Have you ever faced the challenge of picking the right din rail enclosure with terminals for a new project? You might ask yourself if you have the correct type for your project, or if your enclosures can handle tough environments. Many engineers run into questions about mounting style, safety, and space for future expansion. As a manufacturer of control cabinet components, we know that the right choice means better reliability and easier installation. If you want expert advice, Linkwell offers a wide range designed to fit your needs.

Key Takeaways

- Identify the correct DIN rail type for your project to ensure smooth installation and compatibility.

- Choose enclosures and terminal blocks based on material, safety features, and airflow to enhance system performance.

- Plan internal layouts carefully to maximize space and allow for future expansion without major rework.

- Select terminal blocks with appropriate current and voltage ratings to ensure safe and reliable operation.

- Verify that your enclosures meet necessary IP ratings and certifications to protect against environmental hazards.

DIN Rail Enclosure Compatibility

Identifying DIN Rail Types

When you start looking at din rail enclosures, the first thing you need to check is the type of din rail your project requires. Not all rails are the same, and picking the right one makes installation smoother. Here’s a quick table to help you compare the main types you’ll see in industrial setups:

| Type of DIN Rail | Description | Standards Used |

|---|---|---|

| Top Hat Rails | Most common, versatile, 35mm wide, available in 7.5mm and 15mm depths. | IEC/EN 60715 |

| C Section | Symmetrical rails with various heights (C20, C30, C40, C50). | EN 50024 (abrogated) |

| G Section | Used for heavier components, mounted with deeper side at the bottom. | EN 50035 (abrogated), BS 5825, DIN 46277-1 |

If you want global compatibility and safety, look for rails that meet IEC/EN 60715 standards. As a manufacturer of control cabinet components, we make sure our din rail enclosures work with all major rail types.

Matching Enclosure and Terminal Block

Choosing the right enclosures and terminal block is more than just picking a size. You need to think about how the enclosure material and mounting options affect the whole system. Here are some tips to help you match everything up:

- Material composition matters for secure connections and system performance.

- Grounding terminals and end covers boost safety and help you meet standards.

- Good spacing and airflow keep your terminal block cool and reliable.

- Organized wiring and secure mounting prevent problems with wire sprawl.

- If you work in tough environments, pick accessories that resist corrosion.

When you use din rail enclosures from Linkwell, you get solutions designed for easy wiring, safe mounting, and long-lasting protection.

Linkwell DIN Rail Features

Every project is unique, so you might need din rail enclosures with special features. Linkwell offers customization options to fit your needs. Check out some choices in the table below:

| Customization Option | Description |

|---|---|

| Modular Designs | Fit different PCB sizes, connectors, switches, displays, and cooling systems. |

| Modification of Standard Enclosures | Services like milling, drilling, color, printing, and fitting displays or keypads. |

| Environmental Sealing | Sealing mechanisms for moisture or dust exposure. |

| Thermal Management | Ventilation slots, fans, heat sinks, or insulation for heat dissipation. |

| Cable Management | Organized wiring solutions to prevent cable damage. |

With Linkwell, you get din rail enclosures that match your terminal block layout, meet international standards, and offer flexible customization. You can trust our expertise to help you build a reliable system.

Specifying DIN Rail Enclosures for Layout & Space

Internal Space Planning

When you start specifying din rail enclosures, you need to ask yourself, “how much room do you need?” The answer depends on your components, wiring, and future expansion plans. If you choose enclosures with modular design, you get flexibility to fit different layouts. Modular din rail enclosures let you customize the interior, so you can optimize space and keep everything organized. You can expand capacity without tearing down your existing setup. Take a look at how modular features help you save space:

| Modular Feature | Contribution to Space Efficiency |

|---|---|

| Customizable interior layouts | Lets you fit components exactly where you want them |

| Easy installation on standardized din rails | Speeds up mounting and saves space in control panels |

| Expandable capacity | Allows upgrades without major rework |

As a manufacturer of control cabinet components, we offer solutions that make planning and expansion easy.

Terminal Block Arrangement

Arranging terminal blocks inside din rail enclosures takes careful planning. You want to maximize accessibility and safety. Here are some best practices:

- Pick terminal blocks based on current and voltage ratings, wire gauge, and connector type.

- Fasten terminal blocks securely to the rail or enclosure.

- Label each terminal block and wire connection for quick identification.

- Inspect regularly for loose connections, corrosion, or overheating.

- Use protective equipment when working with power sources.

- Make sure wires are tight and rated for your application.

If you follow these steps, you keep your din rail enclosures safe and easy to maintain. Different terminal block configurations affect installation time and maintenance. For example, push-in types let you install wires faster and fit more connections in a small space.

| Criteria | Screw Clamp | Spring Clamp | Push-In |

|---|---|---|---|

| Assembly Speed / Labor | Slower | Faster | Fastest |

| Required Tools | Screwdriver | Spring tool | No tools (ferruled) |

| Wire Density | Moderate | High | Highest |

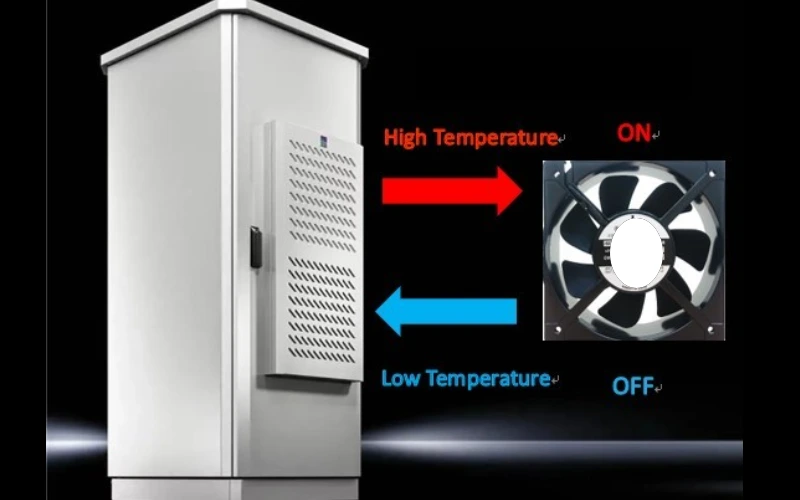

Airflow & Heat Dissipation

You need to think about airflow and heat dissipation when you specify din rail enclosures. Good airflow keeps your equipment cool and running smoothly. If you ignore heat, your components might overheat and fail early. Here are some tips:

- Airflow and heat dissipation prevent overheating in din rail enclosures.

- Stable temperatures help your equipment last longer.

- Ventilation slots and fan-filter units improve heat dissipation.

Linkwell’s enclosures come with options for ventilation and thermal management. You can fit fan-filter units or choose enclosures with built-in slots. These features help you protect your investment and keep your system reliable.

If you plan your layout, arrange terminal blocks carefully, and manage heat, you get din rail enclosures that fit your needs and last longer. We are a manufacturer of control cabinet components, and we design solutions to help you succeed.

Electrical & Mechanical Requirements

Current, Voltage, and Wire Size

When you choose din rail enclosures, you need to look at the electrical ratings for each terminal block. You want to make sure your system runs safely and reliably. Start by checking the current rating and maximum voltage for every terminal. If you pick a terminal block with a current rating that’s at least 150% higher than your system’s maximum, you get extra protection. Always select a block with a maximum voltage rating above your system’s highest voltage. This helps prevent damage from surges.

Here’s a quick table to guide you:

| Factor | Recommendation |

|---|---|

| Current Rating | Pick a terminal block with a current rating at least 150% of your system’s max |

| Maximum Voltage | Choose a block with a maximum voltage rating above your system’s max |

| Wire Sizes | Use AWG for North America, mm² for Europe to fit your application |

If you want expert advice, we are a manufacturer of control cabinet components and can help you select high-quality components that fit your needs.

Terminal Block Structure

The structure of each terminal block affects how many connections you can make inside din rail enclosures. You’ll see different types, like single-feed through, dual-level, and triple-level. Each type lets you fit more terminals in a small space, which boosts design efficiency. Here’s what you should know:

- The structure changes the physical size and wiring method for each terminal block.

- More levels mean more connections in your din rail enclosures.

- Good cable management and heat dissipation keep your system reliable.

- If you use the right terminal block, you can expand your system without crowding the rail.

- Organized wiring helps prevent component failure.

Installation & Orientation

Mechanical factors matter just as much as electrical ones. When you install din rail enclosures, think about vibration resistance and mounting orientation. Industrial environments can be tough, so you need strong rails and secure mounting. Here are some tips:

- Use robust mounting solutions for areas with vibration or shock.

- Stronger profiles like TS35x15 or G32 rails offer better strength and damping.

- Solid rails give you maximum rigidity.

- Fasten components with end clamps to keep everything secure.

- Calculate the total weight of your mounted terminals and include vibration factors.

- Place brackets and supports at the right intervals to prevent sagging.

- Use screws or fasteners that fit your rail type for secure installation.

If you want solutions that last, choose enclosures and rails designed for industrial use. We offer certified products that stand up to tough conditions and keep your system safe.

Safety, Compliance, and Customization

IP Rating & Environmental Protection

When you choose din rail enclosures, you want to make sure your equipment stays safe from dust, water, and other hazards. The IP rating tells you how well the enclosure protects against these elements. Here are some common IP ratings you’ll see:

- IP54: Keeps out most dust and protects against water splashes.

- IP55: Blocks dust and low-pressure water jets.

- IP65: Stops all dust and water jets.

- IP66: Handles powerful water jets.

- IP67: Protects against short-term immersion in water.

A higher IP rating means better protection. If you work in a tough industrial setting, you need enclosures with at least IP65. This keeps your din rail enclosures reliable, even when dust and water are everywhere. The material matters too. Stainless steel works best for harsh places because it resists corrosion. Aluminum is light and resists rust, but it may not fit every hazardous area. Polycarbonate is strong and good for less harsh spots. Always match the enclosure material and IP rating to your environment.

Tip: Picking the right IP rating helps you avoid costly repairs and downtime.

Standards & Certifications

You want your din rail enclosures to meet strict safety and quality standards. Certifications show that your enclosures follow international rules. Here’s a quick look at the most important ones:

| Certification | Description |

|---|---|

| UL | Safety standards from Underwriters Laboratories |

| CE | Meets European Union safety requirements |

| RoHS | Restricts hazardous substances in electrical equipment |

We are a manufacturer of control cabinet components, and our products carry TUV certifications. This means you get high quality din rail enclosures that meet global standards for safety and performance.

Customization & Branding Options

Every project is different. You might want enclosures that show off your brand or fit your exact needs. Custom options let you add your logo, pick your colors, and design the enclosure to fit your components perfectly. Our process keeps tolerances tight—down to 0.2mm—so everything fits just right. Custom branding helps your project stand out and gives your setup a professional look.

Note: Custom enclosures make your solutions unique and help you build trust with your clients.

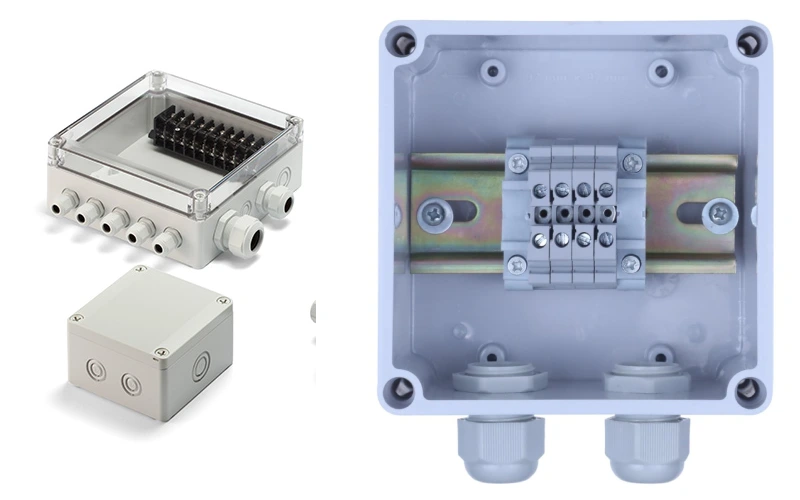

When you work with us, you get more than just din rail enclosures. We offer a full range of control cabinet components to complete your system. These include fan and filter units, roof and filter solutions, panel heaters, distribution terminal blocks, control transformers, automation products, cabinet air conditioners, thermostat-hygrostats, lamps and switches, AL.CU universal terminals, CMS cable management, and electrical boxes. Each product is designed to fit your needs and deliver reliable performance.

You can count on us for quality, safety, and custom solutions that help your project succeed.

Final Checklist for Choosing DIN Rail Enclosure with Terminals

Choosing the right din rail enclosure with terminals can feel overwhelming, but you can break it down into simple steps. This checklist will help you make sure you cover every detail, from technical specs to supplier support. As a manufacturer of control cabinet components, we want you to feel confident in your selection and get the best results for your project.

Step-by-Step Selection Guide

You can use this step-by-step guide to make sure you pick the right din rail enclosure with terminals for your needs:

- Define Your Application

Start by listing all the devices and connections you need. Think about the number of terminal blocks, the type of terminal, and the space required for wiring. - Identify the DIN Rail Type

Check which rail profile fits your enclosure. Top Hat, C-section, and G-section rails each have their own strengths. Make sure your terminal block and enclosure match the rail type. - Assess Electrical Load and Terminal Ratings

Look at the current and voltage your system will handle. Choose a terminal block with a current rating at least 150% of your system’s maximum. Always select a terminal with a voltage rating above your highest system voltage. - Consider Environmental Conditions

Think about where you will install the enclosure. If you expect dust, moisture, or temperature swings, pick a terminal block and enclosure with the right IP rating and material. For high temperatures, use terminals made from heat-resistant materials. - Plan Internal Layout and Space

Map out where each terminal block will go. Leave enough room for wiring and future expansion. Modular enclosures make it easy to adjust your layout as your needs change. - Check Protection and Compliance

Verify that your enclosure and terminal block meet international standards. Look for certifications like UL, CE, and TUV. Confirm the IP rating matches your environment. - Review Customization Needs

Decide if you need custom colors, branding, or special features. Custom enclosures can help your project stand out and fit your exact requirements.

Tip: Always double-check your list before placing an order. Missing a single terminal or picking the wrong rating can cause delays and extra costs.

Common Pitfalls to Avoid

Many people make the same mistakes when choosing a din rail enclosure with terminals. You can avoid these issues by watching out for the following:

- Not recognizing the different types of terminal blocks. This can lead to improper selection and wiring problems.

- Ignoring the environmental conditions. If you skip this step, your terminal or enclosure might fail in harsh settings.

- Overlooking electrical load requirements. If your terminal block cannot handle the load, it may overheat or break down.

- Forgetting to check the IP rating. Without the right protection, dust and moisture can damage your system.

- Failing to plan for future expansion. If you fill your enclosure to the limit, you will struggle to add new terminals later.

Alert: Selecting the right terminal block and enclosure is not just about today’s needs. Always think ahead and consider how your system might grow.

Sourcing from Linkwell

When you choose a supplier for your din rail enclosure with terminals, you want more than just a product. You need support, reliability, and proven quality. Here’s what you should look for when evaluating suppliers:

| Criteria | Details |

|---|---|

| After-Sales Support | Look for technical documentation, CAD models, and sample kits. |

| Reliable suppliers deliver on time (over 95% on-time rate) and respond quickly to questions. | |

| Warranty coverage should last at least 2 years, with a clear claims process. | |

| Performance & Quality | Check for thermal stability under continuous load (like 85°C operation). |

| Ask about mechanical durability, including vibration and impact testing. | |

| Top suppliers share failure rate data (less than 0.5% over 5 years). |

You can count on Linkwell for all these advantages. We offer a wide range of din rail enclosure with terminals, including options for temperature and humidity control. Our team provides technical support, fast delivery, and customization services. As a Gold Member supplier with a strong track record, we help you avoid common pitfalls and deliver reliable solutions for your project.

| Manufacturer | Product Range | Customer Service |

|---|---|---|

| Linkwell Electric | Wide variety of DIN rail thermostats and enclosures, including controllers. | Gold Member since 2015, audited supplier, average lead time of 1-3 months. |

| Yueqing Winston | Similar certifications and partnerships with Fortune 500 companies. | Not specified. |

| Yueqing Xiqi | Lowest entry price, good for pilot projects. | Not specified. |

| Wenzhou Chuangzuo | Strong in electronic hygrostat integration. | Not specified. |

| FEMAN | Scalable solutions and strong bulk pricing. | Not specified. |

Note: When you work with us, you get more than just enclosures. You get a partner who supports your project from start to finish.

If you want a din rail enclosure with terminals that meets your technical needs and gives you peace of mind, Linkwell is ready to help. We are a manufacturer of control cabinet components, and we stand behind our products with proven quality and expert support.

Choosing the right DIN rail enclosure with terminals gets easier when you follow a few key steps:

- Pick the right DIN rail size and material for your terminal blocks.

- Plan terminal block positions for easy access and maintenance.

- Secure the rail and select terminal blocks that fit your wiring needs.

- Keep your wiring neat for a tidy, reliable setup.

A checklist helps you check the environment, safety standards, and materials. You boost safety and efficiency when you match specs to your project. If you want expert support, reach out to us at Linkwell—we are a manufacturer of control cabinet components. Have tips or stories to share? Drop them in the comments!

FAQ

What devices can I mount on a DIN rail enclosure?

You can mount circuit breakers, terminal blocks, relays, power supplies, and controllers. These snap onto the rail for quick installation. If you need help choosing, we are a manufacturer of control cabinet components and can guide you.

How do I choose the right DIN rail type?

Check your device size and weight. Top Hat rails fit most components. G-section rails support heavier equipment. Always match the rail to your enclosure and terminal blocks. Need advice? Our team at Linkwell can help you select the best fit.

Can I customize my DIN rail enclosure?

Absolutely! You can add your logo, pick colors, or request special layouts. Customization helps your project stand out. We offer tailored solutions as a manufacturer of control cabinet components.

What IP rating do I need for harsh environments?

For dusty or wet areas, pick at least IP65. This rating keeps out dust and water jets. Higher ratings offer more protection. If you are unsure, ask us for recommendations.

How do I order samples or get technical support?

Just contact us through our website or email. We provide free samples, technical drawings, and fast support. As a manufacturer, we make your project easier from start to finish.

Conclusion

Selecting the right DIN rail enclosure with terminals is crucial for your project’s reliability and ease of installation. As outlined, the key is matching the correct rail type, terminal blocks, layout, and safety certifications to your specific needs.

As a leading manufacturer of control cabinet components, Linkwell offers the high-quality, compliant products and expert guidance to ensure your success. Don’t compromise on performance or safety—contact Linkwell today for reliable solutions and professional support tailored to your project. Let us be your trusted partner from concept to completion.