You probably see din rails everywhere in electrical panels and control cabinets. The most common standard din rail dimensions you will find are 35mm wide by 7.5mm high and 35mm wide by 15mm high. These sizes make it easy to mount different devices securely. If you need something smaller, mini top hat din rails measure 15mm by 5.5mm. Some setups use 32mm wide rails for special needs.

When you look at profiles, standard din rail dimensions include top hat, C section, and G section. Check out this table for a quick view:

| Type | Description |

|---|---|

| Top hat (TH) | Hat-shaped cross section |

| C section | Standard C-shaped profile |

| G section | G-shaped profile for special uses |

You use these standard din rail dimensions to organize circuit breakers, terminal blocks, and relays in real projects. Linkwell offers a full line of din rail solutions that meet international standards, so you always get reliable quality.

Ready to protect your control cabinets from moisture and temperature swings?

Contact us today for quotes, OEM service, or technical support.

We respond quickly and support small, medium, and large orders.

Key Takeaways

- DIN rails come in standard sizes, with the most common being 35mm wide by 7.5mm or 15mm high. Choose the right size for your devices to ensure a secure fit.

- Different profiles like Top Hat, C, and G offer unique benefits. Top Hat is versatile for most applications, while C and G provide extra strength for heavier equipment.

- Material matters! Use aluminum for lightweight needs, stainless steel for corrosion resistance, and cold-rolled steel for cost-effective strength.

- Proper installation is key. Ensure a clean, flat surface, secure the rail tightly, and snap on your devices for a safe and organized setup.

- Regular maintenance of DIN rails helps prevent issues. Check for loose connections and corrosion to keep your electrical system running smoothly.

Standard DIN Rail Dimensions

When you work with electrical panels, you need to know the exact size of each din rail. These rails follow strict standards, so you can trust that your devices will fit every time. Let’s break down the most common types and their official measurements.

Top Hat (35mm) and Mini (15mm) Rails

You’ll see the top hat rail almost everywhere. This is the classic 35 mm mounting rail, and it’s the backbone of most modern control cabinets. The mini version is perfect for tight spaces or smaller devices. Both types follow the IEC/EN 60715 standards, which means you get reliable sizing and compatibility.

Here’s a quick look at their main dimensions:

| Type | Width (mm) | Height (mm) | Thickness (mm) |

|---|---|---|---|

| Top Hat | 35 | 7.5 / 15 | 1.0 – 1.5 |

| Mini | 15 | 5.5 | 1.0 |

You can use the top hat rail for mounting circuit breakers, relays, terminal blocks, and PLCs. The mini top hat rail works well for signal terminals and compact relays. Both types make your panel neat and organized.

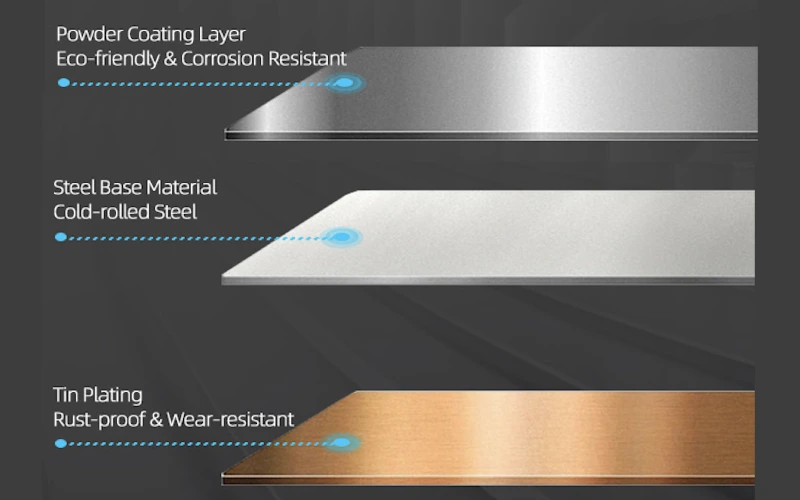

When you choose a din rail, you also need to think about the material. Linkwell offers several options, each with its own strengths:

| Material | Advantages |

|---|---|

| Cold-rolled carbon steel | Corrosion resistance, strong, cost-effective |

| Aluminum | Lightweight, good for sensitive electronics |

| Stainless steel | Highly resistant to corrosion, great for harsh areas |

- Aluminum is best if you want something light and easy to handle.

- Stainless steel stands up to tough environments, like food plants or outdoor panels.

You can always count on Linkwell to supply din rails that meet all the latest standards. Every rail is IEC 60715 certified, so you know you’re getting quality that matches global requirements.

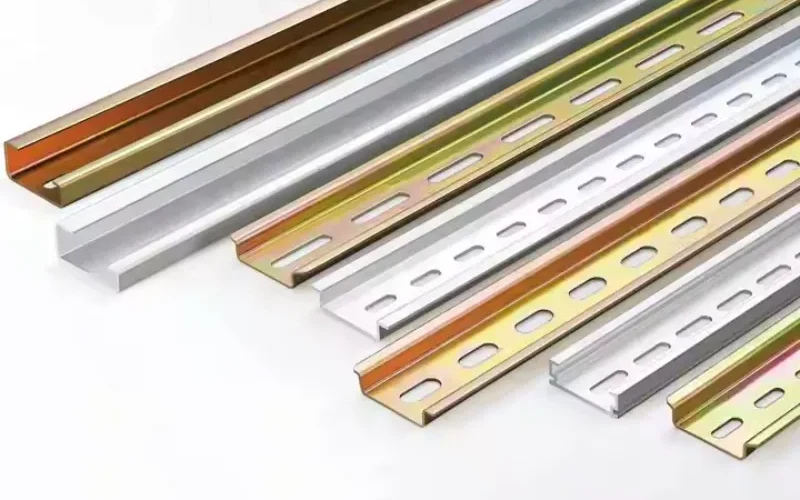

C and G Section Rails

Sometimes, you need a din rail that can handle heavier equipment or special mounting needs. That’s where C and G section rails come in. These rails have unique shapes and sizes, making them perfect for industrial setups.

Here’s how they compare:

| Type | Width (mm) | Height (mm) | Applications |

|---|---|---|---|

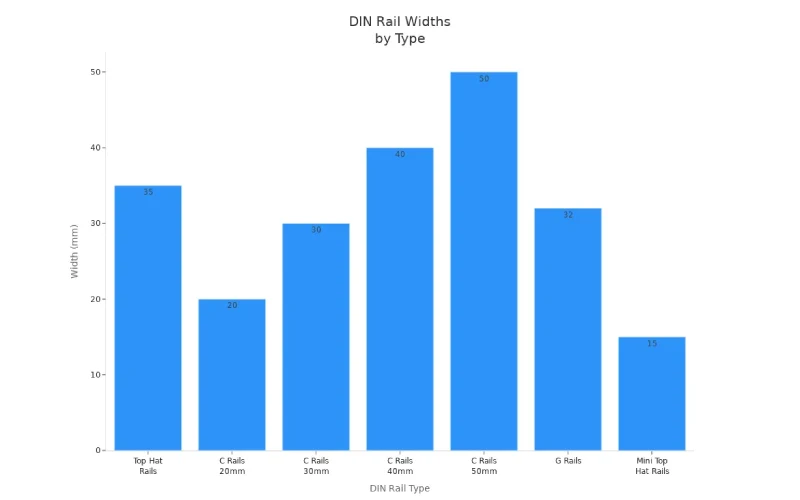

| C Rails | 20 / 30 / 40 / 50 | 15 – 25 | Heavy equipment, robust mechanical hold |

| G Rails | 32 | 15 | Industrial relays, older systems |

You’ll find C rails in places where you need extra strength. G rails are common in older panels or when you need to mount large relays. Both types follow the same strict din rail standards as the top hat rail, so you never have to worry about fit or safety.

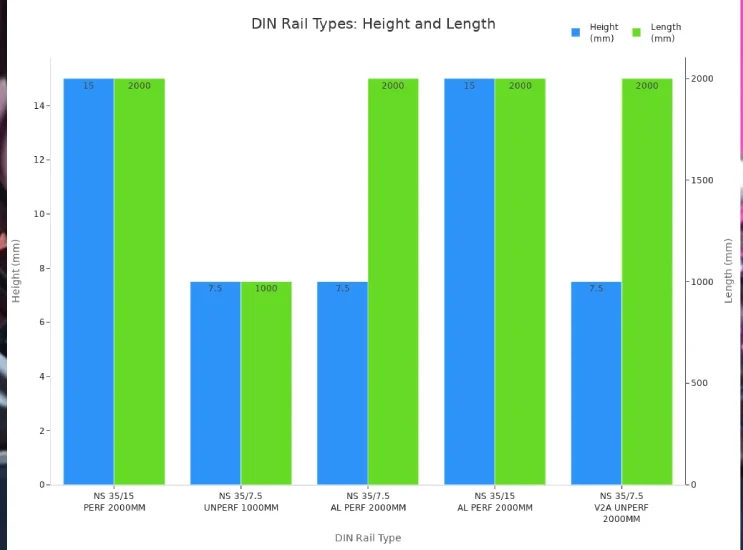

Check out this chart to see how the different din rail widths stack up:

Linkwell’s din rails come in all these sizes and materials. Every product meets international standards, so you can use them in any project, anywhere in the world. Whether you need a top hat rail, a mini rail, or a heavy-duty C or G section, you’ll find the right fit for your application.

DIN Rail Types and Profiles

When you look at electrical panels, you’ll notice that din rails come in a few main profiles. Each type has its own shape and purpose. Let’s break down the three most popular profiles you’ll find in real-world setups.

Top Hat (TH) Profile

You’ll probably see the top hat din rail first. This profile gets its name from the hat-like shape of its cross section. The edges flare outward, which makes it easy to snap on circuit breakers, relays, and terminal blocks. You can use this din rail in almost any control cabinet or automation panel. It’s the go-to choice for most modern electrical systems. The top hat profile supports quick installation and removal, so you can keep your wiring neat and organized. If you need a reliable solution for mounting devices, this din rail is a safe bet.

C Profile

The C profile din rail stands out because of its unique design. You’ll notice the C-shaped cross section, which lets you attach components using clip mechanisms that grip the inside channels. Here’s what makes this din rail special:

- The C profile is rated for systems up to 600 V.

- It has a total face width of 35 mm.

- You can use it for heavier equipment that needs a strong mechanical hold.

Unlike the top hat profile, the C profile din rail gives you extra flexibility for mounting. You’ll find it in setups where you need to secure larger devices or want more options for attachment.

G Profile

If you work in tough environments, the G profile din rail is your friend. This rail features a deep, G-shaped channel that locks components in place and prevents accidental dislodging. Manufacturers use this din rail for heavy-duty applications, especially where vibration and stability matter. Take a look at some typical use cases:

| Use Case | Description |

|---|---|

| Heavy-duty applications | Designed for high vibration and mechanical stability |

| Marine environments | Ideal for equipment exposed to harsh conditions and constant movement |

| Manufacturing panels | Secures components in industrial machinery and control systems |

You’ll see the G profile din rail in factories, ships, and places where equipment needs to stay put no matter what.

Note: Linkwell’s din rails meet IEC 60715 standards and carry UL/CE compliance. You get reliable quality and compatibility with all major electrical brands. No matter which din rail profile you choose, you can trust Linkwell to deliver products that work worldwide.

You can pick the din rail profile that fits your project best. Whether you need the quick mounting of top hat, the flexible attachment of C profile, or the rugged stability of G profile, Linkwell has you covered.

DIN Rail Uses and Applications

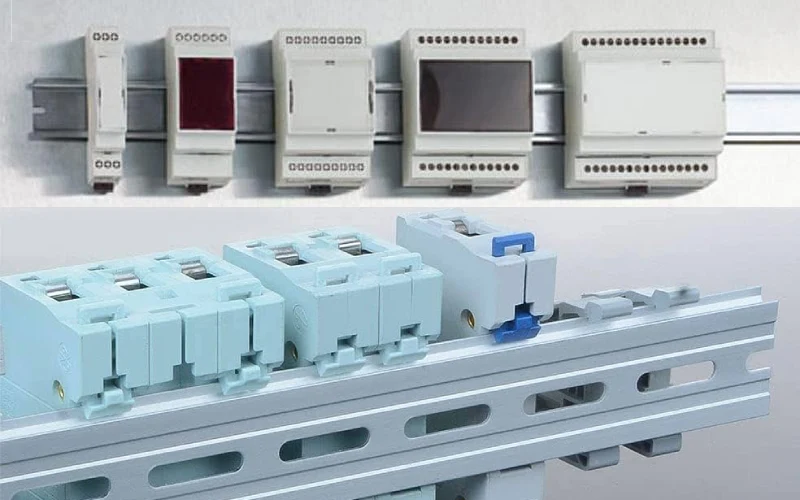

Mounting Electrical Components

When you open a din rail enclosure, you see how organized everything looks. The din rail sits at the heart of the panel, holding all your important devices in place. You can quickly snap on or remove components, which makes your job much easier. Here are some of the most common electrical parts you’ll mount on a din rail:

- Circuit breakers

- Terminal blocks

- Cabinet Fan

- Relays

- Contactors

- PLCs (Programmable Logic Controllers)

- Power supplies

- Industrial automation products

Terminal blocks play a big role in keeping your wiring neat. They let you connect and distribute wires safely, which helps you manage even the most complex systems. The din rail makes it simple to add or move these blocks as your needs change.

You get more than just convenience with a din rail. You also boost safety and efficiency. The rail keeps your devices secure, even when there’s vibration. It helps with airflow, so your equipment stays cool and lasts longer. The organized layout means you can spot problems fast and fix them without hassle. The modular design lets you expand or rearrange your setup whenever you want.

Tip: If you use a din rail enclosure, you can swap out a faulty relay or breaker without disturbing the rest of your system.

Industrial and Commercial Environments

You’ll find din rail systems in all sorts of places. Factories, power plants, and office buildings all rely on din rail enclosures to keep their electrical panels safe and tidy. In industrial applications, the din rail supports heavy-duty devices and stands up to tough conditions. You can add, remove, or move components without taking apart the whole panel. This flexibility means your system can grow as your needs change.

The din rail also helps you keep spare parts simple. Since most devices follow the same din standards, you don’t need a huge inventory. You can mix and match brands, which makes upgrades and repairs a breeze. The standardization of din rail technology means your installations stay organized, efficient, and ready for any challenge.

Linkwell’s din rail solutions work in automation, energy, and infrastructure projects around the world. If you need a reliable din rail enclosure for your next project, you can count on Linkwell to deliver quality and support every step of the way.

Selecting and Installing DIN Rail

Choosing the Right Size and Material

Picking the right din rail for your project can make your job much easier. You want to match the din rail size and material to your equipment and environment. Here’s what you should look for:

- Width and height compatibility matter. Make sure your devices fit the din rail. Most power supplies and components use a 35mm wide rail, with heights of either 7.5mm or 15mm.

- Think about the material. Steel and aluminum din rails work well for most jobs. If you need extra corrosion resistance, stainless steel is a smart choice.

- Check your environment. If you install the din rail outdoors or in a place with lots of vibration, pick a rail that can handle those conditions.

- Look at the size of your devices. Smaller power supplies usually fit on a 7.5mm high din rail. Larger equipment may need a 15mm high rail.

The material you choose affects how your din rail performs. Galvanized steel and aluminum offer strength and resist corrosion. These features help your din rail last longer, even in tough industrial settings.

Linkwell gives you more than just standard options. You can order custom lengths, private labeling, and even OEM or ODM support. Take a look at some of the value-added services:

| Service Type | Description |

|---|---|

| Customization & Flexibility | Adapt sizes, terminals, and colors to fit your panel and brand. |

| Cost Efficiency & Supply | Bulk packaging and large inventory for fast delivery and lower costs. |

| Service & Support | Technical help, dedicated managers, and after-sales support. |

If you need a din rail that matches your exact needs, Linkwell can help you create a solution that fits your project perfectly.

Installation Tips and Best Practices

Getting your din rail installation right keeps your panel safe and organized. Here’s a simple step-by-step guide:

- Pick the right din rail type and size for your devices.

- Make sure the mounting surface is clean and flat. Use a level to check.

- Fix the din rail in place. Use screws or fasteners so it stays secure and doesn’t wobble.

- Snap your electrical equipment onto the din rail after you finish the installation.

A good din rail installation means your devices stay put, even if there’s vibration or movement. Always double-check that everything is tight and secure before you close the panel.

Tip: Private labeling and OEM/ODM support from Linkwell help you meet special requirements. You can get din rails with custom branding, colors, or even unique features for your application.

With the right din rail and careful installation, you set up a system that’s safe, reliable, and easy to maintain.

You’ve seen how din rail sizes and materials shape your electrical setup. Check out this table for a quick summary:

| Type | Width (mm) | Height (mm) | Material |

|---|---|---|---|

| Top Hat | 35 | 7.5 / 15 | Steel, Aluminum |

| Mini | 15 | 5.5 | Steel |

| C/G Rail | 32 | 15-25 | Steel, Aluminum |

Choosing the right din rail keeps your connections secure and your system safe. You get certified din products from Linkwell, meeting CE, ROHS, and UL standards. If you want expert advice, you can call, email, or visit Linkwell’s website for help with din rail selection.

FAQ

What devices can you mount on a DIN rail?

You can mount circuit breakers, relays, terminal blocks, power supplies, and PLCs. Most modern control panels use DIN rails to keep these devices organized and easy to access.

How do you remove a device from a DIN rail?

Just release the mounting clip or latch on the device. Most components snap off the rail without special tools. This makes upgrades and quick swaps simple.

Can you reuse a DIN rail?

Yes, you can reuse a DIN rail if it stays straight and undamaged. Many electricians move rails to new panels or systems when needed.

Why is DIN rail maintenance important?

Regular maintenance helps you spot loose connections or corrosion early. This keeps your electrical system safe and running smoothly.

Are DIN rails safe for outdoor use?

DIN rails made from stainless steel or aluminum resist rust and moisture. You can use them in outdoor or harsh environments without worry.