion.

Here’s a quick look at common materials and their advantages:

| Material | Advantages | Applications |

|---|---|---|

| Stainless steel | Excellent corrosion resistance, strong in many settings | Water-based and industrial systems |

| Copper/alloys | High thermal conductivity for fast heat transfer | HVAC and refrigeration |

| Aluminum | Lightweight, good for heat transfer | Automotive and air conditioning |

| Titanium | Handles harsh chemicals and saltwater | Marine and chemical processing |

| Nickel alloys | Stays strong at high temperatures | Petrochemical and aerospace |

Linkwell uses high-grade aluminum and stainless steel for most models. These materials help the unit resist rust and damage, even if you use it outdoors or in humid places. You also get IP65 or IP68 protection, which means the unit keeps out dust and water. That’s important if you need to cool cabinets in factories, telecom towers, or outdoor enclosures.

If you have special needs, Linkwell can customize the size, finish, and controls for your project. The heat exchanger system fits many cabinet types and works in a wide range of environments. You get peace of mind knowing your electronics stay safe and your cooling system keeps running strong.

Tip: Choosing the right materials and protection level helps your equipment last longer and saves you money on repairs.

Applications of Liquid-to-Air Heat Exchanger

Industrial Uses

You’ll find liquid-to-air heat exchangers in all sorts of industries where reliable cooling is a must. These devices help you manage heat in places where temperatures can rise quickly and sensitive equipment needs protection. Take a look at some of the most common industrial applications:

| Application Area | Description |

|---|---|

| Chemical | Keeps processes safe by managing heat in systems with corrosive fluids. |

| Oil & Gas | Delivers cooling during extraction and refining, where heat can build up fast. |

| HVACR | Supports heating, ventilation, and air conditioning systems for comfort. |

| Petrochemical | Handles thermal processes in chemical production plants. |

| Power Generation | Improves efficiency by managing heat in power plants. |

| Food & Beverages | Maintains the right temperature during food processing. |

In these settings, cooling isn’t just about comfort—it’s about safety and keeping your operations running smoothly. Linkwell’s solutions stand out because they use rugged construction and smart design to deliver reliable cooling, even in harsh conditions. You get corrosion-resistant materials and weather-tight seals that protect your electronics from dust, moisture, and other hazards. The closed-loop design keeps contaminants out, so your equipment lasts longer and works better.

Cabinet and Enclosure Cooling

You probably know how important cooling is for electrical enclosures and control cabinets. Without proper cooling, heat can damage sensitive electronics and cause unexpected shutdowns. Here are some key requirements for effective cabinet cooling:

- Install devices according to the manufacturer’s instructions.

- Make sure cooling air flows from top to bottom, and don’t block air intake openings.

- Leave enough space between components for airflow.

- Keep internal temperatures around +35°C to avoid condensation.

- Set up a regular cleaning cycle for your cooling system.

Passive cooling moves heat without powered parts, while active cooling uses fans or pumps. Picking the right type helps you protect your equipment.

You also need to think about the environment. If your enclosure faces lots of dust, moisture, or contaminants, a sealed cabinet with the right protection rating is essential. Linkwell’s water to air heat exchangers give you the cooling you need, even in tough spots like telecom towers, outdoor panels, or industrial plants. Their products adapt to different cabinet sizes and offer customizable cooling options, so you always get the right fit.

When you choose Linkwell, you get more than just cooling. You get peace of mind, knowing your equipment stays safe and your operations stay on track.

Benefits of Linkwell Water to Air Heat Exchanger

Efficiency and Reliability

When you choose a Linkwell water to air heat exchanger, you get a solution built for top efficiency and long-term reliability. These systems move heat quickly, so your equipment stays cool even in tough conditions. You save money because the design uses water’s natural ability to carry heat, which means less energy is needed to keep things running smoothly. Using air-to-water heat exchangers can lead to big reductions in energy use and lower your operating costs, especially if you work in an industry with high thermal loads. That’s a win for your budget and your peace of mind.

You also help the environment.

Heat exchangers can reduce greenhouse gas emissions by up to 20% in certain industries. They boost energy efficiency and cut down on fossil fuel use by recovering waste heat.

You want a product that lasts. Linkwell’s heat exchangers are built to serve you for years. Here’s what you can expect:

- Typical service life ranges from 10 to 20 years.

- Lifespan depends on how well you maintain the unit and the conditions where you use it.

You get a system that keeps working, year after year, with less downtime and fewer repairs.

Customization and Support

Every project is different. Linkwell understands that you need a heat exchanger that fits your exact needs. You can pick from different sizes, materials, and mounting options. The team helps you choose the right type for your application, whether you need a compact unit for a small cabinet or a heavy-duty model for a large enclosure.

Here are some key factors to consider when selecting your heat exchanger:

- Type of heat exchanger for your application.

- Material that matches your environment.

- Fluid flow setup for best efficiency.

- Surface area for optimal heat transfer.

- Temperature difference between fluids.

- Maintenance needs to keep things running smoothly.

You also get fast delivery and expert technical support. Linkwell’s team is ready to answer your questions and help you solve problems. You can count on them for guidance from start to finish.

Tip: Customization and support mean you get a solution that works for you, not just a one-size-fits-all product.

You now know how a water to air heat exchanger keeps your equipment cool and safe. This device uses smart design to move heat from water to air, protecting your electronics and saving energy. When you choose Linkwell, you get reliable solutions built for today’s needs and tomorrow’s trends. The market keeps growing as new technologies and smart features make cooling even easier. If you want peace of mind for your next project, Linkwell stands ready to help you move forward with confidence.

FAQ

What is a liquid-to-air heat exchanger?

You use a liquid-to-air heat exchanger to move heat from water or another liquid into the air. This device helps you keep your equipment cool and safe. You often find it in control cabinets and electrical enclosures.

How does a liquid-to-air heat exchanger protect electronics?

A liquid-to-air heat exchanger keeps the inside of your cabinet at a safe temperature. It moves heat out, so your electronics do not overheat. You also get protection from dust and moisture because the system stays sealed.

Where can you install a liquid-to-air heat exchanger?

You can install a liquid-to-air heat exchanger in control cabinets, telecom signal cabinets, and outdoor enclosures. The flexible mounting options let you place it on the side, top, or back of your cabinet.

Tip: Always follow the manufacturer’s instructions when you install a liquid-to-air heat exchanger. This helps you get the best cooling results.

What makes a liquid-to-air heat exchanger different from other cooling systems?

A liquid-to-air heat exchanger uses water or coolant to collect heat and air to release it. You get higher heat transfer capacity compared to air-to-air systems. This makes it perfect for places with high thermal loads.

| Cooling System | How It Works | Best Use Case |

|---|---|---|

| Liquid-to-air heat exchanger | Moves heat from liquid to air | Cabinets, enclosures |

| Air-to-air system | Moves heat between air streams | Simple ventilation |

| Water-to-water system | Moves heat between water sources | Industrial processes |

Can you customize a liquid-to-air heat exchanger for your project?

Yes, you can customize a liquid-to-air heat exchanger. You choose the size, material, and control options. Linkwell offers tailored solutions, so you get the right fit for your cabinet and environment.