You might wonder how a cooling fan goes from an idea to a finished product inside your cabinet. Linkwell leads the way in this field, combining quality and innovation to deliver reliable solutions. The Cabinet Fan Manufacturing Process: From Design to Assembly involves several steps, each shaping the final product you trust. The market keeps growing, with cabinet filter fans valued at $0.92 billion in 2024 and expected to reach $1.51 billion by 2033. Here’s how these fans serve different industries:

| Type of Fan | Main Applications |

|---|---|

| Electrical Enclosure Fans | Used in HVAC systems for temperature control and in ventilation systems for clean air flow. |

| Computer Chassis Fans | Primarily used for cooling electronic components and maintaining optimal operating temperatures. |

| Axial Fans | Employed in duct exhaust systems to remove hot exhaust gases and in boiler systems to manage exhaust temperatures. |

Key Takeaways

- Understand the cabinet fan manufacturing process, which includes design, material selection, and assembly. Each step ensures quality and reliability.

- Choose high-quality materials for durability. Linkwell selects strong plastics and metals to withstand tough conditions, ensuring long-lasting performance.

- Follow proper installation steps for optimal fan operation. Ensure correct wiring, secure mounting, and perform safety checks to protect your equipment.

- Utilize advanced technology in fan blade fabrication and motor assembly. This enhances airflow efficiency and reduces noise, improving overall performance.

- Stay informed about safety standards and certifications. Linkwell fans meet UL, CE, and RoHS standards, ensuring safe and reliable operation.

Design and Planning

Product Design

When you start thinking about a cabinet fan, you probably want it to be quiet, efficient, and reliable. At Linkwell, you get a design process that puts your needs first. The team looks at every detail to make sure your fan works perfectly in your space. Here are some key things they consider:

- They shape the fan case to avoid sharp corners and narrow ducts, which can make noise.

- They pick the right fan type for your installation site and the amount of air resistance.

- They manage airflow to keep things cool without making extra noise.

- They use smart fan controls to adjust cooling and keep noise low, even when the fan is not running at full speed.

- If you need a super quiet solution, they can use conduction cooling methods.

You can ask for custom features, too. Maybe you need a special size, a certain airflow, or a unique mounting style. Linkwell listens to your ideas and helps you choose the best options.

Technical Drawings

Before building anything, Linkwell creates detailed technical drawings. These drawings show every measurement and part, so nothing gets missed. The team also checks that your fan will meet important industry standards and certifications. Here’s a quick look at some of the standards they follow:

| Standard/Certification | Description |

|---|---|

| UL 508A Listed | File Number E61997 |

| cUL Listed | per CSA C22.2 No. 94 |

| Solid Door | Type 3R |

| Window Door | Type 1 |

| NEMA / EEMAC | Type 1 or 3R |

| IEC 60529 | IP30 or IP32, IK 10 |

Material Selection

You want your cabinet fan to last a long time and work in tough conditions. Linkwell picks high-quality materials for every part. They choose strong plastics, durable metals, and reliable bearings. If you have special needs, like a fan for a humid or dusty place, they help you select the right materials.

Note: Linkwell always talks with you to understand your needs. They offer advice on parameters, styles, and custom applications. You get a fan that fits your project, not just a standard product.

| How Linkwell Integrates Customer Requirements |

|---|

| Listens to your needs and offers selection help |

| Gives suggestions for parameters and styles |

| Communicates fully to understand your project |

| Provides careful, patient service |

| Helps you pick the most suitable model |

Material Preparation

Sourcing Materials

You want your cabinet fan to last, so you need the best materials from the start. At Linkwell, the team takes sourcing seriously. They look for suppliers who meet strict standards. You get fans made from strong plastics, sturdy metals, and reliable bearings. These materials help your fan handle tough jobs and harsh environments.

When Linkwell chooses suppliers, they check for more than just price. They look at reputation, experience, and product range. They also care about fast delivery and eco-friendly practices. Here’s a quick look at what matters most:

| Criteria | Description |

|---|---|

| Reputation | Trustworthy suppliers mean better quality. |

| Experience | Long history shows they know what you need. |

| Range of Products | More options help you get the right fit. |

| Price | Fair prices, but not at the cost of quality. |

| Warranty | Good warranties protect your investment. |

| Location and Lead Times | Closer suppliers mean faster shipping. |

| Certifications and Standards | Meeting standards means reliable products. |

| Environmental Policies | Eco-friendly choices support sustainability. |

| Customer Support and Training | Help when you need it, from setup to troubleshooting. |

| Innovation and Future-Readiness | Suppliers who invest in new tech keep you ahead. |

Tip: Always ask about certifications and support. These can make a big difference in your project’s success.

Cutting and Shaping

Once you have the right materials, it’s time to shape them into fan parts. Linkwell uses advanced technology to make sure every piece fits perfectly. You get blades, housings, and frames that meet tight tolerances.

Here are some of the top tools and methods used:

| Technology Name | Description |

|---|---|

| Laser Cutting | Cuts materials with a laser for smooth, precise edges. |

| CNC Systems | Uses computer controls for accurate shaping and drilling. |

| Abrasive Waterjet Cutting | Slices through tough materials with high-pressure water and grit, leaving clean finishes. |

These methods help Linkwell create fans that run quietly and last longer. You benefit from parts that fit together easily and work right the first time.

Note: Advanced cutting and shaping not only improve quality but also speed up production, so you get your fans faster.

Parts Production

Fan Blade Fabrication

You might think fan blades are simple, but they play a huge role in how well your cabinet fan works. At Linkwell, the team uses advanced machines to shape each blade for maximum airflow and low noise. They pick strong, lightweight materials so the blades last longer and spin smoothly.

Quality matters here. Every blade goes through a series of checks to make sure it meets high standards. Take a look at some of the steps Linkwell uses to keep quality high:

| Quality Control Measure | Description |

|---|---|

| Functional Testing | Checks how blades perform under stress and vibration. |

| Simulated Engine Environment | Uses computer models to see airflow and stress patterns. |

| Temperature Mapping | Tracks heat using special cameras and crystals. |

| Stress and Strain Measurement | Measures how much the blade bends or stretches. |

| Fatigue Testing | Spins blades through thousands of cycles to test durability. |

| Real-World Performance | Tests blades in actual working fans to gather real data. |

Tip: These steps help you get a fan that runs quietly and lasts for years.

Motor Assembly

The motor is the heart of your cabinet fan. Linkwell uses high-quality bearings and windings to make sure the motor runs smoothly and quietly. Skilled workers assemble each motor with care, checking for balance and proper fit. They test every motor before it leaves the line, so you know your fan will start up every time you need it.

You can also choose motors with special features, like energy-saving designs or smart controls. This means your fan can work just the way you want, whether you need steady cooling or automatic speed changes.

Housing Construction

The housing protects your fan and keeps everything running safely. Linkwell uses tough materials like aluminum, stainless steel, and different grades of steel. Each material has its own strengths:

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, spark-resistant | Fan housing and wheels |

| Stainless Steel | Corrosion-resistant, handles high temperatures | Industrial fan construction |

| Steel (various) | Durable, cost-effective, fits many environments | General fan applications |

Linkwell shapes and finishes each housing to fit your needs. You get a fan that stands up to tough jobs, whether you use it in a factory, a telecom cabinet, or a computer case.

Note: With Linkwell, you always get parts built for performance and reliability.

Cabinet Fan Manufacturing Process: From Design to Assembly

You might wonder what really happens between the first sketch and the moment you open a box and see your new cooling fan. The cabinet fan manufacturing process: from design to assembly brings together many steps, each one important for quality and reliability. Let’s walk through what happens at Linkwell, so you know exactly what goes into every fan you use.

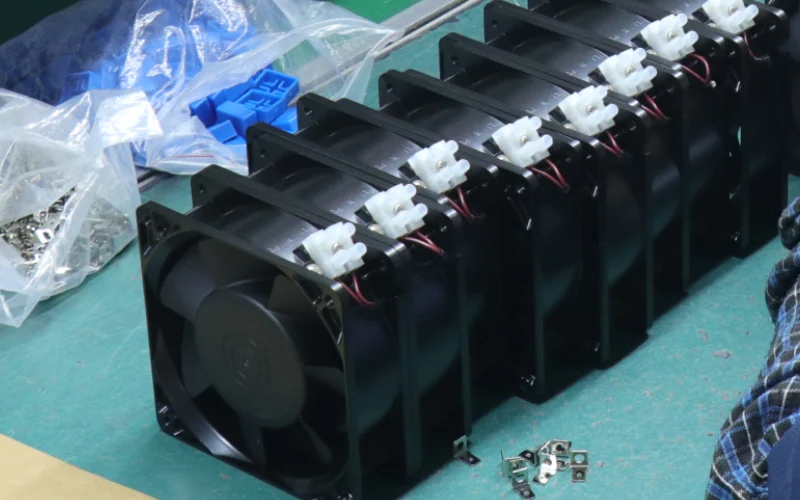

Assembly Steps

When you reach the assembly stage, you see all the careful planning and parts come together. The cabinet fan manufacturing process: from design to assembly starts with a clean, organized workspace. Skilled technicians gather the blades, motor, housing, and other components. They follow a step-by-step checklist to make sure nothing gets missed.

Here’s how the assembly usually goes:

- Component Preparation

Workers inspect each part again before assembly. They check for any scratches, dents, or defects. Only perfect pieces move forward. - Motor and Blade Integration

The motor gets mounted inside the housing. Technicians attach the blades to the motor shaft, making sure everything lines up for smooth spinning. - Wiring and Electrical Connections

Next, they connect the wires and secure them with clips or ties. This step keeps the inside neat and safe. If your cooling fan has smart controls or sensors, those get installed now. - Filter and Cover Installation

Many cabinet fans include a filter to block dust and debris. Workers snap the filter and cover into place, checking that it fits tightly. - Final Fastening and Sealing

The team tightens all screws and seals any gaps. They use gaskets or weatherproof tape if the fan will face harsh conditions. - Initial Function Test

Before moving on, they power up the fan for a quick spin. If it runs quietly and smoothly, it passes this stage.

Tip: Every step in the cabinet fan manufacturing process: from design to assembly helps prevent problems later. You get a fan that works right out of the box.

Certification and Logistics

After assembly, your cabinet fan isn’t quite ready to ship. The cabinet fan manufacturing process: from design to assembly includes strict quality checks and certifications. These steps make sure your fan meets safety and performance standards in your country.

Linkwell knows that different markets have different rules. Here’s a quick look at the main certifications you might need:

| Market | Certification |

|---|---|

| US | UL |

| EU | CE |

| Asia | RoHS, CCC |

You can see that a cooling fan for the US needs UL certification, while fans for Europe require CE. In Asia, RoHS and CCC are important. Linkwell tests every fan to meet these standards. They check for safe wiring, strong materials, and reliable performance.

Once your cabinet fan passes all tests, the logistics team steps in. They pack each fan with care, using foam, sturdy boxes, and clear labels. The team organizes shipments based on your location and delivery needs. You get tracking info and support until your order arrives.

Note: The cabinet fan manufacturing process: from design to assembly doesn’t end until your cooling fan is in your hands, ready to install. Linkwell’s team stays with you every step, from the first drawing to final delivery.

If you ever need help after delivery, Linkwell offers 24/7 support. You can ask questions, request spare parts, or get advice on installation. This full-circle approach makes the cabinet fan manufacturing process: from design to assembly smooth and stress-free for you.

Install a Cooling Fan

Ready to install a cooling fan in your cabinet? You can handle this process with a few simple steps. Whether you’re working with a Linkwell Electrical Enclosure Fan or a Computer Chassis Fan, you’ll find the process straightforward and rewarding.

Wiring and Integration

First, gather your tools and the cooling fan. Make sure you have everything you need before you start. Here’s a quick guide to help you with installation:

- Gather your tools, supplies, and the cooling fan.

- Prepare your installation site by cleaning the area and checking for obstructions.

- Mount the fan using the right brackets and screws.

- Handle the electrical wiring safely and connect the fan to the power source.

- Calibrate and balance the fan for smooth operation.

- Perform final safety checks before powering up.

Tip: Always double-check your wiring and connections before turning on the power.

Safety matters during installation. Take a look at these important precautions:

| Safety Precaution | Description |

|---|---|

| Correct Wiring | Make sure wiring is correct to prevent fire or electrical shock. |

| Grounding | Ground all wires securely to avoid electric shock. |

| Avoid Explosive Areas | Never use the fan in explosive atmospheres. |

| Exposed Live Parts | Do not operate with live parts exposed. |

| Power Off | Turn off power if you notice anything unusual. |

| Qualified Personnel | Let qualified personnel handle installation and wiring. |

| Static Electricity | Protect against static electricity during wiring. |

Final Enclosure Assembly

You want your cooling fan to work at its best. Follow these best practices for final enclosure assembly:

| Best Practice | Description |

|---|---|

| Fan Placement | Position the fan for clear airflow. Make sure cool air enters and hot air exits without obstacles. |

| System Impedance | Use fans that match your airflow needs, especially if your system has high resistance. |

| Noise Reduction | Choose fans with low noise ratings and use vibration-dampening mounts. |

| Filtration | Add air filters at the intake to keep dust out and protect your equipment. |

| Power Delivery | Provide a stable power source and route cables neatly to avoid blocking airflow. |

When you install a cooling fan the right way, you protect your equipment and keep everything running smoothly. Take your time, follow each step, and enjoy the benefits of a well-cooled cabinet.

Quality Control

Inspection Procedures

You want every cabinet fan to work perfectly. Linkwell makes sure of that by using a thorough inspection process. Skilled technicians check each part for scratches, dents, or defects. They use visual checks and precise measuring tools. You see them test the fit of blades, motors, and housings. If anything looks off, they fix it right away. You get fans that meet strict standards every time.

Here’s what happens during inspection:

- Technicians look for surface flaws.

- They measure parts to make sure everything matches the design.

- They check moving parts for smooth operation.

- They confirm that all fasteners are tight and secure.

Tip: Careful inspection helps prevent problems before your fan ever leaves the factory.

Performance Testing

You expect your cabinet fan to deliver reliable cooling. Linkwell tests every fan to make sure it meets performance standards. They run fans at different speeds and measure airflow, noise, and temperature. You see them use special equipment to check how well the fan moves air and how quiet it runs.

Linkwell follows industry standards for testing. Here’s a quick look at the main ones:

| Standard | Description |

|---|---|

| AMCA Standards | Standardized methods for testing fan performance and reliability. |

| AMCA Certified Ratings | Fans tested and rated for consistent results. |

| ASME PTC11 | Guidelines for fan performance testing. |

| AMCA 203 | Methods for fan performance testing. |

| AMCA 803 | Additional fan performance testing standards. |

| ISO Standards | Compliance for regulated industries. |

You also see these standards in action:

- ASME PTC11

- AMCA 203

- AMCA 803

Note: These tests help you get fans that work efficiently and last longer.

Safety Checks

Safety matters to you. Linkwell checks every fan for safe operation before shipping. Technicians test wiring and grounding. They look for exposed live parts and make sure all covers fit tightly. You get fans that meet UL, CE, and RoHS safety standards.

Here’s what you can expect:

- Electrical safety tests for wiring and connections.

- Checks for proper grounding.

- Tests for overheating and fire risk.

- Verification of protective covers and seals.

If you ever have questions about safety, Linkwell’s support team is ready to help. You get peace of mind knowing your cabinet fan is safe and reliable.

Finishing and Packaging

Surface Finishing

You want your cabinet fan to look great and last a long time. Linkwell gives each fan a careful surface finish. The team uses advanced paint and coating methods to protect against rust, scratches, and harsh weather. You get a fan that stays clean and sharp, even in tough places.

Here’s what you can expect from Linkwell’s surface finishing:

- Powder Coating: Adds a thick, even layer that resists chips and fading.

- Anodizing: Makes metal parts stronger and more resistant to corrosion.

- Protective Films: Shields surfaces during shipping and installation.

Tip: A good finish does more than look nice. It helps your fan last longer and work better.

Labeling

You need clear information on every product. Linkwell puts easy-to-read labels on each cabinet fan. These labels show you the model, voltage, airflow, and safety certifications. You can spot the details you need at a glance.

Here’s what you’ll find on a typical label:

| Label Info | What It Tells You |

|---|---|

| Model Number | Identifies your exact fan type |

| Voltage/Current | Shows power requirements |

| Airflow (CFM) | Tells you how much air it moves |

| Certifications | Confirms safety and quality |

| Serial Number | Helps with tracking and support |

Note: Clear labeling makes installation and maintenance much easier for you.

Packaging

You want your fan to arrive safe and ready to use. Linkwell uses strong, protective packaging for every shipment. The team wraps each fan in foam or bubble wrap, then places it in a sturdy box. They add clear labels and instructions so you know what’s inside.

- Foam Inserts: Keep the fan from moving during shipping.

- Sealed Bags: Protect against dust and moisture.

- Custom Boxes: Fit the fan’s size and shape for extra safety.

You get your order in perfect condition, ready to install right away.

Kitchen and Range Hood Applications

You might not realize how much a good fan can change your kitchen. If you want to keep your cooking space fresh and free from smoke, Linkwell fans make a big difference. Many people use bath fans in kitchens and range hoods because they offer strong airflow and quiet operation. You get a fan that fits right into your cabinet or hood, making your kitchen more comfortable.

DIY Range Hood Fan

Thinking about building your own range hood fan? You can do it with the right tools and a little planning. Linkwell fans work well for DIY projects because they are reliable and energy efficient. Here’s why you might choose them for your kitchen:

- You get proven reliability with over 15 years of trusted performance.

- These fans save energy, which helps lower your bills.

- Essential filtration features keep grease and odors under control.

- Many bath fans from Linkwell come with quiet motors, so your kitchen stays peaceful.

Tip: Always check the size of your cooking area before you start. A fan that’s too small won’t clear the air, while one that’s too big might be noisy.

How to Make a Range Hood Fan

Ready to put together your own range hood fan? Follow these steps to make sure you get the best results:

- Measure the space above your stove and check your ceiling height.

- Pick a fan that matches your kitchen’s style and color.

- Choose quality materials for long-lasting performance.

- Make sure your fan fits with your current ventilation system.

- Look at the CFM rating to match your cooking habits.

- Select the right filters for grease and odor control.

- Test the noise level to keep your kitchen pleasant.

- Decide if you want a ducted or ductless setup.

When you build your own range hood, you get to balance looks and function. Bath fans from Linkwell help you create a kitchen that feels fresh and looks great. You can trust their quality, whether you’re upgrading an old hood or starting from scratch.

Note: A well-chosen fan keeps your kitchen air clean and your cooking experience enjoyable.

You’ve seen how every step matters when making cabinet fans, from design to packaging. Linkwell gives you options like voltage choices, custom connectors, and even your own logo or packaging. You can start with a small order to test the quality before going bigger. With certifications like UL94-V0, CE, and RoHS, you know your bath fans meet strict standards. Bath fans from Linkwell arrive fast, look sharp, and work hard in both kitchens and industry. You can trust these bath fans for reliable, energy-saving performance. When you need bath fans that deliver, Linkwell stands out.

FAQ

How do you install a bath fan in a cabinet?

You start by choosing the right spot for your fan. Secure the mounting bracket, connect the wiring, and test the fan. Always follow safety tips for bath fan installation to keep your workspace safe.

What tools do you need for installing bath fans?

You need a screwdriver, wire stripper, drill, and mounting hardware. Some fans may require a voltage tester. Check the instructions before you begin. This makes installing bath fans easier and faster.

Why is air circulation important in cabinets?

Good air circulation keeps your equipment cool and prevents overheating. You protect sensitive electronics and extend their lifespan. Fans help move air efficiently, so your cabinet stays safe and reliable.

Can you use a bath fan for kitchen range hood projects?

Yes, you can use a bath fan for range hood projects. Pick a fan with enough airflow for your cooking space. Make sure it fits your cabinet and matches your kitchen’s style.

How often should you clean or replace filters in your cabinet fan?

You should check filters every three months. Replace them if you see dust buildup or reduced airflow. Clean filters help your fan work better and keep your cabinet fresh.