So, what is a terminal strip? You use a terminal strip to connect and organize multiple wires in one place, making electrical wiring simpler and neater. When you secure wires under each screw, you create a safe path for electricity.

Picking the right electrical connector really matters—mistakes like using the wrong type or a damaged strip can cause electric shocks, fires, or equipment failures. That’s why many professionals trust Linkwell for reliable terminal strips and terminal blocks built for safety and performance.

Terminal Strip Key Takeaways

- Terminal strips connect and organize multiple wires safely, making electrical wiring neat and easy to maintain.

- Terminal blocks offer more flexibility and safety features than terminal strips, ideal for complex or expandable wiring systems.

- Choosing the right terminal strip means matching current, voltage, wire size, and environmental needs to ensure safe, reliable connections.

- Proper installation and regular maintenance of terminal strips prevent loose connections, corrosion, and electrical hazards.

- Linkwell provides high-quality terminal strips and blocks that meet international safety standards and perform well in tough conditions.

Recommended products

What is a Terminal Strip

Terminal Strip Basics

If you’ve ever wondered what is a terminal strip, you’re not alone. A terminal strip is a simple but powerful tool for joining wires in electrical circuits. You use it to connect two or more wires together, making sure each wire has a secure spot. This helps you organize your wiring, keep things neat, and avoid messy tangles inside control panels or electrical boxes.

A terminal strip gives you a safe and reliable way to make electrical connections. You just insert each wire into its own slot and tighten it down with a screw. This keeps the wires from slipping out and helps prevent short circuits or loose connections.

Here’s what makes a terminal strip so useful:

- You can connect and secure multiple wires or cables safely.

- It helps you organize wiring, saving space and making everything easier to find.

- You can quickly assemble or change connections without special tools.

- It improves safety by reducing the risk of exposed wires or accidental contact.

- It makes maintenance and troubleshooting much easier because you can see and access each wire.

- The insulation between each terminal keeps wires from touching and causing faults.

- Some terminal strips even include extra features like fuse holders or indicator lights.

International standards, like IEC 60947-7 and NEMA, define what a terminal strip is and how it should work. These standards make sure terminal strips meet strict requirements for voltage, current, wire size, and safety. They also set rules for how strong and durable the strip needs to be, so you can trust it in all kinds of environments.

When you look at the materials, you’ll find that most terminal strips use tin-plated copper for the terminals. This gives you great electrical conductivity. The base is usually made from heat-resistant plastics or special insulating materials, so the strip can handle high temperatures and tough conditions. The metal parts, like screws and clamps, are often made from brass, copper, or steel for strength and durability.

How a Terminal Strip Works

So, how does a terminal strip actually work? You start by stripping the insulation off the end of each wire. Then, you insert the bare wire into the terminal and tighten the screw. This creates a strong mechanical and electrical connection. The screw presses the wire against the metal terminal, making sure electricity flows smoothly from one wire to the next.

Most terminal strips have multiple terminals lined up in a row. This lets you connect several wires at once, all in one place. The plastic barriers between each terminal keep the wires separated, which helps prevent accidental short circuits. Some strips even have clear covers or extra safety features to protect you while you work.

Here’s a quick look at typical ratings for terminal strips:

| Voltage Range (V) | Typical Current Rating (A) | Application Type |

|---|---|---|

| 51 – 150 | ~2.4 | General industrial |

| 151 – 300 | 1.6 – 9.5 | Commercial and industrial |

| 301 – 600 | 3.2 – 12.7 | Industrial applications |

| 601 – 1000 | ~21.6 | High voltage terminal blocks |

| 1001 – 1500 | ~30.5 | High voltage terminal blocks |

You’ll usually see terminal strips rated for up to 600 volts and anywhere from 15 to 65 amps, depending on the design. Always pick a strip with ratings higher than your maximum expected current to keep things safe.

When you choose a terminal strip from Linkwell, you get more than just a basic connector. Linkwell’s terminal strips and terminal blocks meet international standards like CE, UL, and RoHS. The company uses high-quality materials and advanced designs to make sure every connection is safe, reliable, and easy to maintain. With over 20 years of experience and a global reach, Linkwell stands out for its flexible options, strong certifications, and commitment to customer satisfaction. You can count on Linkwell for solutions that fit your needs, whether you’re wiring a simple appliance or a complex industrial panel.

Terminal Strip vs Terminal Block

Terminal Block Overview

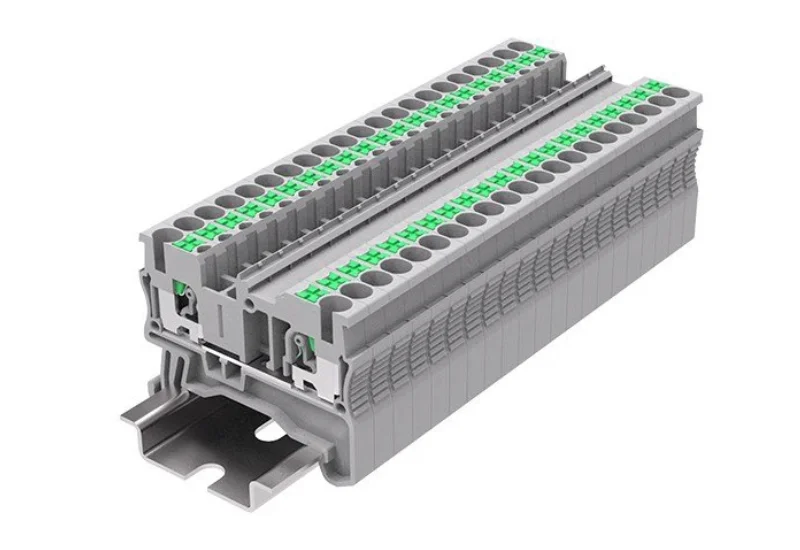

When you look at a terminal block, you see more than just a connector. Terminal blocks are modular devices that help you connect different circuits safely and efficiently. Each terminal block has a sturdy body, metal contacts, clamps, and clear identification tags. You can find many types, like spring terminal blocks for tool-free wiring or DIN rail terminal blocks for quick mounting in control panels. These blocks handle tough environments, resist heat and vibration, and keep your wiring organized. The main advantages of using terminal blocks include secure connections, easy installation, and reliable performance even in harsh conditions. You can use them to connect multiple terminals, isolate circuits, or add features like fuses and disconnects. With terminal block characteristics like high insulation, clear labeling, and modularity, you get a flexible solution for almost any wiring job.

Key Differences

You might wonder how a terminal strip compares to a terminal block. Here’s a simple table to help you see the differences:

| Feature/Aspect | Terminal Block | Terminal Strip |

|---|---|---|

| Structure | Modular, individual units often mountable on DIN rails | Single, fixed piece with multiple terminals arranged in a row |

| Modularity | High; can be expanded, reconfigured, and combined with specialized types | Low; fixed number of terminals, less adaptable for changes |

| Connection Types | Diverse clamping methods: screw, spring, push-in; specialized functions like fusing, disconnect, grounding | Primarily screw-down connections; basic insulation barriers |

| Safety Features | Enhanced electrical isolation, higher voltage/current ratings, specialized safety features | Basic insulation; relies on external enclosures; generally lower ratings |

| Application Suitability | Suitable for complex control systems, industrial automation, precise wiring, modular needs | Suitable for simple wiring, appliance hook-ups, lighting, basic power distribution |

| Maintenance Ease | High; individual circuits easily isolated and identified | Moderate; less intuitive for complex troubleshooting |

Terminal blocks stand out because you can expand or reconfigure them as your system grows. Spring terminal blocks and DIN rail terminal blocks make installation fast and secure. Terminal strips, on the other hand, offer a straightforward way to connect wires in a row, but they don’t have the same flexibility or advanced safety features.

When to Use Each

You should pick a terminal strip when you need a simple, visible, and reusable screw connection. Terminal strips work well for quick voltage checks, joining or isolating wires, or when you want to connect different circuits in a basic setup. They shine in appliance wiring, lighting, or anywhere you want easy access to connections.

If your project involves complex control panels, automation, or you expect future changes, terminal blocks are the better choice. You get organized wiring, secure and semi-permanent connections, and the ability to expand or modify your system. Applications of terminal blocks include industrial automation, building wiring, and any job where safety and reliability matter most. Spring terminal blocks and DIN rail terminal blocks make installation and maintenance even easier, especially in tight spaces.

Tip: For long-term projects or systems that may grow, choose terminal blocks for their flexibility and safety. For quick fixes or simple circuits, terminal strips save time and keep things neat.

With Linkwell Electric, you can find both terminal strips and terminal blocks designed for durability and ease of use. Whether you need an electrical terminal block for a control cabinet or a terminal strip for a lighting project, you’ll get reliable connections every time.

Types of Terminal Strips

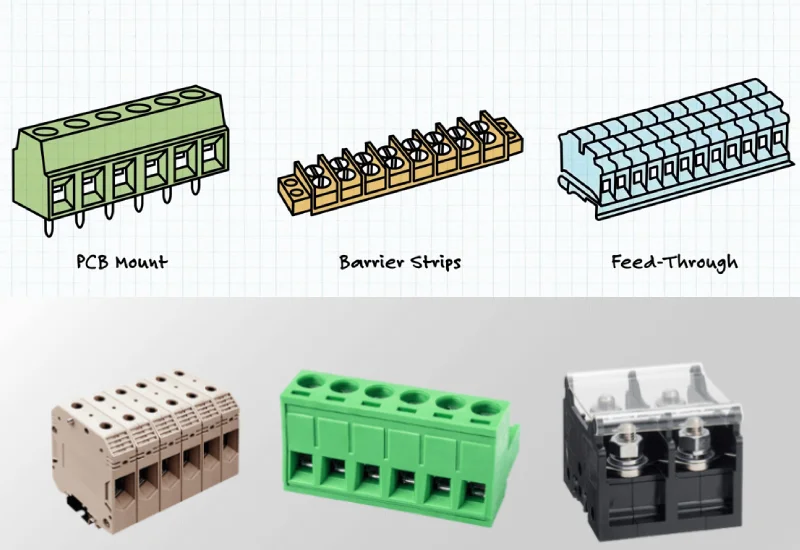

When you start looking at terminal strips, you’ll notice there are several types you can choose from. Each type has its own strengths and works best in certain situations. Here’s a quick look at some of the most popular options you’ll find:

- Interlocking terminal blocks

- Single-piece terminal blocks

- Pluggable blocks

- Screw terminals

- Push-in terminals

- Spring-clamp terminals

You’ll also see feed-through terminals and barrier strips used in many industries. These types help you create safe, organized connections for everything from vehicles to control panels.

Screw Terminal Strip

If you want a reliable and easy way to connect wires, screw terminal strips are a great choice. You just insert the wire, tighten the screw, and you’re done. Linkwell’s screw terminal blocks stand out because they use flame-retardant, corrosion-resistant materials. You can use them with both solid and stranded wires, and they last for thousands of connect and disconnect cycles. These strips come in different sizes and colors, so you can match them to your project. You’ll also find that they meet strict certifications like UL, CE, and RoHS, which means you can trust them for safety and performance.

Tip: Screw terminal blocks make wiring simple and secure, even if you need to change things later.

Barrier Strip

Barrier strips give you another way to keep your wiring neat and safe. You attach a ring or spade terminal to your wire, then tighten it onto the screw inside the housing. This design works especially well in places with lots of vibration, like industrial machines or vehicles. The barriers between each terminal help prevent accidental shorts and keep your connections stable. You’ll often see barrier strips in power distribution and circuit isolation jobs.

Applications in Industry

You’ll find terminal strips in all kinds of industrial settings. They show up in control systems, power distribution panels, and wiring assemblies. Here’s a quick table to show where you might use them and what features matter most:

| Industrial Application | Key Features Needed |

|---|---|

| Automation Systems | Impact resistance, easy handling, strong insulation |

| Transformers & Cable Links | High current, corrosion resistance, wide temperature range |

| Automotive & Motors | Durability, high current, reliable under stress |

| Power Distribution | Multiple poles, long-term use, minimal maintenance |

No matter the job, you want terminal strips that handle the right voltage and current, fit your wire size, and meet safety standards. Linkwell’s products check all these boxes, giving you peace of mind for every project.

How Do Terminal Blocks Work

Working Principle

You might wonder, how do terminal blocks work? A terminal block gives you a simple way to connect wires safely and securely. When you use a terminal block, you strip the insulation off the end of each wire. You then insert the bare wire into the terminal block and tighten a screw or clamp. This action presses the wire against a metal contact inside the terminal block, creating a strong electrical connection.

Here’s what happens inside a terminal block:

- The clamp system holds each wire tightly, so it won’t slip out.

- The metal contact, usually made of copper or brass, lets electricity flow smoothly.

- The insulated housing keeps each connection safe and separated from others.

- Clear labeling on the terminal block helps you identify each wire quickly.

- The modular design lets you add or remove terminal blocks as your project grows.

You can use a terminal block to connect two or more wires, distribute power, or split signals. The design makes installation and maintenance easy. If you need to change something, you just loosen the screw, swap the wire, and tighten it again. This makes the electrical terminal block a favorite in control panels and industrial wiring.

Safety and Reliability

Safety is a big reason why you see terminal blocks everywhere. Modern terminal blocks come packed with features that protect you and your equipment. Check out this table to see some of the main safety features:

| Safety Feature | Description |

|---|---|

| Insulated Modular Housing | Prevents accidental contact with live parts |

| Compliance with UL and IEC | Meets global safety standards |

| Current and Voltage Ratings | Matches system needs to prevent overheating |

| Touch-proof Design | Reduces risk of electrical shock |

| Wire-Securing Methods | Uses screws, push-buttons, or clamps for secure connections |

| Color Coding | Makes it easy to identify connections and avoid mistakes |

| Mechanical Robustness | Stands up to vibration and harsh environments |

| Pluggable Terminal Blocks | Allows safe, quick disconnection during maintenance |

Terminal blocks organize your wiring and keep everything neat. The touch-proof design and strong insulation help prevent shocks and short circuits. You can trust terminal blocks to hold up under heat, vibration, and heavy use. The different wire-securing methods, like screws or push-in clamps, make sure every wire stays put.

Linkwell Terminal Blocks in Practice

When you choose Linkwell, you get terminal blocks built for safety and performance. Linkwell uses flame-retardant, high-strength materials in every terminal block. Each unit goes through strict testing for voltage resistance and thermal endurance. The designs follow IEC and UL standards, so you know your terminal blocks meet global safety rules.

Linkwell terminal blocks use aluminum with tin plating for better corrosion resistance. The optimized torque ensures each connection stays tight, even in places with lots of vibration. You’ll find certifications like CE, RoHS, and UL94-V0 flame retardant rating on every terminal block. Linkwell checks every step, from raw materials to finished products, to make sure you get reliable terminal blocks every time.

You can use Linkwell terminal blocks in many places. The applications of terminal blocks include control panels, power distribution, and automation systems. No matter where you use them, you get safe, organized, and easy-to-maintain wiring. If you want a terminal block that stands up to tough jobs, Linkwell has you covered.

Choosing and Installing Terminal Strips

Selection Tips

Picking the right terminal strip for your project can make all the difference. You want safe, reliable electrical connections that last. Here’s what you should look for:

- Current rating: Always choose a terminal strip rated at least 150% higher than your maximum expected current. This helps prevent overheating.

- Voltage rating: Make sure the voltage rating is above your system’s needs, especially if you expect surges.

- Pole count: Count how many circuits you need to connect.

- Pitch: Check the spacing between terminals to fit your design.

- Wire size and type: Match the strip to your wire gauge and whether you use stranded or solid wires.

- Wire entry orientation: Decide if you want horizontal, vertical, or angled entries for easier wiring.

- Environmental factors: Think about temperature, humidity, and vibration. Pick a strip that can handle your environment.

- Color coding: Use colored housings or markings to make assembly and maintenance easier.

Tip: Always buy from trusted brands like Linkwell to ensure your terminal strips meet industry standards.

Installation Guide

You want your connection to be safe and secure. Follow these steps for a smooth installation:

- Prepare: Read the manufacturer’s manual. Gather tools like screwdrivers, wire strippers, and a multimeter. Work in a clean, well-lit area.

- Mount the strip: Attach the terminal strip firmly to your panel or DIN rail. Use end clamps to keep it steady.

- Wire preparation: Strip wires to the recommended length. For stranded wires, twist the ends or use ferrules.

- Make the connection: Insert each wire into the correct terminal. Tighten screws just enough—don’t overtighten.

- Protect and test: Add covers if needed. Power up and use a multimeter to check each connection.

Note: Avoid common mistakes like using the wrong tools, skipping torque checks, or mixing metals. These can cause loose connections or corrosion.

Maintenance and Safety

Keeping your terminal strips in top shape is easy if you stay proactive:

- Inspect regularly for rust, cracks, or loose fittings.

- Clean terminals and apply protective coatings if you work in damp or corrosive areas.

- Use the right tools and handle wires gently to avoid damage.

- Store spare strips in a dry, organized place.

- Perform torque checks to keep screws tight, especially in high-vibration spots.

- Document your maintenance and train your team for consistent safety.

Regular checks and good habits help your electrical connections stay safe and reliable for years.

You now know that a terminal block gives you a safe, organized way to connect wires. Terminal blocks and terminal strips help you keep your wiring neat, secure, and easy to maintain. When you use a terminal block from Linkwell, you get:

- Enhanced safety with insulated connections

- Organized layouts for easy troubleshooting

- Fast installation without soldering

- Flexible, modular designs for any project

- Reliable performance in tough environments

Terminal blocks work in many industries, from automation to clean energy. You can trust a terminal block to handle different voltages and currents. Linkwell terminal blocks come with certifications and support, making them a smart choice for your next project.

Ready to upgrade your wiring? Choose Linkwell terminal block solutions for safe, reliable, and cost-effective connections. Reach out today for expert advice or a quote.

FAQ

What is the main difference between a terminal strip and a terminal block?

You use a terminal strip for simple, fixed wire connections. Terminal blocks give you more flexibility, modularity, and safety features. If you want to expand or reconfigure your wiring, terminal blocks work better for you.

Can I reuse terminal strips and blocks?

Yes, you can! Just loosen the screws, remove the wires, and reconnect as needed. Linkwell designs its products for repeated use, so you get a secure connection every time.

Are Linkwell terminal strips safe for outdoor use?

Absolutely. Linkwell terminal strips use flame-retardant, UV-stable, and corrosion-resistant materials. You can trust them in both indoor and outdoor environments, even in tough weather.

How do I choose the right terminal strip for my project?

Start by checking your wire size, current, and voltage needs. Pick a strip with ratings above your requirements. Look for certifications like UL or CE. If you need help, Linkwell’s team can guide you.

Do I need special tools to install Linkwell terminal strips?

No special tools needed! A standard screwdriver and wire stripper will do the job. You can install Linkwell terminal strips quickly and easily, even if you’re new to electrical work.

Conclusion

What a terminal strip is helps ensure safe, organized, and efficient electrical connections in control panels, machinery, and other systems. Whether you’re managing a large project or building industrial panels, choosing the right terminal strip matters.

As a manufacturer, we offer high-quality, customizable solutions built for reliability. Reach out to us for expert support, fast delivery, and tailored designs that meet your exact needs.